Embarking on a journey into the world of sewing and embroidery, one quickly discovers that the fabric used is just the canvas, and the stitches are the art.

Yet, between these two lies a crucial element: stabilizers. These unsung heroes provide the stability, structure, and support essential for crafting beautiful, professional-quality projects.

In this exploration, we delve into the diverse universe of sewing stabilizers, uncovering their unique characteristics, applications, and advantages.

Whether you’re a seasoned sewist or a novice, understanding the various types of stabilizers and when to use them can make all the difference in the quality and precision of your work.

Join us as we unravel the secrets of tear-away, cut-away, wash-away, heat-away, adhesive, fusible, mesh, heavy-duty, no-show mesh, and multi-purpose stabilizers, revealing how each one contributes to the artistry of sewing and embroidery.

1. Tear-away Stabilizers

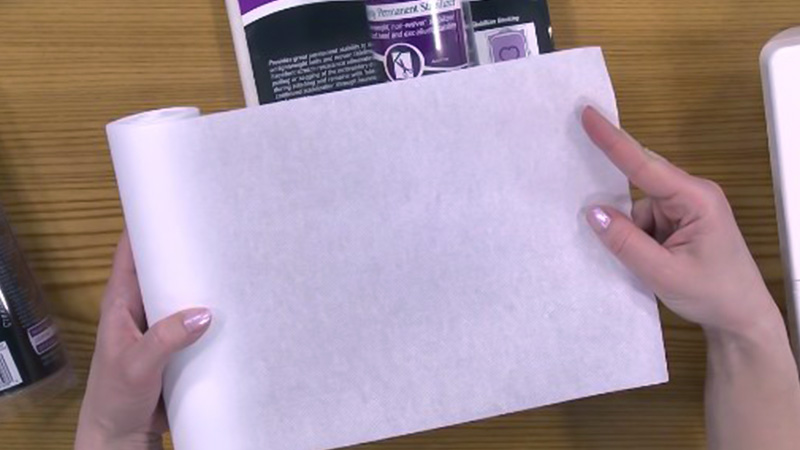

Tear-away stabilizers are a valuable tool in the world of sewing. These stabilizers are typically made from non-woven materials and serve as temporary support for fabrics during stitching.

They are particularly useful for lightweight and medium-weight fabrics, providing stability while allowing for easy removal once the sewing is complete.

Tear-away stabilizers tear cleanly and neatly along the stitch lines, leaving behind no residue. This makes them a popular choice for machine embroidery and decorative stitching projects.

They simplify the sewing process, ensuring that the fabric remains taut and distortion-free, resulting in professional-looking, precise stitching on a variety of materials.

2. Cut-away Stabilizers

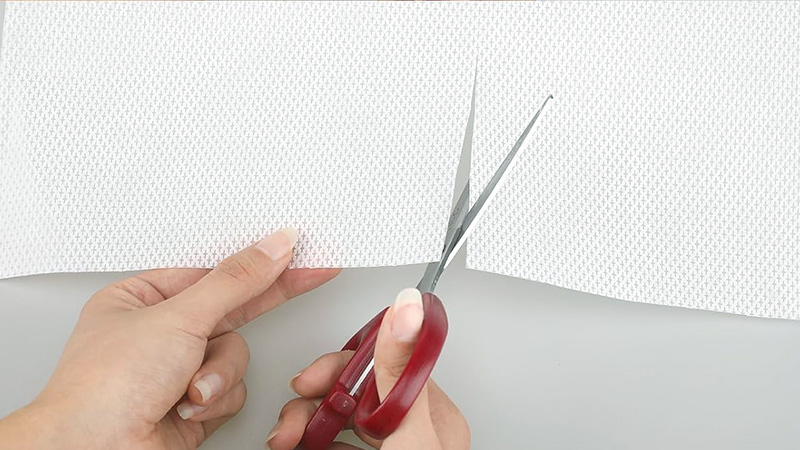

Cut-away stabilizers are indispensable in sewing, especially when working with stretchy or delicate fabrics. These stabilizers are constructed from strong, non-woven materials designed to provide lasting support.

Unlike tear-away stabilizers, cut-away varieties remain attached to the fabric after stitching, offering robust reinforcement that prevents distortion over time.

Seamstresses typically trim away the excess stabilizer close to the stitch line, leaving only what’s necessary for stability. This method results in clean, professional finishes for garments and embroidery on challenging materials.

Cut-away stabilizers are versatile and reliable, making them a top choice for projects requiring enduring support and impeccable results.

3. Wash-away Stabilizers

Wash-away stabilizers are a sewing marvel, especially for intricate and delicate projects. Crafted from water-soluble materials, these stabilizers dissolve when exposed to water, leaving no trace behind.

They are indispensable for applications like lace embroidery and freestanding lace designs, where complete removal of the stabilizer is crucial for the finished product’s appearance and feel.

