Fabric crocking, an important consideration in textiles, pertains to the potential color transfer from a fabric’s surface to other materials when subjected to friction or abrasion.

Understanding this phenomenon is crucial for manufacturers, designers, and consumers alike.

It encompasses a range of factors, including dye quality, fixation processes, fabric type, and care practices. The consequences of crocking can be significant, affecting the appearance and longevity of fabrics.

This phenomenon is not limited to specific fabric types, impacting natural fibers like cotton, wool, and synthetic materials.

Exploring the causes, effects, and mitigation strategies is vital in maintaining textiles’ quality and aesthetic appeal.

What Does It Mean Fabric May Crock?

Crocking, in the context of textiles, is the unintended transfer of color from a fabric’s surface to another material when subjected to friction.

This can occur due to various factors, including the type of dye or printing method used, as well as the fiber composition of the fabric itself.

It’s important to note that crocking is not limited to a specific type of fabric; it can affect natural fibers like cotton and wool and synthetic materials like polyester and nylon.

Crocking can occur in different situations, such as when a person wearing a freshly dyed garment comes into contact with light-colored furniture or when two fabrics rub against each other during wear.

The level of crocking can vary depending on factors like the quality of the dye, the fabric’s finish, and the intensity of the friction.

Here’s how crocking can affect the appearance of fabrics:

Color Transfer

When crocking occurs, the color from the fabric can transfer onto other surfaces. For example, if a person wearing a garment prone to crocking leans against a light-colored sofa, the dye may rub off the upholstery, potentially causing staining.

Fading and Dullness

With repeated instances of crocking, the original vibrancy of the fabric’s color can diminish. This is especially noticeable in areas that experience frequent friction, such as collars, cuffs, and seams. Over time, the fabric may appear dull and less vibrant.

Loss of Print Detail

In fabrics with printed designs, crocking can lead to a loss of sharpness and clarity in the pattern. This is because the ink used in printing may not adhere firmly to the fabric fibers and can be easily rubbed off.

Uneven Wear and Tear

Areas of the fabric prone to crocking may experience accelerated wear and tear compared to other parts of the garment. The constant friction weakens the fibers, leading to premature deterioration.

Reduced Longevity

Fabrics that exhibit excessive crocking may have a shorter lifespan. The frequent color transfer and wear can significantly impact the overall durability and appearance of the fabric.

Causes of Crocking on Fabric

Crocking on fabric can occur due to several factors, primarily related to the dyeing or printing process, as well as the fiber composition of the fabric itself.

Here are some of the leading causes of crocking:

Poor Dye Penetration

When dyed, the dye molecules should penetrate deep into the fabric fibers to bond with them. If the dye penetration is insufficient, the surface color may rub off easily when subjected to friction.

Inadequate Fixation

Proper fixation of dyes is crucial to ensure they are securely bound to the fabric. If the fixation process is not executed correctly, the dyes may not be firmly anchored, making them more prone to cracking.

Low-Quality Dyes

The quality of the dyes used can significantly affect crocking. High-quality dyes are designed to adhere better to fibers and resist rubbing off, while lower-quality dyes may not have the same level of durability.

Printed Fabrics

In the case of printed fabrics, the type of ink and printing method can impact crocking. If the ink does not adhere well to the fabric surface or the printing is not set correctly, it can lead to crocking as the ink rubs off.

Fabric Type

Different types of fabrics have varying levels of susceptibility to crocking. For instance, tightly woven fabrics may be less prone to crocking than loosely woven ones. Natural fibers like cotton and wool can behave differently from synthetic fibers like polyester and nylon.

Fabric Finish

The finish applied to a fabric can influence crocking. Some finishes are designed to enhance color fastness and reduce crocking, while others may not provide the same level of protection.

Washing and Care

Incorrect washing and care practices, such as using harsh detergents, washing at high temperatures, or machine-drying when not recommended, can contribute to crocking by compromising the stability of dyes and finishes.

Environmental Factors

Exposure to environmental conditions like sunlight and moisture can affect the stability of dyes and fabrics. UV radiation, for example, can cause fading and weaken the colorfastness of fabrics.

Chemical Interactions

Interaction with chemicals, such as bleach or specific cleaning agents, can lead to color loss and crocking if the fabric is incompatible with these substances.

Age and Wear

Over time, even well-dyed and properly finished fabrics can experience crocking as they endure wear and abrasion. This is a natural consequence of fabric aging.

Types of Crocking

Crocking can occur in various forms, and understanding these types can help identify and address specific issues related to color transfer in fabrics.

