Fraying fabric is a problem that can be prevented with some simple steps. Keep embroidery fabrics taped when not in use to prevent them from fraying. Be sure to store your fabric properly so it doesn’t get tangled and stretched out over time, which will cause it to fray.

Consider using special fabrics designed for preservation or laundering – they will hold up better than regular fabric and won’t suffer from fraying problems as much. If you do experience frayed edges, don’t panic – there are ways to repair them without completely replacing the garment.

How Do I Stop Embroidery From Unraveling?

Fraying embroidery fabric is a common problem that can be prevented with a few simple tips. Keep the fabric taped when it’s not in use to help prevent fraying.

When washing the fabric, make sure to use delicate cycle and low water temperatures to preserve its integrity. Avoid putting heavy items on top of the embroidered piece while it’s drying, as this may cause further damage.

If you notice any signs of fraying, take action quickly and replace the damaged area before it becomes too difficult or expensive to fix.

Prevent Fraying

Don’t overdo it. Avoid tying your embroidery too tightly, stretching it out of shape or doing anything that might cause it to fray. Keep a close eye on how often you wash your fabric – frequent washes help prevent the fabric from becoming brittle and prone to unraveling.

Use materials like silk thread, which are less likely to fray or tear than other types of threads. Store your embroidery away from direct sunlight – ultraviolet light can damage fibers and lead to fraying. If all else fails, consider using a protective adhesive sheet for added protection against wear and tear.

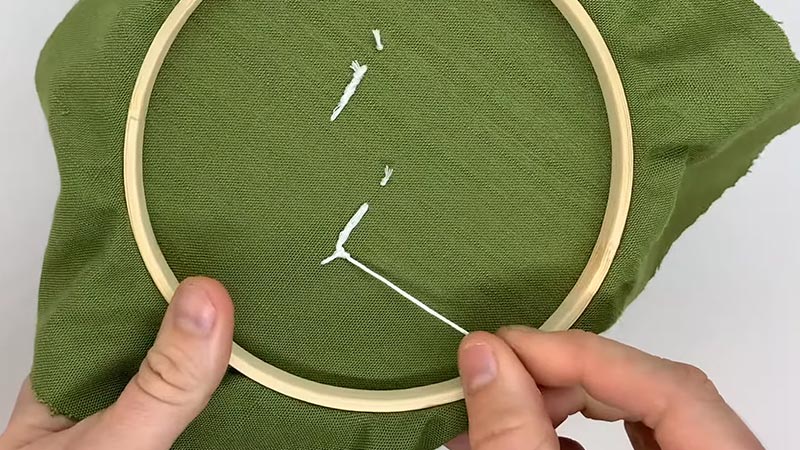

Keep Embroidery Fabric Taped

Keep embroidery fabric taped together at the ends to prevent it from unraveling. Apply a layer of clear adhesive tape around the edges of the fabric before stitching them together.

Place weights on top of your project to keep it in place while you sew, and avoid sewing over knots or stitches that have already been made. If necessary, remove adhesive tape after stitching is complete by using a seam ripper or scissors, and be sure to cut within 1/8 inch of stitching line for best results.

Always test an area first before taping entire pieces together as mistakes can be easily corrected if they occur during assembly.

How do you keep embroidery from coming undone?

There are a few ways to keep embroidery from coming undone. One is to use stitch holding fluid or gel. This will help the thread stay in place and prevent it from moving around. Another way is to make sure the stitches are tight enough. If they’re loose, the fabric can move and cause unraveling.

- One way to keep embroidery from coming undone is to add embroidery stabilizer to the back of your garment. This will help keep the fabric taut and prevent it from stretching or warping over time.

- Another option is to buy iron on embroidery stabilizer, which can be applied in just a few minutes using a heat gun or an iron.

- If you are having trouble keeping your embroidery intact, try placing it on thicker fabrics that won’t stretch as much as thinner fabrics do. Additionally, make sure that you’re stitching slowly and carefully so that you don’t pull the stitches too tight and cause damage to your work.

How do you fix unraveled embroidery?

If you notice unraveled embroidery on a garment, there are several ways to fix it. You can try using starch or stitching tape to hold the fabric together while sewing. You can also use a machine appliqué kit to make new pieces of embroidery where the old ones have come undone.

There are a few different ways that you can fix unraveled embroidery. The first step is to pull out the last two strings from the embroidered piece. Next, tie together the string front and back so that there is no visible knot on the front of the fabric. Finally, do it from the back so that any knots will be hidden by the design on the front of your fabric.

How do you seal embroidery?

There are many ways to seal embroidery, but the most common is with heat and pressure. You can use a hot iron or steam to press down on the fabric, sealing it inside the stitch.

- Ironing over embroidery can help to seal the fabric and protect it from dirt, water, and other elements. To do this, you will need to preheat your iron for 1-2 seconds before applying it to the embroidery. Use a pointed end of the iron to help seal any irregular edges and make sure that you heat up all sides of the paper evenly.

- You can also use heat n bond paper as a temporary solution if you don’t have access to an iron or want something more permanent. Simply place side down on top of your embroidered surface and preheat your iron for 1-2 seconds before pressing firmly into the adhesive strip so that it seals both surfaces together.

- If you ever need to remove an embellishment or repair damage done by fire, flood, or extreme weather conditions, simply apply heat n bond paper in a crosshatch pattern across the area that needs protection then press firmly onto the fabric until cool enough to peel off safely (usually within 10 minutes).

What is used to prevent edges from unraveling?

Fabric sealant is a type of glue that attaches fabric together so it doesn’t unravel. You can also use fabric glue to keep edges from coming undone. If you have any questions about how to attach your fabric or if it’s starting to come undone, don’t hesitate to ask a professional.

Why does my embroidery thread keep fraying?

Embroidery thread is designed to be strong and durable, but it can sometimes start to fray after a while. This happens because the fibers in the thread are constantly being pulled apart by friction. If this problem persists, it can eventually lead to unraveling of the fabric.

Tension Issues

The most common cause of embroidery thread fraying is tension issues. When the threads are pulled too tightly, they can fray and break. This can be caused by a number of factors including machine timing, thread path interference, old or rayon thread, and poor digitizing.

Machine Timing

If your machine is not running at the correct speed, it will create more tension in the embroidery thread than necessary. This excess tension causes the threads to break easily.

Thread Path Interference

When two different types of fabric are being worked with parallelthreading (using one continuous strand), there is a risk of cross-contamination between them due to their close proximity to each other on the spool or bobbin winder shafts while they’re moving around during stitching operations Cross-contamination can lead to broken stitches and frayed embroidery threads 4 Old or Rayon Thread

Old or rayon threads have little give when stretched which makes them much less forgiving when it comes to breaking stitches – even if you’re using high quality materials like cotton twill for your project’s base fabric. 5 Poor Digitizing.

Why does my thread keep coming undone?

You may be experiencing insufficient thread tension on your sewing machine. This could be due to an incorrect needle setting or a damaged seamstress foot.

If the fabric is wrinkled and you’re not sure why, it might be because of poor thread handling – often caused by weak hands. Check your machine’s tension level and make sure that the material being attached to the sewing machine needle is of equal thickness all around so there are no wrinkles in between stitches.

Finally, if problems persist despite taking care of these issues, it might be time for a new seamstress foot or even a whole new sewing machine.

To Recap

Embroidery that unravels can be prevented by following a few simple steps. First, make sure the embroidery is properly secured to the fabric. Next, avoid using too much tension when stitching; use just enough to achieve the desired look and feel.

And finally, be careful not to pull on the embroidery while it’s in progress – this can cause it to come undone.

Leave a Reply