In the world of crafting and garment creation, a Juki sewing machine stands as a reliable companion. However, like any mechanical device, it may encounter occasional hiccups.

This comprehensive guide is designed to empower you with the knowledge to identify, address, and potentially resolve common issues that may arise with your Juki machine.

From thread tension dilemmas to needle-related challenges, we’ll walk you through step-by-step solutions.

Whether you’re a seasoned seamstress or just starting your sewing journey, this guide equips you with the skills to keep your Juki sewing machine in top-notch working order, ensuring your projects always meet their full creative potential.

Common Juki Sewing Machine Problems

Juki sewing machines, like any other machinery, can experience various issues.

Here are some common problems you might encounter and their potential solutions:

Thread Bunching

Thread bunching under the fabric or creating a messy tangle, often called bird’s nesting, can be frustrating. This issue is usually caused by incorrect threading.

Carefully rethread the machine, ensuring the thread is correctly guided through all the necessary points.

Additionally, check and adjust the tension settings for the upper and lower threads according to the fabric you’re working with.

Needle Breakage

Breaking needles can disrupt your sewing project and indicate several issues. Ensure you’re using the right type and size of needle for your fabric. Thicker fabrics generally require larger needles.

Also, examine the needle for any rough spots or burrs that may cause it to break.

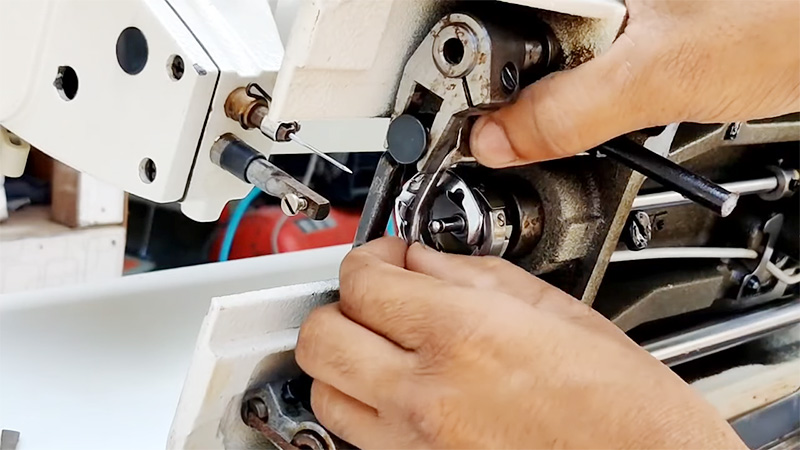

Machine Jamming

If your Juki sewing machine jams or stops unexpectedly, inspect the bobbin area first. Look for any tangled or improperly wound thread in the bobbin case and rethread it if necessary.

Regularly cleaning the bobbin area, feeding dogs, and needle plates can also help prevent jamming issues.

Uneven Stitches

Uneven stitches can result from several factors. Check the needle position, ensuring it is correctly inserted and facing the right direction. Also, inspect the feed dogs to ensure they are clean and moving freely, engaging with the fabric properly.

Noisy or Excessive Vibration

Unusual noises or excessive vibrations from your sewing machine can be bothersome. Check for any loose screws, bolts, or components, and tighten them as needed.

Following the manufacturer’s recommendations, proper lubrication can also help reduce noise and vibration.

Thread Tension Problems

Start by checking the bobbin tension when you’re experiencing thread tension issues. Ensure the bobbin thread is correctly seated and wound. Experiment with the upper thread tension dials to achieve balanced tension across your stitches.

Fabric Not Feeding Smoothly

Difficulty in feeding fabric smoothly can disrupt your sewing. Ensure the feed dogs are in the correct position and adjust their height if necessary. Regularly clean the feed dogs and surrounding areas, and make sure they are adequately lubricated.

Machine Overheating

When your sewing machine overheats, give it time to cool down by turning it off. Ensure it’s receiving the correct voltage and isn’t overloaded by other appliances sharing the same circuit.

How to Troubleshoot Juki Sewing Machine Problems?

Troubleshooting issues with your Juki sewing machine is essential for smooth sewing operations.

This guide will walk you through common problems and their solutions, helping you keep your machine in excellent condition.

