Sewing is a delicate dance of precision and creativity, where the perfect stitch can transform fabric into artistry.

At the heart of this intricate process lies the timing of a sewing machine, a hidden but pivotal element that wields considerable influence over the tension of your stitches.

Timing, in this context, refers to the harmonious synchronization of the needle and the bobbin hook or shuttle, dictating the precise moment when they meet to form stitches.

This synchronization is paramount because it directly impacts the tension of your stitches and the overall quality of your sewing projects.

In the following exploration, we will delve into the intriguing connection between timing on a sewing machine and the elusive art of achieving the ideal tension in your stitches.

What Is a Sewing Machine Tension?

Sewing machine tension refers to the balance of thread tension in a sewing machine. It is crucial for achieving neat and even stitches in various fabric types.

Tension is typically controlled by adjusting the tension dial, which regulates the tightness of the upper thread as it interacts with the lower bobbin thread.

Proper tension ensures that the threads lock together within the fabric layers, preventing loose loops or puckering.

Too much tension can lead to thread breakage, while too little can result in loose, loopy stitches. Achieving the right tension is essential for producing high-quality, professional-looking sewing projects.

What Is Timing on a Sewing Machine?

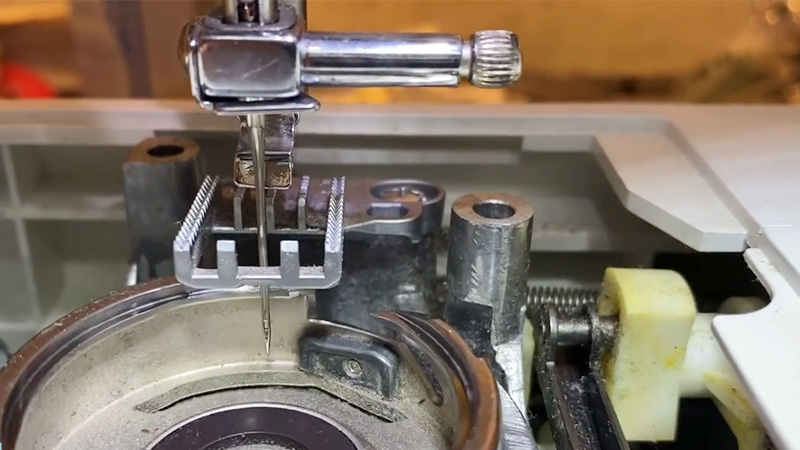

Timing on a sewing machine refers to the precise synchronization of various components within the machine to ensure proper stitch formation.

It involves the alignment of the needle’s entry and exit points, the movement of the shuttle or bobbin case, and the rotation of the feed dogs.

Correct timing is crucial for producing even and consistent stitches. If the timing is off, stitches may skip or become uneven, leading to fabric damage and frustration.

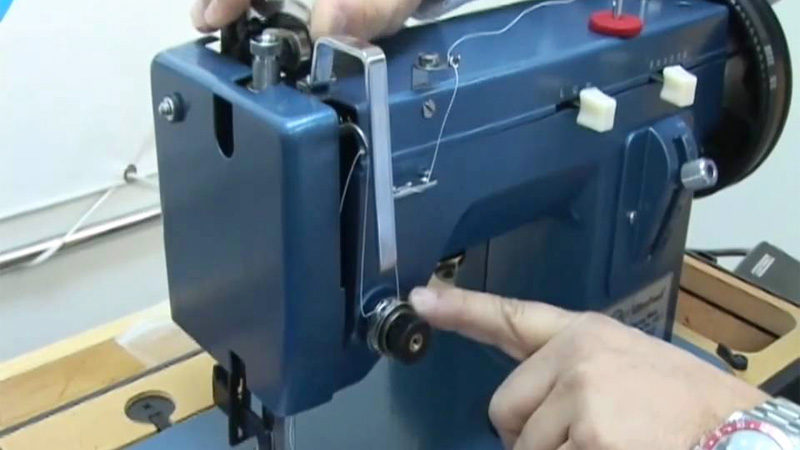

Sewing machine timing can be disrupted by factors like needle strikes, jammed threads, or improper maintenance. To maintain optimal performance, regular checks and adjustments are necessary.

Does Timing on a Sewing Machine Affect Tension?

Timing on a sewing machine plays a crucial role in achieving proper tension and stitch quality.

The timing of a sewing machine refers to the precise coordination of the needle and the sewing machine’s feed dog mechanism. When the timing is off, it can lead to various issues, including uneven tension.

