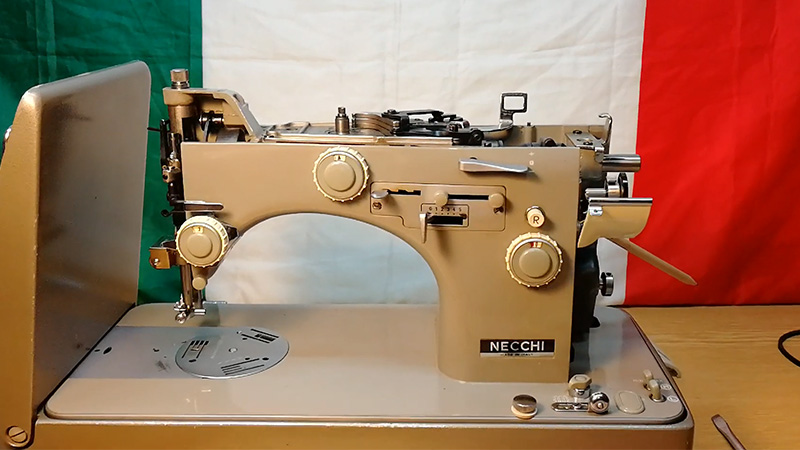

This comprehensive guide provides practical solutions for troubleshooting and repairing your Necchi sewing machine.

Whether you’re an experienced seamstress or just starting your sewing journey, we understand that a malfunctioning machine can be frustrating.

We’ll walk you through a step-by-step approach to diagnose and address common issues that may arise while using your Necchi sewing machine.

From power-related problems to thread issues and mechanical glitches, you’ll find clear and concise instructions for each challenge.

With the knowledge and solutions offered in this guide, you can regain control of your sewing machine’s performance and return to creating beautiful, flawless stitches.

Troubleshooting a Necchi Sewing Machine (Fix & Repair Guide)

Troubleshooting a Necchi sewing machine involves identifying common problems and implementing solutions to get your machine back in working order.

Here’s a step-by-step guide to help you troubleshoot and resolve common issues:

Gather Necessary Tools and Supplies:

- Screwdrivers (both flathead and Phillips)

- Sewing machine oil

- A small brush or compressed air canister

- Replacement parts (needles, bobbins, etc., if needed)

- User manual for reference

Machine Doesn’t Start

Begin by checking the power connections and ensuring the machine receives the necessary electrical supply. Below are steps to address this issue.

Possible Causes:

- The power cord is not plugged in.

- Faulty power outlet.

- Blown a fuse or tripped circuit breaker.

Solutions:

- Check Power Connections: Verify that the power cord is securely connected to the machine and outlet.

- Inspect Power Source: Plug in a different device to the outlet to ensure it’s providing power.

- Check Circuit Breaker/Fuse: If the outlet is functional, check the circuit breaker or replace the fuse if necessary.

Thread Breaking or Tangling

Thread issues can be frustrating, but they are often quickly resolved. Let’s explore the potential causes and their corresponding solutions.

Possible Causes:

- Incorrect threading.

- Tension settings are off.

- Dull or bent needle.

- Poor-quality or old thread.

Solutions:

- Rethread the Machine: Follow the threading guide in your manual carefully. Ensure the thread passes through all necessary guides and tensions correctly.

- Adjust Tension: Experiment with higher tension settings for thicker fabrics and lower tension for thinner ones.

- Replace the Needle: A dull or bent needle can cause thread breakage. Install a new needle suitable for your fabric.

- Use Quality Thread: Low-quality or old thread can lead to frequent breakage. Switch to a fresh, high-quality thread.

Uneven Stitches

Stitching problems can mar the quality of your projects. This section will delve into the typical culprits behind uneven or skipped stitches and how to rectify them.

Possible Causes:

- Incorrect needle size for fabric.

- Improperly inserted or bent needle.

- Bobbin issues, such as improper winding or tension.

Solutions:

- Needle Compatibility: Ensure you use the right needle for your fabric type. Refer to your manual for guidance.

- Proper Needle Insertion: Ensure the needle is inserted correctly and not bent or damaged.

