The sewing machine walking foot, a crucial accessory for achieving even fabric feed, may face wear and tear over time due to various factors.

Constant friction with fabrics, especially heavy or abrasive ones, contributes to gradual wear on the foot’s components.

The quality of materials used in the walking foot, its frequency of use, and the type of fabrics sewn all play roles in its longevity. Regular maintenance, including cleaning and lubrication, can extend its lifespan.

Understanding the factors influencing wear is essential for sewers, prompting timely replacement when necessary to ensure optimal sewing performance and the longevity of this indispensable sewing machine component.

What Is a Walking Foot in a Sewing Machine?

A walking foot, or even-feed foot, is a sewing machine attachment designed to feed multiple layers of fabric evenly through the machine.

It has built-in feed dogs on the foot that work in conjunction with the machine’s feed dogs, preventing fabrics from shifting or stretching during sewing.

This specialized foot is particularly useful when working with thick, slippery, or delicate fabrics, ensuring uniform stitching and preventing issues like uneven seams or puckering.

The walking foot is essential for quilters, garment sewers, and anyone dealing with complex fabric layers, contributing to smoother and more precise sewing results.

Do Sewing Machine Walking Feet Wear Out?

Yes, sewing machine walking feet can wear out over time, especially with regular use. The walking foot, also known as an even-feed foot, is a crucial component of a sewing machine, particularly when working with multiple layers of fabric or slippery materials.

It ensures that the layers move together smoothly, preventing issues such as fabric bunching or shifting.

Several factors contribute to the wear and tear of sewing machine walking feet:

Friction

The constant movement of the walking foot against fabrics leads to friction, causing gradual wear on its components.

This is particularly noticeable when working with heavier fabrics or materials that strain the foot more.

Over time, this friction can decrease the walking foot’s effectiveness, leading to issues like uneven fabric feeding and an overall decline in sewing performance.

Material Quality

The longevity of a walking foot is significantly influenced by the quality of its construction materials.

High-quality, durable materials like metal tend to outlast their cheaper counterparts. Metal walking feet, in particular, are known for their robustness and ability to withstand the rigors of regular use.

Investing in a sewing machine with a well-constructed walking foot can pay off in terms of reduced maintenance and fewer replacements over the machine’s lifespan.

Frequency of Use

The more frequently a sewing machine is used, the more its components, including the walking foot, may wear out faster. Engaging in heavy-duty projects or prolonged sewing sessions can accelerate this process.

Sewers who frequently use their machines should be vigilant about monitoring the condition of their walking foot, as more frequent replacements may be necessary to ensure optimal performance.

Maintenance

Proper maintenance is essential to extend the life of a walking foot. Regular cleaning and lubrication of the sewing machine, especially its walking foot mechanism, can help reduce friction and prevent premature wear.

Cleaning out accumulated lint and debris and applying recommended lubricants will contribute to smooth operation, ensuring that the walking foot remains in good working condition over time.

Type of Fabric

The fabric choice can impact the wear and tear of the walking foot. Working with abrasive fabrics like denim or canvas can contribute to quicker deterioration.

The coarse texture of these materials can increase friction, placing additional stress on the walking foot.

Sewers dealing with such fabrics should take extra care in cleaning and maintaining their walking foot regularly and may need to consider more frequent replacements to preserve their sewing machine’s overall functionality.

How to Use a Walking Foot on a Sewing Machine?

Using a walking foot on a sewing machine is valuable, especially when working with multiple layers of fabric or slippery materials.

The walking foot, also known as an even-feed foot, helps to feed the top layer of fabric through the machine at the same rate as the bottom layer, preventing uneven stitches and fabric distortion.

Here’s a step-by-step guide on how to use a walking foot effectively:

Selecting the Walking Foot

Choosing the right walking foot is the first step in ensuring successful sewing. Sewing machine manufacturers often produce walking feet that are specifically designed for their models.

It’s important to check your machine’s manual or contact the manufacturer to identify the correct walking foot for your particular sewing machine.

Using an incompatible walking foot may result in poor performance or potential damage to your machine.

Install the Walking Foot

Installing the walking foot correctly is crucial for its optimal function. Start by turning off your sewing machine and unplugging it for safety. Most walking feet attach in a similar way – by replacing the standard presser foot.

Loosen the screw or clip holding the regular foot and then align the fork of the walking foot over the needle clamp. Lower it into place and secure it tightly with the screw or clip, ensuring a snug fit.

Engage the Feed Dogs

The walking foot works in tandem with the feed dogs, those toothed mechanisms beneath the needle plate that move the fabric through the machine.

Before starting your project, make sure the feed dogs are engaged. If your machine has a switch to lower or raise the feed dogs, ensure they are in the up or engaged position to facilitate the even feeding of fabric layers.

Thread the Machine

Threading your machine correctly is essential for any sewing project, and using a walking foot is no exception.

Follow the threading guide provided by your machine’s manual, ensuring that the thread passes through the walking foot as specified. Proper threading helps prevent thread snags and ensures smooth stitching.

Adjust the Presser Foot Pressure

Some sewing machines offer the option to adjust the presser foot pressure. This adjustment can be particularly useful when working with different fabric thicknesses.

Consult your machine’s manual to understand how to modify the presser foot pressure and make any necessary adjustments based on the fabric you’re using.

Select the Right Stitch

Walking feet can accommodate various stitches, including straight stitches and zigzag stitches. Depending on your project, select the appropriate stitch on your sewing machine.

Adjust the stitch length and width as needed, considering the type of fabric and the specific requirements of your sewing task.

Position the Fabric

Before starting to sew, position the fabric layers under the walking foot. Align the edges that need to be sewn and ensure the layers are flat and evenly placed. Proper alignment at this stage helps prevent fabric distortion and ensures a neat, even seam.

