Embarking on a sewing project can be thrilling, but uncertainty may arise when faced with unconventional materials like neoprene.

Neoprene, renowned for its versatility and widespread use in wetsuits, laptop sleeves, and more, poses a unique challenge for those wielding a needle and thread. In this exploration, we delve into the question: Is neoprene hard to sew?

What is the right way to cut and sew neoprene? As we unravel the intricacies of working with this synthetic rubber, we’ll uncover tips, tricks, and insights to navigate the sewing process successfully.

Whether you’re a seasoned seamstress or a novice with a passion for crafting, understanding the nuances of neoprene can elevate your sewing skills to new heights.

Join us on this textile adventure as we demystify the art of sewing with neoprene and unveil the secrets to mastering its stitch-perfect intricacies.

Is Neoprene Hard To Sew?

Sewing with neoprene presents a distinctive challenge. However, with the right techniques, cutting neoprene becomes an essential skill for successful projects.

Understanding Neoprene

Before delving into cutting neoprene rubber and how to sew neoprene, let’s understand neoprene’s characteristics. This synthetic rubber, originally developed for wetsuits, is valued for its ability to withstand various conditions.

Neoprene is thick, flexible, and has a distinct stretch, making it suitable for various applications, from fashion to industrial uses.

Challenges in Sewing Neoprene

Embarking on a sewing journey with neoprene opens doors to creativity, but it’s not without its challenges. Let’s delve into the complexities and unravel solutions for seamless neoprene stitching.

Thickness

Neoprene’s robust thickness poses a significant hurdle for standard sewing machines. To conquer this challenge, opting for heavy-duty machines specifically designed for thick fabrics becomes imperative.

These machines boast the power and durability needed to handle neoprene’s substantial composition.

Friction

The inherent friction of neoprene can disrupt the smooth flow through a sewing machine, leading to irregular stitches and potential fabric damage.

Overcoming this obstacle requires strategic measures. Employing clips instead of traditional pins to secure the fabric ensures stability without compromising the integrity of this resilient material.

Seam Sealant

For neoprene’s optimal performance, seam sealing is a non-negotiable step. This process safeguards against water penetration, particularly for applications like wetsuits.

Choosing the right sealant and mastering its application method is essential to maintaining neoprene’s durability and water resistance.

Needle Choice

Selecting the appropriate needle is pivotal when working with neoprene. The wrong needle can damage the fabric and hinder the sewing process.

Opting for a ballpoint or stretch needle is the key to success, preventing potential snags and ensuring a smooth stitching experience through this unique material.

Easy Solutions to the Challenges of Sewing Neoprene

Follow these tips and solutions while sewing Neoprene fabric:

Machine Selection

Invest in a heavy-duty sewing machine designed to handle thick fabrics. Some machines come with features like walking feet, which can aid in moving neoprene smoothly.

Neoprene’s thickness can make it challenging to use traditional pins. Instead, opt for clips to secure the fabric without causing damage.

Stretch Needles

Choose the appropriate needle for neoprene. A stretch needle or ballpoint needle is designed to work well with flexible and thick fabrics.

Research and select the right seam sealant for neoprene. Apply it to the seams to enhance water resistance and durability.

Test Stitches on Scrap Fabric

Before starting your project, test stitches on scrap neoprene to determine the ideal thread tension and stitch length.

If your sewing machine allows, use a walking foot attachment. This helps feed neoprene through the machine evenly, reducing the risk of uneven stitches.

Adjusting Tension

Neoprene may require adjustments to your machine’s tension settings. Experiment with different settings to achieve optimal stitch quality.

Choose patterns designed for stretch fabrics, and if possible, select those specifically tailored for neoprene. This ensures a better fit and ease of sewing.

How to Cut Neoprene for Sewing?

When it comes to sewing with neoprene, the cutting process is critical. In this comprehensive guide, we’ll explore step-by-step instructions on cutting neoprene effectively, ensuring your sewing endeavors are successful and enjoyable.

Prepare Your Workspace and Measure

Set up a clean, spacious workspace with a cutting mat to ensure precision. Use a ruler or straight edge to measure and mark the desired dimensions on the neoprene. A chalk or marker works well for clear visibility.

Secure with Weight

Secure the neoprene with weights or heavy objects before cutting to prevent slippage.

Employ sharp scissors or a rotary cutter for clean, precise cuts. Neoprene can be thick, so ensure your tools are up to the task.

Cutting Techniques

For straight lines, follow the marked measurements using the straight edge. For curves, make small, strategic cuts to maintain control.

Trim any excess material once the main pieces are cut to refine the edges. Before sewing, double-check measurements to ensure accuracy in your project.

How to Sew Neoprene Fabric?

Starting a sewing project with neoprene can be both exciting and challenging. This comprehensive guide will walk you through step-by-step instructions, tips, and techniques to ensure a successful sewing experience with this versatile and resilient material.

