Embarking on sewing projects often involves exploring various materials, and the question of whether it’s acceptable to use wax thread with sewing machines is a common inquiry.

In the realm of traditional hand-sewing, waxed threads are favored for their durability and smooth stitching. However, transitioning this practice to sewing machines demands careful consideration.

Choosing a high-quality waxed thread can minimize potential issues, ensuring a smoother sewing experience. So, is it okay to use wax thread with sewing machines?

While generally permissible, using waxed thread introduces nuances such as potential friction and residue concerns.

This article delves into the compatibility factors, offering insights into needle selection, thread tension adjustments, and machine maintenance.

Manufacturers may provide specific guidelines, and experimenting with small test pieces becomes crucial.

By understanding the dynamics of using wax thread with sewing machines, enthusiasts can strike the right balance for optimal results in their crafting endeavors.

Is It Okay To Use Wax Thread With Sewing Machines?

The waxed thread has long been favored in traditional hand-sewing for its enhanced durability and the smooth finish it imparts to stitches.

This popularity arises from the wax coating on the thread, which not only strengthens it but also allows for easier penetration through fabrics.

This characteristic makes waxed thread particularly appealing for projects that demand robust stitching, such as leatherwork or outdoor gear construction.

However, transitioning from hand-sewing to machine sewing introduces a new set of dynamics. While using waxed thread on a sewing machine is generally acceptable, there are some important factors to take into account to ensure a seamless and trouble-free experience.

Here are more details on whether can you use waxed thread in a sewing machine:

Needle Selection

Choosing the right needle is paramount when working with waxed thread on a sewing machine. The wax coating can create additional friction, so selecting a needle appropriate for the thread size and fabric type is crucial.

A larger needle may help accommodate the waxed thread more smoothly, preventing undue stress on the machine.

Thread Tension Adjustment

Waxed thread may behave differently than regular sewing thread due to its coating. As a result, adjusting the thread tension on the sewing machine becomes essential.

Experimenting with different tension settings on a scrap piece of fabric can help fine-tune the machine for optimal results.

Experimentation and Test Pieces

Before embarking on a full-scale project, it’s advisable to conduct experiments on small test pieces. This allows sewers to observe how the waxed thread interacts with the machine and make necessary adjustments.

It’s an opportunity to refine settings, identify any potential challenges, and ensure that the machine can handle the waxed thread effectively.

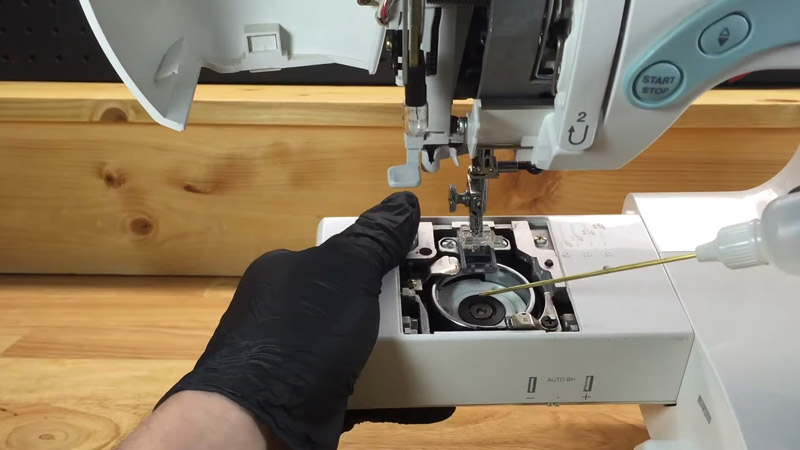

Machine Maintenance

The wax from the thread can leave residue in the sewing machine over time. Regular maintenance, including cleaning the machine and oiling its parts, is crucial to prevent buildup.

Neglecting this aspect could lead to decreased machine performance and potential issues in the long run.

Manufacturer Guidelines

Consulting the sewing machine’s manual and any guidelines provided by the manufacturer is indispensable. Some machines may have specific recommendations or precautions when it comes to using waxed thread.

