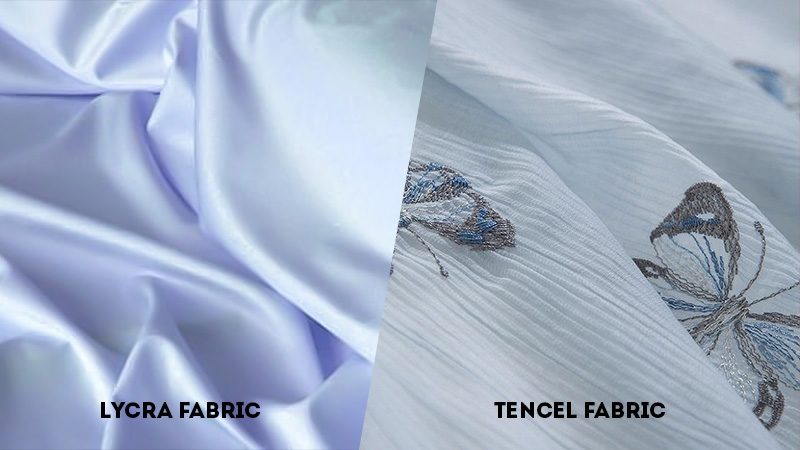

Fabric choices have a significant impact on the performance, comfort, and sustainability of clothing. Two distinct fibers, Lycra (Spandex/Elastane) and Tencel (Lyocell), stand out for their unique properties and applications.

Lycra, a highly elastic synthetic material, excels in providing stretch and support, making it a staple in sportswear and activewear.

On the other hand, Tencel, derived from renewable wood pulp, offers softness, breathability, and eco-friendliness, making it a preferred option for comfortable, sustainable fashion.

This introduction explores the differences between Lycra and Tencel, shedding light on their diverse characteristics and contributions to the textile industry.

Key Differences Between Lycra and Tencel

Fiber Type

- Lycra (Spandex/Elastane): Lycra is a synthetic fiber made from petrochemicals, known for its exceptional elasticity. It is highly stretchable, capable of expanding 5-8 times its size, making it a popular choice for sportswear and form-fitting garments. However, being synthetic, it is non-biodegradable and contributes to plastic waste.

- Tencel (Lyocell): Tencel, on the other hand, is a cellulosic fiber derived from sustainable wood pulp, making it more eco-friendly. It offers moderate elasticity, is exceptionally soft and smooth, and has excellent moisture-wicking properties, making it suitable for apparel and bedding. Its biodegradability sets it apart as an environmentally conscious option.

Elasticity

- Lycra (Spandex/Elastane): Lycra is renowned for its outstanding elasticity, making it one of the most stretchable synthetic fibers available. It can stretch up to 5-8 times its original size and quickly return to its initial shape without losing its elasticity. This unique property makes Lycra ideal for sportswear, activewear, and garments that require a snug fit and excellent shape retention.

- Tencel (Lyocell): Tencel, while also possessing some stretchability, does not match the high elasticity of Lycra. It exhibits moderate elasticity, providing a comfortable and relaxed drape without excessive stretching. Though not suitable for compression garments like Lycra, Tencel’s gentle stretch ensures ease of movement in apparel. This property makes Tencel a preferred choice for loose-fitting clothing and garments that prioritize comfort over compression.

Fabric Softness

- Lycra (Spandex/Elastane): Compared to Tencel, Lycra may not be as soft to the touch. While Lycra’s primary focus lies in its elasticity and stretchability, it does not provide the same level of inherent softness as natural fibers like Tencel. To counteract this, Lycra is often blended with other materials like cotton or modal to combine its stretch with the softness of these natural fibers, creating a more comfortable fabric.

- Tencel (Lyocell): Tencel is highly regarded for its luxurious softness and smooth texture. Derived from sustainable wood pulp, Tencel fibers are naturally soft and gentle against the skin, making them a preferred choice for sensitive skin or individuals seeking comfortable clothing. The fabric’s softness adds to its appeal in garments like shirts, dresses, and bedding, where comfort is paramount.

Moisture Absorption

- Lycra (Spandex/Elastane): Lycra has limited moisture absorption capabilities due to its synthetic nature. While it can wick away some moisture, it is not as efficient in managing sweat or moisture as natural fibers like Tencel. As a result, garments with a high percentage of Lycra may feel clingy and less breathable during intense physical activities.

