A corset is a garment that is worn around the waist to shape and support the body. Historically, corsets were worn to cinch the waist and create an hourglass figure and were often worn under clothing as a foundation garment.

However, some people are interested in using corsets for decorative purposes, such as adding structure and shape to a garment without the need for waist cinching or support. In these cases, it may be necessary to find alternative materials to traditional boning, which is often used to provide support and structure in a corset.

Corset Boning Alternatives

Corsets are clothing items that are designed to shape and support the torso, typically by using boning to provide structure. However, there are alternatives to traditional boning materials that can be used in corsets.

Spiral Steel Boning

Spiral steel boning is a type of boning material that is used in corsets. It is made from a thin, flexible steel wire that is twisted into a spiral shape. This type of boning is more flexible and less restrictive than traditional steel boning.

Advantages of using spiral steel boning

- Flexibility: Spiral steel boning is more flexible than traditional steel boning, which allows for more movement and comfort for the wearer.

- Support and shaping: Spiral steel boning provides support and shape for the torso, just like traditional steel boning.

- Durability: Spiral steel boning is more durable than traditional steel boning and is less likely to poke through the fabric of the corset.

- Comfort: Spiral steel boning is more comfortable than traditional steel boning as it is less restrictive and allows more movement.

- Easy to bend: Spiral steel boning is more pliable and easy to bend, making it a great option for corsets that need to be adjusted to fit the wearer’s shape.

- Easy to maintain: Spiral steel boning is rust-resistant and easy to clean, making it a low-maintenance option for corsets.

Disadvantages of using spiral steel boning

- Cost: Spiral steel boning is typically more expensive than traditional steel boning.

- Durability: Spiral steel boning is less durable than traditional steel boning and may need to be replaced more frequently.

- Less support: Spiral steel boning may not provide as much support as traditional steel boning, which can be an issue for those who need more support for the torso.

- Less restrictive: Spiral steel boning is less restrictive than traditional steel boning, which may not be suitable for those who need more rigid support.

- Less traditional look: Spiral steel boning may not give the traditional and rigid look of a corset as traditional steel boning does.

- Require more care: Spiral steel boning is more prone to rusting so it requires more care and maintenance than traditional steel boning.

Examples of corsets that use spiral steel boning

- “Spiral Steel Boned Waist Training Corset” – This corset is designed to shape and support the torso while allowing for a greater range of movement and comfort. It is made with spiral steel boning to provide flexibility and support.

- “Flexible Spiral Steel Boned Underbust Corset” – This corset is designed to provide support and shape to the torso while also allowing for a greater range of movement and comfort. It uses spiral steel boning to provide flexibility and support.

- “Spiral Steel Boned Overbust Corset” – This corset is designed to provide support and shape to the torso, while also allowing for a greater range of movement and comfort. Spiral steel boning is used to provide flexibility and support.

- “Spiral Steel Boned Steampunk Corset” – This corset is designed in steampunk style and is made with spiral steel boning to provide flexibility and support.

- “Spiral Steel Boned Lace Up Corset” – This corset is designed with a lace-up front and made with spiral steel boning to provide flexibility and support.

These are just a few examples, there may be more corsets that use spiral steel boning. The use of spiral steel boning in corsets allows having a balance between support and flexibility, making them suitable for different occasions and purposes.

Plastic Boning

A. Plastic boning is a type of boning material that is used in corsets. It is made from a lightweight, flexible plastic material and is less expensive than steel boning.

Advantages of using plastic boning

- Affordability: Plastic boning is less expensive than steel boning.

- Lightweight: Plastic boning is lightweight, making it easy to move around in the corset.

- Flexibility: Plastic boning is flexible, allowing for more movement and comfort for the wearer.

- Rust-resistant: Plastic boning is rust-resistant, making it a low-maintenance option for corsets.

- Easy to bend: Plastic boning is easy to bend and shape, making it a great option for corsets that need to be adjusted to fit the wearer’s shape.

