Embarking on a sewing project can be both exciting and rewarding, but nothing dampens the enthusiasm faster than discovering that your carefully crafted stitches are unraveling.

If you’ve ever asked, “Why are my sewing machine stitches pulling out?” you’re not alone.

This frustrating issue can occur for various reasons, from machine malfunctions to user errors. In this guide, we will unravel the mysteries behind this common problem and equip you with the knowledge to troubleshoot and prevent it.

Whether you’re a novice seamstress or a seasoned pro, understanding the factors contributing to stitch unraveling is crucial for achieving professional-looking and durable results in your sewing endeavors.

Let’s dive into the intricacies of sewing machine stitches and discover the solutions to keep your creations intact and beautifully stitched. Join us to learn expert tips and tricks on how to avoid stitches pulling out in the future.

Why Are My Sewing Machine Stitches Pulling Out?

Here, we’ll delve into various factors contributing to stitch unraveling and equip you with the knowledge to troubleshoot and prevent this common problem.

Tension Troubles

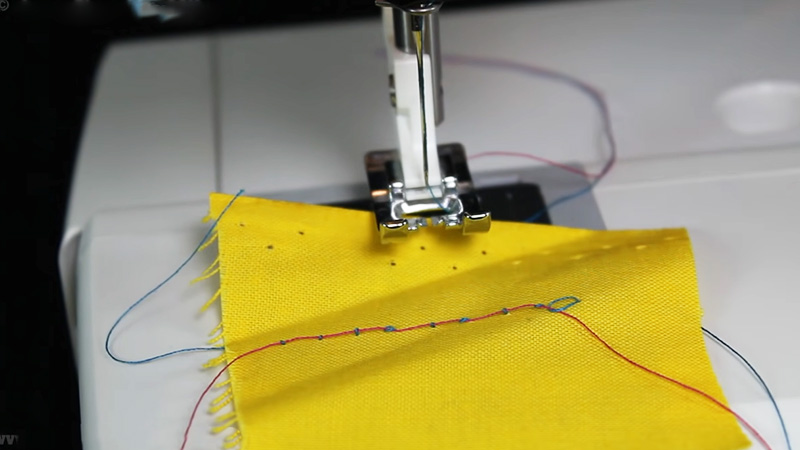

One of the primary culprits behind stitch unraveling is improper tension settings. The tension regulates the tightness of the sewing machine stitches; if it’s not correctly adjusted, the threads may not interlock securely.

Pulling out of fabric from a sewing machine can lead to problems with sewing machine stitches. Begin by checking both the upper and lower thread tensions.

Consult your sewing machine manual for guidance on adjusting tension settings and experiment until you achieve balanced, well-formed stitches.

Needle Matters

The needle you use can significantly impact the integrity of your stitches. A dull or bent needle may struggle to penetrate the fabric smoothly, leading to uneven stitches that are prone to pulling out.

Ensure you are using the correct type and size of needle for your fabric, and replace it regularly. A sharp, properly sized needle can make a world of difference in stitch quality.

Thread Choice and Quality

The type and quality of thread you use are pivotal in stitch durability. Opt for high-quality threads appropriate for your fabric. Cheap or old threads are more likely to break or unravel.

Bobbin Woes

A poorly wound or inserted bobbin can cause stitching nightmares. Ensure that the bobbin is correctly wound and inserted into the bobbin case, following the machine’s instructions.

Threading Tangles

Inadequate threading is a common yet often overlooked culprit. Double-check that the machine is threaded correctly, following the threading guide in your manual.

Ensure the thread passes through all the necessary guides and tension discs to ensure a smooth and even stitch formation.

Fabric Selection

Different fabrics require different settings on your sewing machine. If your stitches are consistently pulling out, consider the type of fabric you are working with.

Adjust the machine settings, such as stitch length and tension, to accommodate the specific needs of the fabric.

Stitch Length Matters

Stitch length directly affects the strength of your stitches. Too short of a stitch may create a perforation effect on the fabric, making it more prone to tearing.

On the other hand, excessively long stitches might not hold the fabric layers securely. Find the right balance by adjusting the stitch length according to the fabric type and project requirements.

Machine Maintenance

Regular maintenance is key to preventing stitch issues. Clean your sewing machine regularly, removing lint, dust, and stray threads.

Lubricate moving parts as recommended in the manual. A well-maintained machine operates smoothly, reducing the risk of stitching problems.

User Error

Sometimes, the issue lies in the hands of the operator. Pulling or pushing the fabric through the machine can disrupt stitching, leading to uneven and weak stitches. Allow the machine to feed the fabric naturally while you guide it.

Pulling Out of Fabric from a Sewing Machine Can Lead to What?

Pulling out of fabric from a sewing machine can have several repercussions, affecting both the aesthetic appeal and structural integrity of your sewing projects.

Understanding the potential consequences is crucial for troubleshooting and preventing such issues. Let’s explore the various implications of fabric pulling out from a sewing machine.

Compromised Aesthetics

One of the most immediate and noticeable effects of fabric pulling out is the compromised aesthetics of your project. Uneven or unraveled stitches disrupt the smooth and professional look you aim to achieve.

This can be particularly frustrating, especially if you’ve invested time and effort into creating something visually appealing.

Weakened Seams

When stitches pull out, the integrity of the seams is compromised. Seams are essential for holding the fabric pieces together, and any unraveling weakens this connection.

This is especially critical in garments or items that undergo stress, such as clothing seams or the seams of bags and accessories. Weakened seams are more susceptible to tearing and may fail under normal usage.

Reduced Durability

Pulling out of fabric from a sewing machine can significantly reduce the overall durability of your project. Whether you’re crafting clothing, home decor items, or accessories, durability is a key factor in the longevity of the finished piece.

