Waterproofing a cardboard boat is crucial to ensure its structural integrity and buoyancy.

While cardboard isn’t a conventional boat-building material, it can serve for temporary or recreational purposes with the right techniques.

This process involves sealing the cardboard surface effectively to prevent water penetration and subsequent damage.

This guide will explore the essential steps, materials, and precautions to waterproof a cardboard boat successfully.

Each step plays a vital role in creating a watertight barrier, from selecting the appropriate sealant to reinforcing critical areas.

Mastering these techniques is key to enjoying a safe and resilient cardboard boat experience on the water.

How to Waterproof a Cardboard Boat?

Waterproofing a cardboard boat is essential to ensure its structural integrity and prevent it from becoming waterlogged and sinking.

While cardboard is not a traditional boat-building material, it can be used temporarily or recreationally.

Here’s a step-by-step guide on how to waterproof a cardboard boat:

Materials Needed:

- Cardboard Sheets.

- Waterproofing Sealant.

- Paint and Brushes/Rollers.

- Tape.

- Plastic Sheeting.

Step-by-Step Guide:

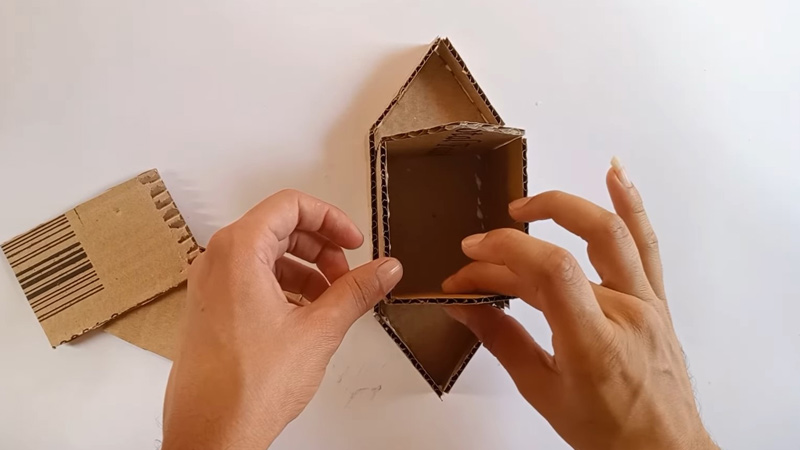

Design and Construct Your Boat

Start by carefully planning the design of your cardboard boat. Ensure that the shape and structure are well-thought-out for stability and functionality.

Use sturdy and thick cardboard sheets, and consider the placement of seams and joints. Reinforce these areas with strong, waterproof tape to create a solid foundation.

Seal the Joints and Seams

Apply a waterproof sealant generously along all joints and seams. Use a brush or your fingers to ensure the sealant penetrates the cardboard fibers, creating a tight bond.

Pay close attention to areas where two pieces of cardboard meet, as these are potential weak points for water infiltration. Allow sufficient drying time for the sealant to set and create a watertight seal.

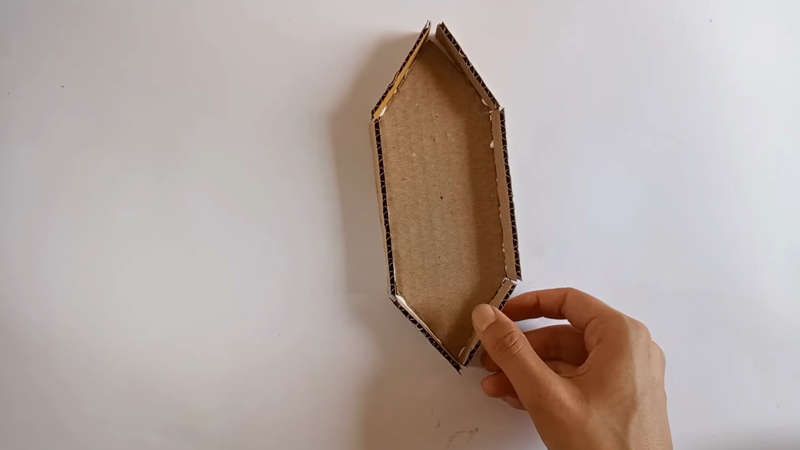

Apply Additional Layers of Cardboard

Identify critical areas of your boat, such as the bottom or stress-prone sections, and reinforce them by adding extra layers of cardboard.

Seal these additional layers with the waterproof sealant, ensuring a seamless integration with the existing structure. This step enhances the overall strength and durability of the boat.

Coat the Entire Boat

Cover the entire exterior of the boat with a layer of waterproof sealant. Use a brush or roller to ensure comprehensive coverage.

If you opt for epoxy resin, follow the manufacturer’s instructions for mixing and application.

This coating acts as a protective barrier, preventing water from seeping into the cardboard. Allow ample drying time to achieve maximum effectiveness.

Use Plastic Sheeting

For an extra waterproofing layer, consider covering the boat’s exterior with plastic sheeting. Pull the plastic tightly over the cardboard surface and secure it in place.

Seal the edges with waterproof tape to prevent water from finding its way underneath the plastic. This additional barrier provides enhanced protection against water penetration.

