Sewing needles, those slender instruments of creativity and precision, play a vital role in the world of crafting and garment construction. As we thread them through fabrics of various textures and thicknesses, they transform our visions into tangible creations.

Yet, like any tool subjected to repeated use, sewing needles inevitably undergo wear and tear. The question arises: Do sewing needles get dull, and if so, why? In this exploration, we’ll delve into the factors behind the gradual blunting of these essential tools.

From the materials they’re made of to the fabrics they encounter and the techniques employed, we’ll unravel the mystery of sewing needle dullness and discover how proper care can ensure the longevity of these indispensable companions in the art of sewing.

Do Sewing Needles Get Dull?

Yes, sewing needles, like any other tool, can indeed become dull over time with regular use. The sharpness of a sewing needle is crucial for its functionality and the quality of your sewing projects.

Here are some factors and reasons why sewing needles can get dull:

Friction with Fabric

Sewing involves the repetitive motion of a needle puncturing fabric layers. Over time, this action causes microscopic damage to the needle’s tip.

The type of stitch you use, such as straight stitch, zigzag, or embroidery, can also affect the rate of dullness as different stitches put varying degrees of stress on the needle.

Needle Material

The choice of needle material is critical. While stainless steel and nickel-plated needles are durable, they are not invincible. Stainless steel needles are known for their resistance to rust, which is especially important if you work with damp or moist fabrics.

Nickel-plated needles offer a smoother surface, reducing friction and wear, but the plating can wear off over time, leading to dullness.

Needle Size and Type

The size and type of needle are crucial considerations. Needles come in various sizes, denoted by numbers, and selecting the appropriate size for your fabric is essential.

For example, a fine needle is suitable for delicate fabrics, while a heavy-duty needle is ideal for thick materials like leather. Choosing the wrong size or type can accelerate needle dullness.

Quality of Fabric

Fabrics come in a wide range of textures and compositions. Coarser fabrics, such as denim, corduroy, or canvas, contain more rigid fibers that can quickly erode the needle’s point.

Fine, lightweight fabrics are gentler on needles but may still contribute to dullness over time if used extensively.

Needle Maintenance

Regularly inspecting your sewing needles is a vital aspect of maintenance. Bent or damaged needles should be discarded immediately, as they can not only cause dullness but also damage your fabric and sewing machine.

Properly storing needles in a needle case or pin cushion when not in use can prevent accidental damage.

Thread Quality

The quality of the thread can indirectly impact needle wear. Threads with irregularities or knots may cause the needle to bend or break more frequently, leading to quicker dullness.

Using high-quality threads that match the fabric you’re working with can reduce friction and prolong the needle’s sharpness.

Sewing Machine Maintenance

If you use a sewing machine, it’s essential to keep it in good working order. Regularly clean and oil your machine according to the manufacturer’s instructions to prevent unnecessary friction and wear on the needle. Additionally, ensure that the machine’s tension settings are correctly adjusted to prevent thread snags and needle damage.

Sewing Technique

Your sewing technique matters. Applying excessive force when guiding the fabric can lead to a faster wear rate for the needle.

Make sure your needle is suitable for the fabric and thread you’re using, and avoid running the machine at excessive speeds, especially when working with challenging materials.

Do Hand Sewing Needles Get Dull?

Yes, hand-sewing needles can indeed get dull over time with regular use. The sharpness of a hand-sewing needle is critical for precise and effortless stitching.

Several factors contribute to the dulling of hand-sewing needles:

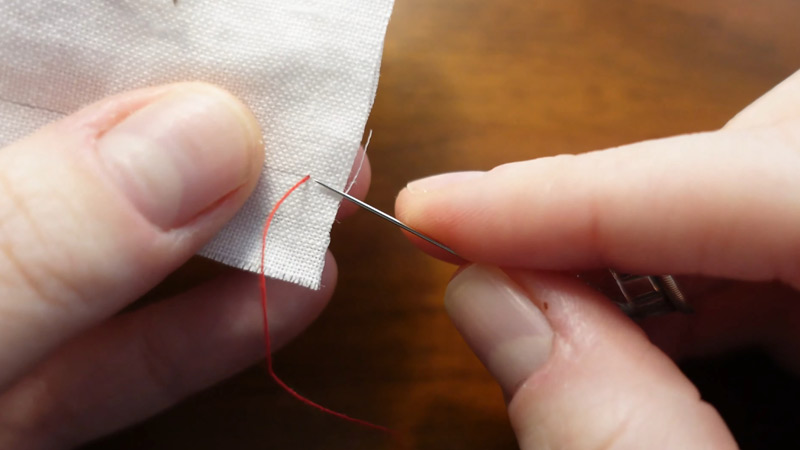

Friction with Fabric

Like machine sewing needles, hand sewing needles experience friction when they pierce through various fabrics. The repetitive motion of pushing the needle through fabric layers can gradually wear down the needle’s point.

