If you notice that your electric motor is smoking, it may be time to take action. There are a few solutions for smoky motors, so don’t panic. Try these tips before calling a technician: clear the throttle plate, replace the belt or pulley and clean the commutator and brushes.

Don’t wait until your electric motor smokes all of the time; find out what’s causing the smoke and fix it sooner rather than later. Motor smokers can sometimes be fixed without any expensive repairs–just follow these steps: check fan speed, filter quality/replacement, insulation levels and voltage regulator settings

Why Does An Old Electric Motor Smoke Sewing?

Overheating is the most common cause of smoking in electric motors. Motors that have been overheated may start to smoke because they are not getting enough air to cool down and run properly.

Other causes can include dirty or clogged filters, worn out bearings, and bad connections. There are many solutions for smoked motors- from replacing the motor all together to cleaning up the problem areas and fixing any underlying issues

What causes a sewing machine motor to smoke?

If your sewing machine is smoking, it’s probably because you’re using it too hard – give it a break and see if the problem goes away. When your motor starts to smoke, there could be a number of reasons: You’re overworking the machine, you’ve got fabric stuck in the gears or something else is blocking the way.

Sometimes when motors start to smoke, all you need is some time off; just turn off the machine and leave it for an hour or so and things should clear up on their own. If nothing seems to work and your motor continues to smoke even after following these steps, take your machine in for service. Be sure not to overload your sewing machines; they can only handle so much before they start giving out on you

How do I know if my sewing machine motor is bad?

If your sewing machine motor is making a buzzing or clicking noise when activated, it may be time to replace the unit. If the sewing machine won’t turn at all and you’ve tried cleaning the gears and replacing other parts, then it’s likely that an internal wiring failure in the motor is preventing it from running properly.

Your best bet would be to replace the entire sewing machine if nothing seems to work – even if there are no obvious signs of damage or malfunctioning on exterior surfaces. In some cases, malfunctions with motors can go unnoticed until they result in significant problems like not being able to start up or produce fabric scraps consistent with bad electrical connections inside of the unit itself- so always keep an eye out for those red flags.

Knowing how to troubleshoot common issues with your particular model Sewing Machine will help ensure years of problem free use.

Can sewing machines overheat?

If your sewing machine becomes warm to the touch, it is probably not in danger of overheating but you should shut it off anyway just to be safe. Sewing machines can generate a fair amount of heat, so make sure you keep them cool by giving them some air circulation and space when they’re not in use.

When your sewing machine starts feeling too hot to the touch, stop what you’re doing and give it some room to breathe. Most automatic features will turn off your machine if it begins to overheat, so don’t worry about ruining anything by accidentally leaving it on. Knowing how your particular sewing machine works is one way to avoid accidental shutdowns; stay alert for any warning signs that may indicate an issue with the motor or heating system

Can sewing machines catch fire?

Sewing machines can pose a fire hazard if their power supply becomes overloaded or damaged. It is important to be cautious when using your machine, and to keep it clean in order to avoid any electrical arcing.

If you experience an overheating issue with your sewing machine, do not attempt to fix it yourself – call a technician instead. Injuries from fires caused by sewing machines are rare but still occur occasionally; take precautions to stay safe and protect yourself.

Keep your sewing machine in a safe place where children cannot access it, and always follow the manufacturer’s instructions for use

What is the problem if sewing machine runs noisy?

If your machine is making noises, it may be because of lint or oil on the hook or needle bar. To fix this, clean the area and follow the instructions in your sewing machine’s instruction manual.

You can also try to lubricate the machine to make it run smoother. Keep in mind that older machines might need more maintenance than newer machines-check with your manufacturer for specific instructions on how to keep them running smoothly.

Try not to overload your stitching as this can create noise too; use lighter fabrics and thinner threads if possible. Finally, pay attention to what you’re doing while sewing-if you’re using a lot of pressure or moving a lot of fabric around, chances are you’ll hear some sort of noise from your machine

What causes a sewing machine to stop working?

If your sewing machine starts to stop working, there are a few things you can do to try and fix the problem. One common cause of sewing machine problems is tangled threads or lint buildup on the bobbin case or upper thread spool.

You can also check for obstructions such as knots or snags in your fabric that may be preventing the stitching from happening correctly. Finally, if none of these work, it might be time to take your sewing machine in for service. Keep these tips in mind when troubleshooting Issues with Your Sewing Machine so you can get back up and running quickly

How do I stop my sewing machine from overheating?

Overheating can be a serious problem for sewing machines, especially if they are not regularly cleaned or serviced. A good way to combat overheating is to clean the interior of your machine regularly.

If you are Sewing for an extended period of time, you should also take breaks to allow the machine to cool down. Your machine will operate more efficiently and cooler when it has been properly maintained and kept free from debris build-up

Frequently Asked Questions

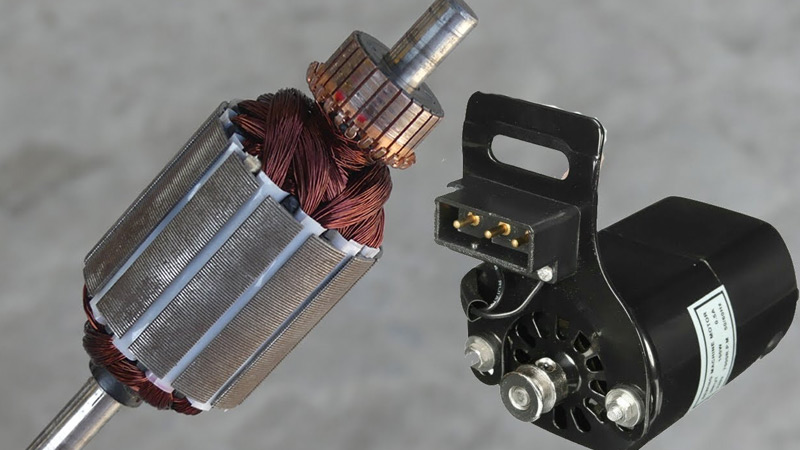

Which type of motor is used in sewing machine?

The clutch motor is used in sewing machines. It uses three-phase alternating current supply and it usually works with efficiency lower than 75%.

How powerful is a sewing machine motor?

The power of your sewing machine motor is typically printed on the label. On old motors you often see 40W or 50W, on modern ones it’s 90W or 110W.

Can I reverse a sewing machine motor?

You can’t reverse a sewing machine motor by swapping the input leads like you can with a DC motor. To do this, you need to change the phase relationship between the field windings and the rotor windings.

Is it worth repairing a sewing machine?

Yes, it is definitely worth repairing a sewing machine. Well-maintained machines will last longer and save you money than buying new ones. There are plenty of things to look out for during arepair.

Why does my sewing machine sound like a jackhammer?

If your sewing machine needle is bent, it can cause a knocking noise. Clean the machine with a cloth and dry it off. If you are using needles that have sharp tips, be careful not to cut yourself.

To Recap

The electric motor in an old sewing machine may be smoking because of a build-up of material on the blades. This can cause sparks and smoke, which will eventually lead to the motor burning out. To fix this problem, you’ll need to take apart the sewing machine and clean all of the parts.

Leave a Reply