Sewing with spandex, the versatile and stretchy fabric beloved for its comfort and performance, presents a unique set of challenges.

To create resilient and professional-quality garments from spandex, many sewing enthusiasts wonder if a serger is truly necessary.

In this exploration, we delve into the indispensable role of a serger in sewing spandex. We’ll discover how this specialized machine addresses the fabric’s elasticity, seam strength, and finishing needs, while also contributing to the overall aesthetics of spandex creations.

Whether you’re a seasoned seamstress or a novice, understanding the significance of a serger in spandex sewing is essential for achieving superior results and garment longevity.

Do You Need a Serger to Sew Spandex?

Sewing with spandex can be a challenging endeavor, especially if you want to achieve professional-looking results.

Spandex, a stretchy and elastic fabric commonly used in sportswear, swimwear, dance costumes, and other form-fitting garments, requires specialized equipment and techniques to handle its unique properties.

One essential tool for sewing spandex is a serger, also known as an overlock machine.

Here’s why you need a serger to sew spandex effectively:

Seam Finishing

Spandex is a stretchy and delicate fabric that can easily fray along the edges. Sergers are designed to finish seams by trimming the excess fabric and encasing the raw edges with multiple threads.

This prevents fraying and ensures that your spandex garments remain durable and neat over time.

Stretchable Seams

Spandex is known for its exceptional elasticity, and traditional sewing machines may not provide the necessary stretchability in their seams.

Sergers use stretch or overlock stitches that are specifically designed to accommodate the stretchiness of spandex fabric.

This ensures that your finished garments retain their flexibility and shape even when stretched.

Neat and Professional Look

Sergers create a clean and professional finish that is particularly important when working with spandex, as it is often used in activewear, dancewear, and swimwear.

The neatness of serged seams enhances the overall aesthetic appeal of your projects, giving them a polished and high-quality appearance.

Reduced Bulk

Spandex is a thin and lightweight fabric, and using traditional sewing methods with multiple seam allowances can create unnecessary bulk in your seams.

Sergers trim the excess fabric while creating the seam, resulting in flatter and smoother seams that are comfortable to wear and reduce the risk of chafing.

Faster Production

Sergers are known for their speed and efficiency. They can quickly finish seams, trim excess fabric, and stitch simultaneously, making the sewing process faster and more streamlined.

This is especially beneficial when working on multiple spandex projects or when you’re aiming to produce items for sale.

Rolled Hems

Many sergers come with the capability to create rolled hems, which are perfect for finishing the edges of spandex garments, such as dance skirts or lingerie. Rolled hems provide a delicate, elegant edge that adds a professional touch to your creations.

Versatility

While sergers are essential for working with spandex, they are also versatile machines that can handle a wide range of fabrics and sewing tasks.

This means you can use your serger for various projects beyond just spandex, making it a valuable addition to your sewing arsenal.

Is a Serger Worth It?

Yes, a serger is worth it and the worth of a serger in your sewing toolkit depends on your sewing projects, goals, and preferences.

Here are some factors to consider when deciding if a serger is worth it for you:

Types of Projects

Sergers excel at certain types of projects, such as sewing stretchy fabrics like spandex, creating finished seams, and producing professional-looking results. If your sewing primarily involves these kinds of projects, a serger can be highly valuable.

Efficiency

Sergers are known for their speed and efficiency in sewing and finishing seams. If you frequently work on large or time-sensitive projects, a serger can save you a significant amount of time compared to using a conventional sewing machine for seam finishing.

Seam Quality

Sergers produce strong, stretchable, and neatly finished seams. If you prioritize seam durability and a polished appearance, a serger is an excellent investment.

Versatility

Some sergers offer a wide range of stitch options, including rolled hems, flatlock stitches, and differential feed mechanisms.

If you enjoy experimenting with different stitch types and techniques, a serger can enhance your creative capabilities.

Comfort and Aesthetics

Serged seams are comfortable against the skin and look professional, which is especially important for garments like activewear, lingerie, and swimwear. If comfort and aesthetics are priorities for your projects, a serger is worth considering.

Budget

Sergers can vary widely in price, and some can be quite expensive. Consider your budget and how often you’ll use the serger before making a purchase. If you use it frequently for projects that benefit from its features, it may be worth the investment.

Experience Level

If you’re a beginner, a serger can be intimidating due to its multiple threads and settings. However, as you gain experience, you’ll likely find it more valuable.

How to Sew Spandex?

Sewing with spandex, a stretchy and elastic fabric commonly used in sportswear, swimwear, dance costumes, and more, requires some specific techniques to achieve professional results.