- Check Bobbin: Ensure it’s wound evenly and the tension is correct. Rethread the bobbin if needed.

Excessive Noise or Vibration

Unusual noises or excessive vibrations can be indicators of underlying issues. Let’s pinpoint the possible causes and steps to mitigate them.

Possible Causes:

- Loose screws or parts.

- Lack of lubrication.

- Foreign objects stuck in the machine.

Solutions:

- Tighten Screws and Parts: Check for any visibly loose screws or parts. Tighten them, but be cautious not to over-tighten them.

- Lubricate the Machine: Follow the manufacturer’s instructions for oiling. Use appropriate sewing machine oil.

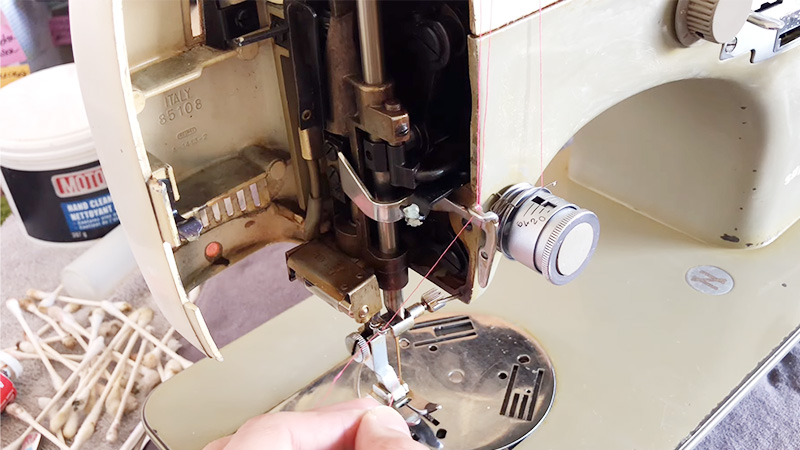

- Remove Debris: Remove the needle plate and check for debris or foreign objects. Clean thoroughly.

Feed Dogs Not Moving Fabric

When the feed dogs fail to advance the fabric, it can impede the sewing process. Here, we’ll examine why this might happen and how to restore proper function.

Possible Causes:

- The feed dog setting is lowered.

- Feed dogs are clogged with lint.

Solutions:

- Check Feed Dog Setting: Ensure the feed dog setting is raised.

- Clean Feed Dogs: Use a brush or compressed air to clean out any lint or debris around the feed dogs.

Bobbin Thread Jamming

A jammed or tangled bobbin thread can be a frustrating setback. This section will guide you through the steps to troubleshoot and fix this issue.

Possible Causes:

- Bobbin incorrectly inserted.

- Bobbin’s tension is too tight or too loose.

- Damaged or warped bobbin.

Solutions:

- Rethread Bobbin: Ensure it’s inserted correctly and the thread flows in the right direction.

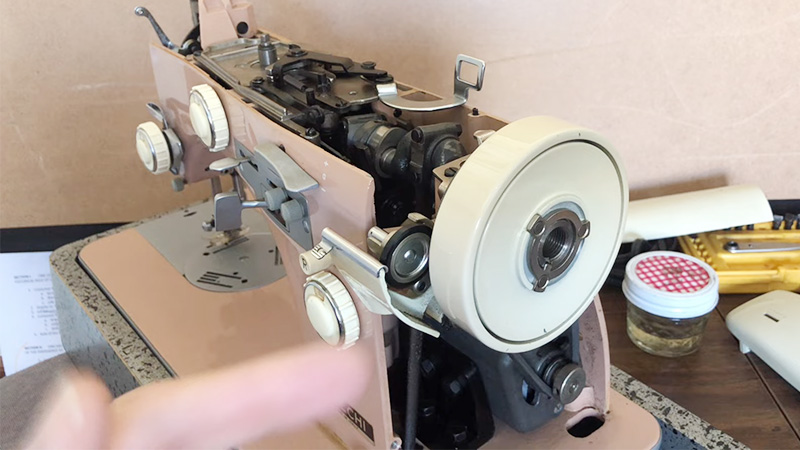

- Adjust Bobbin Tension: Most machines have a small screw for this purpose. Make adjustments as needed.