Here are the primary types of crocking:

Dry Crocking

Dry crocking refers to color transfer that happens when a dry fabric comes into contact with another surface or material. This can occur during regular wear or when a dry fabric rubs against furniture, skin, or other fabrics.

Wet Crocking

Wet crocking involves color transfer when a wet fabric comes into contact with another surface. This can happen during washing or if a garment is worn while damp.

Primary Crocking

Primary crocking is the initial color transfer that occurs when the fabric is first subjected to friction. It may happen during the first few wears or washes of a newly dyed or printed garment.

Secondary Crocking

Secondary crocking refers to color transfer after the initial dyeing or printing process. This can happen as a result of washing, exposure to moisture, or prolonged wear.

Temporary Crocking

Temporary crocking involves color transfer that can be easily removed or minimized with simple actions like brushing or wiping. It typically occurs when excess dye or pigment is not correctly fixed to the fabric.

Permanent Crocking

Permanent crocking refers to color transfer that cannot be easily removed or reversed. This usually occurs when the dye or ink is firmly bonded to the fabric or when the fabric is damaged.

Localized Crocking

Localized crocking is when the color transfer happens in specific areas of a fabric, often where there’s a higher degree of friction. This can lead to uneven color distribution across the garment.

Handling Crocking in Different Fabrics

Handling crocking in different fabrics involves taking specific precautions and using appropriate care methods to minimize color transfer.

Here are some tailored tips for dealing with crocking in various types of fabrics:

Cotton

- Preventative Measures: Wash new cotton garments separately to avoid color bleeding onto other fabrics. Add a cup of vinegar to the wash to help set the dye.

- Care Instructions: Wash in cold water with a gentle detergent. Avoid using bleach or harsh chemicals. Air dry or use low heat when machine drying.

Wool

- Preventative Measures: Use color-safe detergents and avoid excessive agitation when washing. Consider dry cleaning delicate wool garments.

- Care Instructions: Wash your hands in cool water with a mild detergent or use the delicate cycle on your machine. Avoid wringing or twisting the fabric.

Polyester

- Preventative Measures: Polyester tends to be more colorfast, but wash separately if it’s a new garment. Avoid high heat during drying.

- Care Instructions: Machine wash in cool water with a mild detergent. Use a low heat setting if machine drying.

Silk

- Preventative Measures: Silk is delicate, so hand wash or dry clean. Avoid exposure to direct sunlight to prevent fading.

- Care Instructions: Wash your hands in cold water with a mild detergent or take it to a professional dry cleaner. Do not wring or twist; gently squeeze excess water out.

Nylon

- Preventative Measures: Wash new nylon garments separately to prevent color transfer. Avoid high heat during drying.

- Care Instructions: Machine wash in cool water with a mild detergent. Use a low heat setting if machine drying.

Linen

- Preventative Measures: Wash linen garments separately, especially if they are brightly colored. Avoid overloading the washing machine.

- Care Instructions: Machine wash in cool water with a mild detergent. Line drying is recommended to prevent excessive wrinkling.

Rayon

- Preventative Measures: Rayon can be delicate, so hand wash or dry clean to prevent color bleeding. Avoid wringing or twisting the fabric.

- Care Instructions: Wash your hands in cool water with a mild detergent or use a professional dry cleaner. Lay flat to dry.

Leather and Suede

- Preventative Measures: Avoid contact with light-colored fabrics, especially when the leather or suede is new. Use a leather protector spray.

- Care Instructions: Wipe clean with a damp cloth and mild soap. Use a leather conditioner to maintain suppleness.

Synthetic Blends

- Preventative Measures: Follow care instructions based on the predominant fiber in the blend. Wash separately if it’s a new garment.

- Care Instructions: Follow instructions based on the fabric with the highest percentage in the blend.

