Follow these simple steps to remove the top cover of your machine: Disconnect the power cord Open the sewing area by removing four screws at the base of the machine Align the presser foot with the needle plate and push it down slowly until it snaps into place To access and operate various parts of your machine, you’ll need to remove this top cover: Remove the four screws at the base of the machine Lift up on one side of the heel frame and pull outwards, then do same on opposite side to uncover feed dog wheel

How To Thread A Singer Merritt 4530?

Follow these simple steps to remove the top cover of your machine: disconnect the power cord, open the sewing area by removing four screws at the base of the machine, and align the presser foot with the needle plate.

Source: proxibid

Once you’ve completed these steps, lift up on one side of the heel frame and pull outwards to uncover feed dog wheel. Finally, replace all parts in reverse order and connect power cord before re-sewing area closed

Remove the Top Cover

If the machine is not in use, lift up on the handle and then tilt away from you so that the top cover falls off. Remove any material blocking the needle path before starting by removing screws located along both sides of front panel (1) Lift up on latch assembly at rear of machine and then pull out needle unit (2).

The bobbin case can now be removed To clean or adjust spindle, remove screw holding gear wheel in place; lubricate if necessary with sewing machine oil or WD-40 and replace screw Reattach top cover, reversing steps 1-5

Disconnect the Power Cord

Singer provides a few simple steps to disconnect the power cord. This will help you avoid any accidents if the machine becomes tangled in cords or cables.

Follow these easy instructions to safely remove and store your sewing machine when not in use. You can easily keep your Singer Merritt 4530 working like new by following these tips for proper care and maintenance.

Finally, be sure to read our article on how to thread a Singer Merritt 4530 before starting your next project.

Open the Sewing Area by Removing Four Screws At The Base Of The Machine

Singer Merritt 4530 sewing machines have a removable upper threading area by removing four screws at the base of the machine. This will make it easier to get to any under-the-machines parts you may need for repairs or adjustments.

Be sure to label each screw in case you lose them while they’re out; otherwise, you’ll be facing an uphill battle when trying to find and replace them. If your machine doesn’t seem quite right after taking these steps, there’s always the possibility of repairing it yourself–just remember that this is a specialty tool and not something easily found at your local store.

Singer recommends using only high quality replacement parts from their authorized dealers, so keep that in mind if anything goes wrong down the road

Align The Presser Foot With The Needle Plate

Threading a Singer Merritt 4530 is pretty straightforward, but it can be easier with step-by-step instructions. Align the presser foot with the needle plate and push it down slowly until it snaps into place.

Be careful not to pinch your fabric while threading. Keep a close eye on the tension as you go – too much tension and your machine might fly off the table. When you’re finished, remove the presser foot by gently pressing down on both sides of it at once

One Side Of the Heel Frame

To thread a Singer Merritt 4530, lift up on one side of the heel frame and pull outwards, then do same on opposite side to uncover feed dog wheel. The threading process is easy once you have the hang of it- follow these simple steps for a perfect result each time.

When rethreading your machine, make sure to use this special guide so that tension is evenly distributed along the entire width of fabric being sewn. If your machine starts slipping or skipping stitches while sewing – don’t worry.

This common issue can be easily fixed by following these tips from our team here at Sewrella HQ; Singer machines are some of the most reliable in the industry, but like any piece of equipment – they will eventually require proper upkeep and attention to keep them running smoothly for years to come.

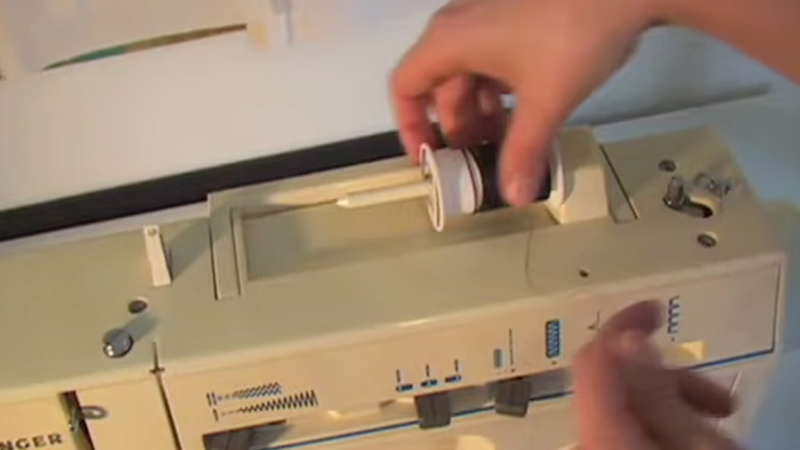

Where do you place the spool of thread?

If you’re trying to sew something and find that the thread keeps getting caught on the spool, it might be because you’re not placing the spool in the right place.

