Polyester fabric, a popular synthetic textile, has become a ubiquitous presence in our lives. With its versatile properties and affordability, polyester has found its way into our clothing, home furnishings, and various other applications.

Derived from petroleum, polyester offers strength, durability, and resistance to wrinkles and moisture. It is easy to care for, quick-drying and retains shape well.

However, polyester poses environmental concerns due to its non-biodegradable nature and energy-intensive production process.

Despite its drawbacks, polyester continues to be widely used and appreciated for its functional benefits.

In this modern age, understanding the pros and cons of polyester fabric is crucial for making informed choices about our consumption and sustainability practices.

What Is Polyester Fabric?

Polyester fabric is a popular synthetic fabric widely used in various industries. It is made from polyester fibers derived from petroleum, coal, air, and water. Polyester is a polymer composed of long chains formed through polymerization.

Its durability makes it suitable for long-lasting performance, and its wrinkle and stain resistance make it convenient for clothing and home textiles.

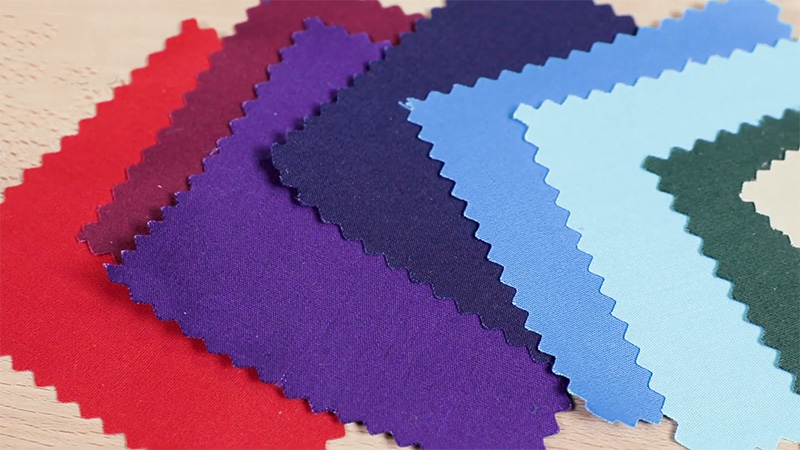

Polyester fabric is versatile, allowing diverse applications with different textures, weights, and finishes. It is commonly used in the fashion industry for clothing, printing techniques, and home furnishing for upholstery, curtains, bedding, and carpets.

However, polyester fabric generates static electricity and may pill. It is also a concern for the environment due to its lack of biodegradability and the release of microplastics during washing. Efforts are underway to develop sustainable polyester fabrics and reduce microplastic pollution.

Types of Polyester Fabric

Polyester is a versatile synthetic fiber that can be spun and woven into various fabrics. Here are some common types of polyester fabrics:

Polyethylene Terephthalate (PET)

PET is the most commonly used type of polyester fabric. It is derived from ethylene glycol and terephthalic acid and is known for its strong, lightweight, and thermoplastic properties.

PET polyester is highly resistant to creases and wrinkles, making it ideal for garments and home textiles. It is widely used in clothing, bedding, curtains, upholstery, and various accessories.

Plant-Based Polyester

As sustainability becomes increasingly essential, plant-based polyester fabrics have gained popularity. These fabrics are made from renewable resources such as corn, sugarcane, or recycled materials.

Plant-based polyester aims to reduce fossil fuel dependency and decrease traditional polyester production’s environmental impact. It offers similar properties to conventional.

PCDT Polyester

PCDT (poly-1,4-cyclohexylene-dimethylene terephthalate) polyester is a polyester fabric with cyclohexane rings in its molecular structure.

This modification enhances the fabric’s resilience, making it more resistant to stretching and shrinking than PET polyester.

PCDT polyester is commonly used in producing sportswear, outdoor clothing, and other applications where durability and flexibility are essential.

Microfiber Polyester

Microfiber polyester is a lightweight and ultrafine polyester fabric. It is made from tightly woven synthetic fibers, resulting in a fabric that is incredibly soft, smooth, and breathable.

Microfiber polyester is often used to manufacture sportswear, activewear, and performance clothing. It has excellent moisture-wicking properties, which help keep the wearer dry and comfortable during physical activities.

Characteristics of Polyester Fabric

The polyester fabric has several distinctive characteristics, making it a popular choice in various applications. Here are some critical characteristics of polyester fabric:

Strength

Polyester fabric is known for its strength and durability. It is resistant to tearing and has a high tensile strength, making it suitable for items that require long-lasting performance.

This strength also contributes to the fabric’s ability to retain shape and resist stretching and shrinkage over time.

Crisp, Soft Hand

Polyester fabric offers a combination of crispness and softness in its texture, depending on the specific weave and finish.

It can have a smooth, silky feel or a more textured surface, providing options for different preferences and applications.

Resistance to Stretching and Shrinkage

Polyester fabric exhibits excellent resistance to stretching and shrinkage, ensuring that the fabric maintains its shape and dimensions even after extended use or washing.

This characteristic is precious for garments and textiles that require stability and shape retention.

Washable or Dry-Cleanable

Polyester fabric is versatile in terms of cleaning methods. It can typically be washed in a washing machine using regular detergent, making it convenient for everyday use.

Alternatively, some polyester fabrics may be dry-cleaned for more delicate items or to preserve specific finishes or embellishments.

