Cashmere, renowned for its luxurious softness and exceptional warmth, is a fabric of unmatched elegance.

However, it harbors a delicate secret: it tends to fray when cut. The fineness of cashmere fibers, derived from the soft undercoat of cashmere goats, renders them vulnerable to damage when subjected to cutting forces.

This intriguing characteristic of cashmere, combined with its loose weave or knit, demands careful handling and specific techniques to prevent excessive fraying.

In this exploration, we delve into the behavior of cashmere when cut, shedding light on why it frays and how one can manage and minimize this delicate yet captivating fabric’s fraying tendencies.

What Is Cashmere Fiber?

Cashmere fiber is a prized natural textile derived from the soft undercoat of cashmere goats. Renowned for its exceptional softness and insulation properties, it is one of the world’s finest and most luxurious natural fibers.

Cashmere fibers are wonderful, often measuring less than 19 microns in diameter.

This fineness, combined with their length, contributes to the fabric’s sumptuous feel and warmth. Originating primarily from regions like Kashmir, Mongolia, and China, these fibers undergo a meticulous harvesting process.

The goats are combed during the molting season, yielding the valuable undercoat. Due to its rarity and exquisite qualities, cashmere is highly sought after for crafting premium quality garments, accessories, and textiles.

Does Cashmere Fray When Cut?

Yes, cashmere does fray when cut. This characteristic results from the unique properties of cashmere fibers and their delicate nature.

Let’s explore the behavior of cashmere when cut and the observations on fraying, as well as potential consequences.

Delicate Fibers

Cashmere is derived from the soft undercoat of cashmere goats. These fibers are wonderful, often measuring less than 19 microns in diameter.

While this fineness contributes to cashmere’s luxurious feel and warmth, it also makes the fibers more susceptible to damage when cut.

Natural Fraying Tendency

Cashmere fibers naturally tend to separate and fray when exposed to mechanical stress. Cutting cashmere with scissors or another sharp tool severs these fine fibers along the cut edge.

Loose Structure

Cashmere typically lacks such protective structures, Unlike some fabrics with tightly woven or synthetic edges that prevent fraying. This loose weave or knit allows individual fibers to be dislodged and frayed easily.

Observations on Fraying

When you cut cashmere, you’ll likely observe the following:

- Visible Frayed Edges: The cut edges of cashmere will often display visible fraying. You may notice loose or unraveled fibers along the cut line.

- Potential for Unraveling: In some cases, the fraying can lead to the unraveling of the fabric, causing holes or gaps along the cut edge.

Potential Consequences

The fraying of cashmere, when cut, can have several consequences:

- Reduced Aesthetic Appeal: Frayed edges can detract from the overall appearance of cashmere garments or projects, making them look less polished and well-finished.

- Weakened Integrity: The fraying weakens the fabric along the cut edge, making it more vulnerable to further damage or tearing. This can compromise the durability of cashmere items.

- Difficulty in Handling: Frayed edges can make cashmere more challenging for sewing or crafting projects. You may need to take extra steps to address fraying, such as finishing the edges.

Factors Influencing Cashmere Fraying

Cashmere, known for its luxurious softness and warmth, is a highly prized fabric. However, it has a unique challenge: it tends to fray when cut.

The fraying of cashmere is influenced by several factors, which can affect the fabric’s appearance and durability.

Several factors influence the fraying of cashmere fabric when cut. These include:

Fiber Fineness

Cashmere fibers are renowned for their exceptional fineness, often measuring less than 19 microns in diameter. This remarkable thinness contributes to the fabric’s unmatched softness and insulation properties.

However, it also renders the fibers fragile and prone to fraying. The delicate nature of cashmere fibers means they are more likely to separate when subjected to cutting forces, resulting in visible fraying along the cut edges.

Loose Weave or Knit

Cashmere fabric is characterized by its loose weave or knit, a design feature that enhances its breathability and comfort. However, this structural choice leaves the fabric vulnerable to fraying.

Unlike tightly woven materials that can hold fibers in place, the loose structure of cashmere allows individual strands to pull apart easily.

This susceptibility to fraying necessitates careful handling and finishing techniques when working with cashmere.

Cutting Tools

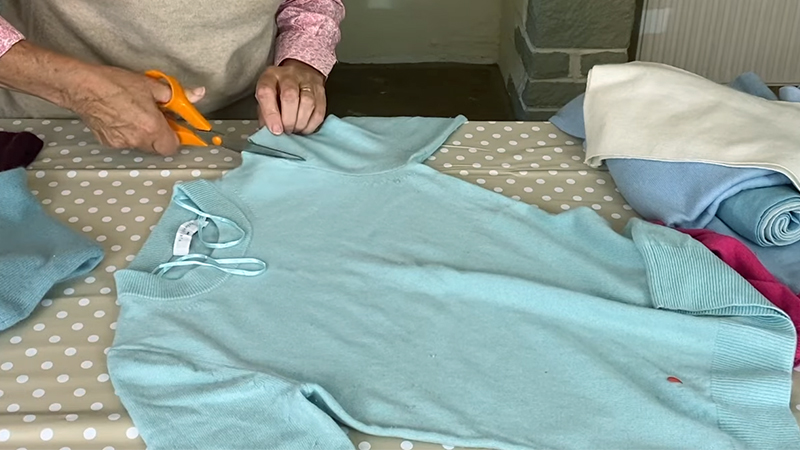

The choice of cutting tools is crucial in managing cashmere fraying. Sharp, high-quality scissors are essential to achieve clean cuts with minimal damage to the fibers.

