The world of sewing and crafting is a diverse landscape, encompassing everything from delicate fabrics for fashion to heavy-duty materials for accessories like shoes and bags.

One common question that arises in this creative realm is whether you need a separate sewing machine for shoes and bags.

As these two categories involve distinctive materials, techniques, and structural requirements, the choice between having one versatile machine or multiple specialized ones can greatly impact your crafting journey.

In this discussion, we will explore the considerations that come into play when deciding whether to invest in separate sewing machines for shoes and bags, weighing the advantages and drawbacks to help you make an informed choice in your sewing endeavors.

Do You Need Separate Sewing Machine Shoes and Bags?

No, you don’t need a separate sewing machine for shoes and bags. When it comes to sewing shoes and bags, you do not necessarily need a separate sewing machine for each of them.

Many sewing machines are versatile enough to handle a wide range of projects, including footwear and bags.

Here are some reasons why you can use the same sewing machine for both:

Stitch Variety

Most modern sewing machines come with a variety of stitch options and adjustable settings. These features allow you to customize your sewing machine to match the requirements of the specific material you’re working with, whether it’s leather for shoes or canvas for bags.

Needle and Thread Compatibility

You can easily switch out sewing machine needles and threads to match the thickness and type of material you’re sewing.

For example, leather needles and heavy-duty threads are suitable for shoe-making, while finer needles and threads are better for lightweight fabrics used in bags.

Foot Attachments

Sewing machines often come with interchangeable presser feet that are designed for various purposes.

Walking feet, zipper feet, and even Teflon-coated feet can be used for sewing both shoes and bags, ensuring precise and smooth stitching on different materials.

Adjustable Feed Dogs

Most sewing machines have adjustable feed dogs that control the fabric’s movement during sewing. This feature allows you to work on thick leather or thin fabric by regulating the feed dog’s pressure.

Power and Speed Control

Sewing machines offer adjustable speed controls, allowing you to sew slowly and precisely when needed, such as when working on intricate details in bags or shoes.

Durability and Maintenance

Investing in a high-quality sewing machine designed for heavy-duty use ensures that it can handle the demands of both shoe and bag-making.

Regular maintenance and proper care of your machine can prolong its life and keep it in good working condition.

When You Need Separate Sewing Machines for Shoes and Bags

Separate sewing machines for shoes and bags may be necessary in specific situations where you require specialized equipment to meet the unique demands of each type of project.

Here are some instances when separate machines for shoes and bags are beneficial:

Different Material Thickness

Shoes are typically made from thicker materials, such as leather or suede, while bags can be crafted from a variety of fabrics, including lightweight cotton, canvas, or even delicate silk.

If you consistently work with significantly different material thicknesses, having separate machines allows you to set up one for heavy-duty sewing (for shoes) and the other for lighter materials (for bags) without constantly adjusting settings.

Specialized Stitching Requirements

Some shoe-making processes, like attaching soles or sewing through multiple layers of leather, require specialized stitching equipment.

A heavy-duty industrial sewing machine designed specifically for shoe-making can handle these tasks more efficiently than a standard home sewing machine.

Production Volume

If you have a high production volume for either shoes or bags, having dedicated machines for each can increase efficiency.

You can set up one machine for continuous shoe production and another for bag-making, avoiding frequent adjustments and reducing downtime.

Workspace Organization

For those with ample workspace and the desire for an organized sewing area, separate machines can help maintain order and streamline your workflow.

Each machine can have its designated spot, making it easier to access the necessary tools and materials for each type of project.

Customization and Precision

Some shoe-making techniques, like custom orthopedic shoe production or intricate leatherwork, demand precise control and specialized attachments.

Dedicated shoe-making machines can provide the level of customization and precision required for such projects.

Professional or Commercial Use

If you run a commercial sewing business specializing in either shoes or bags, dedicated machines are often necessary to meet production demands and maintain consistent quality.