Needle Material

The material from which hand-sewing needles are made can impact their longevity. Most hand-sewing needles are crafted from materials like stainless steel or nickel-plated steel. These materials are relatively durable, but they are not immune to wear and tear.

Needle Size and Type

The size and type of hand-sewing needle are crucial factors. Different sewing projects and fabrics may require specific needle sizes and types, and using the wrong needle can accelerate dullness.

For example, a fine needle is suitable for delicate fabrics, while a heavy-duty needle is ideal for thicker materials.

Quality of Fabric

The type and quality of fabric you work with can also affect needle dullness. Rough or coarse fabrics, such as denim or canvas, can expedite the dulling process due to their abrasive nature. Softer and smoother fabrics may have a milder effect on the needle’s sharpness.

Technique

Your hand-sewing technique plays a significant role in needle wear. Excessive force, incorrect needle placement, or repeatedly pulling the needle through tight or tough spots can lead to quicker dulling.

Thread Quality

The quality of the thread you use can indirectly affect the sharpness of your hand-sewing needle. Threads with irregularities or knots may cause more friction and wear on the needle.

How to Tell if Your Sewing Machine Needle Is Dull

Recognizing when your sewing machine needle is dull is crucial for maintaining the quality of your sewing projects and preventing potential damage to your fabric and machine.

Here are some signs that can help you determine if your sewing machine needle is dull:

Uneven or Skipped Stitches

When your sewing machine needle is dull, it struggles to pierce through the fabric cleanly. This can result in uneven stitches where some are tightly formed while others are loose or skipped altogether.

Inspect both the top and bottom sides of your fabric for this issue, as it may affect the overall quality of your sewing.

Puckering Fabric

Dull needles can cause the fabric to pucker or gather unintentionally as you sew. This puckering is usually not the desired effect and can be particularly problematic when working on delicate or lightweight fabrics where even minor irregularities are noticeable.

Fabric Snags or Runs

As the needle loses its sharpness, it may not smoothly penetrate the fabric. Instead, it can catch on fabric fibers, resulting in snags, pulls, or runs. This not only damages your fabric but also disrupts the flow of your sewing project.

Thread Breakage

Frequent thread breakage can be a frustrating consequence of a dull needle. When the needle struggles to pierce the fabric and thread efficiently, it can lead to breaks. This interruption in the stitching process can be time-consuming and affect the quality of your work.

Audible Clicking or Popping

Pay attention to the sounds your sewing machine makes. A dull needle can create audible clicking or popping noises as it encounters resistance while sewing. These sounds can be quite noticeable and indicate that the needle is not performing optimally.

Visible Damage

Inspect the needle closely for visible signs of wear and tear. A dull needle may have a bent or blunted tip.

Even slight damage to the needle’s point can hinder its ability to sew accurately, leading to various stitching issues.

Fabric Fibers on the Needle

A dull needle may accumulate fabric fibers, lint, or other debris on its tip. This buildup can further reduce the needle’s sharpness and impede its ability to cleanly pierce through the fabric. Regularly checking and cleaning your needle can help prevent this issue.

Difficulty in Sewing Thick Fabrics

When sewing through thick or multiple layers of fabric, a dull needle may struggle to penetrate them effectively.

This can result in uneven stitching or even jams in the machine. If you frequently work with heavy fabrics, consider switching to a heavier-duty needle when needed.

Frayed or Damaged Thread

Dull needles can cause your thread to fray or become damaged more quickly than usual. The friction between the thread and the blunt needle point can weaken the thread, leading to breakage and potentially compromising the integrity of your stitches.

How to Sharpen Sewing Needles?

Sewing needles, whether hand-sewing or machine needles are typically not designed to be sharpened.

Unlike knives or scissors, sewing needles have a very fine and delicate point, and attempts to sharpen them may damage the needle or result in an uneven point that could damage fabric or thread.

