When it comes to the world of embroidery, there’s one question that often crops up – are embroidery needles blunt? It’s a valid query, given that the sharpness or bluntness of your needle can significantly impact your stitching experience.

So, let me set the record straight.

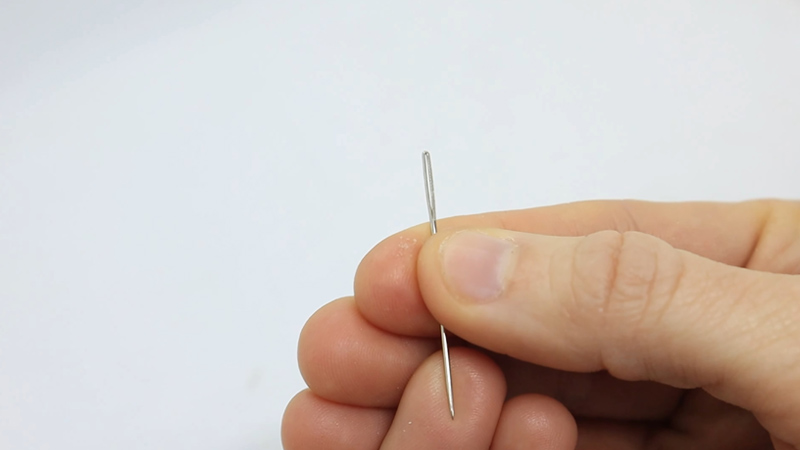

Embroidery needles are not typically blunt; they’re rather sharp. The reason for this is simple: they must penetrate various types of fabric smoothly and cleanly without snagging or damaging the material.

A well-kept, sharp needle glides through even tightly woven fabrics easily, creating neat and precise stitches. However, over time and use, an embroidery needle might become dull or ‘blunt.’

That’s when a blunting needle becomes more challenging to work with, as it tends to push threads aside rather than going through them fluidly. This is why it’s essential to maintain your tools regularly and replace them when necessary.

Discovering the 7 Essential Roles of Needles in Embroidery

Embroidery needles play a crucial role in embroidery, and their importance cannot be overstated.

Here are several key reasons why needles are essential in embroidery:

1. Precision and Control

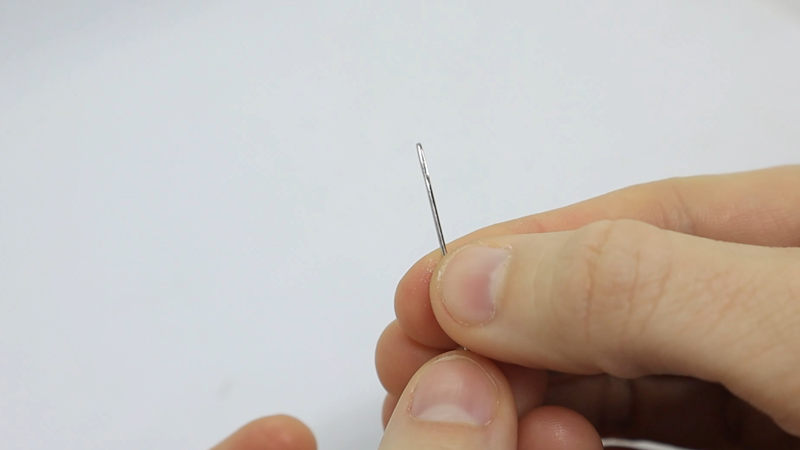

Embroidery needles are designed with sharp points that penetrate fabric quickly and accurately. This precision is essential for creating intricate stitches and delicate designs with accuracy and control.

2. Compatibility with Fabric

Different fabrics require different types of needles to achieve the best results. For example, sharp needles are suitable for piercing through thick fabrics without causing damage, while blunt needles are ideal for weaving through loose-weave fabrics without snagging or tearing.

3. Thread Management

The size and shape of embroidery needles influence how effectively they hold and maneuver thread. Using the appropriate needle ensures smooth thread flow and prevents breakage, tangling, or knotting during embroidery.