Adhering to these guidelines can help avoid unnecessary complications and ensure the longevity of the machine.

Friction Concerns

One of the primary considerations when using waxed thread with sewing machines is the potential for increased friction. The wax coating can generate more heat during the sewing process, affecting both the thread and the machine.

Monitoring the sewing speed and making adjustments as needed can mitigate excessive friction and prevent overheating.

Residue Management

Addressing residue concerns is pivotal for maintaining the integrity of the sewing machine. Regularly cleaning the machine, especially in areas where wax residue may accumulate, prevents clogs and ensures smooth operation.

This practice is particularly important for those who frequently work with waxed thread.

Regular Maintenance

While using wax thread with sewing machines is permissible and even advantageous for certain projects, it demands a proactive approach from the user.

The delicate balance lies in understanding the unique characteristics of waxed thread, adapting machine settings accordingly, and prioritizing ongoing maintenance.

What Is Waxed Thread Used For?

Waxed thread, a versatile and durable material, finds application across various crafting disciplines, adding strength, resilience, and a distinctive finish to projects.

Whether in traditional handcrafts or modern creations, the unique properties of waxed thread make it a popular choice for a wide range of applications.

Waxed Thread for sewing Leather

One of the primary domains where waxed thread shines is in leatherworking. It’s probably the best thread for leather sewing. The robust nature of waxed thread makes it ideal for stitching leather, a material known for its toughness.

Whether crafting leather accessories, belts, bags, or even saddlery, the waxed thread enhances the overall durability of the stitches and provides a polished appearance.

The wax coating also aids in smooth needle penetration, ensuring a secure and lasting bond in leather projects. Wax thread for leather is the most widespread use of this unique sewing accessory.

Outdoor Gear and Equipment

Waxed thread‘s resistance to environmental elements makes it a preferred choice for outdoor gear and equipment. Items like tents, backpacks, and outdoor clothing often require strong and weather-resistant seams.

Waxed linen thread excels in such applications, contributing to the longevity and reliability of these products.

The wax coating provides an additional layer of protection against moisture, enhancing the performance of outdoor gear in challenging conditions.

Shoemaking

In the realm of shoemaking, where endurance and quality are paramount, waxed thread is a staple. It is employed for stitching various components of shoes, from attaching soles to securing leather uppers.

The waxed thread not only reinforces the structural integrity of the footwear but also contributes to a polished and refined aesthetic.

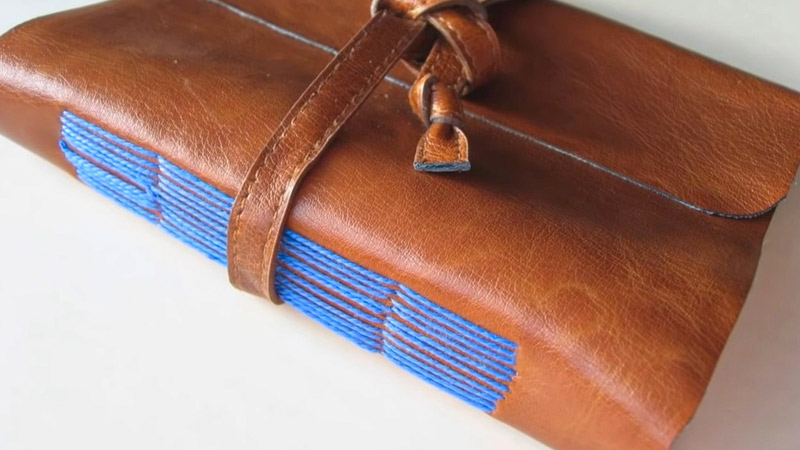

Bookbinding

In the meticulous art of bookbinding, where precision and durability are essential, waxed thread plays a crucial role. Bookbinders use waxed thread to sew together signatures, securing the pages and creating a sturdy spine.

This application ensures that the bound books withstand the test of time, maintaining their structural integrity even with frequent use.