Apply Waterproof Paint

Once the waterproof sealant has fully dried, you may choose to apply a layer of waterproof paint. Select a marine-grade paint for its durability and resistance to water.

Besides offering an extra layer of protection, the paint can enhance the appearance of your cardboard boat. Allow the paint to dry completely before proceeding to the next steps.

Inspect and Reinforce

Thoroughly inspect the entire boat for any signs of weakness, gaps, or areas that may require additional reinforcement.

Pay special attention to seams, joints, and areas where extra layers of cardboard were applied. Address any identified issues by reapplying sealant or tape to ensure the boat’s structural integrity.

Test in Controlled Conditions

Before venturing into open water, conduct a controlled test in a shallow area. Place the boat in the water and observe its performance.

Check for any signs of weakness or water penetration. This step allows you to identify and address any remaining issues before taking your cardboard boat into more challenging conditions.

Mistakes to Avoid When Waterproofing a Cardboard Boat & Solution

Waterproofing a cardboard boat is crucial in ensuring its stability and longevity. However, certain mistakes can compromise the effectiveness of the waterproofing process.

Here are some common mistakes to avoid when waterproofing a cardboard boat:

Insufficient Sealant Application

- Mistake: Applying too little waterproof sealant or not ensuring thorough coverage can leave vulnerable spots that allow water to penetrate.

- Solution: Apply a generous amount of sealant, paying extra attention to seams, joints, and areas prone to stress. Make sure the sealant penetrates the cardboard fibers for a tight bond.

Neglecting Drying Time

- Mistake: Failing to allow sufficient drying time between sealant or paint coats can compromise the effectiveness of the waterproofing.

- Solution: Follow the manufacturer’s recommended drying times for each coat of sealant or paint. Rushing the process may lead to inadequate adhesion and reduced waterproofing capabilities.

Using the Wrong Sealant

- Mistake: Using a sealant that is not suitable for cardboard can result in poor adhesion and inadequate waterproofing.

- Solution: Choose a sealant specifically designed for cardboard. Polyurethane, epoxy resin, or waterproof wood glue are commonly used options. Ensure compatibility with the material to achieve the best results.

Overlooking Seams and Joints

- Mistake: Neglecting to reinforce seams and joints adequately can be a significant oversight, as these areas are more prone to water penetration.

- Solution: Strengthen seams and joints with waterproof tape and apply additional sealant to ensure these critical areas are well-protected against water ingress.

Skipping Additional Layers

- Mistake: Failing to add extra layers of cardboard to critical areas, such as the bottom of the boat, can compromise its structural integrity.

- Solution: Identify stress-prone areas and reinforce them with additional layers of cardboard. Seal these layers with a waterproof sealant to enhance overall durability.

Not Testing in Controlled Conditions

- Mistake: Skipping a controlled water test before taking the cardboard boat into open water can lead to unexpected issues and potential failures.

- Solution: Conduct a test in a controlled environment, such as a shallow pool or calm water, to evaluate the boat’s performance and identify any weaknesses. This allows you to address problems before exposing the boat to more challenging conditions.

Ignoring Plastic Sheeting

- Mistake: Neglecting the use of plastic sheeting as an additional layer of waterproofing can leave the boat vulnerable to water penetration.

- Solution: Cover the boat’s exterior with plastic sheeting, pull it tightly over the surface, and seal the edges with waterproof tape. This extra layer acts as a barrier against water.

Neglecting Regular Inspections

- Mistake: Failing to inspect the boat regularly for signs of wear, damage, or areas needing resealing can lead to gradual deterioration of the waterproofing.

- Solution: Periodically inspect the boat for any issues and address them promptly. Reapply sealant or make necessary repairs to maintain the boat’s waterproofing over time.

FAQs

What type of sealant is best for waterproofing a cardboard boat?

Choose a sealant specifically designed for use with cardboard materials.

Can I use regular paint to waterproof a cardboard boat?

While regular paint provides some protection, it’s advisable to use marine-grade waterproof paint for better durability and resistance to water.

Is it necessary to apply multiple coats of waterproof sealant?

Applying multiple coats may be necessary for optimal waterproofing, depending on the type of sealant. Follow the manufacturer’s instructions and allow each coat to dry thoroughly before applying the next.

Should I conduct a water test before using my cardboard boat in open water?

It’s highly recommended to perform a controlled water test in a shallow area before venturing into open water. This helps identify any weaknesses or potential issues with the waterproofing.

Wrap Up

Waterproofing a cardboard boat is a meticulous yet essential process to ensure its seaworthiness.

Adhering to the outlined steps and avoiding common mistakes can enhance the cardboard’s resistance to water, prolonging the boat’s life and usability.

The combination of robust cardboard construction, effective sealants, and optional reinforcements creates a reliable barrier against water ingress.

Regular inspections and testing in controlled conditions contribute to ongoing maintenance and safety.

While cardboard boats may not rival traditional materials, mastering the art of waterproofing empowers enthusiasts to embark on enjoyable and secure aquatic adventures, turning an unconventional choice into a viable and satisfying watercraft option.

Leave a Reply