- Durable: Plastic boning can be durable, especially if it’s made with high-quality materials

- Variety: Plastic boning comes in a variety of colors, sizes, and shapes, giving more options for the designer or the user.

Disadvantages of using plastic boning

- Support: Plastic boning may not provide as much support as steel boning, which can be an issue for those who need more support for the torso.

- Durability: Plastic boning is less durable than steel boning and may need to be replaced more frequently.

- Shape Retention: Plastic boning may lose its shape over time and may not provide the same level of support as steel boning.

- Quality: Not all plastic boning is created equal, low-quality plastic boning may not provide enough support, may be brittle, and may lose its shape easily.

- Heat: Plastic boning may be affected by heat, it can warp or melt, and this can be an issue if the corset is going to be worn in hot environments.

Examples of corsets using plastic boning

- “Plastic Boned Waist Training Corset” – This corset is designed to shape and support the torso while also being affordable and lightweight. It is made with plastic boning to provide flexibility and support.

- “Flexible Plastic Boned Underbust Corset” – This corset is designed to provide support and shape to the torso while also being affordable, lightweight and easy to move in. It uses plastic boning to provide flexibility and support.

- “Plastic Boned Overbust Corset” – This corset is designed to provide support and shape to the torso, while also being affordable and lightweight. Plastic boning is used to provide flexibility and support.

- “Plastic Boned Steampunk Corset” – This corset is designed in steampunk style and is made with plastic boning to provide flexibility and support.

Synthetic Whalebone

A. Synthetic whalebone is a man-made alternative to natural whalebone, which was traditionally used in corsets. Synthetic whalebone is made from a variety of materials, including plastic and nylon, and is designed to mimic the properties of natural whalebone.

Advantages of using synthetic whalebone

- Affordability: Synthetic whalebone is typically more affordable than natural whalebone.

- Sustainability: Synthetic whalebone is a sustainable alternative to natural whalebone, as it does not require the hunting of whales.

- Lightweight: Synthetic whalebone is lightweight, making it easy to move around in the corset.

- Flexibility: Synthetic whalebone is flexible, allowing for more movement and comfort for the wearer.

- Easy to bend: Synthetic whalebone is easy to bend and shape, making it a great option for corsets that need to be adjusted to fit the wearer’s shape.

- Variety: Synthetic whalebone comes in a variety of colors, sizes, and shapes, giving more options for the designer or the user.

- Durable: Some types of synthetic whalebone can be durable, especially if it’s made with high-quality materials

Disadvantages of using synthetic whalebone

- Support: Synthetic whalebone may not provide as much support as natural whalebone, which can be an issue for those who need more support for the torso.

- Durability: Synthetic whalebone is less durable than natural whalebone and may need to be replaced more frequently.

- Shape Retention: Synthetic whalebone may lose its shape over time and may not provide the same level of support as natural whalebone.

- Quality: Not all synthetic whalebone is created equal, low-quality synthetic whalebone may not provide enough support, may be brittle, and may lose its shape easily.

Examples of corsets that use synthetic whalebone

- “Synthetic Whalebone Waist Training Corset” – This corset is designed to shape and support the torso while being sustainable, lightweight, and flexible. It is made with synthetic whalebone to provide support and shape.

- “Flexible Synthetic Whalebone Underbust Corset” – This corset is designed to provide support and shape to the torso while also being sustainable, lightweight, and easy to move in. It uses synthetic whalebone to provide support and shape.

- “Synthetic Whalebone Overbust Corset” – This corset is designed to provide support and shape to the torso, while also being sustainable and lightweight. Synthetic whalebone is used to provide support and shape.

Bamboo

Bamboo is a type of plant that is known for its strength, durability, and sustainability. In corsetry, bamboo is used as a boning alternative. Bamboo is used in corsetry because of its strength, it’s lightweight and it’s eco-friendly characteristics.

Advantages of using bamboo as boning in corsets

- Sustainability: Bamboo is a fast-growing, renewable resource that is more sustainable than other boning materials, such as steel or plastic.

