Sewing Technology in Industrial Training Institutes (ITI) represents a specialized vocational training program that delves into the intricacies of garment production and textile craftsmanship.

These ITI courses are meticulously designed to equip aspiring professionals with the knowledge and practical skills necessary to thrive in the dynamic world of sewing and fashion.

Covering a broad spectrum, from operating sewing machines with precision to fabric cutting, pattern creation, and quality control, Sewing Technology in ITI empowers students with the expertise required in the garment industry.

This comprehensive training not only fosters technical proficiency but also emphasizes safety measures, industrial standards, and soft skills, ensuring that graduates are well-prepared for rewarding careers in the ever-evolving textile sector.

What Is Sewing Technology in ITI?

Sewing technology in an Industrial Training Institute (ITI) refers to the education and training programs designed to equip individuals with the knowledge and skills needed to work in the field of sewing, garment production, and related industries.

ITIs are vocational training institutes that offer practical and job-oriented training to prepare students for various trades, including sewing technology.

Here’s an overview of what sewing technology in ITI encompasses:

Curriculum and Courses

ITIs typically offer a range of courses related to sewing technology. These courses cover various aspects of sewing, such as garment construction, pattern making, fabric cutting, sewing machine operation, and quality control.

The curriculum is designed to provide students with a comprehensive understanding of the sewing process.

Theory and Practical Training

Sewing technology programs in ITIs balance theoretical knowledge with hands-on practical training. Students learn about different types of fabrics, sewing techniques, garment design, and production processes.

They also gain proficiency in operating different types of sewing machines and equipment.

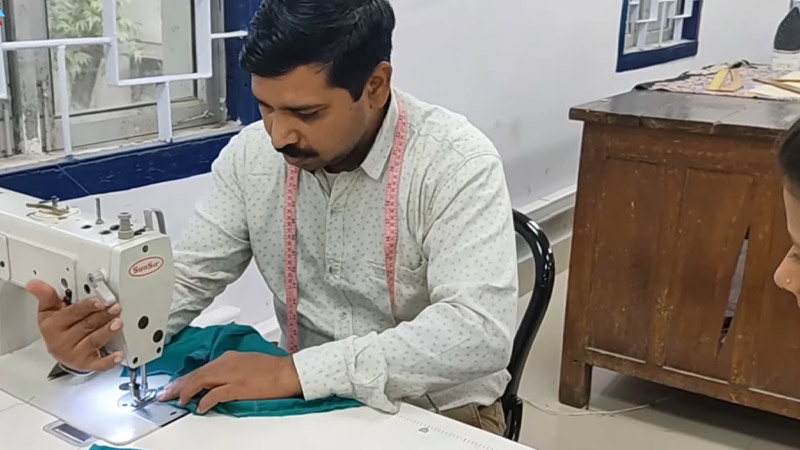

Machine Operations

A significant part of sewing technology training involves teaching students how to operate and maintain sewing machines and equipment.

Students learn to use single-needle and multi-needle machines, overlock machines, and other specialized equipment used in the garment industry.

Pattern Making and Cutting

ITI sewing technology programs often include instruction in pattern making and fabric cutting. This involves creating patterns for garments, marking and cutting fabrics accurately, and ensuring minimal fabric wastage.

Quality Control

Quality control is a critical aspect of sewing technology. Students are taught to inspect finished garments for defects, ensure proper stitching and finishing, and maintain quality standards in the production process.

Industrial Sewing Techniques

ITI programs in sewing technology focus on industrial sewing techniques used in mass production settings. Students learn how to produce garments efficiently and meet production targets.

Safety Measures

Safety is paramount in any industrial setting, including garment production. ITI programs educate students on safety procedures and the proper use of protective equipment to minimize workplace accidents.

Soft Skills

In addition to technical skills, sewing technology programs often emphasize soft skills such as time management, teamwork, and communication. These skills are essential for success in the workplace.

Industry Exposure

Some ITIs collaborate with local garment manufacturers or textile industries to provide students with real-world exposure. This may include industrial visits, internships, or apprenticeship programs, allowing students to apply their skills in a professional setting.

Certification

Upon completing the sewing technology program, students typically receive a certification or diploma that attests to their skills and knowledge in the field. This certification can enhance their employability in the garment and textile industries.

