Leno fabric, also known as gauze fabric or cross weave, is a unique and captivating textile that combines sheer delicacy with surprising durability. Its distinct open weave structure sets it apart from other fabrics, allowing light and air to pass through and creating a mesh-like appearance.

Leno fabric has a rich history, originating from ancient weaving techniques and evolving over time to meet contemporary fashion and design needs. This versatile fabric finds its application in various areas, from elegant window treatments to lightweight apparel and accessories.

With its breathability, flexibility, and visual appeal, Leno fabric adds a touch of elegance and ethereal beauty to any project. Understanding the characteristics and uses of Leno fabric opens up a world of creative possibilities for designers, fashion enthusiasts, and interior decorators alike.

What is Leno Fabric?

Leno fabric, also known as gauze fabric or cross weave, is a type of woven fabric characterized by its open and sheer structure. It is created using a special weaving technique where pairs of warp threads are twisted around each other, trapping the weft threads in between.

This twisting action creates a stable and durable fabric with a distinctive mesh-like appearance. Leno fabric is lightweight, breathable, and allows light and air to pass through, making it suitable for applications such as window treatments, sheer layers in clothing, and lightweight accessories. Despite its delicate appearance, Leno fabric can exhibit surprising strength and resilience.

History of Leno Fabric

The history of Leno fabric dates back centuries. The technique is believed to have originated in India and was later adopted by different cultures around the world.

Leno weaving gained popularity in Europe during the 19th century. Initially woven by hand, Leno fabric production transitioned to power looms during the industrial revolution.

The open and airy nature of Leno fabric made it suitable for various applications, including lightweight garments and window coverings. Over time, advancements in textile machinery and techniques have further refined the production of Leno fabric.

Today, it continues to be appreciated for its delicate yet durable characteristics and its versatile uses in fashion and interiors.

Characteristics of Leno Fabric

Sheer

Leno fabric is known for its sheer and transparent appearance. It features an open weave structure that creates a mesh-like pattern, allowing light to pass through easily.

This property makes Leno fabric ideal for applications where a lightweight and delicate appearance is desired.

Durable

Despite its delicate appearance, Leno fabric is surprisingly durable. The interlacing yarns in the open weave construction provide strength and stability to the fabric.

This durability makes Leno fabric capable of withstanding regular use and washing without easily tearing or losing its shape.

Staple

Leno fabric is often considered a staple in the textile industry due to its versatility. It can be used for various purposes, ranging from fashion garments such as sheer blouses, dresses, and scarves to practical items like curtains, mosquito nets, and bandages.

Open Weave

Leno fabric is characterized by its open weave structure, which is created by crossing two warp yarns over a weft yarn in a figure-eight pattern. This unique weaving technique results in a stable fabric with an open, breathable structure.

The open weave allows air to circulate freely through the fabric, making it ideal for warm-weather clothing and applications where breathability is essential.

Gauze-like

Leno fabric is often referred to as gauze fabric due to its similarities in appearance and texture to traditional medical gauze. This resemblance is primarily because both fabrics feature an open mesh-like structure that allows for enhanced air circulation and comfort.

Light and Air Can Pass Through

Leno fabric is lightweight and has a loosely woven structure, allowing both light and air to pass through it easily. This property contributes to the fabric’s breathability, making it comfortable to wear in hot and humid conditions.

Breathable

The open weave structure of Leno fabric facilitates air circulation, resulting in excellent breathability. This characteristic makes Leno fabric ideal for clothing items that need to be comfortable and cool, particularly in warm climates or during physical activities.

Flexible

Leno fabric has a certain degree of flexibility and drape, which allows it to conform to the body’s contours or adapt to various design requirements. This flexibility makes it easy to work with when sewing garments or creating decorative elements.

