Bevel gears are integral components of sewing machines, responsible for the precision and finesse in stitching. However, like any mechanical parts, these gears are susceptible to breakage if subjected to specific conditions.

Understanding the reasons behind bevel gear breakage in sewing machines is essential for maintaining the machine’s performance and avoiding costly repairs.

Numerous factors can contribute to gear damage, from overloading the machine with heavy materials to using inappropriate thread tension and neglecting regular maintenance.

This knowledge empowers users to take preventive measures, ensuring the longevity of their sewing machines and the uninterrupted pursuit of their sewing projects.

This discussion explores the common causes and provides insights into safeguarding these essential components.

What Causes A Bevel Gear To Break Sewing Machine?

Like any mechanical component, bevel gears in a sewing machine can experience breakage under certain conditions.

Understanding the potential causes of bevel gear breakage is crucial for maintaining your sewing machine’s reliability and avoiding costly repairs.

Here are the key factors that can lead to bevel gear breakage in a sewing machine:

Overloading the Machine

One of the most common reasons for bevel gear breakage is overloading the sewing machine. When you attempt to sew through materials too thick or heavy for the machine’s intended capacity, it exerts excessive force on the bevel gears. This added stress can lead to gear damage or even breakage.

Inappropriate Material Type

The type of sewn material plays a significant role in the stress experienced by the bevel gears. Trying to sew through exceptionally tough materials, such as leather, heavy denim, or multiple layers of thick fabric, can accelerate wear and tear on the gears over time.

Improper Thread Tension

Incorrectly adjusted thread tension can result in various sewing problems, including thread jams and increased resistance. Such issues can strain the gears, potentially causing damage over time.

Maintaining the proper thread tension is crucial for the sewing machine’s smooth operation and its gears’ longevity.

Needle Problems

A damaged or bent sewing machine needle can lead to irregular stitching and may cause the needle to collide with the bevel gears. This collision can result in gear damage or breakage.

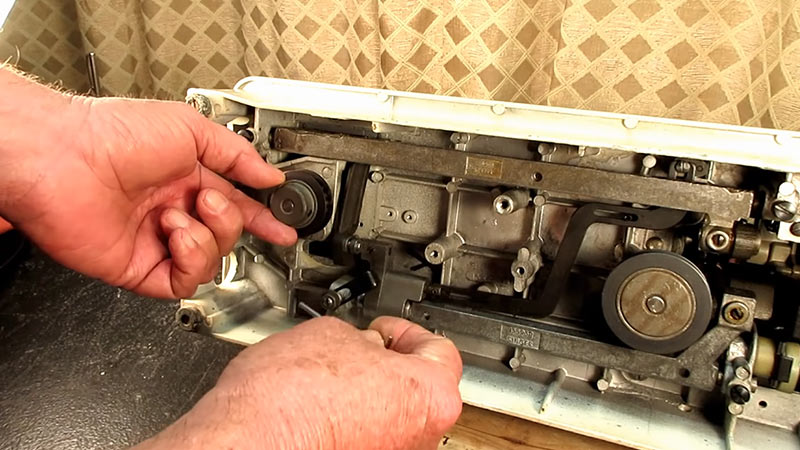

Lack of Maintenance

Failing to perform regular maintenance on the sewing machine commonly contributes to gear issues. Dust, lint, and debris can accumulate within the machine, causing increased friction and wear on the gears.

Regular cleaning and proper lubrication are necessary to maintain the machine’s health.

Worn Components

Over time, the bevel gears can naturally wear down due to regular use. This wear and the stress above factors can increase the risk of gear breakage.

Low-Quality Materials

Some sewing machines may use low-quality or less durable materials for their gears. The gears may be more prone to breakage or wear out faster in such cases.

Impact or Mishandling

Dropping or mishandling the sewing machine can result in mechanical damage, including damage to the bevel gears. Bevel gears are intricate and precise, making them vulnerable to harm when subjected to forceful impacts.

Common Signs That a Bevel Gear in a Sewing Machine Is Damaged or Broken

Detecting signs of a damaged or broken bevel gear in a sewing machine is essential for ensuring the continued functionality of your machine.