Here’s how timing on a sewing machine affects tension:

Needle and Hook Alignment

The timing of a sewing machine is primarily concerned with aligning the movement of the needle and the hook (or shuttle) responsible for forming stitches.

When these components are perfectly synchronized, the needle enters the fabric at the right moment to catch the bobbin thread, creating a well-formed stitch with proper tension.

Tension Release

Inaccurate timing can disrupt the tension balance in the machine. If the needle and hook do not meet at the correct time, it may result in the bobbin thread being pulled too tightly or too loosely, leading to uneven tension in the stitches.

Stitch Quality

Properly timed machines produce consistent and well-defined stitches. When timing is off, you may experience skipped stitches, thread bunching, or thread breakage. These issues can result in an overall decrease in the quality of your sewing projects.

Fabric Handling

Timing also affects how the machine handles different types of fabric. Properly timed machines can smoothly feed various fabrics, from lightweight silk to heavy denim, without causing tension problems.

Misaligned timing may cause the machine to struggle with certain fabrics or produce uneven stitching.

Maintenance

Sewing machines require regular maintenance to ensure proper timing. Over time, wear and tear can affect the alignment of the needle and hook.

Routine servicing by a professional can help maintain the correct timing and prevent tension-related problems.

What Tension Should My Sewing Machine Be On?

The ideal tension setting for your sewing machine can vary depending on several factors, including the type of fabric you’re sewing, the thread you’re using, and your specific sewing machine model.

Tension control is crucial for achieving balanced and even stitches in your sewing projects.

Here are some general guidelines to help you set the tension on your sewing machine:

Refer to Your Sewing Machine’s Manual

The best starting point for determining the correct tension settings for your machine is your sewing machine’s manual.

It will often provide recommendations for tension settings based on different types of fabric and thread.

Test on Scrap Fabric

Before starting a project, it’s a good practice to test your tension settings on a scrap piece of the fabric you plan to use. This allows you to make adjustments and ensure that the stitches look balanced and secure.

Balanced Tension

In most cases, the ideal tension setting is when the upper and lower threads meet in the middle of the fabric layers.

When you examine a seam, you should see no visible loops of the upper thread on the underside or loops of the bobbin thread on the top side.

Adjust Gradually

If you notice tension issues, make adjustments to the tension dial or settings gradually. Small changes can make a significant difference.

If the stitches are too tight (fabric puckers), decrease the tension. If the stitches are too loose (loops appear), increase the tension.

Consider Thread and Fabric

Different fabrics and threads may require specific tension adjustments. Lightweight fabrics often require lower tension, while heavy fabrics may need higher tension.

Specialty threads, such as metallic or elastic threads, may also require specific tension adjustments.

Machine Type Matters

The type of sewing machine you have can influence tension settings. Mechanical machines and computerized machines may have different tension control mechanisms, so be sure to understand your machine’s capabilities.

Practice and Experience

Achieving the perfect tension may take some practice and experience. As you become more familiar with your sewing machine and the types of projects you work on, you’ll develop a better sense of the correct tension settings for various situations.

Sewing Machine Tension Problems and Solution

Sewing machine tension problems are common issues that can be frustrating, but they are usually solvable.

Here are some common tension problems and their solutions:

Uneven Tension (Loops on Top or Bottom)

Cause: Uneven tension occurs when the upper and lower threads are not balanced.

Solution:

- Check Thread Path: Ensure that the upper thread is correctly threaded through the machine, including the tension discs and the take-up lever.

- Bobbin Tension: Adjust the bobbin tension if necessary. For most machines, slightly tightening the bobbin tension can help balance the stitch.

- Needle and Thread Compatibility: Use the correct needle and thread combination for your fabric. Heavy fabrics may require thicker threads and larger needles, while delicate fabrics need finer threads and smaller needles.

- Machine Cleaning: Lint and debris in the tension discs or bobbin area can affect tension. Clean your machine regularly.

Puckering or Gathering of Fabric

Cause: This can happen when the tension is too tight, or the wrong needle or thread is used.

Solution:

- Adjust Tension: Loosen the upper tension by turning the tension dial to a lower number.

- Use the Right Needle: Ensure that you are using the appropriate needle for your fabric. Universal needles work for many fabrics, but specialty needles are available for specific fabric types.

- Thread Quality: Use high-quality thread to reduce the likelihood of puckering.

Thread Breaking

Cause: Thread breakage can occur due to various reasons, including incorrect tension, blunt needles, or poor-quality thread.

