Paint formula color codes are an essential aspect of the automotive and manufacturing industries, as they provide a precise and standardized way to identify, replicate, and match specific colors.

These codes are used to ensure that the final products, whether they be vehicles, appliances, or other consumer goods, are consistent and meet the desired color specifications.

Without accurate color matching, the end result could be visually unappealing or even cause functional problems, such as with vehicle safety equipment.

In this article, we will explore the various types and uses of paint formula color codes, as well as the tools and processes involved in color matching.

How Paint Formula Color Codes Work

Here is a step-by-step explanation of how paint formula color codes work:

Determine the Desired Color

The first step in the process is to determine the desired color. This can be done using color swatches or samples, or by providing a physical sample of the color to be matched.

Measure the Color

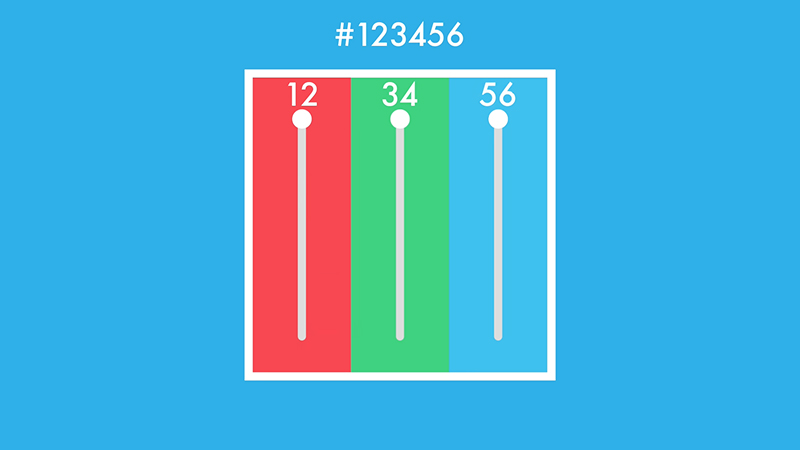

Once the desired color has been identified, the next step is to measure it using a spectrophotometer or similar color measurement tool. The spectrophotometer measures the wavelengths of light reflected by the color, providing a detailed analysis of the color’s hue, saturation, and brightness.

Compare to a Color Library

The measured color is then compared to a color library, which contains a collection of color samples that have been precisely measured and analyzed using a spectrophotometer or other color measurement tool.

By comparing the colors in the library to the desired color, technicians can identify the closest match and use that information to create a custom paint formula.

Create the Paint Formula

Using the information gathered from the spectrophotometer and color library, technicians create a custom paint formula that will replicate the desired color. This formula contains specific measurements of pigment, binder, and solvent that will produce the desired color when combined.

Mix the Paint

Once the paint formula has been created, it is mixed using specialized equipment to ensure that the correct amount of pigment, binder, and solvent are added. The paint is then tested to ensure that it matches the desired color and meets any other quality standards.

Apply the Paint

The final step is to apply the paint to the desired surface using appropriate techniques and equipment. The end result should be a consistent, high-quality finish that matches the desired color and meets any other specifications.

Types of Paint Formula Color Codes

There are several different types of paint formula color codes that are used in the automotive and manufacturing industries. These include:

OEM (Original Equipment Manufacturer) Codes

These codes are used by the original manufacturer of a product to identify the specific colors used in its production.

OEM codes are often provided in the owner’s manual or other documentation that comes with the product. They are used by repair shops and other service providers to ensure that replacement parts or repairs are matched to the original color of the product.

Aftermarket Codes

Aftermarket codes are used by companies that produce replacement parts or custom paint products for vehicles and other products. These codes may be based on OEM codes, but they can also be created by the aftermarket company based on their own color-matching processes.

Generic Codes

Generic codes are not specific to any one manufacturer or product. They are used as a standardized system for identifying and replicating colors that may be used in a variety of different products.

Generic codes may be used by paint shops and other service providers to match colors that do not have an OEM or aftermarket code available.

Overall, it is important to use the correct type of paint formula color code in order to ensure accurate color matching.

Using the wrong code, or using a generic code when an OEM or aftermarket code is available, could result in a poor color match and potentially require additional time and resources to correct.

Using Paint Formula Color Codes at a Paint Shop

If you need to have a specific color matched for your vehicle or other product, the first step is to locate the correct paint formula color code. This code should be provided by the manufacturer or may be available in the documentation that came with the product.

If you are unable to locate the code, you can try contacting the manufacturer or a dealership, or a service center for assistance. Once you have the correct code, you can take it to a paint shop or other service provider that offers color-matching services.

It’s a good idea to call ahead and confirm that the shop has the necessary tools and expertise to match your desired color. You should also be prepared to provide a sample of the color if possible, such as a small piece of the product or a swatch of the desired color.

When you arrive at the paint shop, provide the paint formula color code and any other relevant information to the technician or service representative.

It’s also a good idea to communicate your specific color-matching needs and any potential challenges or considerations that may affect the process.

