Sewing can be a rewarding and creative hobby, but it can be frustrating when the needle keeps falling out of your sewing machine. This common issue can disrupt your sewing projects and leave you feeling stuck.

Fortunately, there are solutions to this problem that can help you get back to your crafting in no time.

In this guide, we will explore Needle Keeps Falling Out of Sewing Machine- how to fix and provide you with practical steps to fix the issue. Whether you’re a seasoned seamstress or a novice crafter, understanding and addressing this problem is essential for a smooth and enjoyable sewing experience.

So, let’s dive into the troubleshooting process and learn how to keep your needle securely in place while sewing.

Needle Keeps Falling Out Of Sewing Machine- How To Fix.

Here are some effective ways to prevent or fix the needle from falling out of your sewing machine:

Check The Needle Orientation And Insertion

Make sure the needle is oriented correctly, usually with the flat side facing the back of the machine. Insert the needle fully into the needle holder and push it up as far as it can go.

Tighten The Needle Clamp Screw Securely

Use a coin or a screwdriver to tighten the needle clamp screw until it is snug but not too tight. Do not over-tighten the screw, as this can damage or deform the clamp or the screw.

Use The Right Needle For Your Machine And Fabric

Choose a high-quality needle that is compatible with your machine model and suitable for the type and weight of fabric you are sewing.

A wrong or poor-quality needle can cause skipping stitches, breaking threads, or falling out of the machine.

Replace The Needle Regularly

A dull, bent, or damaged Needle can cause sewing problems and fall out of the machine easily.

Replace the needle after every project or after sewing for about 8 hours. Also, replace the needle if you hit a pin, a button, or a zipper while sewing.

Inspect The Needle Clamp And Plate

Look for any cracks, wear, or damage on the needle clamp and plate that can affect the needle’s stability and performance.

If you find any defects, replace the parts with new ones that match your machine model.

Adjust The Machine Tension

A too-loose or too-tight tension can cause the needle to fall out of the machine. Check your machine manual for the recommended tension settings for different fabrics and threads. Test the tension on a scrap piece of fabric before sewing your project.

Control The Machine’s Speed

Sewing too fast or too slow can cause the needle to fall out of the machine. Sew at a moderate and consistent speed that matches your skill level and fabric type. Avoid sudden stops and starts that can jerk or pull the needle out of place.

Clean And Oil Your Machine Regularly

Dust, lint, and dirt can accumulate in your machine and interfere with its functions and parts, including the needle holder and clamp.

Clean your machine after every project or at least once a month using a soft brush, a lint remover, or a vacuum cleaner.

Oil your machine according to your manual’s instructions using sewing machine oil only.

Have Your Machine Serviced And Calibrated Periodically

Sometimes, the needle falls out of the machine because of an internal problem that requires professional attention.

Have your machine checked and serviced by a qualified technician at least once a year or more often if you use it frequently or notice any issues.

The technician can also calibrate your machine to ensure proper alignment and performance of all its parts, including the needle holder and clamp.

Why Does the Needle Won’t Stay in a Sewing Machine?

Here are some possible reasons:

The Needle Is Not Inserted Correctly Or Fully

The needle should be oriented according to your machine’s instructions, usually with the flat side facing the back of the machine.

The needle should also be pushed up as far as it can go into the needle holder. If the needle is not inserted properly, it can fall out easily.

The Needle Clamp Screw Is Loose Or Damaged

The needle clamp screw is the part that secures the needle in place. It should be tightened with a coin or a screwdriver until it is snug but not too tight.

If the screw is loose, the needle can slip out of the clamp. If the screw is damaged, such as stripped, deformed, or broken, it cannot hold the needle firmly.

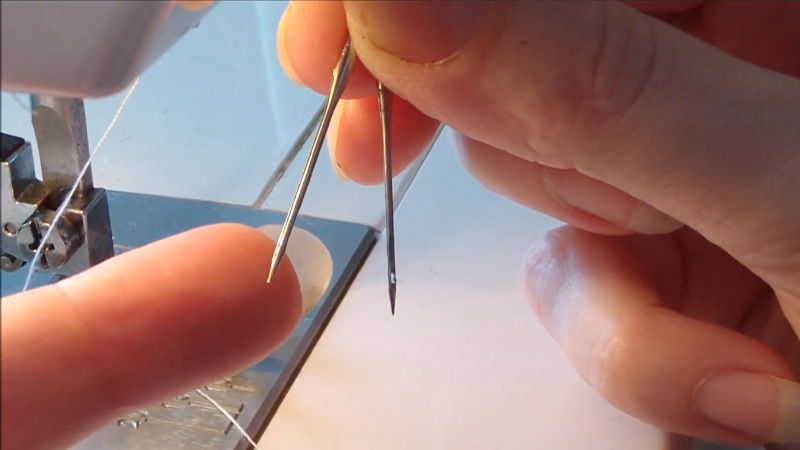

The Needle Is The Wrong Type Or Size For Your Machine Or Fabric

Different machines and fabrics require different needles that are compatible and suitable for them.