Jewelry Making

Waxed thread finds its way into the realm of jewelry making, particularly in creating macramé and knotted jewelry.

Its strength and malleability make it suitable for intricate knotting patterns, providing a stable foundation for various beadwork and embellishments.

The waxed coating also adds a subtle sheen, enhancing the overall visual appeal of the finished jewelry.

Canvas and Fabric Projects

In projects involving canvas or fabric, such as bags, upholstery, or even clothing, waxed thread offers a robust stitching solution.

The waxed coating not only reinforces the thread but also provides a level of water resistance, making it suitable for items exposed to the elements.

This versatility extends to crafting sails for boats, where the combination of strength and weather resistance is paramount.

DIY Crafts and hand-sewing

Beyond specialized applications, waxed thread is a favorite among DIY enthusiasts and hobbyists engaged in various hand-sewing projects.

Its versatility allows for the creation of durable and aesthetically pleasing items, from hand-stitched wallets and accessories to custom clothing pieces.

The added benefit of the waxed coating facilitates smoother stitching, making it accessible for individuals with varying skill levels.

Beading and Loom Work

Waxed thread is a popular choice in beading and loom work due to its strength and ability to maintain tension. It provides a secure foundation for intricate bead patterns and weaving projects.

The waxed coating prevents fraying and tangling, ensuring a smooth beading experience and a durable final product.

Fly Tying

In the world of fly fishing, where precision and strength are critical, waxed thread is often used for fly tying. So, why wax thread? Anglers use it to secure feathers, fur, and other materials to create intricate and effective fly patterns.

The waxed thread’s durability ensures that the flies withstand the rigors of fishing, offering a reliable tool for anglers.

FAQs

Can I use waxed thread with a sewing machine?

Yes, you can use waxed thread with a sewing machine, but it requires some considerations. Adjust the machine settings, choose an appropriate needle size, and monitor for potential friction or residue buildup. Regular maintenance is essential to ensure optimal performance.

What projects are suitable for the waxed thread?

Waxed thread is well-suited for leatherworking, outdoor gear, shoemaking, bookbinding, jewelry making, canvas and fabric projects, DIY crafts, beading, loom work, and fly tying.

Does waxed thread work well with hand-sewing?

Yes, the waxed thread is commonly used in hand-sewing projects. Its wax coating enhances smooth stitching, provides strength to the stitches, and offers a polished finish.

This makes it popular for various crafting disciplines, from leatherworking to DIY crafts.

How do I prevent residue buildup when using waxed thread with a sewing machine?

To prevent residue buildup, regularly clean your sewing machine, especially in areas prone to wax accumulation. Follow the manufacturer’s guidelines for maintenance.

Choosing a high-quality waxed thread can also minimize residue-related issues during machine sewing.

What’s the best thread wax alternative?

Beeswax is a commonly recommended alternative to commercial thread wax. It offers similar benefits, such as reducing friction and strengthening the thread. Simply run the thread through beeswax to coat it before sewing.

Other alternatives include paraffin wax or silicone-based thread conditioners, depending on the project and personal preference.

Conclusion

Delving deeper into the fusion of tradition and modernity, the practice of using wax thread with sewing machines presents a captivating interplay between age-old craftsmanship and contemporary conveniences.

While the essence of waxed threads remains rooted in the time-honored virtues of durability and smooth stitching, seamlessly integrating this tradition with the precision of sewing machines requires a nuanced approach.

In the final stitches of a project, the importance of thoughtful considerations becomes evident. Selecting the appropriate needle size and fine-tuning thread tension emerge as crucial factors, shaping the outcome of the sewing endeavor.

Yet, the journey extends beyond the stitching itself; it encompasses the ongoing care of the machine.

Regular maintenance routines and periodic cleaning rituals become imperative to counteract potential issues like increased friction or residue buildup.

This way, you’re one step ahead in creating a harmonious symphony of tradition and innovation in the vibrant world of sewing.

Leave a Reply