Types of Leno Fabric

Here are some common types of Leno fabric:

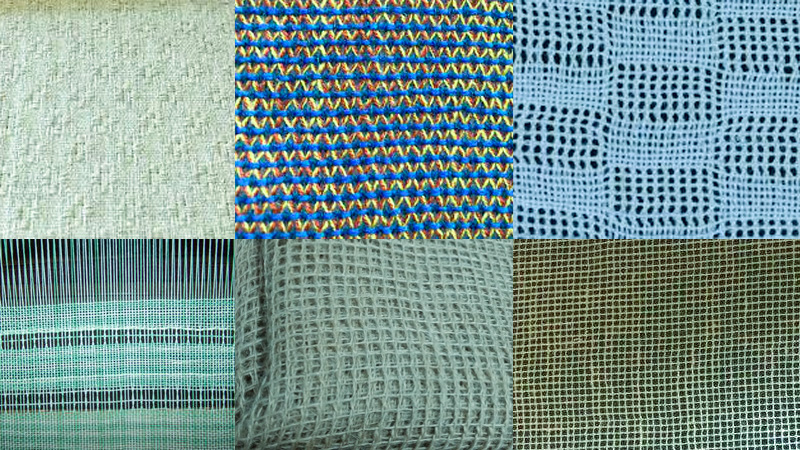

Plain Leno Weave

In plain Leno weave, also known as 2-end plain Leno or triple plain Leno, the yarns cross over each other in a simple figure-eight pattern. This type of Leno fabric is characterized by its open and airy appearance, with a mesh-like structure.

Plain Leno weave is often used for lightweight and sheer fabrics, such as curtains, mosquito nets, and delicate apparel.

Leno Gauze

Leno gauze is a type of Leno fabric that closely resembles traditional medical gauze. It features a loosely woven structure with a high count of warp and weft yarns, resulting in a lightweight, breathable, and highly absorbent fabric.

Leno gauze is commonly used in medical applications, such as wound dressings, bandages, and surgical drapes.

Unidirectional Leno

Unidirectional Leno fabric is designed with a specific directionality in mind. In this type of Leno weave, the figure-eight pattern is modified to create a bias or diagonal effect.

Unidirectional Leno fabric is often used in applications where strength and stability are required, such as reinforcement materials in composites, geotextiles, and technical fabrics for industrial purposes.

What is Leno Fabric Made of?

Yarn Selection

The first step in creating Leno fabric is to select suitable yarns for the warp and weft. The warp yarns are the vertical yarns that run lengthwise in the fabric, while the weft yarns are the horizontal yarns that interlace with the warp yarns during weaving.

The choice of yarns can vary depending on the desired characteristics of the fabric, such as strength, sheerness, or absorbency.

Warping

Once the yarns are selected, the warp yarns are wound onto a warping beam. This process involves carefully measuring and aligning the warp yarns to ensure they are evenly tensioned and ready for weaving.

Loom Setup

The next step is to set up the loom for weaving. The warp yarns are threaded through the loom’s heddles and reed, which are the components that control the up-and-down movement of the yarns during weaving.

The doup yarns, also known as skeleton or twisting yarns, are added to the setup. These doup yarns are paired with the standard warp yarns and play a crucial role in creating the Leno weave structure.

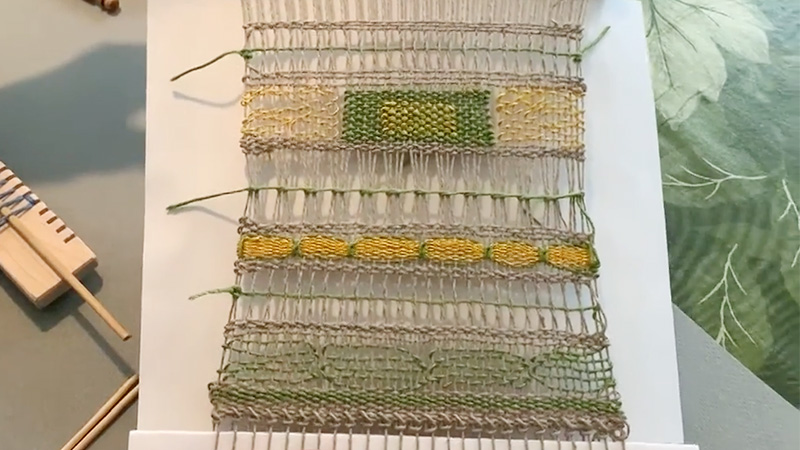

Leno Weaving

With the loom set up, the actual weaving process begins. The weaver operates the loom, passing the weft yarns through the shed created by the up-and-down movement of the warp yarns.

