In the realm of textile manufacturing and sewing, precision and durability are paramount. One crucial technique that embodies these principles is the safety stitch.

A safety stitch is a sewing technique that secures seams that could cause injuries. It is most commonly used when working with material that is fray-sensitive, such as lace or netting.

This ingenious stitching technique not only reinforces the edges of fabrics but also prevents fraying, unraveling, and the dreaded seam failure. Safety stitches are widely employed in the production of clothing, upholstery, bedding, and industrial textiles.

In this article, we will delve deeper into what a safety stitch is, how it works, its applications across industries, and why it plays an indispensable role in ensuring the integrity of stitched products.

What Is A Safety Stitch?

A safety stitch is a sewing technique that secures seams that could cause injuries. It is most commonly used when working with material that is fray-sensitive, such as lace or netting.

What is this? The safety stitch creates a continuous loop around the edge of the seam so it can’t unravel or come undone.

It is commonly used in industrial sewing, particularly for garments and textiles subjected to heavy wear and stress.

Key characteristics of a safety stitch:

Multiple Threads

Safety stitches are typically created using multiple threads. These threads work in tandem to reinforce the seam and securely encase the raw fabric edges.

Strength

Safety stitches are known for their strength and ability to withstand stress and tension. They are often used in garments like jeans, workwear, and sportswear, where durability is crucial.

Flexibility

Despite their strength, safety stitches also provide flexibility, allowing the fabric to move comfortably with the wearer. This makes them suitable for activewear and stretch fabrics.

Clean Finish

Safety stitches result in a clean, flat appearance on both sides of the fabric, making them suitable for reversible garments or situations where the seam may be visible.

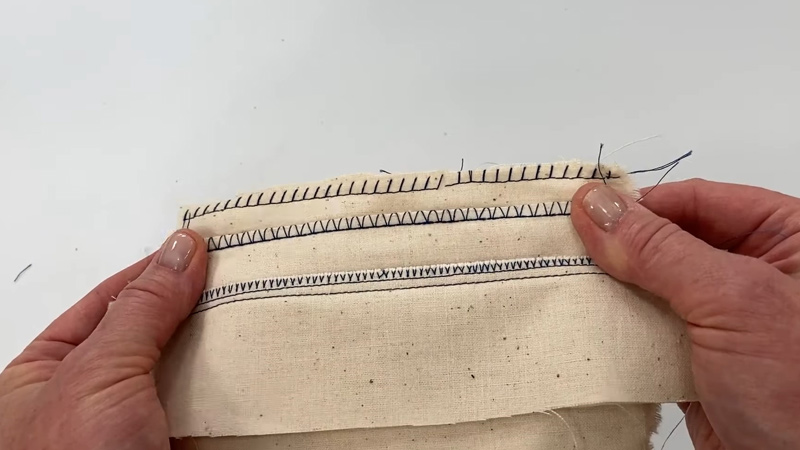

There are several variations of safety stitches, including the two-thread chainstitch and the three-thread chainstitch, each with its own set of characteristics and applications.

These stitches are often produced by specialized industrial sewing machines.

A safety stitch is a robust and secure sewing technique used in industrial and heavy-duty applications to create strong, flexible, and fray-resistant seams.

What Are The Benefits Of A Safety Stitch?

A safety stitch, also known as a serged or overlock stitch, offers several benefits in sewing and garment construction. Here are six key advantages of using a safety stitch:

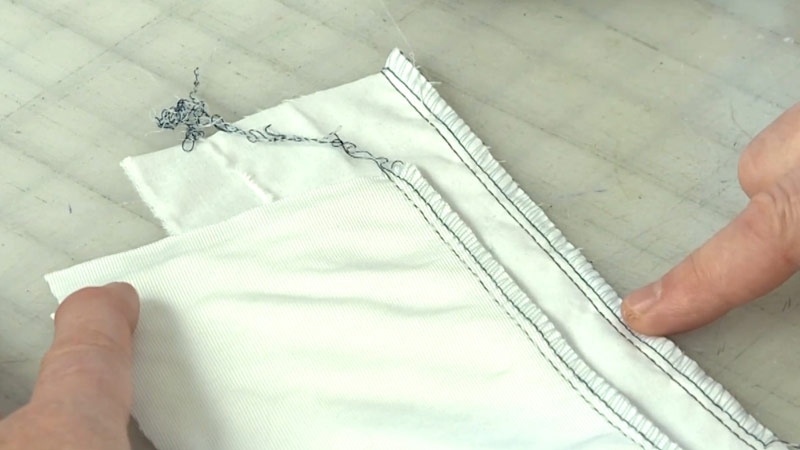

Seam Finishing

Safety stitches are primarily used for seam finishing. They neatly encase raw fabric edges, preventing fraying and unraveling.

