Greetings to the New Home Sewing Machine Troubleshooting Guide. This comprehensive resource is designed to equip you with the knowledge and techniques to address common issues that may arise with your New Home sewing machine.

Whether you’re a seasoned seamstress or just starting, understanding how to troubleshoot and perform basic repairs can save you time, money, and frustration.

From identifying thread tension problems to tackling more complex electronic components, this guide will walk you through step-by-step solutions.

By following these instructions, you’ll be able to maintain your sewing machine in optimal condition, ensuring it continues to serve as your trusted crafting companion for years to come.

Common Issues of New Home Sewing Machine

New home sewing machines are essential tools for many sewers and crafters. However, like any piece of equipment, they can experience various issues from time to time.

Here are some common problems that users might encounter with new home sewing machines:

Thread Tension Problems

Uneven or inconsistent tension can result in loose or tight stitches. Ensure you have correctly threaded the machine and have chosen the appropriate thread and needle for your fabric.

Thread Breakage

This can occur if the thread is not properly threaded or the needle is old or damaged. Use a new, high-quality needle and check the thread path for obstructions.

Skipped Stitches

Skipped stitches can be caused by a dull or bent needle, incorrect needle size, or using the wrong type of needle for the fabric. Replace the needle and use the appropriate one for your project.

Machine Jamming

If the machine is jamming or making a strange noise, a piece of broken needle or thread may be stuck in the bobbin area. Clean the machine and check for any obstructions.

Needle Breakage

Needles can break if old or bent or the fabric is too thick for the chosen needle. Ensure you use the correct needle type and size for your fabric and project.

Uneven Stitch Length

Uneven stitch length can occur if the machine is not properly adjusted. Check the stitch length settings and ensure they are set correctly.

Bobbin Issues

Problems with the bobbin can lead to issues like bobbin thread tangling or not feeding properly. Ensure the bobbin is correctly wound and inserted and the bobbin tension is adjusted properly.

Feed Dog Problems

When the fabric is not feeding properly, the feed dogs (the teeth-like mechanism under the presser foot) might be dirty, damaged, or lowered. Ensure the feed dogs are clean and properly engaged.

Breaking Belts

Some sewing machines have belts that drive the mechanism. These belts can wear out, slip, or break over time. If you notice any issues with the machine’s drive system, it may be a belt problem.

Electrical or Mechanical Issues

Sometimes, there can be issues with the sewing machine’s electrical components or mechanical parts. If the machine doesn’t turn on, stitches irregularly, or has other strange behavior, it might require professional servicing.

Troubleshooting Guide of New Home Sewing Machine

A new home sewing machine is valuable for crafting and creating garments. However, like any mechanical device, it may encounter issues from time to time.

This step-by-step troubleshooting guide will help you address common problems and restore your sewing machine.

What You’ll Need:

- Screwdrivers.

- Lint Brush or Cleaning Brush.

- Needles.

- Replacement Bobbins.

- Thread.

- Seam Ripper.

- Oil and Lubricant.

- Tweezers.

- Small Scissors or Clippers.

- Sewing Machine Manual.

- Flashlight.

- Magnifying Glass.

Thread Tension Check

Begin by inspecting the thread tension. Uneven tension can lead to irregular stitches. Ensure that the machine is correctly threaded and that the thread is of the appropriate type and weight for your fabric. Take care to follow the threading diagram provided in the user manual.

Addressing Thread Breakage

When you find that the thread is breaking, carefully examine the needle. A worn or damaged needle can cause thread breakage. Replace the needle with a new one suitable for your working fabric. Ensure the needle is inserted correctly and securely.

Dealing with Skipped Stitches

Skipped stitches are often indicative of a needle issue. Check the needle for any signs of bending or dullness. If you identify anything, replace it promptly. Select a needle type and size that matches the fabric and project requirements.

Resolving Machine Jamming

When the machine jams or makes unusual noises, it’s essential to investigate promptly. There may be debris, such as thread clippings or lint, lodged in the bobbin area.

Clean the machine thoroughly using a small brush and inspect for any obstructions. Additionally, ensure the bobbin and bobbin cases are inserted correctly.

Needle Replacement

When the needle frequently breaks, it may indicate wear or unsuitability for the used fabric. Replace it with a new needle that matches the project requirements. Double-check that the needle is compatible with both the fabric and thread.