In Leno weaving, instead of the standard over-under interlacement of the weft and warp yarns, the doup yarns twist around the weft yarns. This twisting action helps to secure the weft yarns in place, providing strength to the fabric.

Finishing

Once the desired length of fabric is woven, it goes through a finishing process. This may include procedures such as washing, dyeing, or other treatments to improve the fabric’s appearance, texture, or performance.

What is Leno Fabric Used for?

Window Treatments

Leno fabric is frequently employed for window treatments such as curtains, drapes, and sheer panels. Its sheer and lightweight nature allows diffused light to enter while providing a level of privacy.

Leno fabric’s open weave structure also facilitates airflow, making it an ideal choice for window coverings in warm climates.

Fashion and Apparel

Leno fabric is popular in the fashion industry for creating lightweight and breathable clothing items. It is often used for layering in garments, such as overlays, veils, and sheer panels. Leno fabric can add an ethereal and delicate touch to dresses, blouses, scarves, and other fashion accessories.

Medical and Healthcare Products

Leno gauze, a type of Leno fabric, is commonly utilized in the medical and healthcare sectors. It is used to create wound dressings, bandages, surgical drapes, and other medical textiles.

The open mesh-like structure of Leno fabric allows for enhanced breathability and absorbency, making it suitable for wound care and sterilization purposes.

Technical Textiles

Leno fabric’s durability and strength can be further enhanced by using glass fibers or other strong yarns. When reinforced with such materials or permeated with strengthening compounds, Leno fabric can be employed as an engineering material in construction and technical applications. It is used for applications such as geotextiles, reinforcement materials in composites, and industrial fabrics.

Home Furnishings

Leno fabric finds its way into various home furnishing products. It is used for creating tablecloths, napkins, placemats, and decorative pillow covers. The sheer and lightweight nature of Leno fabric adds an airy and elegant touch to interior decor.

Mosquito Nets

Leno fabric’s open weave structure makes it an excellent choice for manufacturing mosquito nets. The fabric allows air circulation while acting as a barrier against mosquitoes and other insects, providing protection and comfort during sleep.

Crafts and Diy Projects

Leno fabric’s unique appearance and texture make it a popular choice for craft enthusiasts. It can be used for creating decorative elements, such as curtains, lampshades, dream catchers, and textured artwork.

What is the Leno Method?

Here is a breakdown of the Leno method:

Warp Thread Preparation

The first step in the Leno method is to prepare the warp threads. These are the vertical threads that run lengthwise on the loom. Depending on the desired fabric characteristics, the number and type of warp threads can vary. Traditionally, the warp threads are made of a strong and durable material such as cotton, linen, or synthetic fibers.

Pairing and Twisting

In the Leno method, the warp threads are divided into pairs. Each pair consists of two adjacent warp threads. To create the Leno effect, these pairs are twisted around each other.

This twisting action can be done manually by hand or with the help of specialized tools such as a weaving shuttle or a doup attachment on the loom.

Weft Insertion

Once the pairs of warp threads are twisted, the weft threads are inserted. The weft threads, also known as filling or woof, are the horizontal threads that interlace with the warp threads.

The weft is passed through the open areas created by the twisted pairs of warp threads. As the weft passes through, it gets “trapped” or secured by the twist in the warp threads, which prevents the fabric from unraveling and maintains its stability.

Repeating the Process

The pairing, twisting, and weft insertion process is repeated across the entire width of the fabric. The weaver carefully guides the weft thread through the open areas created by the twisted warp pairs, ensuring that the fabric structure remains consistent throughout.

The Leno method is often performed on a simple frame loom or a floor loom, but it can also be done by hand using handheld tools. It requires skill and attention to detail, as the weaver must manage the twisting and insertion process to maintain an even and stable fabric structure.