This feature adds durability to garments and prevents loose threads from becoming visible on the inside.

Clean and Professional Look

Safety stitches create a clean and professional appearance, both on the inside and outside of a garment.

This is especially important for items like activewear, lingerie, and knitwear, where neat seams are essential.

Stretch and Flexibility

Safety stitches are ideal for stretchy and knit fabrics.

The stitch’s natural elasticity allows the seams to stretch and move with the fabric, ensuring comfort and flexibility in clothing, swimwear, and sportswear.

Secures Layers of Fabric

Safety stitches effectively secure multiple layers of fabric together, making them suitable for tasks like attaching elastic, joining seams on knitwear, and reinforcing stress points in garments.

Time Efficiency

Safety stitches can combine two sewing operations into one—seaming and finishing. This saves time in the sewing process, making it a preferred choice for mass production in the garment industry.

Prevents Unraveling

Unlike straight stitches, safety stitches have multiple threads that lock together, reducing the risk of seam failure.

This is especially crucial for high-stress areas in clothing, such as crotch seams in pants or inseams in leggings.

Safety stitches offer seam finishing, a clean appearance, flexibility, fabric security, time efficiency, and enhanced durability.

These benefits make them essential for a wide range of sewing projects, especially when working with knit and stretch fabrics or when aiming for professional and long-lasting results.

How To Do A Safety Stitch? 5 Steps

Performing a safety stitch, also known as an overlock or serged stitch, is a common sewing technique used to finish fabric edges and create secure seams. Here are five steps to execute a basic safety stitch on a sewing machine:

Materials and Tools You’ll Need

- Sewing machine with an overlock or serger stitch capability

- Appropriate thread color

- Fabric to be stitched

Step 1: Prepare Your Machine

Ensure your sewing machine is set up for an overlock stitch. This may involve selecting the appropriate stitch on your machine and installing the right presser foot.

Step 2: Thread Your Machine

Thread your machine with the desired thread color for the overlock stitch. Follow the threading guide provided in your machine’s manual.

Step 3: Set Your Stitch Length and Width

Adjust the stitch length and width as needed, depending on your fabric and the desired result. For most overlock stitches, a medium stitch length and width are suitable.

Step 4: Position Your Fabric

Place the fabric you want to sew under the presser foot, aligning the fabric edge with the seam allowance guide on the machine. The fabric should be sandwiched between the presser foot and the feed dogs.

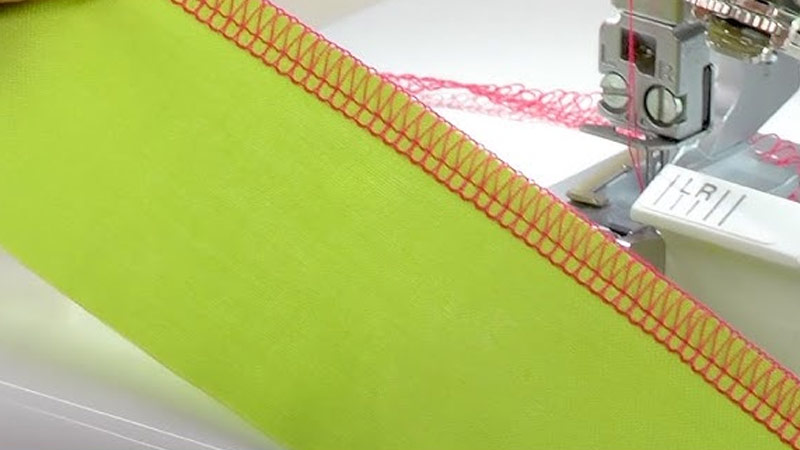

Step 5: Sew the Safety Stitch

Start sewing by gently pressing the foot pedal or operating the machine as per your model’s instructions.

The machine will create an overlock stitch, simultaneously trimming excess fabric and securing the edge with multiple threads.

Keep a steady pace and guide the fabric evenly through the machine, making sure the edge is consistently aligned with the seam allowance guide.

When you reach the end of the fabric, release the foot pedal, and let the machine complete the stitch. Most modern machines have a thread cutter that trims the thread automatically.

Lift the presser foot and remove the fabric from the machine.

Your safety stitch is complete! The overlock stitch will secure the fabric edge, prevent fraying, and give your project a clean and professional finish.

