Rubber stretch belts have emerged as a potential solution for sewing machine enthusiasts and professionals seeking a reliable power transmission component.

The question that often arises is whether these rubber stretch belts are genuinely suitable for sewing machines.

As sewing machines come in various types and serve different purposes, the choice of belt can significantly impact their performance and longevity.

In this exploration, we will delve into the effectiveness of rubber stretch belts for sewing machines, considering factors such as affordability, flexibility, durability, and compatibility.

By examining these key aspects, we aim to provide a comprehensive answer to the question: Are rubber stretch belts any good for sewing machines?

Are Rubber Stretch Belts Any Good for Sewing Machines?

Yes, rubber stretch belts can be a good option for sewing machines in certain situations, but they may not be ideal for all machines and purposes.

The effectiveness of rubber stretch belts depends on several factors, and here are the reasons why they are a good option for sewing machines:

Affordability

Rubber stretch belts are often significantly more budget-friendly than alternative belt options like cogged or V-belts.

Sewing machine owners who are mindful of their expenses or have limited financial resources can find rubber stretch belts to be a cost-effective choice.

This affordability is particularly advantageous when considering that sewing machines may require periodic belt replacements and lower-priced options can help reduce maintenance costs over time.

Flexibility

The inherent flexibility of rubber stretch belts is a valuable feature for sewing machines, especially those that require varying tension levels based on the type of fabric and sewing task.

These belts can adapt to changes in tension requirements without the need for precise sizing or adjustments.

This adaptability allows for smoother transitions between different sewing projects, enhancing the versatility of the sewing machine.

Availability

Rubber stretch belts are widely accessible in the market. Sewing enthusiasts and professionals can easily find them at most sewing machine supply stores or through online retailers.

This widespread availability ensures that replacement belts are readily obtainable, reducing downtime when a belt replacement is necessary.

The convenience of obtaining these belts when needed is a practical advantage for users, ensuring that their sewing projects can continue without prolonged interruptions.

Sewing Machine Belt Problems & Solutions

Sewing machine belt problems can be frustrating and disrupt your sewing projects.

Here are some common issues associated with sewing machine belts and how to address them:

Belt Slippage

The most frequent problem is belt slippage, where the belt loses traction with the machine’s pulleys, resulting in uneven stitching or the machine failing to operate.

To fix this issue, ensure that the belt is properly tensioned. If it’s loose, tighten it according to your sewing machine’s manual. Sometimes, replacing an old or worn-out belt with a new one can also resolve this problem.

Belt Breakage

Over time, sewing machine belts can become brittle and eventually break. If your belt snaps, you’ll need to replace it.

Make sure to purchase the correct size and type of replacement belt for your sewing machine model. Follow the manufacturer’s instructions for belt installation carefully.

Excessive Noise

If your sewing machine belt is making a loud noise while in operation, it could be due to misalignment or wear.

Check for any obstructions or foreign objects in the belt’s path and remove them. Additionally, inspect the belt for signs of wear, such as cracks or fraying, and replace it if necessary.

Belt Not Engaging

In some cases, the sewing machine belt may not engage the handwheel or pulleys correctly. Ensure that the belt is properly seated on the pulleys and handwheeled. Refer to your sewing machine’s manual for guidance on how to properly engage the belt.

Inconsistent Stitching

If you notice inconsistent stitching or skipped stitches, the belt tension may be the culprit. Incorrect tension can affect the sewing machine’s performance.

Adjust the belt tension according to the manufacturer’s recommendations to achieve consistent stitching.

Difficulty in Starting the Machine

Sometimes, sewing machines may be hard to start due to a worn-out or loose belt. Check the condition and tension of the belt, and if necessary, replace or tighten it to ensure the machine starts smoothly.

Uneven Stitches

Uneven stitches can result from a misaligned belt or a belt that’s not properly tensioned. Inspect the belt’s alignment and tension, making adjustments as needed.

Additionally, ensure that the sewing machine’s timing is correct, as this can also affect stitch quality.

How to Stretch a Rubber Belt?

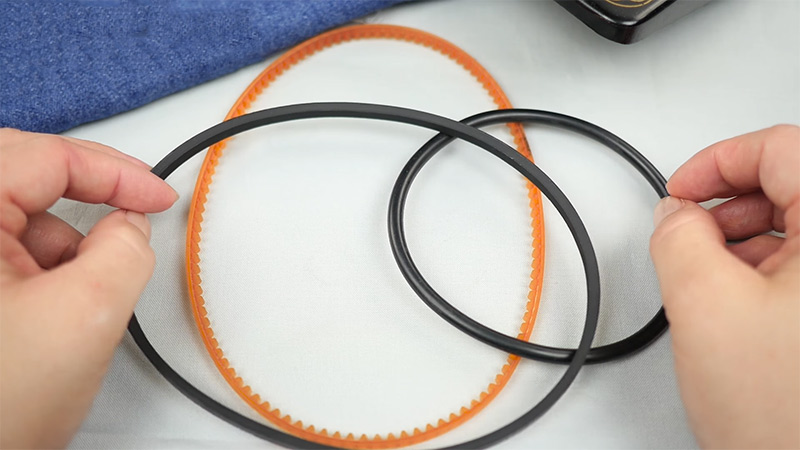

Stretching a rubber belt can be a useful technique in certain situations, such as when you need to install a new belt on a sewing machine, a car engine, or another mechanical device.

