Embarking on a sewing journey opens a world of creativity and craftsmanship, but choosing the right tools is key to success. One pivotal feature often considered is foot pressure adjustment on a sewing machine.

This crucial mechanism allows control over the pressure the presser foot applies onto the fabric, influencing stitch quality and fabric handling.

In this exploration, we explore the question: “Do I Need a Sewing Machine With Foot Pressure Adjustment?”

Understanding the significance of this feature can empower sewers to tailor their machines to diverse fabrics, intricate projects, and varied techniques, ensuring a seamless and gratifying sewing experience.

Foot Pressure Adjustment on a Sewing Machine?

Foot pressure adjustment on a sewing machine refers to the ability to control the force applied by the presser foot on the fabric.

Typically controlled by a dial or lever, this feature allows sewers to customize pressure based on the fabric type.

Adequate pressure ensures smooth fabric feeding, preventing issues like puckering or slippage. It is crucial to achieve optimal stitch quality, especially when working with diverse fabrics or using different sewing techniques.

Foot pressure adjustment enhances versatility, providing a tailored sewing experience for various projects and materials.

Do I Need a Sewing Machine With Foot Pressure Adjustment? How Decided

Deciding whether you need a sewing machine with foot pressure adjustment hinges on your sewing goals and the diversity of your projects. Foot pressure adjustment is a feature that empowers you to control the pressure exerted by the presser foot on the fabric.

Here’s a breakdown to help you decide:

Fabric Variety

Foot pressure adjustment becomes crucial if you frequently work with diverse fabrics – from delicate silks to heavy denim. It ensures that your machine adapts to different materials, preventing issues like puckering or stretching.

Project Complexity

For intricate projects or varied sewing techniques, such as quilting or attaching zippers, foot pressure adjustment offers the precision needed for professional-looking results.

User Preference

If you appreciate customization and fine-tuning your sewing experience, having control over foot pressure can be satisfying.

Budget Considerations

While machines with foot pressure adjustment may be slightly more expensive, the investment can be justified if the feature aligns with your sewing needs.

Skill Level

Beginners may not initially require this feature, but as your skills progress and you tackle more diverse projects, foot pressure adjustment can become valuable.

How Does Foot Pressure Adjustment Work in Sewing Machines?

Foot pressure adjustment in sewing machines allows the user to control the pressure applied by the presser foot on the fabric being sewn.

Here’s a step-by-step explanation:

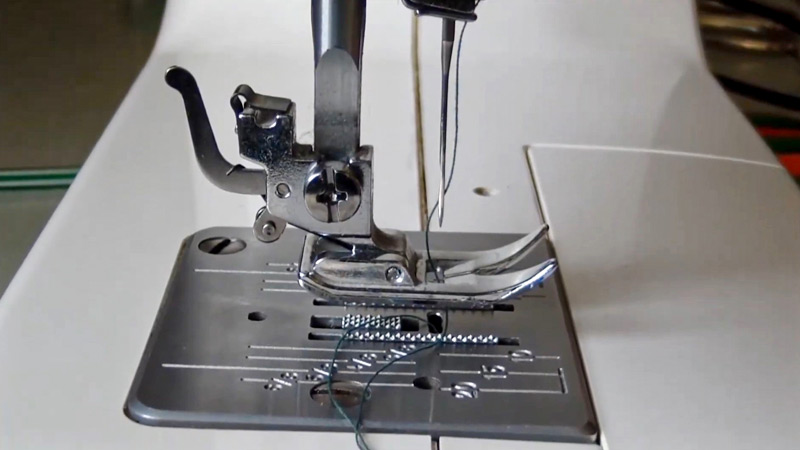

Presser Foot and Spring Mechanism

The presser foot is a component located beneath the needle of a sewing machine. Inside the machine is a spring mechanism connected to the presser foot.

Default Tension

The spring exerts a default tension on the presser foot, determining the force with which it holds the fabric in place. This tension is set to a general level that works well for various fabrics.

Adjustment Controls

Sewing machines with foot pressure adjustment have controls, typically in the form of dials, levers, or buttons. These controls allow users to modify the tension in the spring and, consequently, adjust the pressure the presser foot applies.

Customization for Fabrics

Different fabrics have varying thicknesses and characteristics. By adjusting the foot pressure, sewers can customize the machine’s settings to accommodate the specific requirements of the fabric they are working with.

Preventing Issues

Proper foot pressure is essential for preventing issues during the sewing process. If the pressure is too high, it may result in difficulties feeding the fabric or distortions in stitching. On the other hand, if the pressure is too low, the fabric might slip or fail to feed properly.

Adapting to Sewing Techniques

Foot pressure adjustment is particularly useful when employing various sewing techniques. It ensures the machine can adapt to different requirements, such as sewing curves, corners, or zippers.

Stitch Quality

The pressure applied by the presser foot directly affects stitch quality. Adjusting the foot pressure allows for optimal stitch formation, preventing issues like loose or tight stitches.

Versatility

This feature provides versatility, making the sewing machine adaptable to various fabrics and sewing projects. It is especially beneficial for those working with diverse materials and using various sewing techniques.

