In the intricate world of sewing machines, the seamless dance of fabric and thread is orchestrated by ingenious mechanisms.

Components like the cam and follower are at the heart of this mechanical symphony. Sewing machines utilize a cam and follower system to bring precision and versatility to stitching patterns.

Cams, with their uniquely shaped lobes, direct the movement of a follower, a crucial intermediary.

This follower, whether in the form of a lever or arm, faithfully translates the cam’s contours into specific actions, guiding the needle and determining stitch styles.

Understanding the symbiotic relationship between the cam and follower unveils the artistry and functionality of the modern sewing machine.

What Is a Cam in a Sewing Machine?

A cam in a sewing machine is a mechanical device that controls the movement of the needle and, consequently, the stitching pattern.

Cams are typically interchangeable disks or lobes, each designed with a specific pattern, such as zigzag or decorative stitches.

When engaged, the cam guides the sewing machine’s internal mechanisms to produce the desired stitch.

This allows for versatile and creative sewing options without the need for complex electronic controls.

Cams have been widely used in older sewing machines, providing users with various stitching possibilities and contributing to the machine’s adaptability for various sewing projects.

What Is a Follower in a Sewing Machine?

A follower in a sewing machine is a component that interacts with the cam to translate its irregular or non-uniform shape into a smooth and controlled movement.

Typically, followers are small, rounded discs or pins that trace the contours of the cam’s profile. As the cam rotates, the follower follows its intricate pattern, transmitting the motion to other parts of the sewing machine.

This synchronized movement is crucial for regulating the needle and creating diverse stitch patterns.

The follower ensures precision in stitch formation by converting the cam’s irregular motion into a consistent and predictable motion for the sewing machine’s mechanical components.

Do Sewing Machines Use a Cam and Follower?

Yes, sewing machines often use cam and follower mechanisms to control and diversify stitch patterns.

The cam, a shaped rotating disk, determines the specific stitching pattern. Meanwhile, the follower, a component that tracks the cam’s contours, translates the irregular motion of the cam into a smooth and controlled movement.

This synchronized motion influences the needle and other sewing machine parts, enabling the creation of various stitches.

Cams and followers add versatility to sewing machines, allowing users to easily switch between different stitch styles without needing complex electronic controls.

This mechanical system has been a fundamental feature in many traditional sewing machines, contributing to their adaptability and functionality in accommodating a wide range of sewing tasks.

How Does Cam Work in a Sewing Machine?

A cam in a sewing machine plays a crucial role in controlling the movement of various components, guiding the needle, and determining the stitching pattern.

Cams are mechanical devices with irregularly shaped lobes or projections that transform rotational motion into a specific movement pattern.

In sewing machines, cams are often found in the cam stack, which is a set of interchangeable discs or attachments.

Here’s a breakdown of how cams work in a sewing machine:

Location

Cams are intricately positioned within the cam stack, a critical component situated beneath the sewing machine’s top cover.

The cam stack’s strategic location ensures precise control over stitch formation and facilitates easy accessibility for the seamless interchangeability of cams.

Function

The fundamental role of cams in a sewing machine is to govern the intricate movements of the needle bar and other essential components.

As the sewing machine springs into action, the main drive shaft executes a pivotal function by rotating, thereby transmitting power to the cam stack.

The irregular shapes of the cam lobes, thoughtfully designed, dictate the precise and coordinated motion of various machine parts, ensuring the creation of well-defined stitches.

Stitch Selection

Cams serve as the artisans of stitching patterns, offering many possibilities. From the simplicity of straight stitches to the intricacy of zigzag stitches, decorative stitches, and the precision of buttonhole stitches, different cams open up a world of creative sewing.

Sewing machines are ingeniously equipped with a set of interchangeable cams, allowing users to effortlessly transition between stitching styles, adding versatility to their sewing endeavors.

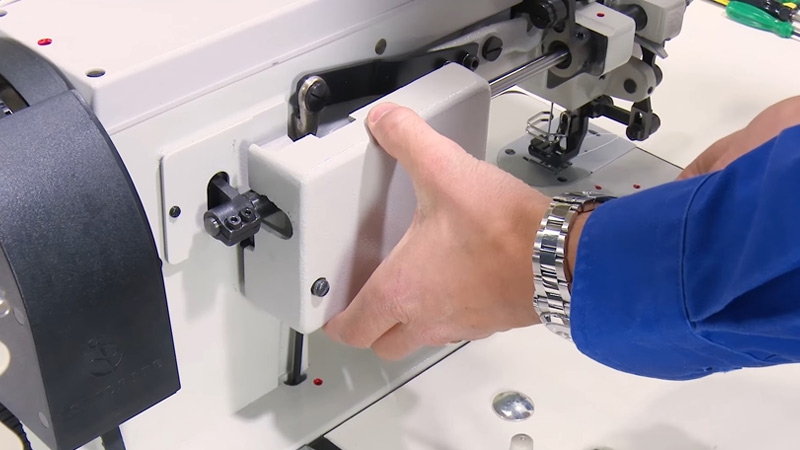

Cam Replacement

Empowering users with creative control, the ability to change cams based on the desired stitch pattern is a hallmark of sewing machine adaptability.