- Tencel (Lyocell): Tencel is renowned for its exceptional moisture absorption and moisture-wicking properties. The cellulosic structure of Tencel fibers enables them to efficiently absorb moisture from the skin, dispersing it across the fabric’s surface and allowing it to evaporate quickly. This moisture management feature makes Tencel perfect for activewear, as it keeps the wearer cool and dry during workouts and other physical activities.

Breathability

- Lycra (Spandex/Elastane): Due to its synthetic nature and limited moisture absorption capabilities, Lycra is generally less breathable than natural fibers like Tencel. While Lycra provides excellent support and stretch, garments with a high Lycra content may trap heat and moisture, leading to discomfort, especially in hot and humid conditions.

- Tencel (Lyocell): Tencel is highly breathable, allowing air circulation through the fabric. Its moisture-wicking properties, combined with its softness, contribute to a comfortable and cool wearing experience. Tencel’s breathability makes it an excellent choice for warm weather clothing and activewear, ensuring the wearer stays fresh and dry throughout the day.

Eco-friendliness

- Lycra (Spandex/Elastane): Lycra is a synthetic fiber derived from petrochemicals, making it less eco-friendly than natural fibers. Its production process involves the use of petroleum-based resources, which have a significant environmental impact. Additionally, being non-biodegradable, Lycra contributes to plastic waste and takes a long time to decompose, further adding to environmental concerns.

- Tencel (Lyocell): Tencel stands out for its eco-friendliness. It is made from sustainably sourced wood pulp, typically obtained from eucalyptus or beech trees. The production of Tencel involves a closed-loop manufacturing process where the solvent used to dissolve the wood pulp is recycled and reused, minimizing waste and reducing the impact on the environment. Moreover, Tencel is biodegradable, meaning it can naturally break down without harming the environment.

Manufacturing Process

- Lycra (Spandex/Elastane): The manufacturing process of Lycra involves a complex chemical synthesis using petrochemical-derived materials. This process requires significant energy consumption and produces harmful chemical by-products, contributing to environmental pollution. The production of Lycra is more energy-intensive and less sustainable compared to the manufacturing of natural fibers.

- Tencel (Lyocell): Tencel is manufactured using an environmentally friendly lyocell process. It begins with the dissolving of wood pulp in a non-toxic solvent called NMMO (N-Methylmorpholine N-oxide). The solvent is almost entirely recycled and used repeatedly in a closed-loop system, resulting in minimal waste generation. This closed-loop process reduces water consumption and chemical emissions, making Tencel a sustainable and eco-conscious choice.

Origin of Raw Material

- Lycra (Spandex/Elastane): The raw materials used to produce Lycra are derived from petrochemicals, which are non-renewable resources. The extraction and processing of these materials involve extensive drilling and refining of crude oil, which has a detrimental impact on the environment. Additionally, the dependence on non-renewable resources makes Lycra less sustainable in the long term.

- Tencel (Lyocell): The raw material for Tencel is obtained from renewable wood pulp. Eucalyptus and beech trees, which are commonly used to produce Tencel, are fast-growing and require minimal water and pesticides. This sustainable sourcing of raw materials ensures the long-term viability of Tencel as an eco-friendly fiber option.

Sustainability

- Lycra (Spandex/Elastane): Due to its synthetic nature and reliance on petroleum-based resources, Lycra has limited sustainability. The production process and non-renewable raw materials contribute to its overall environmental impact. While Lycra does offer durability and long-lasting performance, its sustainability credentials are comparatively lower than natural, biodegradable alternatives.

- Tencel (Lyocell): Tencel is considered highly sustainable. Its manufacturing process employs a closed-loop system, reducing waste and water consumption. The use of renewable wood pulp as raw material and its biodegradability contribute to its eco-friendliness. Tencel’s sustainable attributes make it a popular choice for environmentally conscious consumers seeking greener textile options.

Biodegradability

- Lycra (Spandex/Elastane): Lycra is not biodegradable, as it is made from synthetic petrochemical-derived materials. When disposed of, Lycra takes a long time to break down, contributing to microplastic pollution in the environment. This lack of biodegradability poses environmental challenges and highlights the need for sustainable alternatives.

- Tencel (Lyocell): One of Tencel’s standout features is its biodegradability. As a cellulosic fiber derived from wood pulp, Tencel can naturally decompose without causing harm to the environment. When discarded, Tencel fibers can biodegrade, closing the loop in the product life cycle and minimizing environmental impact.

Strength and Durability

- Lycra (Spandex/Elastane): Lycra is known for its excellent strength and durability. Its high elasticity allows it to withstand repeated stretching and recovery without losing its shape or integrity. This makes Lycra a reliable choice for sportswear, swimwear, and garments that require stretch and support. Its strength contributes to the longevity of clothing items, ensuring they maintain their fit and performance over time.