For example, if you are trying to match a faded or altered color, it may be necessary for the technician to adjust the formula to account for these changes.

Once the technician has the necessary information, they will begin the process of color matching. This may involve using a spectrophotometer or other color measurement tools to analyze the sample and determine the precise formula for the desired color.

The technician will then use this information to create a custom paint product that matches the desired color as closely as possible. The final paint product may be provided in a variety of forms, such as a liquid, spray, or powder, depending on the specific needs of the customer.

Challenges and Considerations in Color Matching

While paint formula color codes provide a standardized and accurate way to identify and replicate specific colors, there are still a number of challenges and considerations that can arise in the color-matching process. Some of the most common issues include:

Faded or Altered Colors

Over time, the color of a product may fade or become altered due to environmental factors such as sunlight or pollution. This can make it more difficult to accurately match the original color, as the current shade may be different from the one that was originally intended.

In these cases, it may be necessary for the technician to adjust the formula to account for these changes and create a custom color that matches the current shade as closely as possible.

Differences in Color Perception

Different individuals may perceive colors differently due to variations in their visual acuity and other factors. This can make it difficult to achieve consensus on the exact shade of a color, which can be particularly challenging when working with a large team or trying to match a color for a client or customer.

To mitigate these differences, it can be helpful to use standardized color libraries and measurement tools that provide objective data on the characteristics of color.

Variations in Color Between Production Batches

In some cases, the color of a product may vary slightly between different production batches or due to differences in the materials used. This can make it difficult to achieve a perfect match, even with the use of paint formula color codes.

To minimize these variations, it is important for manufacturers to maintain strict quality control standards and to use consistent materials and processes whenever possible.

Overall, color matching can be a complex process that requires the use of specialized tools and techniques, as well as a trained and skilled workforce

. By understanding the challenges and considerations involved in color matching, manufacturers and service providers can take steps to ensure that the final products meet the desired color specifications and satisfy their customers’ needs.

Paint Formula Color Code Comparison

| Type of Code | Description | Use |

|---|---|---|

| OEM | Used by the original manufacturer of a product to identify the specific colors used in its production | To ensure that replacement parts or repairs are matched to the original color of the product |

| Aftermarket | Used by companies that produce replacement parts or custom paint products for vehicles and other products | To provide accurate color matching for replacement parts or custom paint projects |

| Generic | Not specific to any one manufacturer or product; used as a standardized system for identifying and replicating colors that may be used in a variety of different products | To match colors for which an OEM or aftermarket code is not available |

FAQs

A paint formula color code is a standardized system for identifying and replicating specific colors. These codes are used in the automotive and manufacturing industries to ensure that the final products, such as vehicles and appliances, meet the desired color specifications. Paint formula color codes are typically provided by the manufacturer and are used by repair shops and other service providers to ensure that replacement parts or repairs are matched to the original color of the product.

The correct paint formula color code for your product should be provided by the manufacturer or may be available in the documentation that came with the product. If you are unable to locate the code, you can try contacting the manufacturer or a dealership or a service center for assistance.

It is generally recommended to use the correct type of paint formula color code in order to ensure the most accurate color match. Using a generic code when an OEM or aftermarket code is available could result in a poor color match and potentially require additional time and resources to correct. If you are unable to locate the correct code for your product, it may be necessary to use a generic code, but it is important to be aware that this may result in a less accurate color match.

There are a number of factors that can affect the accuracy of a color match, including faded or altered colors due to age or environmental factors, differences in color perception among individuals, and variations in color between different production batches or materials. To minimize these challenges, it is important to use standardized color measurement tools and libraries, as well as trained and skilled technicians, to ensure the most accurate color match possible.

Yes, you can use a paint formula color code to match a color for a custom project or product. Many paint shops and other service providers offer color matching services, and you can provide them with the correct paint formula color code for your desired color. You may also need to provide a sample of the color if possible, such as a small piece of the product or a swatch of the desired color. Keep in mind that it may be necessary to adjust the formula to account for any faded or altered colors, and it may be helpful to communicate your specific color-matching needs and any potential challenges or considerations to the technician or service representative.

Conclusion

Paint formula color codes play a vital role in the automotive and manufacturing industries, as they provide a standardized and accurate way to identify and replicate specific colors.

These codes are essential for ensuring that the final products, whether they be vehicles, appliances, or other consumer goods, meet the desired color specifications and satisfy the needs of customers.

The process of color matching involves the use of advanced tools and technology, such as spectrophotometers and color libraries, as well as skilled technicians who are trained to use these tools and techniques to achieve accurate and consistent results.

By utilizing these tools and following established protocols, manufacturers and paint shops can ensure that the final products meet the desired color specifications and satisfy their customers’ needs.

Overall, the importance of accurate paint formula color codes cannot be overstated, as they play a critical role in ensuring a satisfactory end result for both manufacturers and customers.

By understanding the various types of codes and the tools and processes involved in color matching, manufacturers and service providers can take steps to ensure that their products meet the desired color specifications and exceed the expectations of their customers.

Leave a Reply