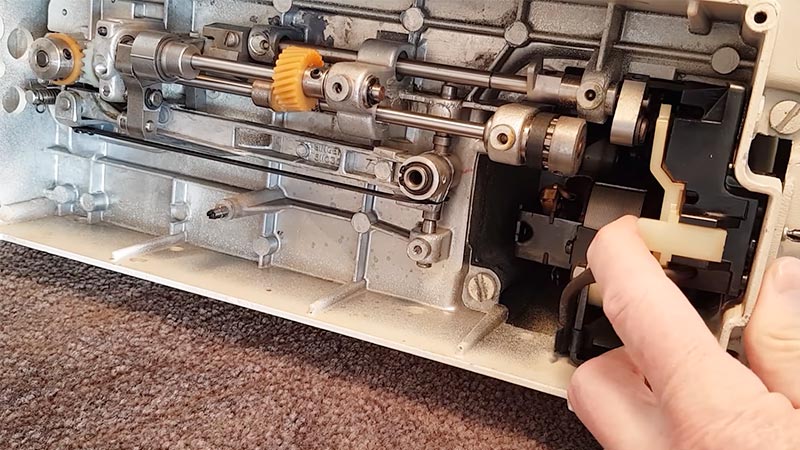

Bevel gears play a critical role in translating power and motion within the sewing machine, and when they are compromised, they can disrupt the sewing process.

Here are the common signs to look for to determine if a bevel gear in your sewing machine is damaged or broken:

Unusual Noise

Unusual noise is one of the most noticeable signs of bevel gear issues. You may hear grinding, clicking, clunking, or even squeaking sounds during sewing. These sounds often indicate gear teeth not meshing correctly, increasing friction and noise.

Inconsistent Stitching

It can be a red flag when your sewing machine produces uneven or inconsistent stitches. Gear damage can disrupt the precise movement of the needle, affecting the quality of stitches.

Increased Vibration

Excessive vibration during sewing, especially if it’s a new development, can be attributed to gear problems. When the gears are damaged, they may not transfer power smoothly, causing increased vibration.

Thread Jams

Frequent thread jams, where the thread gets stuck or tangled, are often a result of misalignment or damage to the gears. The gears may not be guiding the fabric and thread correctly.

Thread Breakage

Unexpected thread breakage can be linked to gears not functioning correctly. If the gears are damaged, they may cause increased tension, leading to thread breakage.

Sewing Machine Stalls

A sewing machine that stops abruptly during operation can signal gear issues. The gears may not engage as they should, causing the machine to stall.

Needle Alignment Problems

Damaged bevel gears can result in the needle not moving or aligning correctly. This affects the sewing process and can lead to skipped stitches or fabric damage.

Difficulty in Rotating Handwheel

If the handwheel is hard to turn or feels blocked, it may indicate gear damage. The handwheel is directly connected to the machine’s internal gears, and any resistance may be due to gear problems.

Increased Backlash

Backlash is the amount of play or movement in the gears when the direction of the machine changes. An increase in backlash may suggest gear problems and a lack of precision in the gear movement.

Visible Gear Damage

A visual inspection of the bevel gears may reveal physical damage. Look for chipped, cracked, or misshapen gear teeth. If you see any apparent damage, it’s a clear sign that the gears are compromised.

How to Prevent Bevel Gear Breakage in a Sewing Machine?

Preventing bevel gear breakage in a sewing machine is crucial for maintaining the longevity and efficient operation of your machine. Bevel gears are vital components that facilitate the intricate movements required for sewing.

To avoid costly repairs and keep your sewing machine in optimal condition, here’s a comprehensive guide on how to prevent bevel gear breakage:

Use the Right Materials

Start by using the appropriate materials for your sewing project. Select the right type and thickness of fabric, suitable thread, and the correct needle size.

Overloading your machine with too thick or heavy materials can exert excessive force on the bevel gears, potentially leading to breakage.

Proper Thread Tension

Regularly check and adjust the thread tension on your sewing machine according to the specific requirements of your project. Correct thread tension ensures that the fabric flows smoothly through the machine, reducing the risk of extra strain on the gears.