4. Stitch Quality

The right needle size and type contribute to the overall quality and appearance of stitches. Using the wrong needle can result in uneven stitches, puckering, or distortion of the fabric, affecting the final outcome of the embroidery project.

5. Versatility

Embroidery needles come in various sizes and types to accommodate different techniques, thread weights, and fabric thicknesses. Having a selection of needles allows embroiderers to tackle a wide range of projects confidently and quickly.

6. Longevity and Durability

High-quality embroidery needles are durable and long-lasting, capable of withstanding repeated use without bending, breaking, or dulling. Investing in good-quality needles ensures consistent performance and reliable results over time.

7. Craftsmanship and Artistry

Embroidery is a labor-intensive craft that requires attention to detail and skillful execution. The needle choice reflects the embroiderer’s dedication to craftsmanship and commitment to achieving professional-quality results in their work.

Types of Embroidery Needles

Embarking on the captivating journey of embroidery unveils a world where the choice of needle becomes an art form.

Each needle type possesses unique characteristics tailored to specific fabrics, techniques, and projects, influencing the final outcome with every delicate stitch.

Let’s explore the diverse array of embroidery needles to empower you with the knowledge needed to elevate your craft:

1. Chenille Needles

Chenille needles boast a robust build with a sharp point and a generous eye. Their thick shafts make them ideal for navigating through heavy or coarse fabrics like wool or felt with ease.

Whether embellishing garments or crafting textured designs, Chenille needles are reliable companions for tackling projects that demand durability and strength.

2. Tapestry Needles

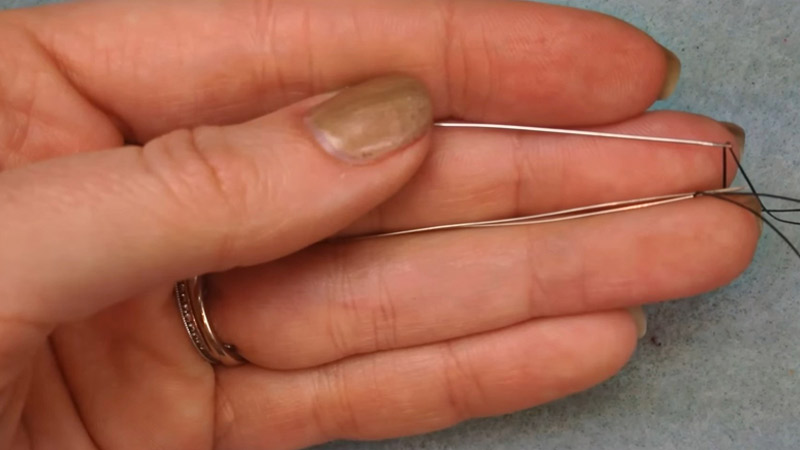

Tapestry needles, characterized by blunt tips and large eyes, are indispensable for delicate work on loosely woven fabrics.

Perfect for cross-stitching and needlepoint, these needles gracefully glide through the fabric without splitting threads, ensuring flawless execution of intricate patterns and designs.

3. Crewel (or Embroidery) Needles

Crewel needles, also known as embroidery needles, feature long eyes and sharp points, making them versatile allies in embroidery.

Their ability to effortlessly pierce through close-weave fabrics without causing damage makes them indispensable for various embroidery techniques and projects.

4. Milliners (or Straw) Needles

Milliner’s needles, distinguished by their round eyes and elongated shafts, excel in techniques like bullion knots and intricate wrapping stitches.

Their slender build allows for precise thread manipulation, resulting in beautifully embellished designs with impeccable detail and finesse.

5. Beading Needles

Beading needles stand out for their slender profiles and small eyes, making them effortlessly pass through tiny bead holes with precision.

Whether adding intricate beadwork to garments or creating dazzling embellishments, these needles offer unparalleled mastery and control, elevating the artistry of bead embroidery.

6. Blunting Needles

While not a distinct type, blunting needles remind us of the importance of maintenance in embroidery. As needles are extensively used, they gradually lose their sharpness, necessitating regular replacement to ensure optimal results.

By prioritizing needle care, embroiderers safeguard against compromised stitches and preserve the integrity of their work.

Do Embroidery Needles Become Blunt?