Is Leno Weave Durable?

Leno weave is known for its durability despite its sheer and open structure. The durability of Leno fabric is attributed to the unique weaving technique employed in its creation.

In Leno weave, four warp threads are twisted around each other, creating a stable and secure fabric structure. This twisting action helps to lock the weft threads in place, preventing them from slipping or unraveling.

The resulting fabric is able to withstand regular use, washing, and general wear without easily tearing or losing its shape. Leno weave’s durability makes it suitable for a range of applications, including window treatments, apparel, and technical textiles where both strength and sheerness are desired.

How Do You Wash Leno Fabric?

Check the Label

Always refer to the care label or any specific instructions provided by the manufacturer. The label may include specific washing instructions tailored to the particular Leno fabric you have.

Hand Wash or Gentle Machine Wash

In most cases, it is recommended to hand wash Leno fabric to avoid excessive agitation that may damage the delicate open weave. Fill a basin or sink with lukewarm water and a mild detergent suitable for delicate fabrics. Gently agitate the fabric in soapy water, taking care not to twist or wring it.

Avoid Bleaching

Bleaching agents, including chlorine bleach, should be avoided when washing Leno fabric. They can weaken the fabric and cause discoloration.

Rinse Thoroughly

After washing, rinse the fabric thoroughly with clean water to remove any residual soap or detergent. Press the fabric gently between your hands or against the side of the basin to remove excess water.

Drying Leno Fabric

To dry Leno fabric, avoid wringing or twisting it. Instead, lay the fabric flat on a clean, dry towel or hang it on a clothesline, ensuring it is supported evenly to maintain its shape. Avoid direct sunlight and heat sources that can cause fading or damage.

Ironing

If needed, iron the Leno fabric on a low heat setting while it is still slightly damp. Place a pressing cloth or a clean, white cloth between the iron and the fabric to prevent direct contact. Avoid using a steam setting, as it can distort the open weave.

How to Care for Leno Clothes?

Here are some tips on how to care for Leno’s clothes:

Read the Care Label

Always check the care label attached to your Leno clothing for specific instructions provided by the manufacturer. The label may include information about washing, drying, and ironing methods tailored to the specific fabric.

Hand Washing

It is generally recommended to hand wash Leno clothes to prevent damage to the delicate fabric. Fill a basin or sink with lukewarm water and add a mild detergent suitable for delicate fabrics. Gently swirl the clothes in the soapy water, avoiding excessive agitation. Rinse thoroughly with clean water.

Machine Washing

If the care label permits machine washing, place the Leno clothes in a mesh laundry bag to protect them from snagging or tangling with other garments.

Select a gentle or delicate cycle with cold water and use a mild detergent. Avoid mixing Leno clothes with heavy or abrasive items.

Avoid Bleaching

Bleaching agents, including chlorine bleach, should be avoided when washing Leno clothes. They can weaken the fabric and cause discoloration. Instead, opt for gentle, color-safe bleach alternatives if necessary.

Drying

After washing, gently squeeze out excess water from the Leno clothes without wringing or twisting them. Lay them flat on a clean, absorbent towel and roll the towel to remove more moisture.

Reshape the clothes and lay them flat to air dry on a clean, dry surface away from direct sunlight or heat sources that could damage the fabric.

Ironing

If needed, iron Leno clothes on a low heat setting while they are still slightly damp. Place a pressing cloth or a clean, white cloth between the iron and the fabric to prevent direct contact. Avoid using a steam setting as it can distort the open weave. Iron gently, in short strokes, and avoid excessive pressure.

Storage

When not in use, store Leno clothes in a cool, dry place away from direct sunlight to prevent fading. It is recommended to fold them instead of hanging to maintain their shape and minimize stretching.

How to Sew Leno Fabric?

Here are some tips on how to sew Leno fabric:

Use a Sharp Needle

When sewing Leno fabric, it’s essential to use a sharp needle that is appropriate for the fabric type. A fine or microtex needle is a good choice, as it can easily penetrate the fabric without causing excessive damage or creating large holes.

