Interfacing and stabilizer are fundamental tools in sewing, both serving distinct yet complementary roles in achieving professional and polished results. While they share similarities, they are not the same.

Interfacing is a fabric-like material applied to the wrong side of the fabric to add structure, shape, and support to specific garment areas, such as collars and cuffs.

Conversely, the stabilizer is a temporary material used during embroidery or decorative stitching to prevent fabric puckering, stretching, or distortion.

Understanding the differences between interfacing and stabilizer is crucial for achieving desired outcomes in sewing projects, ensuring functionality and aesthetic appeal.

What Is Interfacing?

Interfacing is a textile material used in sewing to add structure, support, and stability to fabric pieces.

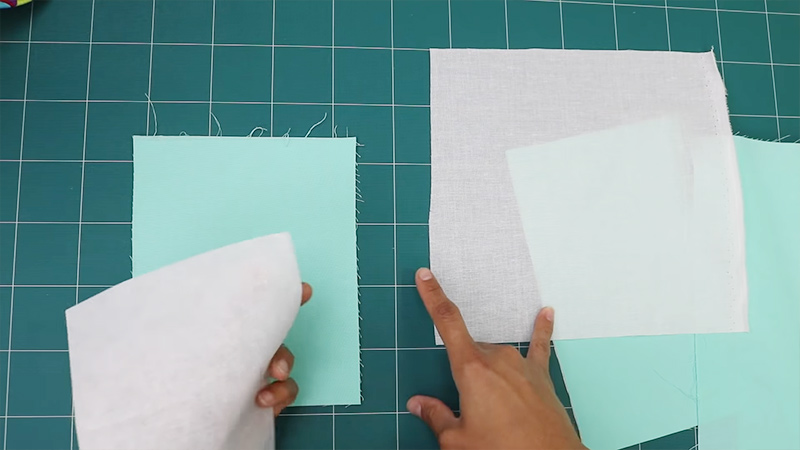

Typically applied to the wrong side of fabric sections, interfacing comes in various types, including woven, non-woven, fusible, and sew-in.

Fusible interfacing features an adhesive side activated by heat, bonding permanently when ironed. Sew-in interfacing requires stitching onto the fabric.

Interfacing serves several purposes, such as reinforcing collars, cuffs, and waistbands, preventing stretching or distortion, and providing the body with lightweight fabrics.

It helps maintain the shape and crispness of garments, enhancing their overall appearance and durability. Understanding interfacing is crucial for achieving professional results in garment construction.

What Is Stabilizer?

Stabilizer is an essential material in machine embroidery that supports fabrics during stitching, preventing distortion, puckering, or stretching.

It comes in various types, including tear-away, cut-away, and wash-away. Tear-away stabilizer can be easily torn off post-embroidery, while cut-away requires trimming and provides longer-lasting support.

Wash-away stabilizer dissolves in water, leaving no residue. Each type caters to specific project needs. Stabilizer ensures clean, precise stitching, particularly on delicate or stretchy fabrics.

It enables intricate designs and improves stitch quality. Understanding and selecting the right stabilizer type is crucial for achieving professional embroidery results and enhancing embroidered projects’ overall appearance and durability.

Is Interfacing the Same as Stabilizer?

No, Interfaces and stabilizers are related, but they are distinct elements used in sewing and crafting projects. Interfacing is a material applied to the back of the fabric to add structure, stability, or reinforcement to areas such as collars, cuffs, and facings.

It comes in various weights and types, including fusible and sew-in varieties, and is typically used to prevent stretching or distortion in fabric.

Stabilizer serves a similar purpose but is generally temporary and used during the stitching process.

It supports fabric during embroidery, appliqué, or decorative stitching, preventing puckering, distortion, or stretching. Stabilizers can be tear-away, cut-away, or water-soluble, depending on the project’s needs.

While both interfacing and stabilizer contribute to the stability and quality of a finished project, they serve different functions and are applied at various stages of the sewing process.

Interfacing provides permanent reinforcement to fabric, while stabilizer is temporary and removed after stitching.

Understanding the distinction between the two is essential for achieving professional results in sewing and crafting endeavors.

What Is Interfacing Used For?

Interfacing is a versatile material used in sewing and garment construction to add structure, stability, and support to various fabric components.

It serves several vital purposes in creating well-constructed garments and textile projects:

Reinforcing Garment Components

Interfacing is crucial in reinforcing various garments’ parts, ensuring they maintain their intended shape and structure.

Collar stands, for instance, often require interfacing to provide the necessary stiffness and support for the collar to stand upright.