Dull or improper scissors can cause more fiber disruption, leading to increased fraying. Additionally, a rotary cutter with a sharp blade can provide a cleaner cut than conventional scissors, reducing the likelihood of fraying.

Handling and Tension

How cashmere is handled during cutting and sewing significantly influences fraying. Excessive tension, pulling, or rough handling can exacerbate the fraying process.

It’s imperative to handle cashmere with care, applying gentle and controlled pressure to minimize stress on the delicate fibers. By adopting a cautious approach, individuals can mitigate the risk of excessive fraying.

Edge Finishing Techniques

Employing appropriate edge-finishing techniques is a critical step in reducing fraying. Techniques like serging, overcasting, or fabric glue provide a protective barrier along the cut edges.

These methods secure the fibers in place, preventing further unraveling and maintaining the integrity of the fabric.

Proper edge finishing is essential in sewing projects involving cashmere to ensure a professional and durable outcome.

Fabric Thickness

The thickness of cashmere fabric can impact its fraying tendencies. Thicker cashmere fabrics may be less susceptible to fraying compared to thinner ones.

A thicker fabric offers more resistance to fiber separation, providing a degree of natural protection against fraying. Extra care should be taken to minimize fraying when working with thinner cashmere fabrics.

Fabric Blends

Cashmere is sometimes blended with fibers such as silk or wool to create unique textures or enhance specific properties. The presence of these additional fibers can influence the fabric’s fraying behavior.

For instance, silk blends may introduce a different level of smoothness, while wool blends could add resilience. Understanding how these blends interact with the cutting process is crucial in managing fraying effectively.

Minimizing Fraying During Cutting

Minimizing fraying during cutting is crucial when working with delicate fabrics like cashmere.

Here are some effective techniques and tips to help you achieve clean cuts with minimal fraying:

Use High-Quality, Sharp Scissors

Investing in a pair of high-quality, sharp-fabric scissors is paramount. Look for scissors designed for precision cutting with a fine, sharp blade.

Quality scissors will cut cleanly through the fabric without causing excessive fiber damage.

Consider a Rotary Cutter

A rotary cutter is an excellent alternative to scissors, particularly for delicate fabrics like cashmere.

Its circular blade provides a smooth, even cut with minimal pressure. When using a rotary cutter, ensure the blade is sharp and replace it as needed for optimal results.

Apply Minimal Pressure

Less is often more when it comes to cutting cashmere. Excessive pressure can cause fibers to fray and may lead to jagged edges. Let the cutting tool do the work, guiding it smoothly along the cutting line.

Use Pattern Weights

Pattern weights are heavy objects used to secure the pattern during cutting. They help prevent the fabric from shifting or stretching, ensuring clean, accurate cuts. This is particularly important when working with delicate fabrics prone to fraying.

Tape the Fabric Edges

Applying masking or painter’s tape along the cutting line can act as a stabilizer, holding the fibers in place and reducing fraying. Be sure to use low-tack tape to avoid leaving residue on the fabric.

Employ a Cutting Mat

A self-healing cutting mat provides a protective surface for your work area. It safeguards your tabletop and offers a smooth, stable surface for clean cuts. The markings on the mat can aid in achieving precise measurements.

Make Straight Cuts

Accurate cutting lines are crucial for minimizing fraying. Using a clear ruler or cutting guide helps maintain straight lines, reducing the likelihood of jagged edges that can lead to fraying.

Test on Scrap Fabric

Practice cutting on a scrap piece before cutting into your main cashmere fabric.

This allows you to familiarize yourself with how the fabric responds to your chosen cutting tool, ensuring a smoother and more controlled cutting process.

Finish Edges Immediately

After cutting, it’s essential to address the cut edges promptly.

Techniques like serging (using a serger machine), overcasting (using a sewing machine), or applying a fabric glue designed for fraying prevention can secure the edges and prevent further unraveling.

Preventative Measures

Preventative measures are essential to minimize fraying when working with delicate fabrics like cashmere.

Here are a variety of strategies and precautions you can take to prevent fraying at different stages of your project:

Pre-Purchase Considerations

Start with high-quality cashmere fabric or garments. Well-made cashmere tends to fray less compared to lower-quality options.

Pre-Cutting Preparations

Wash and gently iron cashmere before cutting to relax the fibers and reduce tension, making it less prone to fraying during the cutting process.