Solution:

- Tension Adjustment: Check and adjust the tension as needed. If it’s too tight, it can cause the thread to break.

- Needle Replacement: Replace a dull or damaged needle. A sharp needle reduces stress on the thread.

- Thread Quality: Invest in good-quality thread, as cheap threads may be more prone to breaking.

- Bobbin Issues: Ensure that the bobbin is wound evenly and correctly. Uneven winding can lead to thread breakage.

Thread Bunching or Nesting Underneath

Cause: This typically happens when the upper thread is not properly seated in the tension discs or when the bobbin thread is not threaded correctly.

Solution:

- Check Upper Thread: Ensure the upper thread is correctly threaded through all the guides and tension discs. Re-thread if necessary.

- Bobbin Thread: Make sure the bobbin is inserted correctly and that the bobbin thread is properly threaded through the bobbin case’s tension spring.

- Tension Adjustment: Check the upper thread tension. It may need to be slightly tighter.

Skipped Stitches

Cause: Skipped stitches can result from a variety of factors, including a dull needle, incorrect needle size, or improper threading.

Solution:

- Needle Replacement: Replace the needle with a new, sharp one that is appropriate for your fabric type.

- Thread Quality: Use high-quality thread that doesn’t easily break or fray.

- Proper Threading: Ensure that the upper thread is correctly threaded through the machine’s guides and tension discs.

How to Tell if Sewing Machine Timing Is Off?

Detecting if your sewing machine’s timing is off is crucial for maintaining stitch quality and preventing sewing issues.

Here are some common signs that may indicate your sewing machine’s timing is out of sync:

Skipped Stitches

If your machine frequently skips stitches or fails to catch the bobbin thread properly, it could be a sign of timing issues. The needle may not be entering the fabric at the correct time to form stitches.

Thread Bunching Underneath

When the upper and lower threads do not meet correctly, you may notice thread bunching on the underside of your fabric. This can lead to loops or knots of thread forming on the wrong side of the material.

Uneven Stitches

Poorly timed sewing machines can produce uneven or irregular stitches. You might see inconsistent stitch lengths or uneven tension in your seams.

Needle Strikes Bobbin Case

A clear sign of timing problems is when the needle hits or collides with the bobbin case, shuttle, or hook. This can cause damage to both the needle and the machine.

Excessive Noise and Vibration

When the timing is off, the machine may produce more noise and vibration than usual. This can be due to the needle and other components not moving in harmony.

Difficulty Sewing Heavy Fabrics

Timing problems can become more evident when sewing heavy or thick fabrics. The machine may struggle to penetrate the material or may produce uneven stitches in such cases.

Thread Breakage

If the timing is off, the thread may experience more tension and friction, increasing the likelihood of thread breakage during sewing.

Visible Misalignment

In some cases, you may be able to visually observe misalignment between the needle, bobbin case, or hook when the machine is in operation.

FAQS

Can timing issues on a sewing machine be prevented with regular maintenance?

Yes, routine maintenance by a professional can help prevent timing problems and ensure consistent tension in your sewing projects.

Are there any common signs that indicate a sewing machine may have timing issues?

Yes, some common signs include skipped stitches, thread bunching or nesting, uneven tension, and a generally poor stitch quality.

Can timing problems vary depending on the type of sewing machine?

Yes, timing issues can differ between different sewing machine models and brands.

Is it possible to retime a sewing machine at home, or should I always seek professional help?

While it’s possible to attempt retiming at home, it’s recommended for experienced users. If unsure, consulting a sewing machine technician is the safest approach to ensure accurate timing adjustments.

How frequently should I check and adjust the timing on my sewing machine?

The frequency of timing checks and adjustments depends on your sewing machine’s usage. For regular users, an annual checkup is generally sufficient. However, heavy or industrial machines may require more frequent assessments.

To Recap

In sewing, precision and attention to detail are paramount. Throughout this exploration, we’ve delved into the critical role that timing plays in a sewing machine’s performance and how it directly influences tension.

A well-timed machine can be the difference between achieving flawlessly balanced stitches and encountering frustrating tension issues.

Whether you’re creating delicate embroidery or sturdy seams on heavy fabrics, timing is the silent conductor orchestrating the symphony of your sewing experience.

It’s a reminder that even the most intricate aspects of sewing equipment, often overlooked, have a profound impact on the final outcome of your creative endeavors.

So, next time you sit down at your sewing machine, remember that mastering the art of timing is a vital step toward achieving perfection in your stitches and realizing your sewing aspirations.

Leave a Reply