- Strength: Bamboo is known for its strength and durability, making it a suitable alternative for boning in corsets.

- Lightweight: Bamboo is lightweight which makes it comfortable for the wearer, it does not add extra weight to the corset.

- Eco-friendly: Bamboo is an eco-friendly alternative to traditional boning materials and it is biodegradable.

- Variety: Bamboo comes in a variety of colors and sizes, giving more options for the designer or the user.

- Hypoallergenic: Bamboo is hypoallergenic, which means it won’t cause allergic reactions on the skin, this is an advantage for people with sensitive skin.

Disadvantages of using bamboo as boning in corsets

- Cost: Bamboo is typically more expensive than traditional boning materials, such as steel or plastic.

- Durability: Bamboo may not be as durable as other traditional boning materials, and may need to be replaced more frequently.

- Availability: Bamboo may not be as readily available as other traditional boning materials, making it harder to find and purchase.

- Shape Retention: Bamboo may not retain its shape as well as other boning materials, which can affect the support and shape provided by the corset.

- Quality: Not all bamboo is created equal, low-quality bamboo may not provide enough support, may be brittle, and may lose its shape easily.

- Chemical resistance: Some types of bamboo may not be resistant to certain chemicals, this can be an issue if the corset is going to be worn in certain environments where chemicals may be present.

Examples of corsets that use bamboo as boning

- “Bamboo Boned Waist Training Corset” – This corset is designed to shape and support the torso while also being sustainable, strong, and lightweight. It is made with bamboo boning to provide support and shape.

- “Flexible Bamboo Boned Underbust Corset” – This corset is designed to provide support and shape to the torso while also being sustainable, strong, and lightweight. It uses bamboo boning to provide support and shape.

- “Bamboo Boned Overbust Corset” – This corset is designed to provide support and shape to the torso, while also being sustainable, strong, and lightweight. Bamboo boning is used to provide support and shape.

These are just a few examples, there may be more corsets that use bamboo as boning. The use of bamboo as boning in corsets allows for sustainable, strong, and lightweight corsets, making them suitable for different occasions and purposes.

Flexible Metal Mesh

Flexible metal mesh is a type of boning material that is made from a thin, pliable metal material. It is designed to provide support and shape to the torso while also being flexible and durable.

Disadvantages of using flexible metal mesh as boning in corsets

- Cost: Flexible metal mesh is typically more expensive than other boning materials, such as steel or plastic.

- Support: Flexible metal mesh may not provide as much support as other boning materials, which can be an issue for those who need more support for the torso.

- Durability: Flexible metal mesh may not be as durable as other traditional boning materials, and may need to be replaced more frequently.

- Shape Retention: Flexible metal mesh may lose its shape over time and may not provide the same level of support as other boning materials.

- Quality: Not all flexible metal mesh is created equal, low-quality flexible metal mesh may not provide enough support, may be brittle, and may lose its shape easily.

Examples of corsets that use flexible metal mesh as boning

- “Flexible Metal Mesh Waist Training Corset” – This corset is designed to shape and support the torso while also being durable and pliable. It is made with flexible metal mesh to provide support and shape.

- “Flexible Metal Mesh Underbust Corset” – This corset is designed to provide support and shape to the torso while also being durable, pliable, and easy to move in. It uses flexible metal mesh to provide support and shape.

- “Flexible Metal Mesh Overbust Corset” – This corset is designed to provide support and shape to the torso, while also being durable and pliable. Flexible metal mesh is used to provide support and shape.

These are just a few examples, there may be more corsets that use flexible metal mesh as boning. The use of flexible metal mesh in corsets allows for durable, pliable, and supportive corsets, making them suitable for different occasions and purposes.

Tips for using boning in a corset

Choose the right type of boning

Consider the type of support and shape you want for your corset, and choose the appropriate type of boning. Different types of boning have different properties, such as flexibility, durability, and support.

Use enough boning

Make sure to use enough boning to provide the necessary support and shape for your corset. Not using enough boning can result in a corset that lacks support and shape.