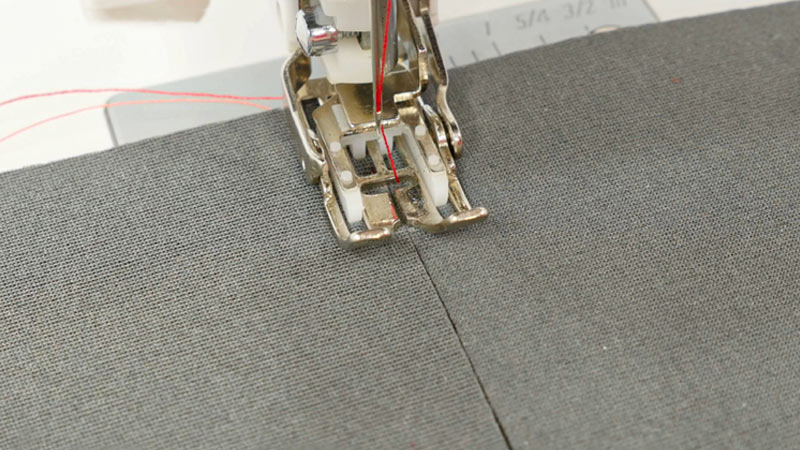

Secure with Clips

Instead of traditional pins, use clips to secure the neoprene. This prevents damage to the fabric and ensures stability during sewing.

Install a ballpoint or stretch needle suitable for neoprene on your sewing machine. This prevents potential snags and ensures smooth stitching.

Adjust Machine Settings

Neoprene may require adjustments to your machine’s tension settings. Test on scrap fabric to find the optimal tension for smooth stitches.

Use a straight stitch for sewing neoprene seams. Ensure a consistent stitch length for a professional finish.

Double-needle stitching for Hems

Consider using a double needle for decorative hems. This adds a stylish touch and reinforces the seams for added durability.

Utilize topstitching to add both aesthetic appeal and reinforcement to seams. This helps prevent rolling and enhances the overall durability of your project.

Seam Sealing

If your project requires water resistance, apply seam sealant to the stitched seams. Follow the manufacturer’s instructions for the specific sealant you’ve chosen.

Account for seam allowance when measuring and cutting neoprene to achieve the desired final dimensions in your project.

Tips for Successful Neoprene Sewing

Before starting your main project, practice sewing on scrap neoprene to familiarize yourself with its behavior and fine-tune your technique.

Keep an even tension on the fabric while sewing to avoid uneven stitches and potential puckering.

Neoprene can leave residue on your machine. Regularly clean your machine to prevent build-up and ensure smooth operation.

Does Neoprene Fray When Cut?

Neoprene typically does not fray when cut. Its cellular structure and composition contribute to a clean edge after cutting, reducing the likelihood of fraying.

This characteristic makes neoprene an advantageous material for various applications, as it eliminates the need for additional finishing techniques to prevent fraying.

Understanding Neoprene’s Composition

Neoprene, a synthetic rubber prized for its durability, features a unique closed-cell foam structure. This composition, characterized by tiny trapped air bubbles within the rubber, is crucial in preventing fraying when the material is cut.

Fray-Resistant Nature of Neoprene

Due to its closed-cell structure, neoprene exhibits a remarkable resistance to fraying. Unlike many traditional fabrics, neoprene’s edges remain clean and well-defined after cutting, contributing to the material’s user-friendly characteristics.

Influence of Cutting Tools and Techniques

While neoprene inherently resists fraying, the choice of cutting tools and technique can further enhance this property.

Utilizing sharp scissors or a rotary cutter ensures a smooth and precise cut, minimizing the potential for unintended fraying along the edges.

Guided Cutting with Marking Techniques

Marking cut lines with chalk or a fabric marker before cutting is a practical guide to maintain clean edges. This step helps reduce the likelihood of irregularities, contributing to a more polished and professional finish in neoprene projects.

Testing on Scrap Material

Despite neoprene’s general resistance to fraying, variations in thickness and type may influence its behavior.

Testing on a small, inconspicuous piece of scrap neoprene before initiating a larger project allows for a better understanding of the material’s specific characteristics and aids in refining cutting techniques if necessary.

FAQs

Does neoprene require a special sewing machine?

Yes, neoprene’s thickness typically demands a heavy-duty sewing machine. Machines designed for thick fabrics, often equipped with features like walking feet, effectively provide the necessary power and precision for sewing neoprene.

Can neoprene be cut with regular scissors?

While neoprene can be cut with regular scissors, it is recommended to use sharp scissors or a rotary cutter for clean and precise cuts. Neoprene’s thickness benefits from the precision these tools offer.

Does neoprene fray when cut?

No, neoprene generally does not fray when cut. Its closed-cell foam structure prevents edges from unraveling. Using sharp cutting tools and proper marking techniques enhances this fray-resistant property.

What type of needle is best for sewing neoprene?

For sewing neoprene, it’s advisable to use a ballpoint or stretch needle. These needles are specifically designed for stretch fabrics and prevent potential snags, ensuring smooth stitching through the resilient neoprene material.

Can neoprene projects be waterproof?

Neoprene itself is water-resistant due to its closed-cell structure. However, applying seam sealant to stitched seams is recommended for projects requiring complete waterproofing.

This additional step enhances water resistance, making neoprene suitable for applications like wetsuits.

Conclusion

Sewing with neoprene is indeed a unique undertaking, demanding a blend of precision and adaptability. While its rubbery composition may present initial challenges, the journey through this fabric unveils a rewarding experience for dedicated crafters.

One can transform neoprene into functional and stylish creations with insights into the right tools, techniques, and a touch of patience.

The malleability and durability of neoprene open doors to a world of possibilities, making it a valuable addition to any sewing repertoire.

So, fear not the challenge of neoprene; embrace it as an opportunity to expand your craftsmanship horizons. Now you know how to sew Neoprene correctly.

As needles meet rubber in a dance of creativity, the fusion of innovation and skill may yield remarkable results.

Neoprene’s resilience offers a creative canvas for sewing enthusiasts. Embrace its unique nature, experiment with techniques, and discover the artistry within each stitch.

Leave a Reply