Stretching the belt temporarily allows you to fit it over pulleys and wheels that may otherwise be difficult to access.

Here’s a step-by-step guide on how to stretch a rubber belt:

Tools and Materials Needed:

- Rubber Belt

- Warm Water

- Heat Source

- Gloves

Steps to Stretch a Rubber Belt:

1. Safety Precautions

Ensure that you’re working in a safe and well-ventilated area. Wear gloves to protect your hands.

2. Heat the Belt

If the rubber belt is particularly tight or resistant to stretching, you can use a heat gun or hairdryer to warm it up.

Heat makes rubber more pliable and easier to stretch. Hold the heat source a few inches away from the belt and move it along the length of the belt evenly. Be cautious not to overheat the rubber, as excessive heat can damage it.

3. Soak the Belt

Fill a bucket or container with warm water. The warmth of the water will help soften the rubber and make it more flexible. Submerge the rubber belt in the warm water for several minutes, ensuring it’s fully soaked.

4. Stretch the Belt

After soaking, take the rubber belt out of the water and start stretching it gently but firmly. Work your way around the belt, applying even pressure.

You can use your hands to stretch it, or if it’s a long belt, you may need assistance from a second person. Stretch it slowly to avoid damaging the rubber. Ensure you’re pulling it evenly and not causing any distortions or twists in the belt.

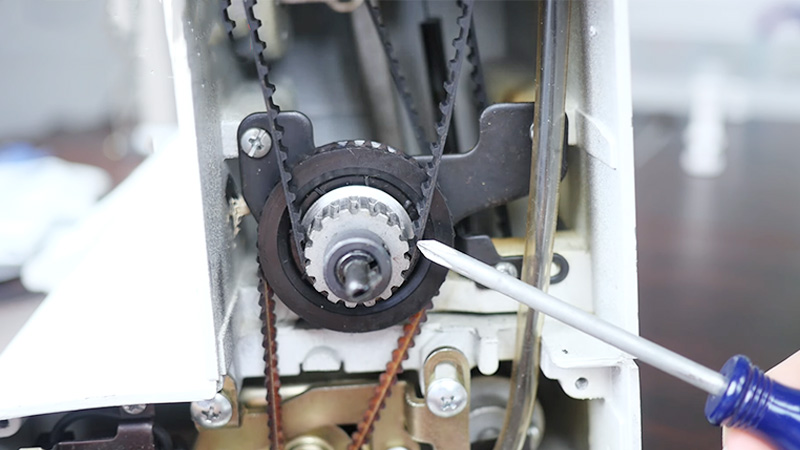

5. Install the Belt

While the rubber belt is still warm and pliable from the water and stretching, quickly install it onto the pulleys or wheels of your machine or device. Make sure it’s properly aligned and seated on the pulleys.

6. Cooling and Settling

Allow the rubber belt to cool down and settle into its stretched position. It will naturally contract slightly as it cools.

This cooling process helps the rubber regain some of its original shape and maintain tension on the pulleys.

7. Final Tension Adjustment

After the rubber belt has cooled and settled, check its tension. If necessary, adjust the tension to the manufacturer’s specifications to ensure proper operation.

Over time, the rubber belt may naturally stretch a bit, so periodic tension adjustments may be required.

FAQS

Can I use a rubber stretch belt on any sewing machine?

Rubber stretch belts can be used on many sewing machines, but it’s essential to check your sewing machine’s manual or consult with a technician to ensure compatibility.

Are there any alternatives to rubber stretch belts for sewing machines?

Yes, alternatives include cogged belts, V-belts, or even timing belts.

How often should I replace a rubber stretch belt on my sewing machine?

Generally, rubber stretch belts can last several years, but it’s a good practice to inspect them regularly for signs of wear and replace them as needed.

Are there any maintenance tips for rubber stretch belts?

Yes, to prolong the life of a rubber stretch belt, store it away from direct sunlight and extreme temperatures.

Can I stretch a rubber belt that has become too loose?

It’s not recommended to stretch a rubber belt that has become loose over time.

To Recap

The suitability of rubber stretch belts for sewing machines is contingent on specific circumstances and requirements.

These belts present an appealing option for those on a budget, offering affordability without compromising functionality.

Their flexibility can accommodate varying tension needs, promoting versatility in sewing tasks. However, their durability may raise concerns in heavy-duty applications, potentially necessitating more frequent replacements.

Compatibility with specific machine types and load-bearing capacity are also factors to consider.

In essence, rubber stretch belts can be an excellent choice for many sewing machines, particularly for hobbyists and lighter-duty applications.

However, for heavy-duty and precision-focused tasks, exploring alternative belt options might yield more suitable results.

Leave a Reply