Similarly, cuffs benefit from interfacing to maintain crisp edges and prevent them from becoming limp or misshapen over time.

Waistbands and plackets also rely on interfacing to retain shape and prevent stretching, particularly in tailored shirts or pants.

By reinforcing these critical areas with interfacing, garments maintain their professional appearance and structural integrity through repeated wear and laundering.

Adding Body and Volume

Interfacing offers an effective means of adding body and volume to various fabric components, allowing sewists to achieve a more structured and tailored look.

Sleeves, for example, may require interfacing along the seam allowances to provide extra support and maintain their shape when worn.

Additionally, interfacing can be applied to hems or entire garment panels to add fullness and create a more pronounced silhouette.

Whether used with lightweight fabrics to add structure or with heavier fabrics to enhance drape, interfacing allows for greater versatility in garment construction, enabling sewists to achieve desired aesthetic effects with precision and control.

Supporting Fasteners and Closures

Interfacing is vital in supporting fasteners and closures, ensuring they remain secure and functional over time.

By reinforcing the areas around buttons, buttonholes, snaps, and zippers with interfacing, garments are better equipped to withstand the tension and stress exerted on these components during wear.

This reinforcement prevents fabric distortion and sagging, resulting in a more professional finish and prolonging the garment’s lifespan.

Interface maintains garment integrity and functionality, Whether in tailored garments with intricate closures or casual wear with simple fastenings.

Creating Smooth and Clean Edges

Interfacing is an invaluable tool for creating smooth and clean fabric edges, mainly when working with fabrics prone to fraying or unraveling.

By interfacing along fabric edges, sewists can prevent fraying and ensure a neat, professional finish.

This is especially beneficial when sewing garments with exposed seams or using delicate fabrics requiring extra reinforcement.

Whether applied to raw edges before stitching or used to finish seam allowances, interfacing helps achieve clean lines and polished edges, enhancing the overall appearance and durability of the garment.

Facilitating Construction Techniques

Interfacing is essential for facilitating various construction techniques, providing stability and support throughout the sewing process.

Fusible interfacing, for instance, is commonly used for hemming, as it adheres to the fabric when pressed with an iron, creating a crisp, clean edge.

Additionally, interfacing helps stabilize seams and prevent stretching or distortion during construction, ensuring seams lie flat and maintain their shape.

Whether used for seam reinforcement, dart shaping, or neckline stabilization, interfacing enhances the accuracy and durability of garment construction, resulting in a professionally finished product.

Enhancing Decorative Details

Interfacing is a foundation for enhancing decorative details such as appliqué, embroidery, and embellishments, ensuring they lay flat and remain securely attached to the fabric surface.

By providing stability and support, interfacing prevents distortion and puckering of decorative elements, resulting in a polished and professional-looking finish.

Whether used to reinforce fabric before applying intricate embellishments or to stabilize fabric during embroidery work, interfacing enhances the visual impact and longevity of decorative details, allowing sewists to achieve their desired aesthetic with precision and confidence.

What Is Fabric Stabilizer Used For?

Fabric stabilizer, also known as fabric interfacing or simply stabilizer, is used in sewing and crafting to add support, structure, or stability to fabrics during construction.

It comes in various forms, including woven, non-woven, fusible, and adhesive-backed types, each serving different purposes depending on the project and fabric used.

Here are the common uses of fabric stabilizers:

Reinforcing Thin or Stretchy Fabrics

Lightweight or stretchy fabrics like chiffon, jersey, or knits often lack the inherent structure needed for sewing.

When working with these fabrics, the stabilizer maintains their shape and prevents distortion.

By applying a stabilizer to seams, hems, or edges, sewists can ensure the fabric remains stable throughout the sewing process.

This prevents issues like sagging or stretching out of shape, resulting in a more polished and professional-looking garment.

Embroidery and Appliqué

In embroidery and appliqué work, achieving precise and flawless stitching is paramount. Stabilizer serves as the foundation for this by supporting the fabric and preventing puckering or distortion of stitches.

Different stabilizers, such as tear-away, cut-away, or water-soluble varieties, are chosen based on the fabric and design requirements.

Tear-away stabilizers are easily removed after stitching, while cut-away stabilizers offer long-term support, and water-soluble stabilizers dissolve entirely, leaving behind only the stitched design.

Quilting

Quilting projects often involve working with delicate or loosely woven fabrics, making stabilizers indispensable for maintaining the integrity of quilt blocks.

By adding structure and stability to the fabric, the stabilizer helps quilt blocks retain their shape during piecing and quilting.

