The art of sewing transcends the mere joining of fabrics; it involves the intricate science of structure and form. Boning is a critical element in this art, providing garments with shape, support, and the ability to transform fabric into stunning silhouettes.

As a sewist or designer, understanding the various types of boning available is akin to wielding a painter’s palette, each type offering a unique brushstroke to your creations.

Whether you’re crafting a historical corset, an elegant evening gown, or simply seeking to enhance the fit of everyday wear, the choice of boning material matters.

This guide will delve into the diverse world of boning, shedding light on the different types, their characteristics, and the best scenarios for their use, empowering you to breathe life and structure into your sewing projects.

1. Plastic Boning

Plastic boning, a versatile sewing essential, consists of flexible plastic strips encased in fabric. This lightweight, easy-to-cut material adds structure and support to garments like corsets and bodices.

Plastic boning is ideal for projects requiring moderate shaping and flexibility. Its affordability and ease of sewing make it a popular choice for beginners and casual sewers.

It’s available in different widths to suit various garment needs and is machine-washable, ensuring practicality for everyday wear. Whether enhancing a strapless dress or giving structure to a costume piece, plastic boning offers a cost-effective solution for achieving the desired shape and fit in sewing projects.

2. Metal Boning

Metal boning, often in the form of steel, is a robust support material used in sewing to create structured, form-fitting garments. It offers unparalleled strength and rigidity, making it ideal for corsets, historical attire, and garments requiring substantial shaping and support.

Available in spiral or flat varieties, metal boning retains its shape, providing a pronounced silhouette. While it offers exceptional structure, it can be more challenging to work with due to its stiffness.

Nevertheless, its durability and ability to maintain intricate designs make it a valuable choice for sewers seeking to craft garments with a timeless and striking appeal.

3. Steel Boning

Steel boning is a robust and inflexible support material frequently utilized in sewing to create garments that require substantial structure and shaping, such as corsets, bodices, and historical attire.

Typically available in spiral or flat forms, steel boning provides exceptional rigidity and support, maintaining the desired silhouette over time. Its durability ensures longevity, making it an ideal choice for garments that will see frequent use or require intricate shaping.

While it offers outstanding structure, working with steel boning may necessitate careful handling and specialized tools. Nevertheless, the results are garments that boast both enduring strength and a distinctive, elegant form.

4. Spiral Boning

Spiral boning is a flexible and versatile support material frequently employed in sewing to add structure and shaping to various garments, including corsets, bodices, and eveningwear.

Comprising coiled steel wires encased within a fabric or plastic covering, spiral boning offers a balanced combination of support and flexibility. This allows garments to maintain their shape while permitting some freedom of movement.

It’s particularly well-suited for projects where comfort and ease of wear are essential. Its flexibility also makes it relatively easy to sew into garments, making it a favored choice among sewers aiming to achieve both style and comfort in their creations.

5. Natural Corset Boning

Natural corset boning typically refers to materials used historically before the advent of modern synthetic alternatives. Historically, materials like reeds, cane, and even animal bones, often from whales (baleen), were employed as boning in corsets and structured garments.

These natural materials provided rigidity and support while allowing some flexibility. However, due to ethical and environmental concerns, the use of such natural boning has diminished significantly.

Modern sewing relies more on synthetic options, such as plastic and steel boning, which mimic the properties of their natural predecessors without causing harm to animals or ecosystems. Natural corset boning remains a relic of historical garment construction.

6. Hoop Boning

Hoop boning, also known as hoop steel, is a type of structural support material used primarily in historical costumes and garments like hoop skirts, crinolines, and panniers.

It consists of flexible steel wires formed into circular or hoop shapes, designed to create and maintain a voluminous, wide shape in the lower part of garments.

Hoop boning provides the necessary structure to support layers of fabric, creating an elegant and exaggerated silhouette in fashion styles from various historical periods, particularly the 18th and 19th centuries.

Although less commonly used today, hoop boning is essential for achieving historically accurate and dramatic costume designs.

7. Extra Wide Bones

Extra wide bones, often referred to as wide boning or wide whalebone, are specialized support materials used in garment construction, particularly for historical and period costume designs.

These bones are wider and stiffer compared to standard boning materials, providing significant structure and rigidity to garments. They are typically made from flat steel or synthetic materials and are employed in projects where an exceptionally pronounced and structured silhouette is desired, such as in historical corsets or hoop skirts.

The use of extra wide bones allows for the creation of historically accurate and visually striking garments that maintain their distinctive shape and elegance.

