Choosing between embroidery and sublimation printing is a pivotal decision when seeking to create custom apparel or promotional items.

Each technique offers distinct advantages and considerations, making it essential to weigh their merits against the project’s specific requirements.

Embroidery, a centuries-old craft, imbues garments with timeless elegance and durability, ideal for intricate designs and professional aesthetics.

In contrast, sublimation printing boasts vibrant, full-color graphics that seamlessly integrate into the fabric, perfect for complex designs and photo-realistic imagery.

To determine whether embroidery reigns supreme over sublimation or vice versa, one must consider design complexity, desired aesthetic, durability, and intended use of the final product.

What Is Embroidery?

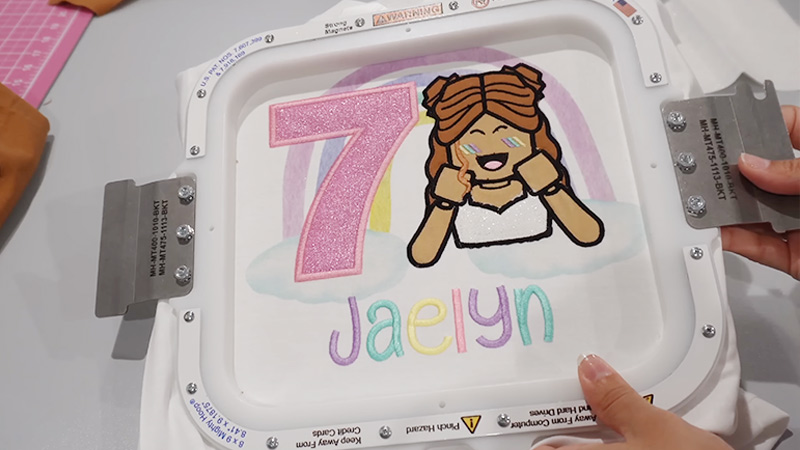

Embroidery is a decorative technique that stitches thread or yarn onto fabric to create designs, patterns, or images.

It is often used to embellish clothing, accessories, and home decor items, adding texture, color, and visual interest. Embroidery can be done by hand using a needle and thread or by machine for larger-scale projects.

The process typically follows a pattern or design outline, with various stitches such as satin stitch, chain stitch, and French knot used to fill in areas and create intricate details.

Embroidery is valued for its craftsmanship, versatility, and ability to add a personal touch to items.

What Is Sublimation?

Sublimation is a printing technique that transfers dye onto materials such as fabric, metal, or ceramic using heat and pressure.

Unlike traditional printing methods where the ink sits on the surface, sublimation ink becomes a gas when heated, bonding with the material’s molecules and becoming part of the substrate.

This results in vibrant, high-resolution prints with excellent color reproduction and durability.

Sublimation is commonly used for producing custom apparel, promotional items, and personalized gifts, offering the flexibility to create intricate designs, gradients, and photographic prints.

It is particularly effective on polyester-based materials due to their ability to absorb the sublimated dye.

Is Embroidery Better Than Sublimation?

Yes, embroidery can be considered better than sublimation in certain situations. Embroidery offers a timeless, high-quality aesthetic that can elevate the look of apparel, especially for small and intricate designs.

The tactile nature of embroidery adds depth and texture to garments, creating a luxurious feel often associated with premium branding.

Additionally, embroidery is highly durable and long-lasting, as the threads are stitched directly into the fabric, making it resistant to fading and wear over time.

This durability makes embroidered designs ideal for frequent washing or heavy use.

Furthermore, embroidery allows for a broader range of customization options, including specialty threads, metallic accents, and three-dimensional effects, adding visual interest and sophistication to the design.

Overall, for those seeking a classic, high-quality look with tiny, intricate designs, embroidery can be a superior choice to sublimation printing.

Advantages of Embroidery Over Sublimation

Embroidery offers several advantages over sublimation printing, particularly for certain types of designs and applications:

Durability

Embroidery’s durability is unparalleled due to its unique construction. Unlike other printing methods where the design sits on the surface, embroidery involves stitching threads directly into the fabric.

This integration creates a bond that withstands repeated washing and abrasion without losing its vibrancy or integrity.

Whether it’s the everyday wear and tear of work uniforms or the rigorous demands of sports apparel, embroidered designs maintain their quality over time, ensuring longevity and value for the wearer.