A wrong or poor-quality needle can cause sewing problems, such as skipping stitches, breaking threads, or falling out of the machine.

You should choose a high-quality needle that matches your machine model, fabric type, and weight.

The Needle Is Dull, Bent, Or Damaged

A needle that has been used for too long or has hit a hard object, such as a pin, a button, or a zipper, can become dull, bent, or damaged.

A dull needle can cause skipped stitches and fabric damage. A bent or damaged needle can cause thread breakage and needle drop. You should replace your needle after every project or after sewing for about 8 hours.

The Needle Clamp Or Plate Is Cracked, Worn, Or Defective

The needle clamp and plate are the parts that hold and guide the needle during sewing. They should be smooth and intact to ensure the needle’s stability and performance.

If they are cracked, worn, or defective, they can affect the needle’s alignment and movement and cause it to fall out of the machine.

The Machine Tension Is Too Loose Or Too Tight

The machine tension is the amount of pressure applied to the thread by the upper and lower thread guides. It should be adjusted according to your machine’s manual and the fabric and thread you are using.

If the tension is too loose, the thread can form loops and knots that can pull the needle out of place. If the tension is too tight, the thread can snap and cause the needle to drop.

The Machine Speed Is Too Fast Or Too Slow

The machine speed is the rate at which you sew with your foot pedal or speed control button. It should be moderate and consistent to match your skill level and fabric type.

If you sew too fast or too slow, you can cause the needle to fall out of the machine due to jerking, pulling, or skipping motions.

The Machine Is Dirty Or Poorly Lubricated

Dust, lint, and dirt can accumulate in your machine and interfere with its functions and parts, including the needle holder and clamp.

They can cause friction, corrosion, or jamming that can affect the needle’s position and movement and cause it to fall out of the machine.

You should clean your machine after every project or at least once a month using a soft brush, a lint remover, or a vacuum cleaner.

The Machine Needs Servicing Or Calibration

Sometimes, the needle falls out of the machine because of an internal problem that requires professional attention.

Your machine may have worn-out parts, loose screws, misaligned components, or faulty wiring that can affect its performance and safety.

You should have your machine checked and serviced by a qualified technician at least once a year or more often if you use it frequently or notice any issues.

How Do You Realign A Sewing Machine Needle?

Here are 9 tips to follow:

Turn Off And Unplug Your Machine Before Starting

This is a safety precaution to avoid any electric shock or injury from the moving parts of the machine. You should also remove the presser foot and the bobbin case to have a clear view of the needle area.

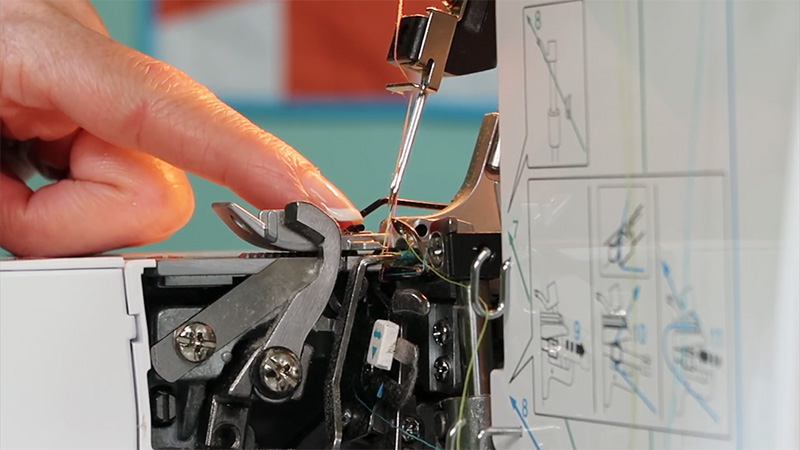

Locate The Needle Holder And Clamp

The needle holder is the part that holds the needle in place and moves it up and down. The needle clamp is the part that secures the needle with a screw.

You can find them at the lower end of the needle bar, which is the metal rod that connects to the hand wheel.