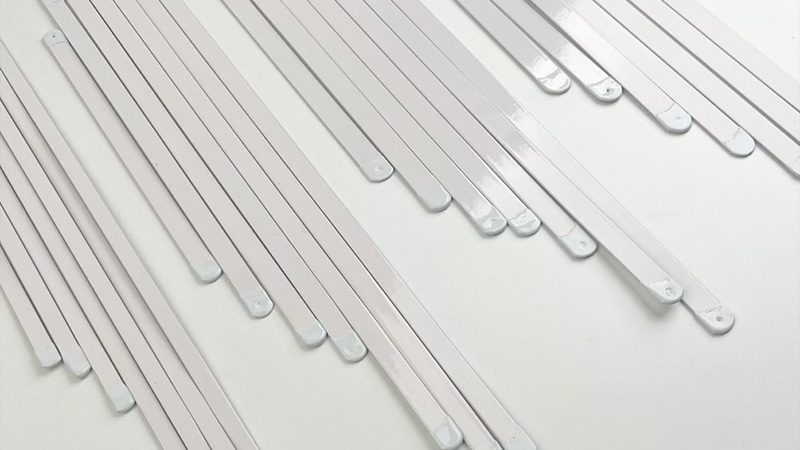

8. Flat Steel Boning

Flat steel boning is a firm and rigid support material commonly used in sewing, particularly in garments like corsets, bodices, and historically inspired clothing.

It consists of flat, thin steel strips encased in fabric or plastic casings. Unlike the more flexible spiral steel boning, flat steel boning provides substantial structure and support, ensuring garments maintain their shape and silhouette.

This type of boning is ideal for projects requiring a high level of control and definition, making it a favorite among historical reenactors and costume designers.

While it offers exceptional structure, sewing with flat steel boning may require specific techniques and tools.

9. Whalebone (Baleen)

Whalebone, scientifically known as baleen, was historically used as a stiff and flexible material in garment construction, particularly in corsets, crinolines, and hoop skirts.

It is derived from the baleen plates found in the mouths of certain species of whales. Whalebone was valued for its ability to maintain shape while allowing for movement and comfort, making it an essential component in shaping fashion throughout history.

However, due to ethical and environmental concerns surrounding the whaling industry, whalebone has been replaced by synthetic alternatives like plastic and steel boning in modern garment construction. Today, it serves as a historical relic of a bygone era in fashion.

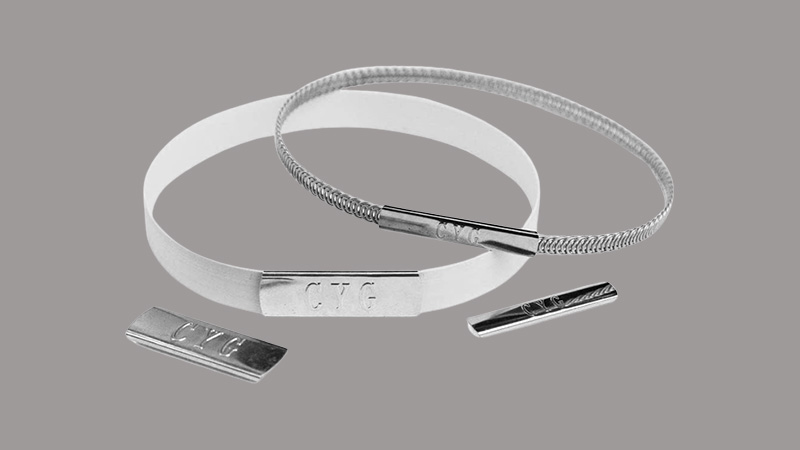

10. Cable Cord Boning

Cable cord boning, often referred to as cable boning, is a flexible support material commonly used in sewing to provide structure and stability to garments like corsets, bodices, and strapless dresses.

It consists of a cord, usually made of nylon or a similar material, encased within a fabric or plastic casing. Cable cord boning is valued for its moderate flexibility, which offers both support and a degree of comfort.

It is an excellent choice for projects requiring controlled shaping without excessive rigidity. Sewers can easily cut and sew cable cord boning to suit the contours of the garment, making it a versatile choice for various sewing applications.