Testing for Crocking

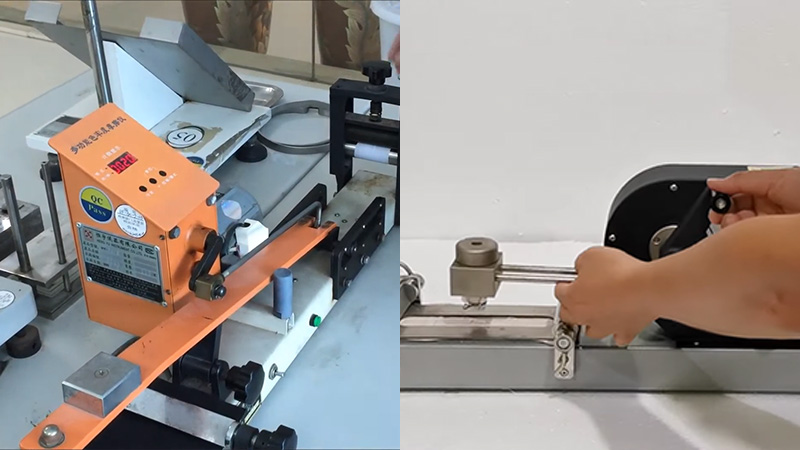

Testing for crocking is an essential quality control measure to assess the potential for color transfer in fabrics. Several standardized methods and equipment are used in the textile industry to perform crocking tests.

Here are some standard techniques:

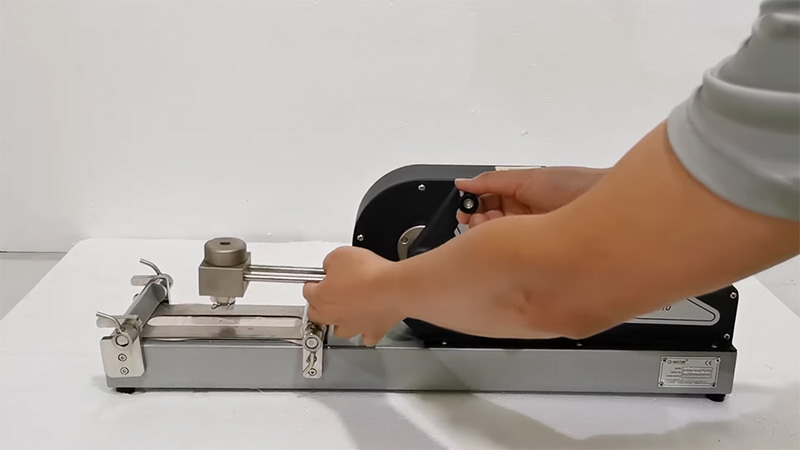

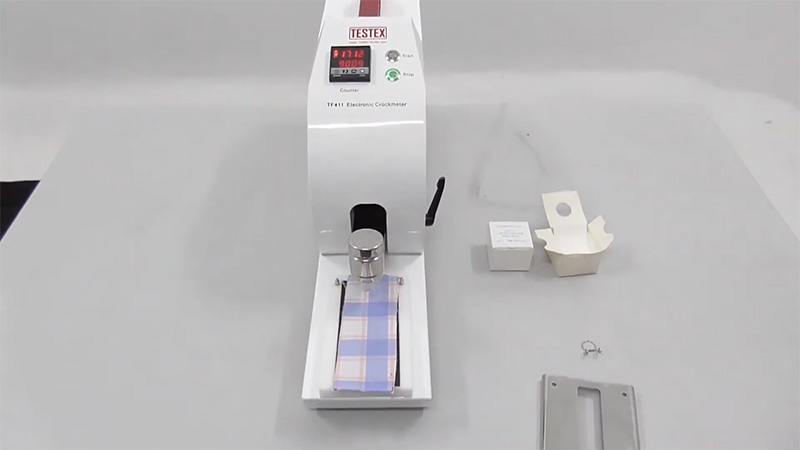

AATCC Crockmeter Test

The AATCC (American Association of Textile Chemists and Colorists) Crockmeter is widely used for testing colorfastness to crocking.

It measures the color transfer from a fabric surface to another material under controlled rubbing conditions. This test can be performed both wet and dry.

ISO Crocking Test

The ISO (International Organization for Standardization) specifies methods for determining colorfastness to crocking. These methods involve using specialized equipment to rub a piece of white fabric against the test specimen under controlled conditions.

Wash Fastness Test

In addition to crocking tests, wash fastness tests assess how well the color holds up during washing. This involves immersing the fabric in water and agitating it, simulating the washing process. It helps determine if the color is adequately set.

Color Transfer Assessment

The fabric is rubbed against a standard white cloth under controlled pressure in a color transfer assessment. The white cloth is then visually examined for color transfer, and the extent of staining is graded based on a standardized scale.

Stain Test Swabs

Stain test swabs are pre-saturated with a solvent that simulates human perspiration. They are rubbed against the fabric to see if color transfers onto the swab. This is particularly relevant for fabrics that may come into contact with skin.

Adhesive Tape Test

In this test, adhesive tape is pressed onto the fabric and removed. Any color transferred onto the tape is assessed. While not as precise as other methods, it can quickly indicate potential crocking issues.