However, there are a few techniques that some sewists use to temporarily improve the sharpness of their sewing needles:

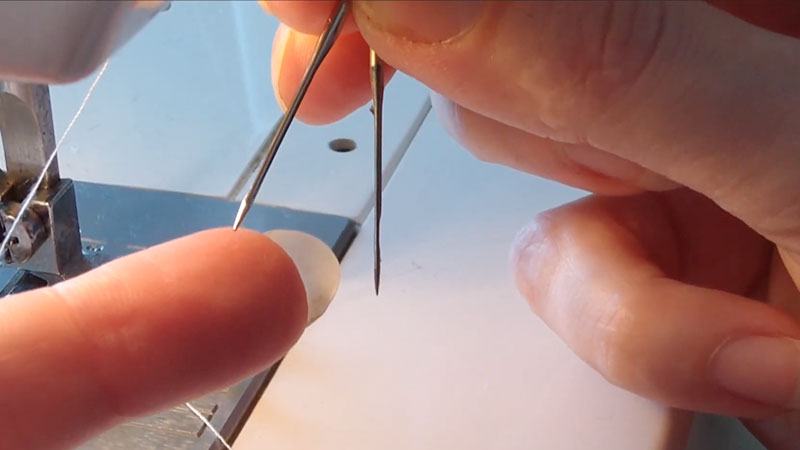

Needle Sharpener

Some specialty needle sharpeners are available on the market. These tools are designed to help maintain the sharpness of your sewing needles.

They typically have a small slot where you can insert the needle and gently twist or rotate it to smooth out minor imperfections on the needle’s point.

While these tools can be useful for extending the life of your needles, they may not be suitable for severely dull needles.

Emery Pincushion

An emery pincushion is a pincushion filled with a fine abrasive material, usually emery sand. You can gently insert your needle into the emery pincushion and slide it in and out a few times. This can help remove tiny burrs and improve the needle’s sharpness temporarily.

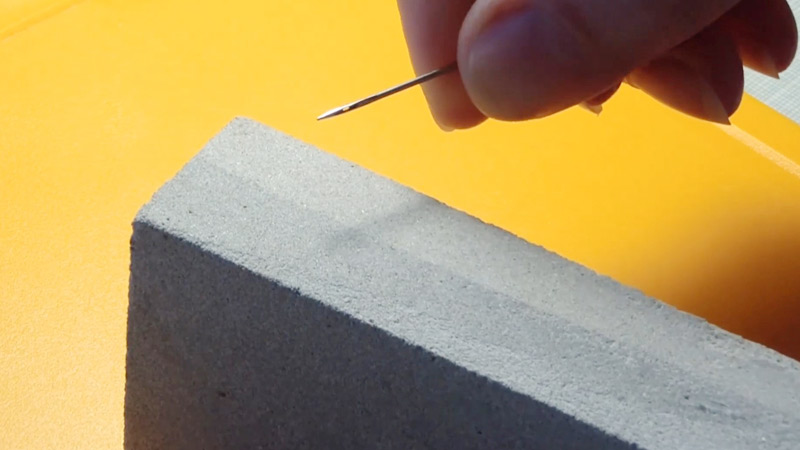

Sandpaper or Nail File

If you don’t have an emery pincushion, you can use fine-grit sandpaper or a nail file to gently rub the needle’s point. Be extremely cautious when doing this, as it’s easy to overdo it and damage the needle.

Use very light pressure and only a few strokes. This method is not recommended for expensive or specialized needles.

Replace the Needle

In most cases, the best solution for a dull needle is to replace it with a new one. Sewing machine needles, in particular, are relatively inexpensive and come in a variety of types and sizes to suit different fabrics and projects.

Hand sewing needles are also affordable, and a fresh needle will provide the best results and prevent damage to your fabric and thread.

FAQS

Can sewing needles get dull even if they are not used frequently?

Yes, sewing needles can become dull over time even if they are not used frequently.

Are there any ways to prevent sewing needles from getting dull?

While sewing needles will eventually dull with use, proper maintenance and care can prolong their lifespan.

Can a dull sewing needle damage the sewing machine?

Yes, a dull sewing needle can potentially damage the sewing machine.

How often should I change my sewing machine needle?

The frequency of changing your sewing machine needle depends on factors such as the type of fabric you sew, the number of hours you sew, and the type of thread you use.

As a general guideline, consider changing the needle after every 8-10 hours of sewing or after completing a significant project.

To Recap

In sewing, the question of whether needles get dull has been explored, revealing that these indispensable tools are not immune to wear and tear.

Delicate as they are, sewing needles gradually lose their sharpness due to factors such as friction with fabric, the materials they’re crafted from, and the quality of threads and fabrics.

Recognizing the signs of a dull needle, such as uneven stitches, fabric snags, or audible clicks, is essential for maintaining the quality of one’s projects.

While there are methods to temporarily improve a needle’s sharpness, such as using a needle sharpener or emery pincushion, the best practice remains regular replacement with a fresh needle.

With this understanding, sewing enthusiasts can continue to create with precision and finesse, ensuring that every stitch tells a story of craftsmanship and care.

Leave a Reply