Make sure that the spool is sitting squarely in your sewing machine’s bobbin case and then turn it so that it’s facing forward. To ensure that the thread doesn’t get tangled up, you’ll need to use a thread stand and thread guides.

A thread stand is an apparatus which holds the spool of thread while you are sewing or embroidering. Thread guides keep your threads taut so they don’t knot together and cause tension problems in your work. The right or back side of the fabric will determine where you should place the spool of thread when starting to sew or embroider.

You’ll want to make sure that the spool is on this side so it won’t get caught in your machine’s needle teeth later on in the project. If you’re using a serger, be sure to place the threaded fabric on to the “mirror” (right-hand) feeder dog first before feeding it through in to the “normal” Feed Dog(left hand). This ensures even coverage across both sides of fabrics being sewn/embroidered.

Where does the bobbin thread go?

The bobbin thread attaches the spindle to the motor shaft, and it also controls how tightly the spindle turns. If this part is damaged or faulty, it can cause a loss of power and possible damage to other parts of the engine.

Bobbin Thread

The bobbin thread is what feeds the fabric through the machine while it’s being sewn. This thread should be of a consistent diameter and length so that your stitching will be accurate and even.

Spool Thread

The spool thread is what you see on either side of the sewing machine needle as it goes through the fabric.

It provides both support for the fabric and keeps everything moving in one direction.

Needle Plate

The needle plate sits atop your sewing machine’s gears, below the needle itself, and helps to guide its movement across fabrics by providing friction against which stitches are formed (along with other small components).

Eye of The Needle The eye of the needle is located at or near where you would typically start a stitch – usually just above or slightly below centerline on your material when working from left to right – making sure that this area properly clears all obstacles before beginning to sew.

Finally, make sure your threads are tightly wound onto your spools; knots can cause distortions in finished products

Why is my Singer sewing machine not picking up the bobbin thread?

If you are having trouble getting your Singer sewing machine to pick up the bobbin thread, there could be a few reasons. First, it may be that the bobbin is loose or not properly secured.

Second, the spindle on the motor shaft could be worn out and causing problems with threading. Third, the tension regulator for the looper might need to be replaced. If these solutions do not work, then it may be time for a new Singer sewing machine.

The Bobbin-Winding Spindle Needs to Be in the Correct Position

The bobbin-winding spindle needs to be positioned so that it can pick up the thread from the bobbin. If this is not done properly, your machine will not be able to sew correctly. To ensure proper thread pickup, your sewing machine needle must be moved down below the feed dog and into contact with the thread as it spins around on its shaft.

Your Sewing Machine Needle Must Be Moved Down for Thread Pickup

If your machine’s needle isn’t lowered far enough, then it won’t have access to all of the threads in your fabric and may cause skipped stitches or inaccurate measurements. Make sure that your needle is always positioned where it can reach every single strand of yarn while stitching.

Check That Your Bobbin Is Inserted Properly Into the Top of Feed Dog

Make sure that you are inserting your bobbin correctly – if it’s not inserted properly, then it won’t wind onto the spindle correctly and there will be no way for your machine to grab onto the thread as you stitch.

Clean or Replace Any Broken Parts on Your Machine

How do I identify my vintage Singer sewing machine?

If you’re looking for a vintage Singer sewing machine, there are a few things to keep in mind. First, look for the trademark “Singer” logo on the front of the machine.

Second, pay attention to the model number. The numbers will vary from machine to machine, but they’ll usually start with either “SM-1,” “SM-2,” or “SM-3.” Finally, check out how old your machine is – older machines tend to be more rare and valuable.

To accurately identify your vintage Singer sewing machine, you’ll need to know the model number and find a serial number which is usually located on the handwheel. The electrical cord receptacle should also be inspected for signs of wear or damage.

If it looks like it’s been damaged in any way, replace the cord as soon as possible to avoid potential mechanical problems down the road. You can also inspect the front panel of your vintage Singer sewing machine for any signs of damage or missing components.

Be sure to look for symbols such as “Singer” and “Made in U S A.”. Finally, make sure you have an understanding of how these machines work before trying to fix them yourself – if something seems wrong, don’t try to take apart or repair it without first consulting a professional.

To Recap

Threading a Singer Merritt 4530 sewing machine is a simple process that can be done by anyone with some basic hand sewing knowledge. But machine sewing is always better than hand sewing. First, identify the bobbin thread path on the machine and match it up to one of the spools of thread on the front panel.

Then, wind your chosen thread onto the correct size bobbin according to the manufacturer’s instructions. Finally, insert the needle into one of the fabric guides and feed the end of thread through until you reach the knot at the another side – make sure not to pull too hard or you may damage your machine.

Leave a Reply