Adjust Foot Pressure According to Fabric Type and Thickness

Adjusting foot pressure on a sewing machine according to fabric type and thickness is essential for achieving optimal stitching results.

Here’s a step-by-step guide:

Refer to Your Sewing Machine’s Manual

Consult your sewing machine manual to understand the specific foot pressure adjustment controls and their location on your machine.

Identify Fabric Type and Thickness

Determine the type and thickness of the fabric you are working with. Fabrics can range from lightweight and delicate to heavy and thick.

Default Foot Pressure Setting

Start with the default or medium foot pressure setting on your sewing machine. This is often a good baseline for many fabrics.

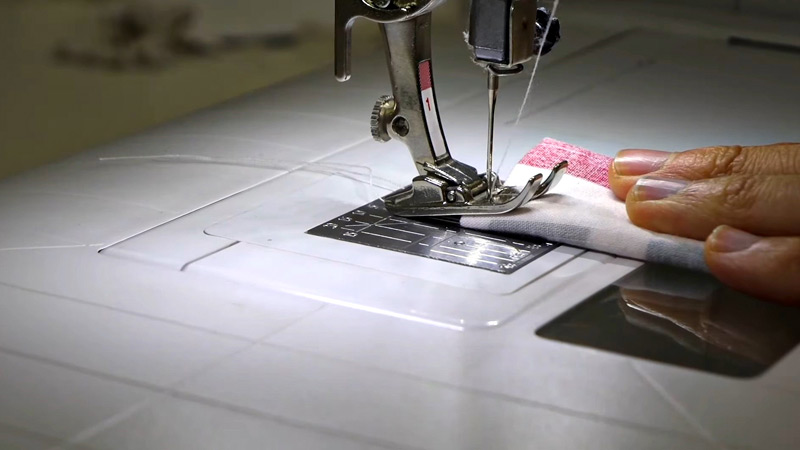

Sew a Test Seam

Cut a small piece of the fabric you’ll be using in your project or use a scrap piece of a similar type and thickness. Sew a test seam using the default foot pressure setting.

Evaluate Stitch Quality

Examine the test seam for stitch quality. Check for issues such as puckering, stretching, or uneven stitches. If the results are satisfactory, your default setting may be suitable.

Make Adjustments

If the stitches are too tight or puckered, reduce the foot pressure. If the stitches are loose, increase the foot pressure. Make small adjustments and sew additional test seams until you achieve the desired stitch quality.

Consider Fabric Behavior

Keep in mind the behavior of the specific fabric. Thicker fabrics may require less pressure to prevent jamming, while delicate fabrics may need more pressure to prevent slipping.

Test with Different Fabrics

Repeat the process for other fabrics you plan to use. Adjust the foot pressure settings accordingly, as each fabric may require a slightly different setting.

Take Notes

Note down the foot pressure settings that work best for each fabric type and thickness. This reference will be helpful for future projects.

Regularly Test and Adjust

Fabric behavior can vary even within the same type. Regularly test and adjust the foot pressure settings based on the specific characteristics of each fabric you work with.

Can You Use a Sewing Machine Without a Pressure Foot?

Yes, you can use a sewing machine without a presser foot, but it’s not generally recommended. The presser foot plays a crucial role in stabilizing the fabric as it passes through the machine, helping to control fabric feeding, maintain stitch consistency, and prevent the fabric from puckering or shifting.

If you decide to sew without a presser foot, you must be extra careful to guide the fabric smoothly and consistently.

This might be necessary in some specific situations, such as when sewing a very thick material that doesn’t fit under the presser foot or when doing free-motion quilting, where you move the fabric freely in any direction.

However, it’s best to use the appropriate presser foot for most sewing tasks for the fabric type and sewing technique. They are available online and in sewing supply stores if you’re missing a presser foot or need a special type.

FAQs

Do all sewing machines come with foot pressure adjustment?

No, foot pressure adjustment is not a universal feature. It is often found in more advanced or specialized sewing machines.

How does foot pressure adjustment benefit different fabric types?

Foot pressure adjustment allows sewers to customize the machine for different fabric thicknesses, preventing difficulties in sewing and ensuring smooth fabric feeding.

Can foot pressure adjustment improve stitch quality?

Yes, proper foot pressure contributes to achieving high-quality stitches by preventing issues like tight or loose stitching.

Is foot pressure adjustment essential for beginners?

While not essential for beginners, foot pressure adjustment becomes more valuable as sewers advance and work with diverse fabrics.

Is foot pressure adjustment necessary for specific projects?

Foot pressure adjustment is particularly useful for intricate projects, diverse fabric types, and various sewing techniques, offering adaptability and precision.

To Recap

Investing in a sewing machine with foot pressure adjustment hinges on the individual’s sewing aspirations and project diversity.

This feature, offering control over the presser foot’s force, proves indispensable for achieving superior stitch quality, adapting to different fabrics, and mastering intricate sewing techniques.

While beginners may initially find it less essential, advancing sewers and those engaging in diverse projects benefit significantly from this customization. Ultimately, the choice depends on the desire for precision, versatility, and a tailored sewing experience.

Whether crafting delicate garments or tackling robust materials, a sewing machine with foot pressure adjustment is a valuable ally in mastering sewing. Happy stitching!

Leave a Reply