Regular Maintenance

Follow the manufacturer’s recommended maintenance schedule. Regular cleaning and lubrication are essential to prevent dust, lint, and debris accumulation, which can increase friction and accelerate wear on the gears.

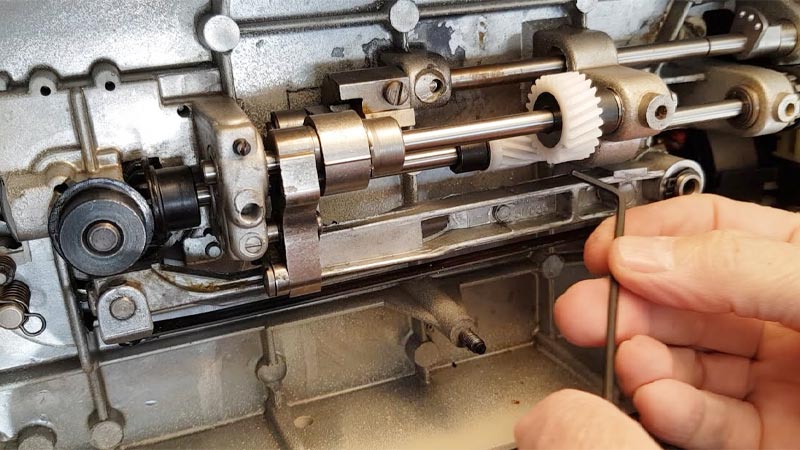

Timely Component Replacement

Pay close attention to the condition of various components within your sewing machine, including needles and bevel gears. If you notice any signs of wear or damage, replace these components promptly to prevent added stress on the gears.

Handle with Care

Treat your sewing machine with gentleness. Avoid rough or careless handling, and be cautious when moving or setting down the machine. Mishandling and impacts can cause damage to the delicate bevel gears.

Avoid Overloading

Be mindful of your sewing machine’s capacity and avoid overloading it with materials that exceed its intended limits. Overloading can place excessive force on the gears, potentially leading to damage. Always stay within the recommended guidelines.

Mind the Material Type

Consider the type of material you’re sewing. Extremely tough materials, such as leather or heavy denim, can accelerate wear and tear on the gears. Adjust your machine’s settings and needle type accordingly to reduce strain on the gears.

Monitor Needle Health

Regularly inspect your sewing machine needles for any signs of damage or bending. A damaged needle can lead to gear damage if not replaced promptly. Maintaining healthy needles is a proactive measure to prevent bevel gear breakage.

FAQs

What is a bevel gear in a sewing machine, and what is its role?

A bevel gear in a sewing machine is a specialized gear with angled teeth that transfers rotational power, enabling the machine to accurately control the needle and bobbin mechanisms.

Can using the wrong materials affect the bevel gears in a sewing machine?

Yes, using the wrong materials, such as excessively thick or heavy fabric, can place undue stress on bevel gears in a sewing machine, potentially causing damage.

How often should a sewing machine be maintained to prevent bevel gear damage?

Regular maintenance for a sewing machine, including cleaning and lubrication, should be performed according to the manufacturer’s recommendations to prevent bevel gear damage.

Is it possible to repair a bevel gear once it’s broken, or does it need to be replaced?

In most cases, a broken bevel gear in a sewing machine must be replaced rather than repaired, as gear damage typically requires complete replacement.

What are the best practices for extending the life of bevel gears in a sewing machine?

Best practices for extending the life of bevel gears in a sewing machine include using appropriate materials, maintaining proper thread tension, regular cleaning, and gentle machine handling.

To Recap

A sewing machine’s durability and smooth operation greatly depend on the condition of its bevel gears. A comprehensive understanding of the potential causes of bevel gear breakage is the first step towards their prevention.

These factors can damage gear and disrupt your sewing projects, whether it’s due to overloading, improper materials, thread tension issues, or neglecting regular maintenance.

You can significantly extend the life of your sewing machine’s bevel gears by implementing simple but effective preventive measures such as using suitable materials, maintaining proper thread tension, and handling the machine carefully.

With a commitment to responsible usage and maintenance, you can ensure your sewing machine’s consistent and high-quality performance for years to come.

Leave a Reply