Here’s a step-by-step process:

Gather Supplies:

- Juki sewing machine manual

- Screwdriver

- Cleaning brush

- New needles

- Quality thread suitable for your fabric

- Bobbins

Power and Basic Setup

Verify that the machine is securely plugged into a functioning power source. Switch on the machine and pay attention to any unusual sounds or vibrations.

If you notice anything unusual, it may indicate an internal issue that requires further investigation.

Thread-Related Issues

One of the frustrating problems you might encounter with your Juki sewing machine is thread bunching or bird nesting.

Thread Bunching

When encountering thread bunching or bird’s nesting, it’s likely due to incorrect threading. Refer to the manual and carefully rethread the machine.

Additionally, adjust the upper and lower thread tension settings to ensure they are appropriate for the fabric you work with. This will help prevent the thread from bunching up underneath the fabric.

Needle Breakage

When your needle breaks, you must ensure you’re using the correct type and size for your fabric. Examine the needle closely for any signs of burrs or damage. If you find any, replace the needle promptly to prevent further issues.

Thread Tension Issues

When encountering thread tension problems, begin by checking the bobbin thread. Confirm that it is correctly seated and wound.

Subsequently, adjust the upper thread tension dial as needed to attain balanced tension across your stitches. This will assist in averting issues like loose or puckered stitches.

Bobbin and Feed Mechanism

Bobbin tension is crucial for achieving balanced stitches. If the tension is too tight or loose, it can result in uneven stitches or thread breakage.

Machine Jamming

When a jam or sudden stop occurs, examine the bobbin area. Open the bobbin case and check for any tangled or improperly wound thread. Should you find any issues, rethread the bobbin.

Additionally, take a moment to clean the bobbin area, feed the dogs, and clean the needle plate. This will remove any accumulated lint or debris causing the machine to jam. This proactive approach will help prevent issues such as loose or puckered stitches.

Uneven Stitches

Uneven stitches can be a result of various factors. Begin by checking the needle position. Ensure that the needle is fully inserted and facing the correct direction.

Next, inspect the feed dogs to ensure they are clean and engaging with the fabric properly. This will help ensure smooth and even stitching.

Noise and Vibration

Excessive noise or vibration can indicate loose components. Carefully check for any screws, bolts, or other parts that may have come loose during use. If you find any, use a screwdriver to tighten them.

Additionally, make sure to lubricate the machine as recommended by the manufacturer. Proper lubrication will help reduce friction and minimize noise and vibration.

Fabric Feeding Problems

Should you encounter difficulties in feeding the fabric smoothly, verify the position of the feed dogs. They should be aligned to grip and advance the fabric effectively. If needed, make adjustments to their height to ensure proper feeding.

Furthermore, it’s vital to consistently clean and lubricate the feed dogs and the adjacent areas. This practice will deter lint accumulation and minimize the likelihood of encountering problems like loose or puckered stitches.

Overheating

When your machine is running slowly or overheating, addressing the issue promptly is crucial. In case of overheating, please turn it off and allow it to cool down before continuing.

Verify the power supply to ensure the machine receives the correct voltage and is not overloaded. If the issue persists, it may indicate a motor problem that requires professional attention.

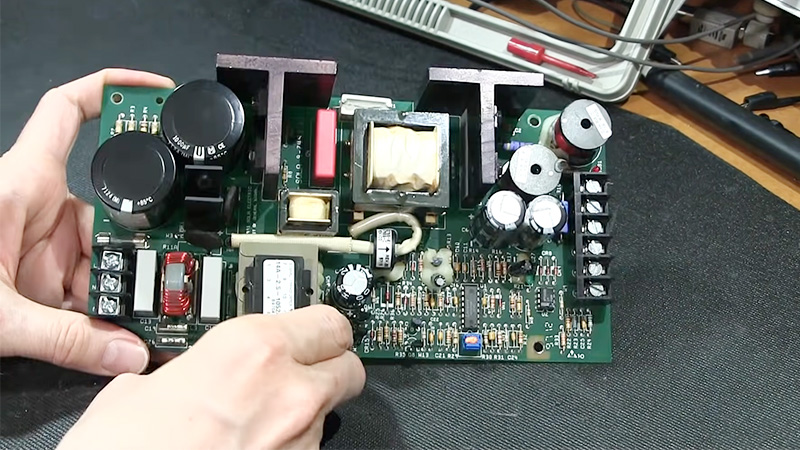

Advanced Troubleshooting for Electronic Components

Advanced troubleshooting for electronic components in a Juki sewing machine involves a deeper understanding of the machine’s electronic systems and the ability to diagnose and potentially repair complex issues.