- Tencel (Lyocell): Tencel exhibits good strength and durability, but it may not match the high level of resilience seen in Lycra. While Tencel can withstand regular wear and washing, it is more prone to damage and wear compared to Lycra, especially when subjected to intense stretching or tension. As a result, Tencel is commonly used in clothing where stretch and compression are not primary requirements.

Weight

- Lycra (Spandex/Elastane): Lycra is a lightweight fabric, which adds to its appeal in sportswear and other athletic apparel. Its low weight contributes to the garment’s overall comfort and allows for ease of movement during physical activities. The lightweight nature of Lycra makes it an ideal choice for activewear, where freedom of movement is essential.

- Tencel (Lyocell): Tencel is also relatively lightweight, but it may be slightly heavier compared to Lycra due to its cellulosic nature. However, the difference in weight is generally minimal, and Tencel is still considered lightweight and comfortable for everyday wear and activewear.

Allergenic Properties

- Lycra (Spandex/Elastane): Lycra, being a synthetic fiber, may cause skin irritation or allergic reactions in some individuals. While it is generally safe for most people, some may experience discomfort or sensitivity to the fabric, especially when it comes into direct contact with the skin.

- Tencel (Lyocell): Tencel is known for its hypoallergenic properties. The smooth and soft texture of Tencel fibers is less likely to cause skin irritation or allergies, making it a suitable choice for those with sensitive skin or allergies to other types of fabrics.

Application

- Lycra (Spandex/Elastane): Lycra finds extensive use in sportswear, activewear, swimwear, and undergarments. Its excellent stretch and support make it an essential component in compression garments, ensuring a snug fit and enhanced performance during physical activities.

- Tencel (Lyocell): Tencel is versatile and can be used in various applications, including shirts, dresses, skirts, bedding, and home textiles. Its softness and breathability make it an excellent choice for comfortable and eco-friendly clothing options, especially for warm weather.

Environmental Impact

- Lycra (Spandex/Elastane): Lycra’s environmental impact is relatively high due to its synthetic origin and non-biodegradable nature. The production process involving petrochemicals and the slow decomposition of Lycra fibers contribute to plastic waste and environmental pollution.

- Tencel (Lyocell): Tencel has a lower environmental impact compared to Lycra. Its eco-friendly manufacturing process using sustainably sourced wood pulp and closed-loop production system helps reduce waste and chemical emissions. Additionally, Tencel’s biodegradability ensures it can break down naturally, leaving a smaller ecological footprint.

Cost

- Lycra (Spandex/Elastane): Lycra is generally more expensive than other types of fibers due to its synthetic nature and complex manufacturing process. The cost of producing Lycra from petrochemicals contributes to its higher price tag, which can impact the final cost of garments made with a significant percentage of Lycra.

- Tencel (Lyocell): Tencel is often considered a premium and slightly more expensive option compared to conventional natural fibers like cotton or regular rayon. The sustainable and eco-friendly manufacturing process, along with the use of quality wood pulp, contributes to the higher cost of Tencel fabrics.

Dyeing

- Lycra (Spandex/Elastane): Lycra can be easily dyed and retains colors well. Its synthetic nature allows for vibrant and long-lasting colorations, making it a popular choice for bright and colorful activewear and swimwear.

- Tencel (Lyocell): Tencel fibers are known for their excellent dyeing properties. They have high affinity for dyes, allowing rich and even color penetration. Tencel fabrics display vibrant colors and retain their color well over time, making them suitable for a wide range of dyed apparel.

Shrinkage

- Lycra (Spandex/Elastane): Lycra is resistant to shrinkage due to its synthetic properties. It retains its shape and size even after multiple washes, making it an ideal choice for form-fitting clothing that requires consistent fit and support.

- Tencel (Lyocell): Tencel exhibits minimal shrinkage after washing. Its fibers are less prone to significant shrinkage compared to some natural fibers like cotton. Garments made from Tencel tend to maintain their original size and shape with proper care.

Pilling

- Lycra (Spandex/Elastane): Lycra fabrics are generally resistant to pilling. The strong and elastic nature of Lycra fibers prevents the formation of unsightly pills on the fabric surface, ensuring that the garment remains smooth and in good condition over time.

- Tencel (Lyocell): Tencel fabrics can be prone to pilling, especially in areas of high friction. While the fabric’s softness and smooth texture are desirable, they may contribute to the formation of pills after extended use or frequent rubbing against other surfaces. Regular care and maintenance can help minimize pilling.