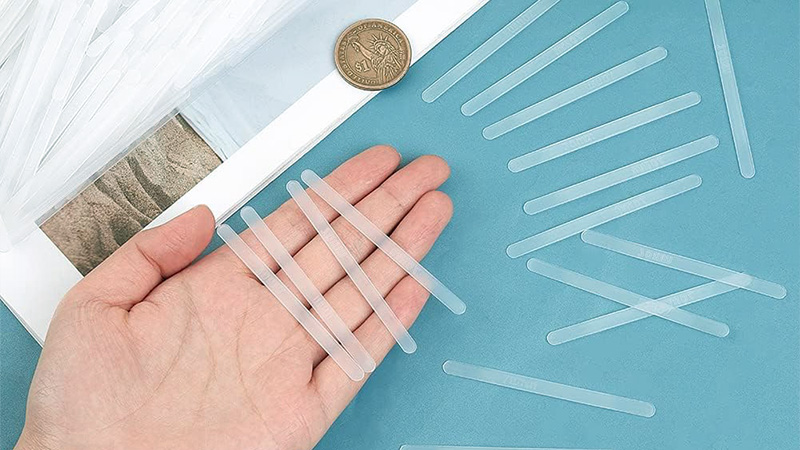

11. Featherweight Boning

Featherweight boning is an ultra-lightweight and flexible support material used in sewing for delicate garments and projects that require minimal structure.

Typically, it consists of thin, narrow plastic strips encased in a fabric covering. Featherweight boning offers subtle shaping and support without adding excessive weight or stiffness to the garment.

It is well-suited for applications like lingerie, lightweight bodices, and eveningwear, where maintaining a natural drape and comfort are essential.

While featherweight boning is not as rigid as some other types, its versatility and ease of use make it a valuable choice for sewers looking to enhance the form and fit of their creations while preserving a lightweight and airy feel.

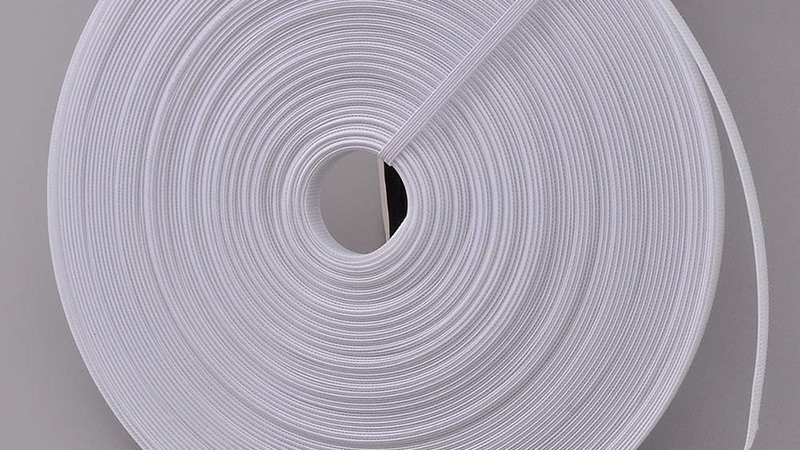

12. Polyester Boning

Polyester boning is a synthetic support material used in sewing to provide structure and shape to garments. It is typically made from polyester fabric encasing flexible, flat plastic or steel strips.

Polyester boning offers a balance between flexibility and rigidity, making it suitable for various applications, including corsets, bridal gowns, and eveningwear.

This type of boning is popular for its durability, resistance to moisture, and ease of maintenance, as it can often be machine-washed. Additionally, polyester boning is available in various widths and lengths, allowing sewers to customize the level of support and shaping required for their specific projects.

13. Side Boning

Side boning refers to flexible support materials inserted along the sides of garments, such as dresses, bras, and bodices. Typically, it consists of narrow strips of plastic or steel boning encased in fabric or casing.

The primary purpose of side boning is to provide structure and support to the sides of a garment, helping it maintain its shape and preventing it from collapsing or bunching up.

Side boning is commonly used in strapless or off-shoulder garments to ensure they stay in place and provide a flattering fit. It helps distribute tension evenly, enhancing comfort and ensuring the garment conforms to the wearer’s body contours.

Conclusion

Understanding the various types of boning available for sewing is essential for achieving the desired structure, shaping, and support in your garments.

Whether you opt for plastic boning for its versatility, steel boning for unparalleled rigidity, or specialized options like cable cord or featherweight boning for specific needs, each type has its unique advantages and applications.

Your choice of boning should align with the project’s requirements, whether it’s a historical costume, a modern couture piece, or everyday wear.

By selecting the appropriate boning material and following best practices for sewing and care, you can ensure that your garments not only look fantastic but also provide the necessary comfort and support for the wearer, creating stunning and functional pieces of fashion.

Leave a Reply