Features of an Industrial Sewing Machine for Bag Making

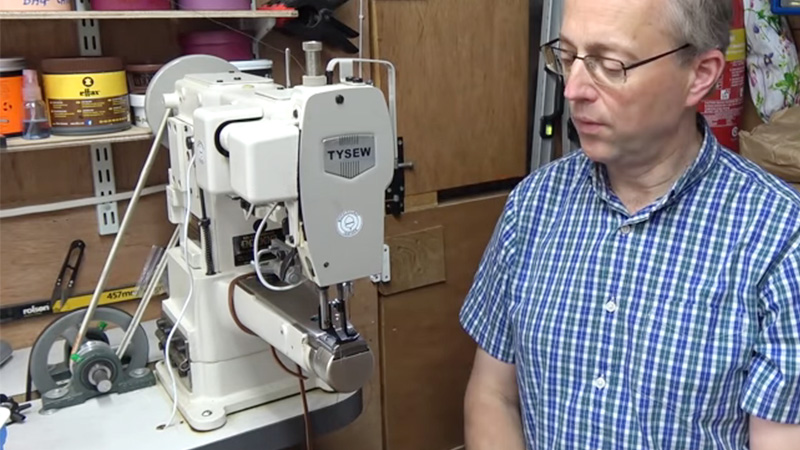

An industrial sewing machine for bag making is a specialized piece of equipment designed to handle the demands of manufacturing bags, backpacks, purses, and other similar accessories.

These machines are essential for businesses or individuals involved in large-scale production or crafting high-quality bags.

Here are some key features and advantages of industrial sewing machines tailored for bag making:

Heavy-Duty Capability

Industrial bag-making machines are built to handle thick and heavy materials commonly used in bag construction, such as leather, canvas, denim, and synthetic fabrics. They can effortlessly sew through multiple layers of material.

Stitch Variety

These machines often offer a wide range of stitch options, including straight stitches, zigzag stitches, and various decorative stitches. This versatility allows for different design elements and functional seams on bags.

Large Workspace

Industrial machines typically have a spacious sewing area, providing ample room for maneuvering and assembling bag components. This is especially beneficial when working on larger bags or projects with intricate details.

High-Speed Operation

Speed is a significant advantage of industrial sewing machines. They can sew much faster than standard home sewing machines, which is crucial for meeting production quotas and deadlines.

Durability and Reliability

Industrial machines are built to withstand continuous use in a commercial setting. They are designed for durability and require less frequent maintenance compared to household machines.

Specialized Attachments

Many industrial bag-making machines come with specialized attachments and accessories, such as walking feet, roller feet, and edge guides, which facilitate precise and efficient sewing on various bag materials.

Consistent Stitch Quality

These machines are known for their ability to produce consistent and high-quality stitches, ensuring the structural integrity and aesthetics of the finished bags.

Automatic Thread Cutting

Some industrial models feature automatic thread trimming functions, reducing the time spent on manual thread cutting and enhancing efficiency.

Customization Options

Industrial sewing machines can often be customized to meet specific bag-making requirements, such as adjusting thread tension, stitch length, and presser foot pressure.

Versatility

While primarily designed for bag making, industrial sewing machines can also handle other heavy-duty sewing tasks, such as leatherwork, upholstery, and canvas projects.

FAQS

What specialty has a sewing machine for shoes and bags?

A sewing machine for shoes and bags is designed for heavy materials, offers specialized stitching options, and often has attachments tailored for these specific projects.

Do I need separate sewing machines for shoes and bags?

It depends on your needs. If you frequently work with vastly different materials, have high production volumes, or require precise stitching, separate machines can be beneficial.

Are shoe sewing machines only for professionals, or can hobbyists use them too?

Shoe sewing machines cater to both professionals and dedicated hobbyists. Their versatility and durability make them suitable for various skill levels.

Can I use an industrial sewing machine for making shoes and bags at home?

Industrial sewing machines can be used at home, but they are larger and may require more space. Ensure you have adequate room and electrical capacity for them.

Can I use the same sewing machine if I frequently switch between making shoes and bags?

Yes, you can use the same sewing machine if you’re comfortable with adjusting settings and attachments for different projects.

Wrap Up

In sewing, the question of whether separate machines are necessary for shoes and bags ultimately hinges on individual preferences, project diversity, and professional aspirations.

While a single, versatile sewing machine can adapt to various tasks, including shoes and bags, the advantages of dedicated equipment become apparent when you delve deeper into these crafts.

Specialized machines offer precision, efficiency, and durability tailored to the unique demands of each.

They become indispensable for professionals, high-volume production, or those committed to perfecting their craft.

However, for hobbyists and occasional projects, a single machine remains a practical choice, showcasing the versatility that modern sewing technology offers to creative minds.

Leave a Reply