Fabrics that pull out easily are more prone to fraying, tearing, and wear over time, diminishing the lifespan of your creation.

Potential for Unraveling

Fabric that pulls out from stitches increases the likelihood of overall unraveling. Once the stitching unravels, it can create a domino effect, spreading to adjacent stitches and compromising larger sections of your project.

Unraveling is unsightly and can render your creation unusable if not addressed promptly.

Functional Issues

Depending on the type of project, pulling out of fabric can lead to functional issues. For example, unraveled stitches in garments may cause discomfort, irritation, or exposure.

Functional compartments may lose shape and utility if the stitching keeps the fabric secure in items like bags or accessories.

Time and Effort Wasted

Dealing with fabric pulling out often means reworking or even starting a project from scratch. This not only consumes additional time but also represents wasted effort.

Whether you’re a seasoned seamstress or a beginner, the frustration of seeing your hard work unravel can be disheartening.

Need for Repairs

In some cases, if fabric pulling out is not addressed immediately, it may necessitate repairs. This can involve re-stitching, reinforcing seams, or even patching and mending damaged areas. Repairs can be time-consuming and may not always restore the project to its original state.

Impact on Overall Project Quality

Fabric pulling out can have a lasting impact on the overall quality of your sewing projects. Achieving high-quality results is often a priority for crafters, and the presence of unraveling stitches can detract from the perceived quality of your work.

Troubleshooting Sewing Machine Stitches

Whether you’re a beginner or an experienced crafter, understanding how to troubleshoot common stitching issues is essential for producing professional-looking and durable projects.

This comprehensive guide will explore various troubleshooting steps to help you overcome the most common problems with sewing machine stitches.

Uneven Stitches

Uneven stitches can result from incorrect tension settings. Check the upper and lower thread tensions to fix such sewing machine stitch problems.

Adjust as needed, ensuring they complement each other for a balanced stitch. Refer to your machine’s manual for specific instructions on tension adjustment.

Skipped Stitches

Skipped stitches may be caused by a dull or bent needle, incorrect threading, or improper needle and thread combination. Replace the needle with a new, appropriate one.

Ensure correct threading by following the machine’s threading guide. Use high-quality thread to match the needle size and type to your fabric.

Fabric Pulling or Gathering

Tension issues, incorrect stitch length, or inadequate fabric handling can lead to pulling or gathering. Adjust tension, ensuring it is suitable for the fabric.

Check and correct the stitch length, adjusting it based on the fabric type. Allow the machine to feed the fabric naturally, avoiding pulling or pushing.

Thread Breakage

Thread breakage can occur due to old or poor-quality thread, incorrect threading, or tension problems. Use high-quality thread suitable for your fabric.

Ensure proper threading, passing the thread through all guides and tension discs. Adjust tension if needed, ensuring it’s not too tight.

Thread Bunching or Bird’s Nesting Underneath

This issue often stems from bobbin-related problems, such as incorrect insertion or tension. Reinsert the bobbin, following the machine’s manual.

Ensure the bobbin thread is correctly wound and inserted. Check bobbin tension, making adjustments if necessary.

Needle Jamming or Breaking

Needle-related issues, such as using the wrong needle for the fabric or a bent needle, can lead to jamming or breakage.

Use the correct needle type and size for your fabric. Replace the needle if it’s bent or dull. Check the needle position and ensure it’s correctly inserted.

Inconsistent Stitch Length

Inconsistent stitch length may result from inconsistent pressure on the foot pedal or uneven fabric feeding.

Practice maintaining a consistent speed on the foot pedal. Ensure the fabric is guided evenly through the machine, avoiding uneven feeding.

FAQs

Why do my sewing machine stitches keep pulling out even after adjusting the tension?

If adjusting the tension doesn’t resolve the issue, consider checking your needle. A dull or incorrectly sized needle can still cause stitches to pull out. Also, ensure you use the right needle type for your fabric.

Can using low-quality thread really impact the durability of my stitches?

Yes, low-quality thread can lead to stitches pulling out. Cheap or old threads are more prone to breakage and unraveling and can compromise the overall integrity of your sewing project. Opt for high-quality threads that match your fabric type.

How often should I change my sewing machine needle to prevent stitch unraveling?

Regularly changing your needle is essential for preventing stitch issues. As a general guideline, replace the needle after every 8–10 hours of sewing or more often if you notice any signs of dullness or bending. A sharp needle contributes to clean and secure stitches.

What’s the significance of stitch length, and how does it affect the strength of my stitches?

Stitch length directly impacts the strength of your stitches. Too short of a stitch may perforate the fabric, making it prone to tearing. Adjust the stitch length based on the fabric type – shorter for delicate fabrics and longer for heavier materials.

Are there specific fabrics more prone to stitch unraveling, and how can I prevent it?

Some fabrics, like loosely woven or delicate ones, are more prone to sewing machine stitch problems. To prevent this, use the appropriate needle and thread, adjust the tension and stitch length accordingly, and handle the fabric gently.

Conclusion

In the realm of sewing, the frustration of unraveling stitches is a challenge that can be overcome with knowledge and a bit of troubleshooting.

As we conclude our exploration into why sewing machine stitches may pull out, it’s clear that attention to detail, proper machine maintenance, and a keen understanding of the stitching process are essential elements for success.

By addressing issues such as tension, needle choice, and threading intricacies, you can elevate your sewing experience and ensure the longevity of your projects. Remember, patience and practice go hand in hand in the sewing world.

With the insights gained from unraveling the mystery behind stitch pull-outs, you’re better equipped to face these challenges head-on.

Leave a Reply