Here’s a step-by-step guide on how to sew spandex:

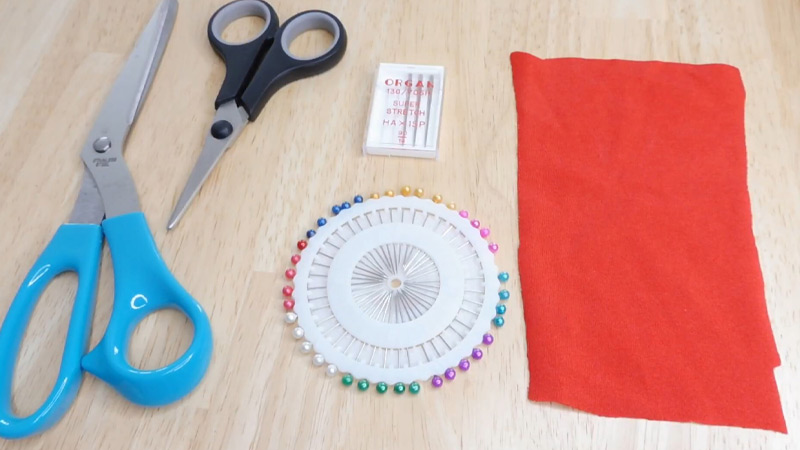

Materials and Tools You’ll Need:

- Spandex fabric

- Ballpoint or stretch needle (size 75/11 or 80/12)

- Polyester or nylon thread

- Scissors or rotary cutter

- Pins or clips (use ballpoint pins if possible)

- Sewing machine with a zigzag stitch or a serger

- Walking foot attachment (optional but helpful)

Steps:

Step 1: Prepare Your Materials

Start by gathering the materials you’ll need, including spandex fabric, a ballpoint or stretch needle, polyester or nylon thread, scissors or a rotary cutter, pins or clips, and a sewing machine with a zigzag stitch or a serger.

Step 2: Pre-wash and Cut the Fabric

Pre-wash and dry your spandex fabric to pre-shrink it if necessary. Lay out the fabric and pattern pieces, ensuring that you cut with the grain or the direction of the greatest stretch.

Step 3: Needle and Thread Selection

Use a ballpoint or stretch needle in your sewing machine to prevent skipped stitches and fabric damage. Thread your machine with polyester or nylon thread, which has some stretch and won’t break easily.

Step 4: Set Up Your Machine

Configure your sewing machine to a narrow zigzag stitch, a stretch stitch, or a narrow overlock stitch if you have a serger. Adjust the stitch length and width to suit your project, with a shorter stitch length (2-2.5) being suitable for most spandex projects.

Step 5: Seam Allowance

Spandex garments typically require a narrow seam allowance of about 1/4 to 3/8 inch. This smaller allowance reduces bulk and allows the fabric to stretch naturally without resistance.

Step 6: Pin or Clip

Traditional straight pins can cause damage to spandex due to their sharp ends. Instead, use ballpoint pins or clips to secure your fabric layers together. These tools hold the fabric in place without snagging or tearing it.

Step 7: Sewing Seams

Begin sewing your seams, ensuring that you maintain an even seam allowance. Gently stretch the fabric as you sew to prevent puckering when it’s stretched later. Backstitch at the start and end of each seam to secure the stitches.

If you’re using a sewing machine, gently pull the fabric from the front and back as you sew to prevent it from becoming stretched out or wavy.

Step 8: Finishing Seams

If using a conventional sewing machine, trim the seam allowances with pinking shears or a rotary cutter to reduce bulk.

Then, employ a zigzag stitch to finish the edges. If you have a serger, use it to sew and finish seams simultaneously, creating a neat and stretchy edge.

Step 9: Hemming

For hems on spandex garments, use a zigzag or twin needle on your sewing machine. These stitches provide a stretchy, professional finish.

Alternatively, if you have a coverstitch machine, it’s ideal for creating secure and aesthetically pleasing hems on spandex.

Step 10: Try It On and Final Touches

Once you’ve completed the sewing and finishing steps, try on your spandex garment to check the fit and make any necessary adjustments. Trim any loose threads, and your spandex project is ready to be worn and enjoyed!

Sewing Lycra Without a Serger

Sewing Lycra without a serger is entirely possible and can yield excellent results. Lycra is a stretchy and elastic fabric commonly used in sportswear, swimwear, dancewear, and other activewear.