The process of cam replacement is a user-friendly task involving the opening of the top cover, accessing the cam stack, and the swift swapping of the current cam with the desired one.

This capability enhances the machine’s versatility, making it suitable for various sewing projects.

Pattern Adjustment

Modern sewing machines often boast a thoughtful feature a dial or lever allowing users to finely adjust the width or length of the stitch pattern created by the cam.

This sophisticated element significantly enhances the flexibility of the sewing machine, accommodating different fabric types and meeting the specific requirements of various sewing projects.

Maintenance

Regular maintenance is imperative to ensure the seamless operation and longevity of the sewing machine.

Being a pivotal part of the system, the cam stack requires diligent attention. Routine cleaning and proper lubrication of the cam stack and other moving parts contribute to the machine’s overall health, ensuring it performs optimally with each use.

Electronic Sewing Machines

In the realm of modern sewing technology, traditional mechanical cams yield electronic controls in some advanced machines.

Electronic sewing machines eliminate the need for physical cam changes. They offer an extensive repertoire of stitches pre-programmed into the system.

This electronic prowess provides users with an effortless and efficient means of achieving a diverse range of stitch patterns, symbolizing the synergy between technology and the artistry of sewing.

How Does Follower Work in a Sewing Machine?

A follower in a sewing machine is a key component that translates the movement of a cam into specific actions, guiding the needle and other essential parts to create diverse stitching patterns.

The follower is an integral part of the cam system, ensuring precise and synchronized movements during the sewing process.

Here’s a detailed look at how the follower functions in a sewing machine:

Location and Structure

Nestled within the intricate machinery of a sewing machine, the follower assumes its position as a diminutive yet pivotal component.

Strategically placed in close proximity to the cam, it often manifests as a delicately crafted lever or arm seamlessly connected to the needle bar or other moving elements.

The precision of its location and structure is essential to ensure synchronized movements during the sewing process.

Interaction with the Cam

The follower’s choreography commences as it engages with the cam’s intricate design—characterized by irregularly shaped lobes or projections.

A harmonious dance unfolds as the cam rotates, and the follower delicately traces the contours of these shapes.

The dynamic interplay is further nuanced by the varying heights and angles of the cam lobes, guiding the follower in graceful movements, be it a subtle ascent and descent or a graceful lateral shift, all dictated by the specific cam design.

Transmission of Motion

As the follower gracefully interprets the cam’s commands, its movements become the orchestrator of the sewing machine’s mechanical symphony.

The kinetic energy generated in response to the cam’s intricacies is then transmitted precisely to the needle bar or other critical machine components.

This seamless motion transmission becomes the driving force behind the creation of each meticulously crafted stitch.

Stitch Formation

The follower emerges as the artisan behind stitch formation, its nuanced movements responding to the distinctive shapes of different cams.

Whether executing a straightforward straight stitch or navigating the intricacies of a zigzag or decorative pattern, the follower’s adaptability ensures the faithful translation of the cam’s design into tangible stitches on the fabric.

Versatility and Stitch Variations

Sewing machines equipped with this mechanical ballet of cam and follower offer users a palette of creative possibilities.

Including interchangeable cams and their corresponding followers provides a dynamic range of stitch variations.

This inherent versatility empowers users to switch between stitching patterns effortlessly, seamlessly transitioning from one creative endeavor to the next.

Adjustment and Fine-Tuning

In the realm of sewing machine sophistication, some models offer users the ability to adjust the follower’s response to the cam finely.

Dials or levers integrated into the machine’s design empower users to customize parameters such as stitch length or width.

This meticulous adjustment capability adds an additional layer of precision to the sewing process, enabling users to tailor stitches according to the specific demands of their projects.

Maintenance

Amidst the ceaseless movements within the sewing machine, the follower demands a regimen of care and maintenance.

Regular lubrication and conscientious checks are essential to preserve the follower’s smooth and precise movements.

This attentive upkeep ensures the sewing machine’s immediate efficiency and contributes significantly to its longevity and sustained optimal performance.

FAQs

What is the role of a cam and follower in a sewing machine?

A cam and follower in a sewing machine work in tandem to translate the rotational motion of the main drive shaft into specific movements that guide the needle and other components.

How does the cam and follower system contribute to stitch formation?

The cam, with its irregularly shaped lobes, dictates the movements of the follower.

As the follower responds to these contours, its motions are transmitted to the needle bar, determining the stitching pattern produced during the sewing process.

Can I change the stitching pattern on my sewing machine?

Yes, many sewing machines come with interchangeable cams and followers.

Users can replace these components to achieve different stitching patterns, providing versatility for various sewing projects.

To Recap

The symbiotic relationship between cams and followers in sewing machines epitomizes the synergy of engineering precision and creative artistry.

These mechanical marvels, nestled within the heart of sewing machines, transform rotational motion into a choreography of stitches.

The interplay of cams dictating intricate patterns and followers dutifully translating these designs into motion unveils the versatility that defines modern sewing.

From straight stitches to elaborate embroidery, the cam and follower system empowers sewers with the means to manifest their creative visions.

As timeless as the art of sewing itself, this dynamic duo continues to stitch together the fabric of innovation, offering a seamless blend of technology and craftsmanship.

Leave a Reply