Position the boning correctly

Position the boning correctly in the corset to ensure that it provides the necessary support and shape. This may include placing boning in the center back, side seams, and front center of the corset.

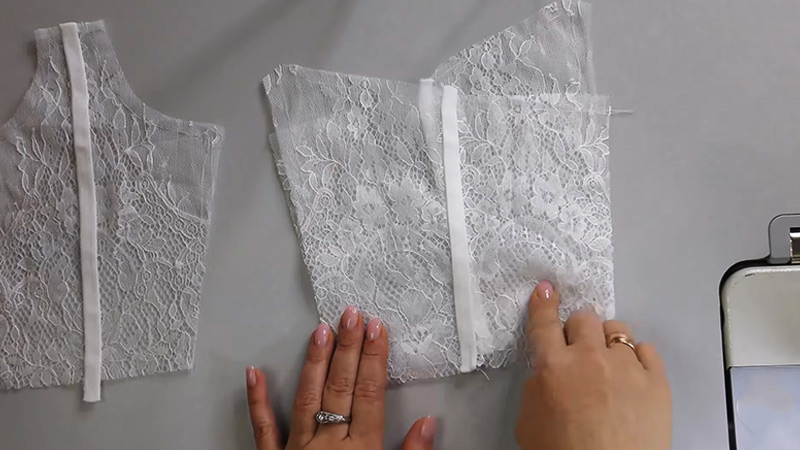

Secure the boning

Make sure to properly secure the boning in the corset to prevent it from shifting or moving around. This can be done by using casings or channels to hold the boning in place.

Consider the fabric

Choose a fabric that is sturdy enough to hold the boning in place and provide the necessary support. Avoid using lightweight or stretchy fabrics, as they may not provide the necessary support.

Test the corset

Before finishing the corset, try it on and move around in it to ensure that the boning is providing the necessary support and shape. Make any necessary adjustments before finishing the corset.

Maintenance

Make sure to keep the corset clean and dry and avoid exposing it to heat or chemicals as it may affect the boning.

FAQs

It’s important to choose a fabric that has the right level of body or drape to support the desired shape and structure of the corset. A medium- to heavyweight woven or stable knit can work well, but it’s always a good idea to test the fabric with your chosen boning material before committing to a full project.

It’s difficult to make a blanket statement about the durability of alternative boning materials, as it can vary depending on the specific material and how it is used. Some options, like cord or reed, may be more prone to breaking or stretching over time, while others, like foam interfacing or fusible foam, may hold up well with regular use. As with any corset, it’s a good idea to handle it gently and avoid excessive stretching or bending to help extend its lifespan.

Alternative boning materials may not provide the same level of support and structure as traditional steel or plastic boning, and as such may not be suitable for tightlacing or waist training. If you are interested in these activities, it’s important to choose a corset with a strong, sturdy boning material that can withstand the pressure and wear and tear of regular cinching.

It’s generally best to hand wash a corset to preserve the shape and structure of the boning. However, some alternative boning materials may be more prone to damage or deformity when wet. It’s important to follow the care instructions for the specific material you are using, and consider using a lingerie bag or other protective measures to keep the corset safe in the wash.

Conclusion

There are several alternatives to traditional boning materials that can be used in corsets for support and shaping. These alternatives include lightweight boning options such as featherweight and cord or reed, as well as softer and more flexible materials like foam interfacing or fusible foam, elastic or stretchy materials, and fabrics with more body or drape.

Each of these options has its own pros and cons in terms of support, comfort, and ease of use, and the best choice will depend on your personal preferences and the level of support you need. It’s important to consider these factors and experiment with different materials to find the right option for your corset.

Overall, it’s important to remember that corsets can be made in a variety of styles and with a range of materials, and there is no one-size-fits-all solution. By exploring the different options available, you can find the best combination of support, comfort, and style for your needs. So, it is always better to experiment with different materials and techniques to find the right balance for your needs.

Leave a Reply