Practice on scrap fabric to become comfortable with the stitch and its settings before using it on your actual sewing project.

What If I Can’t Find A Needle In My Size?

If you can’t find a needle in your size, don’t worry! There are other ways to get the job done. If you have a friend who is able to sew, ask them to help you out. You can also try using a special machine designed for this type of sewing.

If neither of those options works, there are other ways to get the job done such as using thread and a needle made for decorative purposes only. Another option would be to purchase a pre-made curtain from a store or online retailer.

Finally, if all else fails, you can try hiring a professional seamstress or tailor to do the job for you. Otherwise, you’ll also get problems to change needle of the heavy duty sewing machine.

When Should I Replace A Safety Stitch?

A safety stitch is a type of seam that helps keep your clothes together when they are being worn. It is important to replace a safety stitch every few months, depending on the kind of fabric you are using.

If you have heavy fabrics, you may need to replace the stitch more often. You can usually find replacement stitches at sewing stores or fabric retailers. When replacing a safety stitch, it is best to sew slowly and with caution so as not to stretch the fabric too much.

Always make sure you test the new safety stitch before wearing your clothing! When replacing a safety stitch, always start by Tracing the old one onto the new material before sewing.

Safety Stitch vs. Overlock

“Safety stitch” and “overlock” are terms often used interchangeably, but they can refer to slightly different concepts in the context of sewing. Let’s clarify the distinctions:

Safety Stitch

Purpose: The term “safety stitch” generally refers to a stitch that adds strength and durability to a seam while preventing unraveling.

It’s commonly used in industrial sewing, especially for garments subjected to heavy wear and stress, like denim or workwear.

Stitch Type: The safety stitch can come in various forms, including a two-thread chain stitch or a three-thread chain stitch. These stitches lock the seam’s raw edges while providing flexibility and resilience.

Appearance: A safety stitch typically has a clean, flat appearance on both sides of the fabric, making it suitable for reversible garments or those with exposed seams.

Overlock Stitch

Purpose: An “overlock stitch” is a broad term used to describe a type of stitch that trims the fabric edges, encases them with thread, and secures the seam.

The primary purpose is to prevent fraying and create a tidy seam finish.

Stitch Type: Overlock stitches are more diverse and can include three-thread, four-thread, or five-thread overlock variations, each offering different levels of seam security and stretchability.

These stitches are commonly used in home sewing and serger machines.

Appearance: Overlock stitches create a serged edge, which is often seen on the inside of garments.

While they effectively finish seams, they may not have the same strength or appearance as a true safety stitch.

Safety stitch usually emphasizes seam strength and can encompass various specific stitches, while “overlock” broadly describes stitches used for finishing raw fabric edges and securing seams.

In everyday sewing and home sewing machines, “overlock” is the more commonly used term, and it often refers to stitches created by serger machines for neatening and finishing seams.

However, in industrial sewing or specialized contexts, “safety stitch” may refer to specific types of strong, reinforced stitches used for added durability.

FAQs

What is a safety stitch, and how does it differ from regular safety stitching?

A safety stitch, also known as a serged seam, is a specialized sewing technique that involves two lines of stitching and an overcasting of thread. It differs from regular safety stitching by providing added strength and preventing fraying.

Where are safety stitches commonly used in everyday products?

Safety stitches are frequently used in clothing, particularly in the seams of jeans and activewear, to ensure durability. They are also found in bedding, upholstery, and automotive interiors to maintain seam integrity.

Can I create a safety stitch at home using a standard sewing machine?

While it’s possible to create a safety stitch at home with a serger or overlock sewing machine, achieving it with a standard sewing machine can be challenging. A serger is more efficient and specialized for this purpose.

What are the benefits of using a safety stitch in industrial applications?

In industrial settings, safety stitches are preferred for their ability to withstand wear and tear.

They are used in the production of heavy-duty textiles, such as tarps, bags, and industrial equipment covers, to ensure the longevity of the products and prevent seam failures.

Conclusion

In the world of textiles and sewing, a safety stitch is the unsung hero that holds everything together. This versatile and durable sewing technique has proven its mettle in countless industries, from fashion to automotive upholstery.

Its ability to prevent fraying and maintain seam integrity has made it an indispensable part of modern manufacturing.

Whether you’re wearing a sturdy pair of jeans, resting on a well-stitched mattress, or relying on the strength of your car’s upholstery, the odds are that a safety stitch is silently at work, ensuring durability and longevity.

As we continue to innovate and refine our sewing methods, the humble safety stitch remains a timeless example of how small details can make a big difference in the quality and longevity of our everyday products.

Leave a Reply