Here’s a step-by-step guide on how to sew Lycra without a serger:

Materials and Tools You’ll Need:

- Lycra fabric

- Ballpoint or stretch needle (size 75/11 or 80/12)

- Polyester or nylon thread

- Scissors or rotary cutter

- Pins or clips (preferably ballpoint pins)

- Sewing machine with zigzag and straight stitch capabilities

- Walking foot attachment

Steps:

Step 1: Prepare Your Materials

Start by gathering all the necessary materials for your project. This includes your Lycra fabric, a ballpoint or stretch needle for your sewing machine, polyester or nylon thread, scissors or a rotary cutter for cutting the fabric, and pins or clips to hold the fabric together during sewing.

Step 2: Pre-wash and Cut the Fabric

Wash and dry your Lycra fabric before starting to pre-shrink it if necessary. Lay out the fabric and pattern pieces, ensuring that you cut with the grain or in the direction of the greatest stretch. Proper cutting is essential to ensure that your garment stretches properly.

Step 3: Needle and Thread Selection

Choose a ballpoint or stretch needle for your sewing machine. These needles are designed to work well with stretch fabrics like Lycra, preventing skipped stitches and fabric damage.

Thread your sewing machine with polyester or nylon thread as they are stretch-friendly and won’t break easily.

Step 4: Set Up Your Machine

Configure your sewing machine to the appropriate settings for sewing Lycra. You’ll primarily be using a narrow zigzag stitch, which works well with stretch fabrics.

Additionally, you’ll need a straight stitch for certain parts of your project. Adjust the stitch length and width as needed, with a shorter length (around 2-2.5) being suitable for most Lycra projects.

Step 5: Seam Allowance

For Lycra garments, use a 1/4 to 3/8-inch seam allowance. This narrow seam allowance reduces bulk and allows the fabric to stretch naturally without resistance.

Step 6: Pin or Clip

Secure your fabric layers together using ballpoint pins or clips instead of traditional straight pins. Ballpoint pins are gentler on the fabric and prevent damage.

Step 7: Sewing Seams

Start sewing your seams with a straight stitch, remembering to backstitch at the beginning and end of each seam to secure the stitches.

Gently stretch the fabric as needed while sewing to prevent puckering when it’s stretched later. Ensure you maintain an even seam allowance throughout.

Step 8: Finishing Seams

After sewing your seams with a straight stitch, trim the seam allowances using pinking shears or a rotary cutter to reduce bulk.

To prevent fraying and create a neat, stretchy edge, switch to a zigzag stitch and sew along the trimmed seam allowances.

Step 9: Hemming

Create hems on your Lycra garment using either a zigzag stitch or a twin needle on your sewing machine.

These stitches provide stretch and a professional finish. Alternatively, if you have access to a cover stitch machine, it’s ideal for creating secure and attractive hems on Lycra.

Step 10: Try It On and Final Touches

After completing the sewing and finishing steps, try on your Lycra garment to check the fit and make any necessary adjustments. Trim any loose threads, and your Lycra project is ready to be worn and enjoyed!

FAQS

Can I sew spandex with a regular sewing machine if I don’t have a serger?

Yes, you can sew spandex with a regular sewing machine.

What type of thread is best for sewing spandex on a regular sewing machine?

It’s recommended to use polyester or nylon thread when sewing spandex on a regular sewing machine.

Are there any tips for preventing fabric distortion when sewing spandex on a regular machine?

To prevent fabric distortion, use a walking foot attachment if available.

Additionally, avoid excessive pulling or stretching of the fabric while sewing, as this can cause distortion. Gently guide the fabric through the machine.

Can I use a twin needle on a regular sewing machine to hem spandex?

Yes, a twin needle can create a professional-looking hem on spandex with a regular sewing machine.

What are some common mistakes to avoid when sewing spandex without a serger?

Common mistakes include using the wrong needle (not a ballpoint or stretch needle), inadequate thread tension, and failing to use the correct stitch settings.

Ensure your machine is set up correctly and practice on scrap fabric to avoid these issues.

To Recap

While a serger can undoubtedly enhance the sewing experience when working with spandex, it is not an absolute necessity. Sewing spandex without a serger is entirely possible with the right techniques, materials, and attention to detail.

By using a regular sewing machine with a ballpoint needle, appropriate thread, and proper stitch settings, you can achieve secure, stretchable, and professional-looking seams.

The key lies in patience and practice, as mastering the art of sewing spandex on a regular machine may take some time.

Whether you’re a seasoned seamstress or a beginner, the choice to invest in a serger ultimately depends on your specific needs, budget, and desire for added convenience and efficiency.

Leave a Reply