Adjusting Stitch Length

Inconsistent stitch length may be the result of incorrect settings. Refer to your user manual to locate the stitch length adjustment dial or setting on your machine. Experiment with different settings to achieve the desired stitch length for your specific project.

Addressing Bobbin Issues

Tangling or feeding problems with the bobbin thread may indicate issues with the bobbin. Check if the bobbin is wound correctly, ensuring it’s neither loose nor tight.

Insert the bobbin into the bobbin case according to the instructions in your user manual. Additionally, adjust the bobbin tension if necessary.

Checking Feed Dogs

When the fabric is not feeding properly, the feed dogs (the teeth-like mechanism under the presser foot) might be dirty, damaged, or lowered.

Clean the feed dogs using a small brush or a lint brush. Additionally, ensure that the feed dog lever is in the correct position to engage the feed dogs.

Breaking Belts

When issues arise with the machine’s drive system, like belts slipping or breaking, it’s advisable to have a professional technician inspect and replace the belts if necessary. Steer clear of using the machine until this issue is resolved to prevent further damage.

Electrical or Mechanical Issues

When the sewing machine exhibits unusual electrical or mechanical behavior, such as not turning on or stitching irregularly, it likely requires professional servicing. Contacting the manufacturer’s customer support or a qualified sewing machine technician for assistance is recommended.

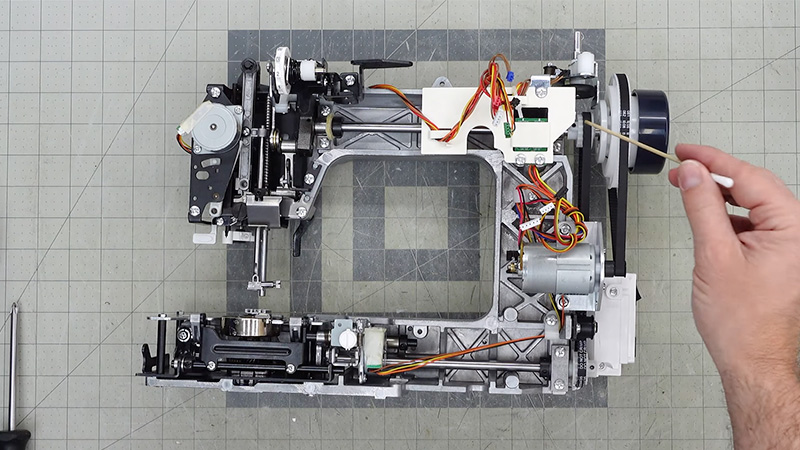

Specialized Troubleshooting for Electronic Components

Electronic components in sewing machines ensure precise stitching and automated functions.

It’s important to follow specialized troubleshooting steps when electronic issues arise to pinpoint and resolve the problem.

Check Power Connection

Ensure that the sewing machine is properly plugged into a functional electrical outlet. Test the outlet with another device to confirm it’s providing power. If necessary, try a different outlet to eliminate power supply issues.

Inspect the Power Cord and Plug

Examine the power cord for any visible damage, fraying, or exposed wires. If you find any issues, replace the cord. Also, check the plug for any signs of wear or damage.

Test Power Switch

Toggle the power switch on and off while observing the machine. If the power switch feels loose or unresponsive, it may need to be repaired or replaced.

Check for Blown Fuses

Some sewing machines have internal fuses that protect the electronic components. Consult the manual to locate and check these fuses. If any are blown, replace them with the correct type and rating.