Crease Resistance

- Lycra (Spandex/Elastane): Lycra has good crease resistance due to its elastic properties. Garments with a significant amount of Lycra tend to recover quickly from folds and creases, making them easy to maintain and ensuring a smooth appearance even after prolonged wear.

- Tencel (Lyocell): Tencel fabrics offer moderate crease resistance. While Tencel garments are less prone to creasing compared to some natural fibers, they may not be as wrinkle-resistant as synthetic fabrics like Lycra. However, Tencel’s soft and flowing drape helps minimize the appearance of creases, providing a comfortable and elegant look.

Lycra Vs Tencel: Comparison Table

| Aspect | Lycra (Spandex/Elastane) | Tencel (Lyocell) |

|---|---|---|

| Fiber Type | Synthetic | Cellulosic (from wood pulp) |

| Elasticity | Highly elastic, can stretch 5-8 times its size | Moderate elasticity, less stretchy than Lycra |

| Fabric Softness | Less soft compared to Tencel | Very soft and smooth texture |

| Moisture Absorption | Limited moisture absorption | Excellent moisture-wicking properties |

| Breathability | Less breathable compared to Tencel | Highly breathable, ideal for warm weather |

| Eco-Friendliness | Not biodegradable, derived from petrochemicals | Biodegradable, made from sustainable wood sources |

| Manufacturing Process | Synthetic production process | Eco-friendly lyocell process using non-toxic solvents |

| Origin of Raw Material | Derived from petroleum by-products | Sourced from renewable wood pulp |

| Sustainability | Not considered environmentally friendly | Regarded as an eco-friendly fabric |

| Biodegradability | Non-biodegradable | Biodegradable, breaks down naturally |

| Strength and Durability | Highly durable, maintains shape well | Moderately strong and durable |

| Weight | Lightweight | Lightweight and comfortable |

| Allergenic Properties | May cause skin irritation in some individuals | Generally hypoallergenic and suitable for sensitive skin |

| Application | Often used for sportswear, swimwear, and undergarments | Commonly used in apparel, bedding, and home textiles |

| Environmental Impact | Contributes to plastic waste | Lower environmental impact due to biodegradability |

| Cost | Generally less expensive than Tencel | Often more expensive than synthetic fabrics |

| Dyeing | Easily dyed and retains color well | Absorbs and retains dyes effectively |

| Shrinkage | Minimal shrinkage | Minimal shrinkage after washing |

| Pilling | Resistant to pilling | Prone to pilling with prolonged use |

| Crease Resistance | Wrinkle-resistant | Moderate resistance to wrinkles |

Frequently Asked Questions

Yes, Lycra and Tencel can be blended together to create a fabric that incorporates the stretch and elasticity of Lycra with the softness and eco-friendliness of Tencel. This blend is often used to enhance the comfort and performance of garments, particularly in activewear and sportswear.

Yes, garments made from Lycra and Tencel blends should be cared for properly to maintain their performance and appearance. Generally, they can be machine washed on a gentle cycle and dried at a low temperature. Avoid using harsh detergents or bleach, as these can damage the fabric. Always follow the care instructions provided by the manufacturer to ensure longevity.

Lycra, being a synthetic fiber, does not have inherent temperature-regulating properties. However, Tencel is known for its excellent moisture-wicking capabilities and breathability, which can help in regulating body temperature by keeping the wearer cool and dry in warm conditions.

Yes, Tencel can be used for outdoor and adventure clothing. Its moisture-wicking properties and softness make it comfortable for outdoor activities. Additionally, its eco-friendly nature aligns with the growing trend of sustainable and environmentally conscious outdoor apparel.

Yes, Lycra and Tencel offer specific advantages in intimate apparel. Lycra provides stretch and support, ensuring a comfortable and snug fit for undergarments. Tencel’s softness and moisture-wicking properties make it a gentle and breathable option, adding to the comfort and freshness of intimate wear.

To Recap

The comparison between Lycra and Tencel reveals their distinct attributes and applications in the world of fabrics. Lycra’s exceptional elasticity and support make it ideal for performance-driven sportswear and activewear, catering to the needs of athletes and fitness enthusiasts.

On the other hand, Tencel’s eco-friendly nature, softness, and moisture-wicking properties offer a comfortable and sustainable choice for everyday clothing and bedding.

Each fiber brings its unique advantages, and the decision between Lycra and Tencel ultimately depends on the specific requirements of the garment and the individual’s preferences for performance, comfort, and environmental impact.

Leave a Reply