This ensures that the finished quilt maintains a professional appearance, with crisp, even seams and smooth edges.

Whether using traditional quilting techniques or experimenting with modern designs, the right stabilizer ensures that every quilt project turns out beautifully.

Fabric Manipulation Techniques

Fabric manipulation techniques like pleating, gathering, or smocking require careful control and precision to achieve the desired effect.

Stabilizer aids in this process by holding the fabric in place, allowing for accurate manipulation without distortion.

Once the desired texture or shape is achieved, the stabilizer can be easily removed, leaving behind the beautifully manipulated fabric.

Whether creating intricate details on garments or embellishing home décor items, the stabilizer provides the temporary support needed to bring creative visions to life.

Adding Body or Volume

Stabilizer is valuable for adding body or volume to fabrics, particularly in garment construction. Interfacing, a stabilizer, is commonly used in collar, cuff, and waistband construction to add structure and crispness to these areas.

By bonding interfacing to the fabric, sewists can create garments with clean lines and defined shapes, enhancing the overall look and fit.

Whether creating tailored jackets, structured dresses, or accessories like bags and hats, stabilizer ensures that garments maintain their shape and drape beautifully on the body.

Repairing and Reinforcing Fabrics

Stabilizers are not only valuable for the construction of new garments but also in repairing and reinforcing damaged fabrics.

Whether dealing with tears, holes, or worn-out seams, stabilizer supports weakened areas, extending the life of the garment or project.

By reinforcing damaged fabric with a stabilizer, sewists can effectively mend imperfections and prevent further deterioration, ensuring that cherished garments remain wearable for years.

Whether performing minor repairs or undertaking extensive alterations, the stabilizer is an invaluable tool in the sewing toolkit.

What Is the Difference Between Interfacing and Stabilizer? Stabilizer vs interfacing

Understanding the nuances between interfacing and stabilizer is crucial for any sewing enthusiast or professional.

While both are indispensable in achieving quality results in sewing projects, they serve distinct purposes and are applied in different contexts.

In this comparison, we’ll delve into the key differences between interfacing and stabilizers to elucidate their respective roles in garment construction and embroidery.

Differences Between Interfacing and Stabilizer:

| Feature | Interfacing | Stabilizer |

| Purpose | Adds structure, support, and stability to fabric | Provides support during stitching to prevent distortion |

| Application | Applied to the wrong side of fabric pieces | Placed beneath fabric during stitching |

| Longevity | Generally permanent once applied | Temporary and removed after stitching |

| Varieties | It comes in woven, non-woven, fusible, and sew-in types | Available as tear-away, cut-away, and wash-away forms |

| Usage | Reinforces collars, cuffs, waistbands, and facings | Used primarily in embroidery, appliqué, or decorative stitching |

| Effects on Fabric | Adds weight and structure, may alter drape | Provides temporary support without altering fabric |

| Removal | N/A – remains part of the finished garment | Removed post-stitching |

| Impact on Sewing Process | Applied before garment assembly | Used during embroidery or decorative stitching process |

| Adhesive Properties | Fusible types adhere with heat, sew-in requires stitching | Some types leave residue, may require trimming after use |

| Stability | Enhances shape and durability of finished garment | Prevents puckering, stretching, or distortion during stitching |

| Fabric Compatibility | Compatible with various fabric types | Compatibility depends on stabilizer type and fabric used |

| Need for Testing | May require testing on fabric scraps before application | May require testing on scraps to ensure compatibility and stability |

FAQs

Can I Use Stabilizer Instead of Interfacing?

No, stabilizer and interfacing have different purposes. Stabilizer is temporary and used during embroidery to prevent distortion, while interfacing adds permanent structure to fabric before construction.

Do interfacing and stabilizer have the same application process?

No, interfacing is applied before garment assembly, while stabilizer is placed under fabric during embroidery.

To Recap

While both interfacing and stabilizer play critical roles in sewing, they serve distinct purposes and are applied at different stages of the crafting process.

Interfacing provides permanent structure and support to fabric, reinforcing areas such as collars and cuffs, whereas stabilizer is a temporary material used during embroidery to prevent distortion.

The application methods, longevity, and effects on fabric vary. Understanding these differences is essential for achieving professional-quality results in sewing projects.

Crafters can ensure optimal durability, appearance, and functionality in their creations by selecting the appropriate interfacing and stabilizer types for each specific task.

Mastering both interfacing and stabilizer enhances the overall craftsmanship and success of sewing endeavors.

Leave a Reply