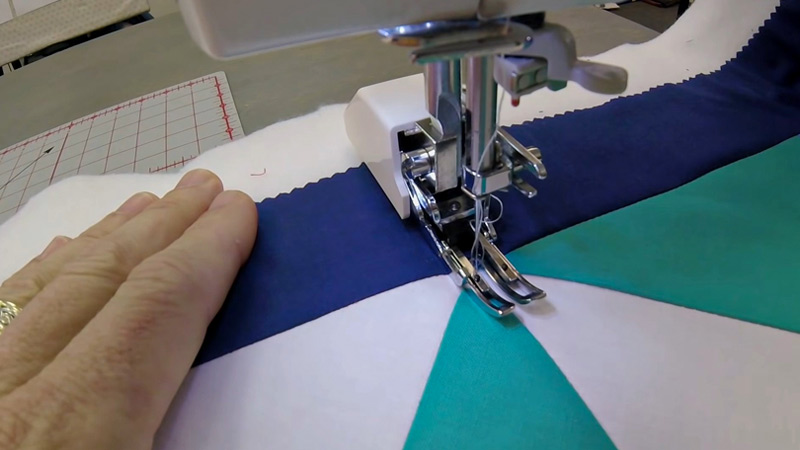

Sewing

Once everything is set up, begin sewing at a slow to moderate speed. Allow the walking foot to feed the fabric layers evenly.

While you guide the fabric through, avoid pulling or pushing excessively, as the walking foot is designed to handle the movement. A steady and controlled pace will yield the best results.

Backstitch and Finish

Use the backstitch function to secure the stitches at the beginning and end of your seam. This is especially important for creating durable and stable seams. After completing the sewing, trim any excess threads and inspect the seam for consistency.

Practice

If you’re new to using a walking foot, take the time to practice on scrap fabric before starting your actual project.

This allows you to familiarize yourself with the feel and operation of the walking foot, ensuring that you are comfortable with its use and can anticipate how it will behave with different fabrics.

Can You Backstitch With a Walking Foot?

Yes, you can backstitch with a walking foot, and it is generally recommended for creating secure and durable seams.

Backstitching is a common technique used at the beginning and end of a seam to lock the stitches in place, preventing them from unraveling over time.

This is crucial, especially in areas of high stress on the fabric, such as seams in garments or quilting projects.

Here’s how you can backstitch with a walking foot:

Position the Fabric

Begin by ensuring that your walking foot is securely attached to your sewing machine. Place your fabric under the walking foot, aligning it with the starting point of your intended seam.

Take a moment to double-check the fabric’s alignment to prevent any issues during sewing. This initial step is crucial for a smooth and precise sewing process.

Lower the Needle

Once the fabric is in position, lower the needle into the fabric at the starting point of your seam. This action helps to anchor the thread and prepares the machine for the backstitching process.

Engage the Reverse Stitch Function

Locate and engage the reverse stitch function on your sewing machine. This is typically done by holding down a button or flipping a lever specifically designed for reverse sewing.

Refer to your sewing machine’s manual to familiarize yourself with the location and operation of this feature.

Begin Backstitching

With the reverse stitch function engaged, gently press the foot pedal to sew backward over the initial stitches.

Backstitching reinforces the beginning of the seam, securing the stitches and preventing them from unraveling.

Be mindful not to overdo the backward stitches; a few stitches are usually sufficient for this purpose.

Release the Reverse Stitch Control

After backstitching for a short distance, release the reverse stitch control. This step is crucial for transitioning seamlessly into the forward sewing motion.

Releasing the control prevents unintended loops or knots from forming as you move forward.

Sew the Main Seam

Guide the fabric under the walking foot and sew the main part of your seam. The walking foot ensures even feeding of the fabric layers, minimizing the risk of puckering or misalignment. Maintain a steady pace and control as you guide the fabric through the machine.

Backstitch at the End

As you approach the end of your seam, engage the reverse stitch function once again. Sew backward for a short distance to the backstitch at the end of the seam.

This secures the stitches at the seam’s conclusion, providing stability and preventing unraveling.

Release the Reverse Stitch Control Again

After completing the backstitching at the end of the seam, release the reverse stitch control and lift the needle out of the fabric. This prepares the machine for the next step and ensures a clean finish to your sewing.

Trim Excess Threads

To complete the sewing process, trim any excess threads at both the beginning and end of the seam using scissors or thread snips.

This final step contributes to the neatness and professionalism of your sewing project while eliminating any unnecessary loose threads.

FAQs

Do all sewing machine walking feet wear out?

Yes, over time, most sewing machines’ walking feet will experience wear and tear due to factors such as friction, fabric types, and frequency of use.

How can I tell if my walking foot is wearing out?

Signs of wear include uneven fabric feeding, increased noise during sewing, or visible damage like cracks.

Regular inspection and attention to changes in performance can help identify wear.

Can I prevent my walking foot from wearing out quickly?

Regular maintenance, including cleaning and lubrication, can extend the life of your walking foot. Choosing the right foot for your fabric and sewing needs also helps minimize wear.

To Recap

The wear and tear of sewing machines’ walking feet are natural outcomes of their vital role in ensuring smooth fabric feed.

Factors like friction, material quality, usage frequency, and fabric types collectively contribute to their eventual deterioration.

Proactive maintenance measures, such as regular cleaning and lubrication, can mitigate premature wear, extending the life of the walking foot.

Recognizing signs of wear and promptly replacing the foot when needed ensures consistent sewing quality.

As sewers embrace the indispensable role of the walking foot, a balance of careful use, routine maintenance, and timely replacements becomes the key to preserving the longevity and effectiveness of this essential sewing machine component.

Leave a Reply