Stitch Length or Width Won’t Adjust

When you’re having trouble with stitch length or width adjustments, it can hinder your sewing projects. Let’s explore the potential causes and how to address them.

Possible Causes:

- The stitch length/width dial is stuck or damaged.

- Mechanical issue within the machine.

Solutions:

- Clean Around Dial: Ensure there’s no debris causing the dial to stick.

- Check for Mechanical Issues: If the dial is damaged, it may need replacement. Refer to the manufacturer’s manual or consult a professional technician.

Precaution for Unwanted Accidents During Repair It

Repairing a sewing machine, including a Necchi sewing machine, involves working with moving parts, electrical components, and sometimes sharp objects like needles.

To prevent unwanted accidents during the repair process, it’s essential to take several precautions:

Unplug the Machine

Always start by unplugging the sewing machine from the power source. This ensures that it cannot accidentally start while you’re working on it, preventing electric shocks or injuries caused by moving parts.

Use Personal Protective Equipment (PPE)

Depending on the repair task, consider wearing safety glasses to protect your eyes from debris, and use appropriate gloves to safeguard your hands from sharp edges or hot components.

Work in a Well-Lit Area

Adequate lighting is essential for spotting small parts, assessing the machine’s condition, and preventing accidents. Make sure your work area is well-lit.

Read the User Manual

Familiarize yourself with the sewing machine’s user manual before attempting any repairs. It provides essential safety information and specific guidelines for your model.

Organize and Label Parts

If you need to disassemble the machine, organize the parts carefully. Label them or take pictures as you go to ensure you can reassemble the machine correctly.

Keep Small Children and Pets Away

Repairing a sewing machine should be done safely, without distractions and potential hazards. Keep small children and pets out of your workspace.

Tips for Avoiding Further Issues

To avoid further issues with your Necchi sewing machine, follow these tips and best practices:

Regular Maintenance

Regularly clean your machine, remove lint, dust, and debris from the bobbin area, and feed dogs and needle plates. Consult your user manual for specific cleaning instructions.

Follow the manufacturer’s guidelines for oiling your machine. Proper lubrication prevents excessive friction and wear on moving parts.

Use High-Quality Supplies

Invest in good-quality threads, as cheap threads can break more easily and cause tension issues.

Use needles from reputable brands and ensure they’re suited to your fabric type. Dull or damaged needles can lead to stitching problems.

Proper Threading

Take your time to thread the machine correctly. Ensure the thread is properly seated in all the thread guides and tension discs.

When threading the needle, make sure the thread passes through the eye from front to back.

Needle Selection

Choose the right needle for the job. Ballpoint needles are suitable for knits, while universal needles work for most woven fabrics. Specialty needles are available for specific tasks like quilting or embroidery.

Bobbin Care

Wind the bobbin evenly and ensure it’s not overfilled. Overfilled bobbins can lead to tension problems.

Regularly check the bobbin for damage, such as cracks or chips, and replace it if necessary.

Tension Adjustment

Please familiarize yourself with your machine’s tension adjustment settings and their effects on different fabrics.

Test your machine’s tension on a scrap piece of fabric before starting your project to ensure it’s set correctly.

Avoid Overloading

Avoid sewing through materials that are too thick for your machine to handle. Consider using a heavy-duty sewing machine if you need to work with heavy fabrics.

Can You Fix Your Necchi Sewing Machine at Home?

Yes, you can attempt to fix your Necchi sewing machine at home, especially for common issues. However, it’s essential to approach the process with care and follow safety precautions.

Here’s a general guideline to get you started:

Diagnose the Problem

Identify the specific issue your sewing machine is facing. This could include thread breaking, uneven stitching, or the machine not starting.

Refer to the User Manual

Consult your Necchi sewing machine’s user manual. It often contains troubleshooting tips and solutions for common problems.

Safety First

Ensure the sewing machine is unplugged from the power source to prevent accidental starts. This is crucial for your safety.

Start with Basic Checks

Check for loose connections, both electrical and mechanical. Ensure that all parts are in their correct positions.