Thread Selection

Opt for a high-quality thread that matches the color and weight of the Leno fabric. A fine thread, such as a lightweight polyester or cotton thread, works well for sewing Leno fabric without adding unnecessary bulk.

Adjust Stitch Length and Tension

Depending on the specific Leno fabric you’re working with, you may need to adjust the stitch length and tension on your sewing machine. Test on a scrap piece of fabric to determine the optimal settings that create secure stitches without causing the fabric to pucker or distort.

Seam Finishing

Since Leno fabric has an open weave, it’s important to finish the seams to prevent fraying. Consider using techniques such as French seams, narrow hems, or serging the edges to enclose the raw edges and provide a clean and neat finish.

Use Lightweight Presser Foot

A lightweight or Teflon-coated presser foot can help glide smoothly over the Leno fabric without catching or pulling the delicate threads. If necessary, you can also place a piece of tissue paper or stabilizer under the fabric to provide extra support during sewing.

Pinning and Tension Control

When pinning Leno fabric, use fine, sharp pins and place them within the seam allowance to minimize visible holes. Be mindful not to pull or stretch the fabric while sewing, as it can distort the open weave. Use your fingers to guide the fabric gently and maintain even tension.

Test and Practice

Before starting your actual sewing project with Leno fabric, it’s advisable to test different stitches, tensions, and techniques on a scrap piece of fabric. This will help you become familiar with how the fabric behaves and determine the best sewing approach for your specific project.

How Does Leno Fabric Impact the Environment?

Material Selection

The choice of materials used in Leno fabric can influence its environmental impact. Natural fibers like cotton and linen are renewable and biodegradable, making them more environmentally friendly options.

However, the production of these fibers can still have environmental implications, such as water consumption and pesticide use. Synthetic fibers, such as polyester, may have a lower impact in terms of water usage but are derived from non-renewable resources and can contribute to microplastic pollution.

Manufacturing Processes

The manufacturing processes involved in producing Leno fabric can have environmental consequences. Energy consumption, water usage, and chemical treatments during the dyeing and finishing stages can contribute to pollution and resource depletion.

Eco-friendly production practices, such as using low-impact dyes, water recycling systems, and energy-efficient machinery, can help reduce the environmental footprint.

Waste and End-of-life

The disposal of Leno fabric can impact the environment. If Leno fabric is made from natural fibers, it can biodegrade over time, minimizing its impact in landfills.

However, if it contains synthetic fibers, it may take a long time to break down, contributing to microplastic pollution. Recycling and upcycling Leno fabric at the end of its life can help reduce waste and extend its usefulness.

Durability and Longevity

Leno fabric’s durability and longevity can influence its environmental impact. If the fabric is well-made and can withstand regular use and washing, it reduces the need for frequent replacements, thus reducing overall resource consumption and waste generation.

Sustainable Production Practices

Some manufacturers and brands are adopting sustainable and eco-friendly practices in Leno fabric production. This includes using organic or recycled fibers, implementing water and energy-saving technologies, and ensuring fair labor practices throughout the supply chain. Choosing Leno fabrics from such sources can help support more sustainable options.

What Are the Advantages and Disadvantages of Leno Fabric?

Advantages of Leno Fabric

- Sheer and Lightweight: Leno fabric is known for its sheer and lightweight nature, allowing light and air to pass through. This makes it ideal for applications where breathability and a delicate appearance are desired, such as in window treatments or lightweight apparel.

- Durability: Despite its open weave, Leno fabric can be surprisingly durable. The twisted pairs of warp threads provide stability and strength to the fabric, making it resistant to tearing or unraveling.

- Versatility: Leno fabric’s unique texture and appearance make it a versatile choice for various applications. It can be used for both decorative and functional purposes, including window coverings, bridal veils, scarves, and lightweight garments.

- Breathability: The open weave structure of Leno fabric allows for good airflow, making it breathable and comfortable to wear in warm weather conditions.

- Visual Appeal: Leno fabric has a distinct mesh-like or gauze-like appearance, which adds visual interest and texture to garments or home decor items. It can create an ethereal and delicate look, adding a touch of elegance to designs.