Embroidery needles, like many other tools, can become blunt over time. It’s a common issue many embroiderers face after extended use of their favorite needle. But it’s not just the passage of time that can dull your embroidery needle.

Factors such as the type of fabric you’re working with and how often you use your needle also come into play. For instance, denser fabrics can cause more wear and tear on your embroidery needles, causing them to blunt faster.

Let’s delve into some statistics:

| Fabric Type | Average Needle Lifespan |

|---|---|

| Silk | 50 hours |

| Cotton | 30 hours |

| Denim | 10 hours |

As the table above shows, blunting is inevitable for all types of embroidery needles regardless of the fabric type used.

Another factor worth considering when discussing the blunting of embroidery needles is how often they are used.

A frequently used needle will blunt quicker than one used infrequently. This might seem obvious, but it’s important to remember when assessing the sharpness of your needles.

Further adding to this complexity is how much pressure one applies during their stitching process. More pressure equals more friction, which then results in quicker blunting.

So yes, embroidery needles become blunt due to various factors including usage frequency, fabric type and stitching pressure applied by the user.

Signs of Blunt Embroidery Needles

Detecting signs of blunt embroidery needles is essential for maintaining the quality of your stitching. Here are some key indicators to watch out for:

Difficulty in Threading

If you find it increasingly challenging to thread your needle, it could be a sign that the tip is becoming blunt. While threading can be fiddly even with sharp needles, a sudden increase in difficulty may indicate dullness.

Resistance when Puncturing Fabric

A sharp needle should effortlessly glide through the fabric. However, if you encounter resistance or hear a thud sound as the needle penetrates the fabric, it suggests that the needle is losing its sharpness.

This resistance can make stitching more difficult and compromise the neatness of your work.

Uneven or Loose Stitches

Blunt needles can result in stitches that appear uneven or looser than usual. A sharp needle creates consistent and tight stitches, whereas a blunt one may struggle to pierce the fabric cleanly, leading to irregular stitching patterns.

Increased Effort and Hand Fatigue

Working with a blunt needle requires more effort, as you must exert additional force to penetrate the fabric. This extra effort can lead to hand fatigue and discomfort, especially during prolonged embroidery sessions.

Why Blunt Needles Can Affect Your Embroidery? 4 Key Reasons to Keep Your Needles Sharp

In the intricate world of embroidery, where every stitch contributes to the beauty of the final piece, the sharpness of your needle is paramount.

Blunt needles, while often overlooked, can significantly compromise the quality and integrity of your embroidery work.

Let’s delve into how blunt needles can adversely affect your stitching:

1. Distorted Fabric Weave

Unlike sharp needles that cleanly pierce through the fabric, blunt needles tend to push through the material, distorting the weave.

This distortion results in less accurate stitches, as the needle fails to navigate smoothly through the fabric fibers.

Over time, this can manifest as uneven tension and irregularities in your embroidery designs.

2. Thread Pulling and Snagging

Blunt needles are more prone to pulling and snagging threads as they struggle to penetrate the fabric effectively. This pulling action disrupts the flow of stitches and creates inconsistencies in the embroidery pattern.

Additionally, the friction caused by blunt needles can lead to thread breakage or fraying, posing a frustrating challenge for embroiderers striving for flawless results.

3. Uneven Stitching and Puckering

The inability of blunt needles to pierce fabric cleanly results in uneven stitching and puckering in the embroidered areas.

These imperfections detract from the overall aesthetic appeal of the design, detracting from its professional appearance.

Embroiderers may find themselves constantly adjusting and correcting stitches affected by dull needles, impeding the fluidity of the creative process.

4. Maintenance of Tool Integrity

Recognizing the detrimental impact of blunt needles underscores the importance of regular maintenance and care of embroidery tools.

Swapping out dull needles for sharp ones may seem like a minor inconvenience, but it is essential for achieving high-quality results and preserving the integrity of your embroidery projects.

Taking proactive measures to keep needles sharp ensures smooth and precise stitching, elevating the craftsmanship of your work.

How to Deal with Blunt Embroidery Needles?