Loosen The Needle Clamp Screw

Use a coin or a screwdriver to loosen the needle clamp screw by turning it counterclockwise. Do not remove the screw completely, just enough to release the needle from the clamp.

Remove The Old Needle And Insert A New One

Pull out the old needle from the holder and discard it safely. Insert a new needle into the holder, making sure it is oriented correctly according to your machine’s instructions.

Usually, the flat side of the needle should face the back of the machine, but some machines may have different orientations. Push the needle up as far as it can go into the holder.

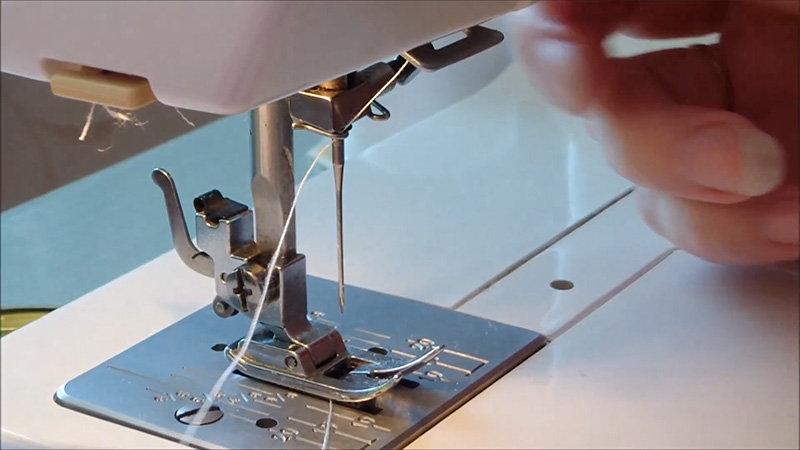

Tighten The Needle Clamp Screw

Use a coin or a screwdriver to tighten the needle clamp screw by turning it clockwise until it is snug but not too tight. Do not over-tighten the screw, as this can damage or deform the clamp or the screw.

Check The Alignment Of The Needle

Turn the hand wheel slowly by hand and observe how the needle moves and interacts with the hook and bobbin case below it.

The hook is the part that catches the upper thread and forms a stitch with the lower thread from the bobbin case.

Adjust The Alignment Of The Needle If Needed

If you notice that the needle is not aligned with the hook or hits it during sewing, you may need to adjust its position slightly.

To do this, loosen the needle clamp screw again and gently nudge or twist the needle until it is aligned with the hook.

You can use a small tool such as a tweezer or a toothpick to help you move the needle without touching it with your fingers.

Test Your Machine On A Scrap Piece Of Fabric

After you have realigned your sewing machine needle, you should test it on a scrap piece of fabric before sewing your project.

Sew a few stitches and check if they are even and smooth without any skipping, breaking, or jamming issues.

Clean And Oil Your Machine Regularly

To prevent your sewing machine needle from falling out or misaligning in the future, you should clean and oil your machine regularly according to your manual’s instructions.

Dust, lint, and dirt can accumulate in your machine and interfere with its functions and parts, including the needle holder and clamp.

They can cause friction, corrosion, or jamming that can affect the needle’s position and movement and cause it to fall out of the machine.

FAQ

The needle can fall out due to several reasons, such as incorrect installation, a damaged needle clamp, or using the wrong needle type for your machine.

Ensure the flat side of the needle faces the back, insert it all the way up into the needle clamp, and tighten the screw securely.

Yes, using an incorrect needle size can lead to instability. Always use the right needle size and type recommended for your sewing machine and fabric.

If you suspect damage, consult your sewing machine’s manual for guidance on repairing or replacing the needle clamp. A loose clamp may need tightening with a screwdriver.

Regularly clean your machine, change needles as needed, and inspect for loose parts. Proper maintenance can reduce the likelihood of the needle falling out and ensure smooth sewing.

Conclusion

Successfully addressing the problem of a needle falling out of your sewing machine is a crucial step in ensuring a frustration-free and productive sewing experience.

By following the troubleshooting steps outlined in this guide, you can identify and rectify the underlying issues causing the needle to dislodge.

Remember to double-check your machine’s compatibility with different needle types, ensure proper insertion and tightening, and keep an eye on wear and tear.

Regular maintenance and attention to detail will help you enjoy countless hours of sewing without interruptions.

With a secure needle, you can confidently pursue your creative sewing projects, from crafting beautiful garments to adding artistic flair to home decor items.

So, don’t let a loose needle slow you down—take charge of the situation, fix the issue, and continue sewing with confidence and ease.

Leave a Reply