Here are some advanced troubleshooting steps for electronic components:

Identify the Affected Component

Begin by identifying which electronic component or system is causing the problem. This might include the control panel, circuit boards, sensors, or motors. Understanding the affected area is essential for focused troubleshooting.

Inspect for Physical Damage

Examine the electronic components for visible physical damage, such as burnt spots, loose connections, or broken wires. Pay close attention to circuit boards and wiring harnesses.

Check for Loose Connections

Electronic issues can often be caused by loose or disconnected wiring or connectors. Carefully inspect and reseat any loose connections to ensure a secure fit.

Diagnose Using a Multimeter

A multimeter is a valuable tool for advanced troubleshooting. Use it to test the continuity of wires, voltage levels, and resistance in electronic components. Refer to the machine’s service manual for specific testing points and expected values.

Check for Faulty Sensors

Sensors are crucial for thread tension control, fabric detection, or safety features in modern sewing machines. Test sensors using a multimeter or oscilloscope to ensure they are functioning correctly.

Test Control Panel Functions

If your machine has a control panel with buttons or a touchscreen, test each function to ensure they respond appropriately. Unresponsive buttons or erratic touchscreen behavior may indicate a problem with the control panel or its connections.

Inspect and Reset Circuit Breakers

Some electronic components may have built-in circuit protection like fuses or circuit breakers. Check for blown fuses or tripped circuit breakers and replace or reset them.

Firmware Updates and Software Issues

In some cases, issues may arise from outdated firmware or software glitches. Check for any available updates for your machine’s software and follow the manufacturer’s instructions to perform updates.

Consult the Service Manual

The manufacturer’s service manual for your specific Juki sewing machine model is valuable for advanced troubleshooting. It often contains detailed diagnostic procedures, wiring diagrams, and component testing instructions.

Preventive Measures for Further Issues

Preventive measures for your Juki sewing machine can help prolong its lifespan, maintain consistent performance, and reduce the likelihood of future issues. Here are some essential steps to take:

Regular Cleaning

Remove lint, dust, and debris from the machine’s internal and external parts, including the bobbin area, feed dogs, and tension discs.

Use a soft brush, compressed air, or a lint roller to clean hard-to-reach areas. Depending on usage, clean your machine after every project or as often as needed.

Oiling and Lubrication

Follow the manufacturer’s recommendations for oiling and lubricating your sewing machine. Different models have varying requirements.

Use only sewing machine oil or lubricants recommended by Juki to avoid component damage.

Thread and Needle Maintenance

Use high-quality threads suitable for your fabric and change the needle regularly, especially if it becomes bent or dull. Ensure the needle is inserted correctly and is the right size and type for your project.

Bobbin Care

Wind bobbins smoothly and evenly, following the recommended guidelines in your machine’s manual. Insert the bobbin correctly, ensuring it unwinds smoothly without resistance.

Proper Storage

Cover your sewing machine with a dust cover or store it in a dedicated sewing machine cabinet when not in use.

Avoid exposing your machine to extreme temperatures, humidity, or direct sunlight, as this can affect its performance.

Correct Threading

Ensure the machine is threaded correctly, following the threading diagram in your manual. Improper threading can lead to tension issues and other problems.

Preventive Maintenance Schedule

Establish a regular maintenance schedule based on your machine’s usage. More frequent maintenance may be necessary if you use your machine heavily.

Consider professional servicing annually or as the manufacturer recommends, especially for electronic components.

Use a Quality Surge Protector

Plug your sewing machine into a high-quality surge protector to protect it from power surges and voltage fluctuations.

Proper Needle Plate

Keep the needle plate and feed dogs clean and debris-free to ensure smooth fabric feeding.

Can You Repair Your Juki Sewing Machine at Home?

Repairing a Juki sewing machine at home can be possible for some fundamental issues and maintenance tasks, but it depends on the complexity of the problem.