Dealing with blunt embroidery needles is a common challenge in needlework projects, but with the right approach, it’s easily manageable.

Here’s how to tackle this issue effectively:

Identify Blunt Needles

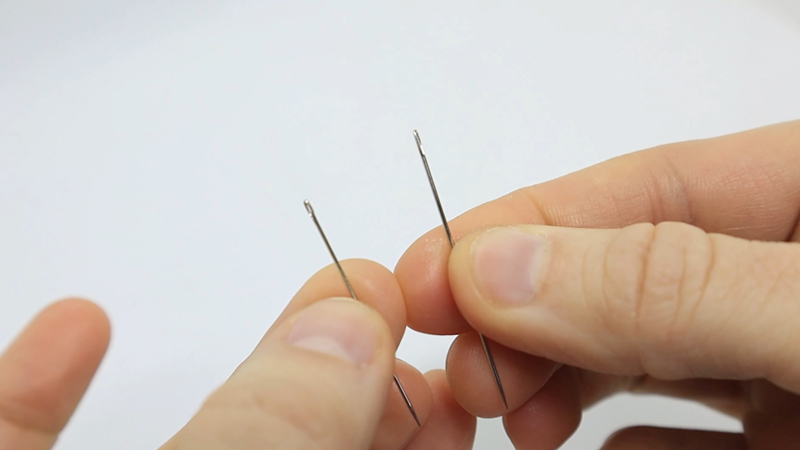

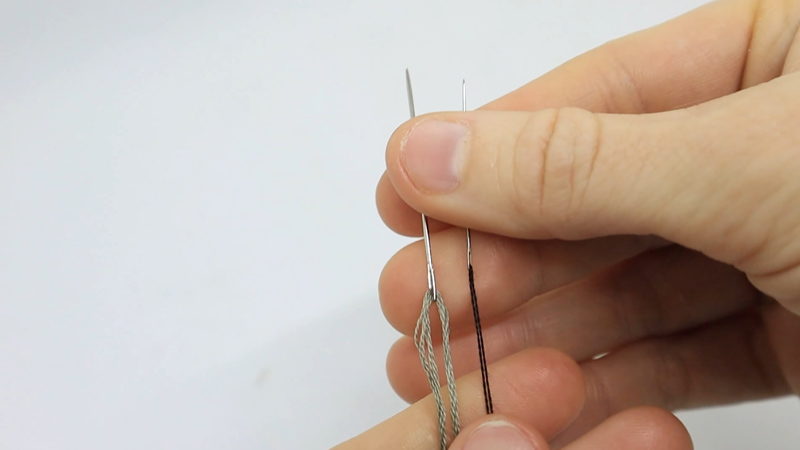

Before addressing the problem, it’s crucial to differentiate between blunt and sharp needles. Look for rough edges and observe if the needle struggles to penetrate the fabric smoothly. Signs such as fraying thread or punctured fabric indicate a blunt needle.

Needle Sharpeners

Invest in needle sharpeners, which come in various forms, such as small stones or strips of sandpaper. Run the needle’s point through the sharpener’s surface a few times to restore its sharpness.

This method is quick and convenient for revitalizing blunt needles.

Consider Replacement

While sharpening can extend the lifespan of needles, there comes a point where replacement is the best option.

Needles are relatively inexpensive, and having fresh ones on hand ensures high-quality work without dealing with blunt needles.

Emery Strawberry

Emery strawberries, often considered decorative accessories, contain emery powder inside, which is excellent for sharpening needles.

Insert the needle into the strawberry and rotate it to sharpen the tip. This method is both practical and charming.

Conclusion

In the intricate world of embroidery, the journey is as much about mastering the tools as it is about crafting beautiful designs. Embroidery needles, though seemingly insignificant, play a vital role in the quality of our work.

As we’ve discovered, they can become blunt over time, impacting the precision and finesse of our stitches.

Understanding the factors influencing needle bluntness, from fabric types to project complexity, empowers us to maintain sharpness and achieve impeccable results.

By investing in high-quality needles and adopting a proactive approach to maintenance, we ensure smooth workflow and elevate our embroidery endeavors to new heights of creativity and craftsmanship.

Leave a Reply