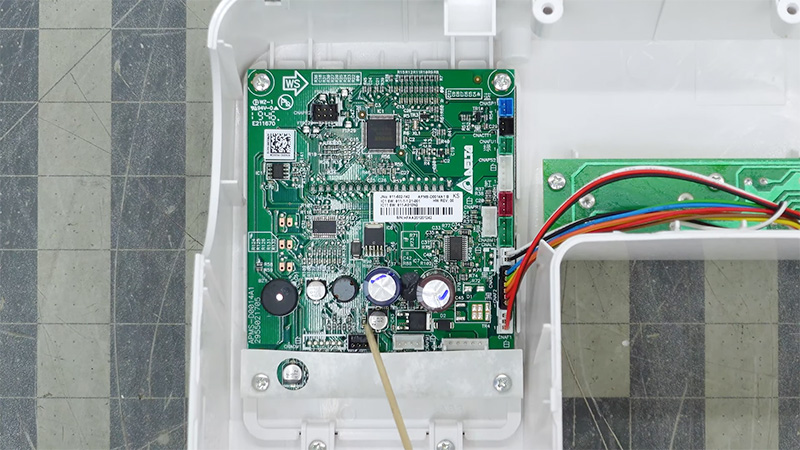

Inspect Control Board

The control board is a vital electronic component. Inspect it for signs of burnt areas, loose connections, or damaged components. If you’re not experienced with electronics, seeking professional assistance at this stage is advisable.

Test Sensors

Modern sewing machines often have sensors that detect thread tension, fabric thickness, and other variables. Test these sensors according to the manufacturer’s guidelines. If a sensor is faulty, it may need calibration or replacement.

Check for Loose

Inspect the wiring harnesses and connections for any loose or disconnected wires. Reconnect any that are not securely attached.

Clean and Inspect Circuit Boards

Dust and lint can accumulate on circuit boards, potentially causing electrical issues. Gently clean the boards using a can of compressed air or an anti-static brush. Be cautious to avoid damaging any components.

Test with Multimeter

If you have experience with electronics, use a multimeter to measure voltages and check for continuity in critical circuits. Refer to the sewing machine’s schematic diagram for guidance.

Seek Professional Assistance

If the specialized troubleshooting steps do not resolve the issue, it’s best to consult a qualified sewing machine technician or the manufacturer’s customer support for further diagnosis and repair.

Routine Maintenance and Cleaning

Regular maintenance and cleaning of your sewing machine will help keep it in top working condition, prevent potential issues, and extend its lifespan.

Follow these steps to maintain and clean your sewing machine.

Power Off and Unplug

Before performing any maintenance or cleaning, ensure the sewing machine is turned off and unplugged to prevent accidents.

Remove Fabric and Thread

Remove any fabric scraps and remove the thread from the machine, including the needle and bobbin threads.

Clean the Bobbin Area

Use the lint or small brush to gently remove lint, dust, and debris from the bobbin area. Pay special attention to the feed dogs, shuttle race, and bobbin cases.

Oil the Machine

Refer to your machine’s manual for specific oiling instructions. Apply small sewing machine oil to designated points, such as the race and moving parts. Use only the recommended type of oil.

Clean the Needle Plate

Remove the needle plate (if possible) and clean underneath it using the brush to remove any accumulated lint or thread bits.

Inspect the Needle

Check the needle for any signs of wear, such as burrs or bent tips. If necessary, replace it with a new, suitable needle.

Clean the Feed Dogs

Use the brush to clean the feed dogs, ensuring they are free from lint or thread remnants that might impede fabric feeding.

Wipe Down the Machine

Use a soft cloth to wipe the machine’s exterior, removing dust or residue. Pay attention to knobs, dials, and levers.

Check and Adjust Tension

Review your machine’s manual for guidance on checking and adjusting thread tension. Ensuring correct tension is essential for even and balanced stitches.

Test the Machine

After cleaning and maintenance, run a few test stitches on scrap fabric to ensure everything works smoothly.

Store Properly

If you’re not using the machine for an extended period, cover it with a dust cover or place it in its case to protect it from dust and moisture.

Frequency of Maintenance

Perform basic cleaning and maintenance after every major project or approximately every 8-10 hours of sewing. Additionally, have your machine professionally serviced once a year or as the manufacturer recommends.

How to Fix a New Home Sewing Machine at Home? Fix Minor Problems

Fixing a new sewing machine at home can be a cost-effective and convenient option for addressing common issues.

Here are some general troubleshooting steps you can take to fix minor problems with your sewing machine:

Thread-Related Issues

If the machine produces uneven or skipped stitches, rethread both the top thread and bobbin thread, ensuring they follow the correct path per the machine’s manual.

Check for tangled or jammed threads in the bobbin area and remove any obstructions. Ensure that you use the appropriate thread type and size for your fabric.

Needle Issues

When the needle frequently breaks or bends, replace it with a new one. Ensure you use the correct needle type and size for your project.