Stabilize the fabric with spray starch to prevent fraying during cutting.

Cutting Stage

Use proper cutting tools such as sharp, high-quality scissors or a rotary cutter with a fresh blade for clean and precise cuts.

Secure the fabric with pattern weights to prevent shifting, and consider using masking or painter’s tape along the cutting lines.

Cut cashmere fabric with the grain whenever possible to reduce fraying.

Edge Finishing Techniques

Use a serger machine to create a finished edge with overlocking stitches that securely encase the raw edges and prevent fraying.

Alternatively, apply an overcasting stitch using a sewing machine along the cut edges to secure the fibers.

Apply a fabric glue designed for fraying prevention along the cut edges, allowing it to dry completely before handling the fabric further.

Seam Allowances

Consider wider seam allowances when sewing cashmere to provide more room for finishing edges and minimize fraying within the seams.

Caring for Cashmere Items After Cutting

Caring for cashmere items after cutting is crucial to maintain their integrity and prevent further fraying.

Here are steps you should take to ensure your cashmere creations remain in excellent condition:

Inspect for Loose Fibers

After the cutting process, inspecting the cut edges thoroughly is crucial. Look for any loose or frayed fibers that may have resulted from the cutting process.

Use sharp scissors to trim away any excess fibers to prevent further unraveling.

Edge Finishing Techniques

Consider employing edge finishing techniques to reinforce and protect the cut edges of the cashmere fabric:

- Serging: Utilize a serger machine to create overlocking stitches along the cut edges. This technique encapsulates and secures the raw fibers, providing a clean finish and preventing fraying.

- Overcasting: In the absence of a serger, use a sewing machine to apply an overcasting stitch. This stitch encloses the raw edges, offering similar protection against fraying.

- Fabric Glue: Apply a specialized fabric glue for fraying prevention along the cut edges. Ensure it dries thoroughly before further handling.

Avoid Rough Handling

Handle the cut cashmere pieces with utmost care. Avoid unnecessary pulling, tugging, or rough handling, as this can place undue stress on the delicate fibers and potentially lead to further fraying.

Store Properly

- Fold, Don’t Hang: When storing cashmere items, fold them rather than hang them. Hanging can cause stretching, particularly at the shoulders, which may lead to fraying.

- Breathable Storage: Store cashmere garments in breathable fabric or garment bags. These protective covers shield the items from dust and pests while allowing air circulation.

Avoid Direct Sunlight

Shield cashmere items from direct sunlight exposure. Prolonged exposure to sunlight can weaken the fibers and result in fading, diminishing the overall quality of the fabric.

Hand Wash or Dry Clean

- Hand Washing: Hand wash cashmere items in cold water using a gentle detergent designed for delicate fabrics for optimal care. Gently agitate the water to clean, then rinse thoroughly. Avoid wringing or twisting the fabric, as this can lead to damage.

- Dry Cleaning: If you prefer professional care, select a reputable dry cleaner experienced in handling cashmere. Be sure to communicate the delicate nature of the fabric.

Lay Flat to Dry

After washing, lay cashmere items flat on a clean towel to dry. This method ensures even drying and minimizes stress on the fibers. Avoid hanging, as this can lead to stretching, particularly at stress points.

Store Away from Moths

To safeguard against potential moth damage, consider using natural moth deterrents such as cedar balls or sachets in your storage area.

These natural repellents can help protect your cashmere items during periods of storage.

FAQs

Does cashmere fabric tend to fray when cut?

Cashmere is known to fray when cut due to its delicate and fine fibers.

Can using sharp scissors help minimize fraying when cutting cashmere?

Yes, using sharp, high-quality scissors is essential to achieve clean cuts and reduce fraying.

What are some techniques to prevent fraying when working with cashmere?

Techniques like serging, overcasting, or fabric glue along the cut edges can help prevent fraying.

Is it recommended to practice cutting on a scrap piece of cashmere before starting a project?

Yes, practicing on a scrap piece can help you understand how the fabric behaves and refine your cutting technique.

Are there specific precautions to take when handling cashmere to minimize fraying?

Handling cashmere gently is important, as avoiding excessive pulling or tugging and using proper cutting tools to minimize fraying.

Wrap Up

Cashmere undeniably possesses exquisite qualities, including unparalleled softness and warmth. However, it is not impervious to fraying when cut.

Cashmere’s delicate, ultra-fine fibers are prone to separation and unraveling when subjected to the shear forces of cutting tools.

Nevertheless, this fraying can be mitigated with careful handling, appropriate cutting techniques, and post-cutting measures such as edge finishing.

Cashmere remains a coveted fabric, with its inherent propensity to fray as a reminder of the need for meticulous craftsmanship and a deeper appreciation for this luxurious natural fiber.

Cashmere continues to grace us with its timeless elegance and comfort when handled with care and respect for its delicate nature.

Leave a Reply