Clean and Lubricate

Remove lint, dust, and debris from the machine using a small brush or compressed air. Apply sewing machine oil to the recommended parts for lubrication.

Address Common Issues

Depending on the problem, here are some steps you can take:

- Thread Breaking or Tangling:

Rethread the machine following the manual’s instructions. Adjust the tension settings. Replace the needle with a suitable one for your fabric. Use high-quality thread.

- Uneven Stitches or Skipped Stitches:

Ensure you’re using the right needle for your fabric. Check the needle for damage and proper insertion. Examine the bobbin for even winding and correct tension.

- Noisy or Excessive Vibration:

Tighten any visibly loose screws and parts (do not over-tighten). Lubricate the machine according to the manufacturer’s instructions. Remove debris from around the feed dogs and needle plate.

- Feed Dogs Not Moving Fabric:

Make sure the feed dog setting is raised. Clean out any lint or debris from around the feed dogs.

Test the Machine

Plug in the machine and conduct a test run to ensure the issue has been resolved.

When You Need to Consult a Professional?

Consulting a professional for sewing machine issues is crucial in certain situations where the problem exceeds your expertise level or the repair’s complexity.

Here are instances when you should seek the help of a professional sewing machine technician:

Electrical Issues

If you suspect a problem with the machine’s wiring or electrical components, it’s best to consult a professional. Attempting to fix electrical issues without proper knowledge can be dangerous.

Complex Mechanical Problems

When you encounter a problem that requires disassembling or adjusting internal parts you’re unfamiliar with, it’s advisable to seek professional help. This includes issues with the motor, gears, or timing mechanisms.

Specialized Repairs

Some repairs may require specialized tools or knowledge that only a professional technician possesses. This could include recalibrating electronic components or working on computerized sewing machines.

Under Warranty Repairs

If your sewing machine is still under warranty, attempting to fix it yourself may void it. It’s best to consult the manufacturer or an authorized service center for any covered repairs.

Vintage or Antique Machines

Older machines, especially those considered antiques or collectibles, may require specialized knowledge and parts that are not readily available. Consulting a professional with expertise in vintage sewing machines is recommended.

Safety Concerns

When you’re unsure about the safety of a repair, especially when it involves electrical components, it’s best to leave it to a professional. Incorrectly repaired machines can pose safety hazards.

Persistent Issues

When you’ve attempted to troubleshoot the machine, and the problem persists, seeking professional help is the next step. Working on a machine without the necessary expertise can sometimes worsen the problem.

FAQs

How often should I clean my Necchi sewing machine?

Regular cleaning is essential. Aim to clean out lint, dust, and debris after every significant sewing project and perform a more thorough cleaning every 6-8 weeks.

What can cause my Necchi sewing machine to make unusual noises?

Unusual noises can result from a variety of issues, such as loose screws, lack of lubrication, or foreign objects in the machine. It’s essential to investigate and address the source of the noise promptly.

Can I use any thread with my Necchi sewing machine?

While Necchi machines are versatile, high-quality thread is recommended to prevent breakage and tension issues. It’s best to avoid old or low-quality threads.

How do I know if my sewing machine’s tension is set correctly?

A balanced stitch has evenly spaced threads on both sides of the fabric. Conducting a test stitch on a scrap piece of fabric before starting your project can help you determine if the tension is set correctly.

What should I do if I encounter a problem I can’t fix at home?

If you encounter a complex issue or are uncomfortable with a repair, consult your Necchi sewing machine’s user manual for guidance or seek assistance from a professional sewing machine technician.

Wrap Up

Mastering the art of troubleshooting and repairing your Necchi sewing machine empowers you to create without interruption. With careful attention to threading, tension, and regular maintenance, you can prevent common issues from impeding your projects.

Should challenges arise, this guide equips you with the knowledge to address them at home confidently. Safety is paramount, so always unplug the machine before attempting any repairs.

For complex or persistent problems, seeking professional assistance ensures the longevity of your trusted tool. By following these steps and best practices, you’ll unlock the full potential of your Necchi sewing machine, enabling you to stitch with precision and confidence.

Leave a Reply