Sewists typically place wash-away stabilizers beneath the fabric, stitch their design, and then submerge the item in water to wash away the stabilizer.

This results in a clean, soft, and flexible final product, making wash-away stabilizers a go-to choice for achieving intricate and detailed stitching on fine fabrics.

4. Fusible Stabilizer

Fusible stabilizers are a versatile tool in sewing, primarily used for reinforcing and adding structure to fabrics. These stabilizers are typically made of non-woven material with adhesive on one side, which activates when heat is applied.

Sewists use an iron to bond the fusible stabilizer to the fabric, creating a durable, integrated layer that offers added stability and support. Fusible stabilizers are commonly employed in garment making to strengthen collars, cuffs, and other areas prone to wear and tear.

They are also useful for various crafts and projects, enabling precise control over the fabric’s characteristics, making them easier to work with and resulting in professional-looking results.

5. Sticky-backed Stabilizers

Sticky-backed stabilizers, also known as adhesive stabilizers, are an essential tool in sewing and embroidery. These stabilizers come with a peel-off backing that reveals an adhesive side.

Sewists can easily adhere them to the fabric, providing temporary support during stitching. They are particularly valuable for appliqué work and intricate embroidery designs, helping to keep fabric pieces in place without the need for pins or basting.

After completing the stitching, the stabilizer can be easily removed, leaving behind a clean, polished finish. Sticky-backed stabilizers streamline the sewing process, ensuring precision and accuracy, making them a favored choice for projects demanding meticulous detail.

6. Heat-away Stabilizers

Heat-away stabilizers are a unique type of stabilizer used in sewing and embroidery. These stabilizers are designed to disappear when exposed to heat, making them ideal for projects where leaving any trace of stabilizer behind is undesirable.

Heat-away stabilizers typically come in a film or sheet form and can be applied to the fabric using an iron or heat press. Once the stitching is complete, the stabilizer is removed by simply applying heat to it, causing it to evaporate or disintegrate.

This leaves the fabric with a clean, residue-free finish, making heat-away stabilizers an excellent choice for delicate or heat-tolerant fabrics and intricate designs where precision is paramount.

7. Heat Transfer Stabilizer

Heat transfer stabilizers are a vital component in various crafting and sewing projects. These stabilizers, usually made from special heat-activated materials, serve as temporary support for fabrics during intricate embroidery, appliqué work, or other sewing endeavors.

They are applied to the fabric using an iron or heat press, bonding securely until heat is reapplied. This bond ensures fabric stability during stitching while also allowing for precise detailing.

Once the project is complete, applying heat once more causes the stabilizer to disintegrate or peel away easily, leaving behind a clean, professional finish without any residue.

Heat transfer stabilizers are indispensable for achieving precise, high-quality results.

8. Topping Stabilizers

Topping stabilizers, also known as embroidery toppers, are essential tools in machine embroidery. These thin, transparent sheets are placed on top of the fabric before stitching to prevent stitches from sinking into the material and getting lost.

Topping stabilizers are particularly useful when working with textured or pile fabrics like terry cloth or velvet, ensuring that the embroidery remains crisp and legible.

They also help prevent stitches from distorting or stretching certain fabrics. After the embroidery is complete, the topping stabilizer is easily removed by tearing it away or washing it, leaving the finished design looking sharp and well-defined. Topping stabilizers are invaluable for achieving professional embroidery results.

9. Mesh Stabilizers

Mesh stabilizers are versatile sewing aids designed to provide support and structure to fabrics without adding excessive bulk. These lightweight, breathable materials are particularly useful when working with delicate or stretchy fabrics like knits and sheers.

Mesh stabilizers offer stability during stitching, preventing puckering or stretching, and ensuring clean and precise results. They are available in various weights and can be easily torn away or trimmed after stitching is complete.

Mesh stabilizers are an excellent choice for projects where maintaining the fabric’s drape and breathability is essential, making them a valuable addition to any sewist’s toolkit, especially for garments and lightweight textiles.

Conclusion

Stabilizers are indispensable allies in the world of sewing and embroidery, offering a wide array of options to meet the unique demands of different fabrics and projects.

Tear-away stabilizers simplify embroidery on lightweight and medium-weight fabrics, while cut-away stabilizers provide enduring support for stretchy or delicate materials.

Wash-away stabilizers vanish entirely, leaving no trace behind, ideal for intricate lacework. Adhesive stabilizers make appliqué a breeze, while fusible interfacing reinforces garments and projects.

Mesh stabilizers maintain fabric breathability and heavy-duty options cater to heavyweight fabrics. No-show mesh stabilizers offer subtlety, and multi-purpose stabilizers provide versatility.

By understanding these stabilizer types and their applications, sewists can elevate the quality and precision of their work, ensuring that every project results in a clean, professional finish.

Whether you’re working on delicate lace, stretchy knits, or heavyweight textiles, choosing the right stabilizer is the key to success in sewing and embroidery.

Leave a Reply