Visual Assessment with Grey Scales

A standardized grey scale visually assesses the degree of color transfer after rubbing. This scale provides a reference for determining the colorfastness of the fabric.

Accelerated Testing

Accelerated tests involve subjecting the fabric to more severe conditions, such as increased friction, heat, or humidity, to simulate long-term wear and exposure. These tests can help predict potential issues over time.

Consequences of Crocking

Crocking can have several consequences, both for the fabric or garment experiencing the color transfer and for the surfaces or materials that come into contact with it.

Here are the primary consequences of crocking:

Staining

The most immediate consequence of crocking is staining. When color transfers from the fabric to another surface, it can leave unsightly stains or marks. This staining can be challenging to remove, depending on the nature of the fabric and the surface affected.

Discoloration

Over time, repeated crocking can lead to the gradual discoloration of the fabric itself. High-friction areas, such as collars and cuffs, may lose their original color and vibrancy, resulting in a dull or faded appearance.

Loss of Print Detail

For printed fabrics, crocking can cause the printed design to lose its sharpness and clarity. The ink may rub off, making the pattern appear less defined and attractive.

Uneven Wear and Tear

Crocking can accelerate the wear and tear of a fabric, especially in areas that experience frequent friction. This can lead to premature deterioration of the garment, reducing its lifespan.

Reduced Aesthetic Appeal

Fabrics that frequently exhibit crocking may not look as appealing as when new. The uneven color distribution and faded areas can detract from the overall aesthetic quality of the garment.

Perceived Poor Quality

Excessive crocking can give the impression of poor quality, even if the fabric or garment is otherwise well-made. Consumers may associate color transfer with inferior materials or artistry.

Consumer Dissatisfaction

Staining or fading caused by crocking can lead to dissatisfaction among consumers, especially if they are unaware of the potential for color transfer. This can result in returns, refunds, or negative reviews for manufacturers and retailers.

Higher Maintenance

Garments prone to crocking may require more careful maintenance, such as separate washing or avoiding contact with light-colored items. This adds to the inconvenience and cost of owning and caring for such items.

Environmental Impact

If colorfastness issues are not addressed during manufacturing, it can lead to higher levels of discarded clothing, contributing to textile waste and environmental concerns.

Troubleshooting and Remedies

Troubleshooting and implementing remedies for fabric crocking issues are essential for addressing color transfer and maintaining the appearance of fabrics.

Here are some standard troubleshooting steps and remedies for dealing with crocking:

Identify the Source

Determine whether the color transfer comes from the fabric or an external source. Sometimes, color may rub off onto the fabric from another material.

Check for Colorfastness

Confirm if the fabric or garment was adequately tested for colorfastness before purchase. Consult the care label for recommended care instructions.

Assess Fabric Type

Consider the type of fabric and its dye composition. Natural fibers like cotton and wool may require different care methods than synthetic materials.

Evaluate Cleaning Products

If you’ve used harsh cleaning agents or bleach on the fabric, this may contribute to color loss and crocking.

FAQs

What is fabric crocking?

Fabric crocking refers to the process where color from a dyed or printed fabric rubs off onto another surface when subjected to friction or abrasion.

Why does crocking happen in fabrics?

Crocking can occur due to poor dye penetration, inadequate fixation, low-quality dyes, and fabric type. Environmental conditions and care practices can also influence it.

How does crocking affect the appearance of fabrics?

Crocking can lead to color transfer, fading, loss of print detail, uneven wear, and reduced longevity. It may result in stains, discoloration, and a diminished aesthetic appeal.

Can crocking be prevented?

Manufacturers can use quality dyes, proper fixation processes, and applying finishing treatments. Consumers can follow care instructions and take precautions during use and washing.

Which fabrics are more prone to cracking?

Fabrics with poor dye penetration, inadequate fixation, or low-quality dyes are more likely to crock. Natural fibers like cotton and wool, as well as specific synthetic blends, can be susceptible.

Wrap Up

Understanding the concept of fabric crocking is essential for both manufacturers and consumers. Fabric crocking signifies the potential for color transfer from a fabric’s surface to other materials when subjected to friction or abrasion.

This phenomenon can result from various factors, including dye quality, fixation processes, fabric type, and care practices—the consequences of crocking range from staining and discoloration to a loss of aesthetic appeal and premature wear.

To address this issue, manufacturers must employ quality control measures, while consumers should adhere to care instructions and exercise caution to prolong the life and appearance of their fabrics. Ultimately, awareness and preventive measures are vital to managing fabric crocking effectively.

Leave a Reply