Disadvantages of Leno Fabric

- Delicate Nature: Leno fabric’s open weave and delicate structure make it susceptible to snagging or catching on sharp objects. It requires careful handling during sewing, wearing, and laundering to avoid damage.

- Limited Warmth: Due to its sheer and lightweight nature, Leno fabric may not provide significant warmth, making it less suitable for cold-weather garments or applications where insulation is required.

- Proneness to Wrinkling: Leno fabric can be prone to wrinkling, especially if made from natural fibers. It may require extra care during storage and ironing to maintain a smooth appearance.

- Special Care Requirements: Leno fabric often requires specific care instructions to preserve its delicate structure and prevent damage. It may need to be hand washed or washed on gentle cycles, and ironed at low temperatures to avoid distortion.

- Limited Opacity: While the sheer quality of Leno fabric is desirable in many applications, it may not be suitable for situations where opacity or privacy is required.

Comparison Table Between Leno Fabric and Other Fabrics

| Property | Leno Fabric | Organza | Voile | Chiffon |

|---|---|---|---|---|

| Sheerness | Sheer | Sheer | Sheer | Very sheer |

| Durability | Durable | Delicate | Delicate | Delicate |

| Breathability | Breathable | Breathable | Breathable | Breathable |

| Weight | Lightweight | Lightweight | Lightweight | Lightweight |

| Drapability | Moderate | Moderate | Moderate | Excellent |

| Texture | Mesh-like | Crisp | Smooth | Soft, flowing |

| Opacity | Semi-opaque | Semi-opaque | Semi-opaque | Translucent |

| Common Uses | Window treatments | Formal wear | Curtains, scarves | Dresses, blouses |

| Fiber Composition | Various | Silk, synthetic | Cotton, silk | Silk, synthetic |

| Cost | Moderate | Moderate to high | Moderate | Moderate to high |

| Care Requirements | Gentle handling | Delicate handling | Delicate handling | Delicate handling |

FAQs

Leno fabric is generally not recommended for prolonged outdoor use, especially in harsh weather conditions. Its open weave structure may make it more susceptible to damage from wind, rain, and UV exposure. However, there are variations of Leno fabric that are specifically designed for outdoor applications and are treated to enhance their durability and weather resistance.

Yes, Leno fabric can be dyed. However, the open weave structure may affect the dyeing process, as the color absorption may be less even or consistent compared to tightly woven fabrics. It’s important to follow the manufacturer’s recommendations for dyeing or consult a professional to ensure the best results.

Leno fabric is not typically recommended for heavy-duty or high-stress applications. While it can be surprisingly durable for its lightweight nature, it may not have the strength or stability required for heavy loads or intense wear and tear. It is best suited for lightweight and decorative applications.

Leno fabric is generally not ideal for upholstery applications. Its open weave may not provide the necessary strength and stability required for upholstery projects that involve regular use and heavy seating. However, Leno-inspired designs or variations with reinforced structures can be used for decorative purposes or in limited upholstery applications.

Yes, Leno fabric can be layered with other fabrics to create interesting textures and visual effects. It can be used as an overlay or as a sheer layer to add depth and dimension to garments, curtains, or other textile projects. Layering Leno fabric with opaque or contrasting materials can create unique design elements.

To Recap

Leno fabric is a unique and versatile fabric known for its sheer, lightweight, and open weave structure. Its durability, despite its delicate appearance, sets it apart from other sheer fabrics.

Leno fabric allows light and air to pass through, making it suitable for various applications such as window treatments, sheer layers in clothing, and lightweight accessories.

Its breathability and flexibility provide comfort in warm weather conditions. While Leno fabric has its advantages, it also has considerations. It requires delicate handling, and special care during sewing, and may not be suitable for heavy-duty or high-stress applications.

However, when used appropriately and with proper care, Leno fabric can add a touch of elegance, texture, and visual interest to a wide range of fashion and interior projects. Its historical significance and continued popularity in the textile industry highlight its enduring appeal and timeless charm.

Leave a Reply