Texture and Depth

One of the most distinctive features of embroidery is its ability to add texture and depth to designs. By layering threads and employing various stitch techniques, embroidery creates a tactile and three-dimensional effect that captivates the senses.

This tactile quality not only enhances the visual appeal of the garment but also elevates its overall feel, providing a sense of luxury and craftsmanship.

Whether it’s the raised stitches of a pique stitch or the intricate patterns of a satin stitch, embroidery brings richness and dimensionality to apparel that other printing methods cannot replicate.

Customization Options

Embroidery offers vast customization options, allowing for endless creativity and personalization.

The possibilities are virtually limitless, from selecting different thread colors and types to incorporating metallic accents or specialty stitches.

This versatility enables designers to achieve intricate and detailed patterns that reflect the unique style and branding of the garment.

Whether a subtle monogram on a dress shirt or a bold logo on a team jersey, embroidery allows for precise and tailored customization that resonates with the wearer.

Timeless Aesthetic

The timeless appeal of embroidery lies in its classic look and enduring elegance. With roots dating back centuries, embroidery has stood the test of time as a symbol of craftsmanship and sophistication.

Whether a traditional floral motif or a contemporary logo design, embroidery adds a touch of refinement and class to apparel, transcending trends and fads.

This timeless aesthetic not only enhances the perceived value of the garment but also ensures its relevance across various contexts and occasions, making it a timeless choice for discerning consumers.

Disadvantages of Embroidery Compared to Sublimation

While embroidery offers many advantages, there are also some disadvantages compared to sublimation printing:

Limited Color Reproduction

Sublimation printing offers unlimited color options, allowing for vibrant, full-color designs with intricate details.

The dye sublimation process penetrates the fabric fibers, resulting in rich, saturated colors that are durable and long-lasting.

In contrast, embroidery is constrained by the available thread colors, which may not perfectly match the desired hues in the design.

This limitation can be particularly problematic for designs requiring precise color matching or subtle gradients, as achieving exact color accuracy through embroidery can be challenging and require additional time and expertise.

Complexity and Cost

Embroidery often involves a more intricate and labor-intensive process than sublimation printing, which can increase production time and expenses.

Each stitch in an embroidered design must be individually programmed and executed by specialized machinery, leading to higher labor costs and potentially longer turnaround times.

Additionally, complex designs with large stitch counts may require more materials and expertise, further driving up the overall cost of embroidery.

In contrast, sublimation printing involves a more straightforward process of transferring dye onto the fabric, making it a more cost-effective option for larger quantities or designs with intricate details.

Limitations on Fabric Types

While sublimation printing can be applied to various fabrics, including polyester blends, cotton, and synthetic materials, embroidery is better suited for specific fabric types.

Thick or stretchy fabrics may pose challenges for embroidery, as they can distort the stitched design or cause puckering.

Sublimation printing offers more versatility in fabric compatibility, allowing for seamless application onto various textile substrates without compromising the quality or integrity of the design.

Limited Detail and Resolution

Embroidery can create textured and three-dimensional designs but may lack the fine detail and resolution achievable through sublimation printing.

Sublimation allows for precise reproduction of intricate patterns, gradients, and small text, making it preferable for designs with complex artwork or small details.

The digital nature of sublimation printing ensures high-resolution output, resulting in sharp and crisp images that maintain their clarity and fidelity even on minor scales.

Bulkiness

Embroidery adds thickness to the fabric due to the stitched threads, which can result in a bulkier feel, especially for densely embroidered designs.

This additional bulkiness may not be desirable for specific applications with a lightweight and smooth finish, such as activewear or performance apparel, which is preferred.

In contrast, sublimation printing produces a seamless, flat surface without any added thickness, allowing for a sleek and streamlined appearance that is often more comfortable.

Sublimation vs Embroidery -What Is the Difference?

Two popular techniques stand out for customizing apparel and promotional items: sublimation printing and embroidery.

Each method offers unique advantages and considerations, making it essential to understand their differences to make an informed decision for your project.