Confirm that the needle is correctly inserted and tightened in the needle clamp.

Thread Tension

When you experience thread tension problems, adjust the tension dial or knob based on your sewing machine’s settings. Refer to the user manual for guidance.

Bobbin Problems

Check if the bobbin is properly wound, inserted, and threaded according to your sewing machine’s instructions. Ensure the bobbin case or shuttle is clean and free from lint and debris.

Cleaning and Lubrication

Regularly clean the sewing machine, especially the bobbin area, feed dogs, and needle plate to remove lint, dust, and debris. Lubricate the machine’s moving parts as the user manual recommends, using sewing machine oil.

Stitch Length and Width

If you are experiencing issues with stitch length or width, adjust these settings according to your project’s requirements and your sewing machine’s capabilities.

Test Stitches on Scrap Fabric

After making any adjustments or repairs, test the machine on scrap fabric to ensure it stitches correctly.

When Should you consult a professional for complex repairs?

Consulting a professional for complex repairs on your sewing machine is advisable in several situations:

Electronic Issues

Suppose your sewing machine exhibits electrical or electronic problems, such as not turning on, malfunctioning LED displays, or issues with the control panel. In that case, it’s best to seek the expertise of a professional technician.

These components can be intricate and delicate, and attempting to repair them without proper knowledge can lead to further damage.

Timing Belt Issues

Problems related to the timing of your sewing machine, including timing belt issues, can be complex to diagnose and fix. Incorrect timing can result in missed stitches or other stitching irregularities. A professional technician can accurately assess and adjust the timing mechanism.

Motor or Drive System Problems

If you encounter issues with the sewing machine’s motor, drive belts, or gears, it’s typically a job for a skilled technician. Repairing or replacing motor components may involve disassembling significant parts of the machine, which can be challenging for the average user.

Bobbin Case and Shuttle Race Problems

Complicated issues with the bobbin case, shuttle race, or hook assembly can disrupt the machine’s functionality. Professional repair is recommended to ensure proper alignment and function since these parts are intricately involved in the stitching process.

Computerized Sewing Machines

Modern computerized sewing machines often have advanced electronic components that control various functions. If these components fail or malfunction, it’s best to consult a professional with expertise in electronic repairs.

Specialized Features or Attachments

If your sewing machine has advanced features or specialized attachments, repairing or troubleshooting these components may require specific knowledge. Professional technicians often have access to manufacturer-specific training and resources.

Warranty Concerns

Attempting to repair your sewing machine yourself may void any existing warranty. If your machine is still under warranty, consult the manufacturer or an authorized service center for repairs to ensure your warranty remains valid.

Safety Precautions

Complex repairs may involve working with delicate or intricate parts, electrical components, and potentially hazardous materials. Professionals have the training and tools to handle such repairs safely.

FAQs

Why is my sewing machine not picking up the bobbin thread?

This could be due to incorrect threading or a misaligned needle. Refer to the user manual to ensure proper threading and check the needle position.

What should I do if my machine makes a loud, unusual noise?

Unusual noises may indicate a mechanical issue. Turn off the machine, inspect for visible obstructions, and consult a professional if the problem persists.

Why are my stitches uneven or skipping?

Uneven stitches can result from incorrect tension settings or a damaged needle. Double-check the threading and replace the needle if needed.

How often should I oil my New Home sewing machine?

Oiling your machine after every 8-10 hours of use is recommended, or as advised in the user manual. Use the recommended sewing machine oil.

What if I’ve tried troubleshooting, but the issue remains unresolved?

If basic troubleshooting doesn’t fix the problem, it’s advisable to consult the manufacturer’s customer support or seek assistance from a professional sewing machine technician.

Wrap Up

Mastering the art of troubleshooting and basic repairs for your New Home sewing machine empowers you to overcome common issues. Regular maintenance, such as cleaning and oiling, ensures smooth operation.

However, for complex electronic or structural problems, consulting a professional technician is paramount. Prioritize safety, especially when dealing with internal components or specialized tools.

Remember, your machine’s manual is an invaluable resource for model-specific guidance. By following this guide, you can enhance the longevity and performance of your sewing machine, turning every project into a seamless and enjoyable endeavor.

Leave a Reply