Yes, you can repair your Juki sewing machine at home for specific issues, such as:

Routine Maintenance

Basic maintenance tasks like cleaning, oiling, and changing needles or bobbins are often simple and can be done at home. Regular maintenance helps keep your machine running smoothly.

Thread and Needle Problems

Issues like thread breakage, needle breakage, or uneven stitching are often caused by straightforward problems like incorrect threading or using the wrong needle size/type.

You can usually address these problems at home by rethreading the machine correctly or replacing the needle.

Bobbin Issues

Problems with the bobbin, such as winding, insertion, or tension, can often be resolved with proper rethreading and cleaning the bobbin area.

Loose Parts or Screws

If you notice loose screws or parts, you can tighten them at home to ensure the machine’s stability and smooth operation.

Cleaning

Regular cleaning to remove lint and dust from the machine’s internal components, especially the bobbin area and feed dogs, is a simple but essential maintenance task you can perform at home.

Tension Adjustment

If you’re experiencing tension issues, you can experiment with adjusting the upper thread tension using the machine’s tension dial.

When You Need Professional Assistance?

You should seek professional assistance for your Juki sewing machine in the following situations:

Complex Mechanical Issues

When you encounter mechanical problems that involve disassembling and repairing internal components, such as the motor, gears, or timing mechanisms, it’s best to rely on a certified technician.

Attempting these repairs without proper knowledge and tools can lead to further damage.

Electronic Problems

If your sewing machine experiences electrical or electronic issues, such as malfunctioning circuit boards, sensors, or control panels, it’s crucial to consult a professional technician.

Working with electronics without expertise can pose safety risks and may cause irreparable damage.

Warranty Concerns

If your sewing machine is still under warranty, attempting to repair it independently or through an unauthorized service center could void the warranty. Always check the manufacturer’s warranty terms and consult an authorized Juki service center for covered repairs.

Safety Hazards

Electrical and mechanical repairs can be hazardous. If you suspect any safety-related issues, such as exposed wires, unusual odors, or overheating, immediately stop using the machine and seek professional assistance to prevent accidents or fire hazards.

Specialized Tools and Expertise

Some repairs require specialized tools and expertise that only certified technicians possess. Professionals can access service manuals, diagnostic equipment, and replacement parts necessary for complex repairs.

Lack of Knowledge and Experience

If you don’t have the necessary knowledge or experience to diagnose and fix a sewing machine issue correctly, avoiding DIY repairs is advisable. Attempting to repair a machine without the appropriate skills can lead to more significant problems.

Persistent Issues

When you’ve attempted basic troubleshooting steps and continue to experience the same problem, or if the issue recurs shortly after a DIY repair, it’s a sign that the root cause may be more complex and require professional evaluation.

FAQs

How often should I clean and maintain my Juki sewing machine?

It’s recommended to clean and perform essential maintenance on your Juki sewing machine after every project or as needed. A thorough cleaning and maintenance routine can help prevent common issues.

What should I do if my Juki machine makes unusual noises or vibrates excessively?

First, check for any loose screws or components. If the issue persists, consult the troubleshooting guide for further steps. If needed, seek professional assistance to address the problem.

Can I use any thread on my Juki sewing machine?

While Juki machines are versatile, using high-quality threads suitable for your specific fabric type is advisable. Using low-quality or old threads can lead to thread-related problems.

Why is my Juki sewing machine experiencing thread tension issues?

Thread tension problems can arise from various factors, including incorrect threading or a need for adjustment. Consult the guide for step-by-step solutions to address tension issues.

When should I seek professional assistance for my Juki sewing machine?

Suppose you encounter complex mechanical or electronic issues safety hazards, or DIY efforts don’t resolve the problem. In that case, it’s best to consult a certified technician or a Juki service center for expert assistance.

Wrap Up

Mastering the art of troubleshooting Juki sewing machine problems is a valuable skill for any avid sewist. Following the comprehensive repair guide provided here, you’ve gained the confidence to tackle common issues precisely and easily.

Remember, regular maintenance and attentive care are the cornerstones of a reliable sewing machine. With these insights, you’ll not only extend the lifespan of your Juki machine but also enhance the quality of your creations.

So, continue to sew with confidence, knowing you have the knowledge and expertise to overcome any possible obstacle.

Leave a Reply