Below is a comparison table highlighting the critical distinctions between embroidery and sublimation:

| Aspect | Sublimation Printing | Embroidery |

| Process | It is ideal for complex designs, gradients, and photographic prints. | It provides excellent durability and resistance to fading, peeling, or cracking, ensuring the longevity of the design. |

| Appearance | Produces vibrant, full-color designs with seamless integration into the fabric. | It is best suited for small, intricate designs or logos, though it can also handle larger designs. |

| Design Complexity | Ideal for complex designs, gradients, and photographic prints. | It offers good durability, though colors may fade over time, especially on polyester fabrics. |

| Durability | It can be done on various fabrics, including cotton, denim, twill, fleece, and leather. | It involves stitching thread or yarn directly onto the fabric by hand or machine. |

| Fabric Compatibility | Works best on polyester-based materials or materials with a polyester coating. | They are widely utilized in uniforms, corporate apparel, hats, bags, and various promotional products. |

| Customization | Allows for easy customization of designs without additional setup costs for each variation. | Each design variation may require additional setup costs, especially for complex designs or multiple thread colors. |

| Quantity | Suitable for producing small to medium quantities of custom-designed apparel or items. | It is ideal for small and large quantities of garments, making it suitable for individual and bulk orders. |

| Application | Commonly used for personalized apparel, promotional items, and photo gifts. | It is ideal for both small and large quantities of garments, making it suitable for both individual and bulk orders. |

Heat Press vs Embroidery

Regarding customizing apparel and promotional items, two popular techniques are often considered: heat press printing and embroidery.

Both methods offer distinct advantages and considerations, making it essential to understand their differences to choose the most suitable option for your project.

Below is a comparison table highlighting the key distinctions between heat press printing and embroidery:

| Aspect | Heat Press Printing | Embroidery |

| Process | Involves using heat and pressure to transfer a design from a printed transfer paper onto the fabric. | It can be done on various fabrics, including cotton, denim, twill, fleece, and leather. |

| Appearance | Offers a smooth, flat finish with vibrant, full-color designs or graphics. | It involves using heat and pressure to transfer a design from a printed transfer paper onto the fabric. |

| Design Complexity | It provides excellent durability and resistance to fading, peeling, or cracking, ensuring the longevity of the design. | It is best suited for small to medium-sized designs, but it can also handle larger ones. |

| Durability | They are widely utilized in uniforms, corporate apparel, hats, bags, and various promotional products. | It is ideal for intricate designs, gradients, and photographic prints. |

| Fabric Compatibility | Compatible with a wide range of fabrics, including cotton, polyester, and blends. | It offers good durability, though colors may fade over time, especially on polyester fabrics. |

| Customization | Allows for easy customization of designs without additional setup costs for each variation. | Each design variation may require additional setup costs, especially for complex designs or multiple thread colors. |

| Quantity | Suitable for producing small to medium quantities of custom-designed apparel or items. | Each design variation may require additional setup costs, especially for complex designs or multiple thread colors. |

| Application | Commonly used for personalized apparel, team uniforms, event merchandise, and promotional items. | Widely utilized in uniforms, corporate apparel, hats, bags, and various promotional products. |

FAQs

Is embroidery more durable than sublimation printing?

Yes, embroidery tends to be more durable as the stitched threads become part of the fabric, making it resistant to fading, peeling, or cracking over time.

Can sublimation printing achieve full-color graphics?

Yes, sublimation printing produces vibrant, full-color graphics with seamless integration into the fabric, making it ideal for designs with complex color schemes or photographic elements.

Is embroidery suitable for all types of fabric?

While embroidery can be done on various materials, it may not suit all fabrics.

Certain fabrics like denim, cotton, and leather are well-suited for embroidery, whereas others may require special considerations.

To Recap

The debate over whether embroidery trumps sublimation or vice versa is nuanced and subjective. Both techniques have unique qualities that cater to design preferences, project requirements, and intended outcomes.

Embroidery offers a classic, textured aesthetic and exceptional durability, making it an excellent choice for small, intricate designs and professional garments.

Meanwhile, sublimation printing produces vibrant, full-color graphics with intricate details, ideal for custom apparel and promotional items requiring complex designs or photographic elements.

Ultimately, the decision between embroidery and sublimation hinges on factors such as design complexity, desired aesthetic, durability, and the intended use of the final product.

Both techniques offer valuable options for achieving diverse and impactful visual outcomes in custom apparel.

Leave a Reply