How to Enroll in a Sewing Technology Course at ITI?

Enrolling in a Sewing Technology course at an ITI (Industrial Training Institute) typically involves a few key steps.

Here’s a guide on how to go about it:

1. Research and Choose an ITI

Start by researching ITIs in your area or a location of your preference. You can use online resources, government ITI websites, or visit the institutes personally to gather information.

Consider factors such as the reputation of the ITI, the availability of Sewing Technology courses, the duration of the courses, and any specific facilities they offer.

2. Check Eligibility Requirements

Review the eligibility criteria for the Sewing Technology course you’re interested in. Eligibility requirements can vary from one ITI to another, but typically, you’ll need at least a high school diploma or its equivalent.

3. Application Process

Obtain the application form for the Sewing Technology course from the ITI of your choice. You can usually get this form from the ITI’s administrative office or download it from their official website.

4. Fill Out the Application Form

Carefully fill out the application form with accurate information. Be sure to provide all the required details, including personal information, educational qualifications, and any other relevant information.

5. Attach Necessary Documents

Prepare a set of documents that are commonly required during the enrollment process.

These may include:

- Copy of your high school diploma or equivalent certificate.

- Passport-sized photographs.

- Proof of age (e.g., birth certificate or Aadhar card in India).

- Address proof (e.g., utility bill or Aadhar card).

- Any other documents specified by the ITI.

6. Submit the Application

Submit the completed application form along with the necessary documents to the ITI within the specified deadline. Make sure to keep a copy of your application and any payment receipts for your records.

7. Entrance Exam (if applicable)

Some ITIs may conduct entrance exams or interviews as part of the admission process. If this is the case, be prepared to appear for the exam or interview on the scheduled date.

8. Merit List and Admission

After the application deadline has passed and any entrance exams/interviews have been conducted, the ITI will typically publish a merit list of selected candidates.

If your name appears on the merit list, you will be notified by the ITI about the admission process. This will include details on when and how to complete the enrollment formalities.

9. Pay Fees and Complete Enrollment

Once you receive confirmation of your admission, you will need to pay the course fees as specified by the ITI.

Be sure to follow the payment instructions provided. Complete any additional enrollment formalities, such as submitting medical certificates or other required documents.

10. Commence Classes

Attend the orientation session, if one is scheduled, and begin your Sewing Technology course as per the academic calendar of the ITI.

FAQS

What does the Sewing Technology course in ITI typically cover in its syllabus?

The Sewing Technology syllabus in ITI typically includes subjects like fabric handling, pattern making, sewing machine operation, quality control, and safety measures.

It also emphasizes soft skills and industry exposure to prepare students for careers in garment production and textiles.

Is Sewing Technology in ITI suitable for those interested in a fashion design career?

While Sewing Technology in ITI primarily focuses on the technical aspects of garment production, it provides a strong foundation for those aspiring to enter the fashion industry.

Are there specialized areas within Sewing Technology ITI courses?

Yes, some Sewing Technology ITI programs offer specialization options.

What factors influence the salary in Sewing Technology ITI careers?

Salary in Sewing Technology ITI careers can be influenced by factors like location, experience, the specific job role, and the demand for skilled professionals in the local job market.

Is there a significant salary difference between entry-level and experienced professionals in sewing technology ITI careers?

Yes, typically, experienced professionals in sewing technology ITI careers tend to earn higher salaries than those starting in entry-level positions.

To Recap

Sewing Technology in Industrial Training Institutes (ITI) represents a vital bridge between traditional craftsmanship and modern industrial practices.

It equips individuals with the intricate skills and knowledge needed to navigate the dynamic textile and garment production industries.

With a focus on fabric handling, machine operation, quality control, and pattern making, ITI courses in sewing technology provide a solid foundation for careers in sewing, fashion design, and textile manufacturing.

As technology evolves, so does the relevance of sewing technology, as it continues to play a pivotal role in meeting the diverse demands of the fashion and textile sectors.

Graduates of ITI sewing technology programs are well-prepared to contribute to these industries while ensuring the timeless art of sewing thrives in a contemporary world.

Leave a Reply