Quick Drying

Polyester fabric has a low absorbency rate and does not retain moisture easily. This quality makes it quick to dry after washing or exposure to moisture, reducing the drying time and increasing the convenience of use.

Resilience and Wrinkle Resistance

Polyester fabric is highly resilient and resistant to wrinkling. It has excellent pleat retention, especially if set in heat.

These characteristics contribute to the fabric’s ability to maintain a smooth, wrinkle-free appearance even after prolonged use or storage.

Abrasion Resistance

Polyester fabric is known for its abrasion resistance, making it suitable for applications requiring durability and wear and tear resistance.

This quality is precious for upholstery, outdoor fabrics, and other items subject to frequent use or exposure to rough conditions.

Chemical Resistance

Polyester fabric resists most chemicals, including common household and industrial substances.

This resistance makes it less susceptible to damage or discoloration when exposed to various substances, enhancing its longevity and versatility.

The combination of strength, crispness, resistance to stretching and shrinkage, washability or dry-cleanability, quick-drying, and resilience.

Wrinkle, abrasion, and chemical resistance make the polyester fabric desirable for various applications in clothing, home textiles, upholstery, and other industries.

History of Polyester Fabric

Polyester fabric has a rich history that dates back to the early 1940s. In 1941, British scientists built upon the work of Caruthers and introduced the first commercial polyester fiber called Terylene.

This breakthrough material caught the attention of DuPont, which acquired the legal rights in 1946 and subsequently developed Dacron, another well-known polyester fiber.

Building on these advancements, Eastman Chemical introduced Kodel in 1958, further expanding the range of polyester fabrics available.

Over the years, polyester has gained popularity due to its durability, wrinkle resistance, and versatility. Today, it is widely used in various applications, including clothing, home furnishings, and industrial textiles.

What Is Polyester Made Of?

Although alternative sources exist, polyester is a manufactured synthetic fiber typically derived from petroleum. Here is a step-by-step breakdown of how polyester is made:

Raw Materials

The primary raw material used in polyester production is a chemical compound known as ethylene glycol. Ethylene glycol is derived from petroleum or natural gas through chemical processes.

Another critical raw material is terephthalic acid or its precursor, purified terephthalic acid (PTA), produced from petroleum or other sources.

Polymerization

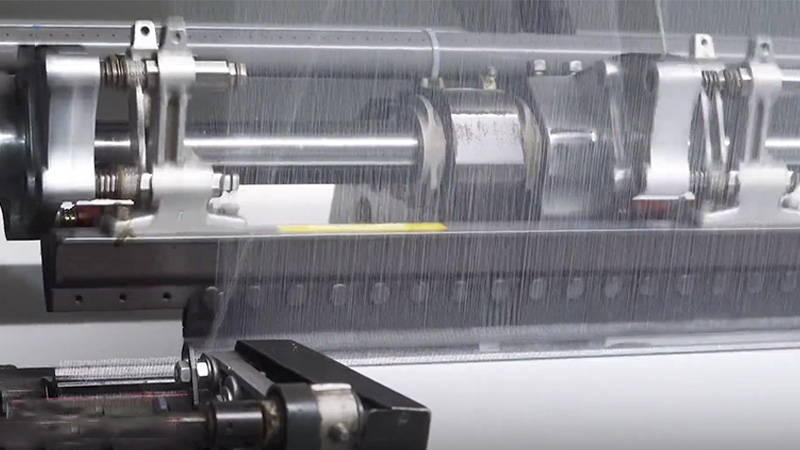

The first step in polyester production is polymerization. Ethylene glycol and terephthalic acid (or PTA) are combined in a reactor and subjected to high temperatures and pressure.

This process, known as condensation polymerization, forms long chains of repeating units called polymers.

Melt Extrusion

The resulting polymer is molten and then extruded through a spinneret, a device with tiny holes.

The molten polymer is forced through these holes, creating long continuous filaments. The filaments are rapidly cooled, solidifying them into individual fibers.

Drawing

The solidified fibers are then subjected to a process called drawing. In this step, the fibers are stretched to align the polymer chains, which increases their strength and orientation.

Drawing also enhances the fabric’s resistance to stretching and improves its performance.

Crimping

After drawing, the fibers may undergo crimping, which introduces intentional bends or waves into the filaments.

Crimping gives the fibers bulk, texture, and loft, making them more suitable for applications such as textiles and upholstery.

Spinning and Texturizing

Once the fibers are drawn and crimped, they can be further processed through spinning and texturizing. Spinning involves twisting the fibers to form yarns, which can be used for various textile applications.

Texturizing involves adding texture or bulk to the yarns through heat treatment or air jet processing.

Finishing

The final step in polyester fabric production is finishing. This involves treating the fabric with various chemical agents to achieve specific properties or enhancements.

For example, the fabric may be treated with chemicals to improve its wrinkle resistance, stain resistance, or flame retardancy.

What Is Polyester Used For?

Polyester is a versatile synthetic fabric that finds numerous applications across various industries. Here are some common uses of polyester:

Clothing

Polyester is widely used in the production of clothing items. It makes shirts, dresses, skirts, pants, jackets, and sportswear.

Polyester fabric offers durability, wrinkle resistance, and easy-care properties, making it suitable for everyday wear and active lifestyles.

Home Furnishings

Polyester fabric is commonly used in home furnishings. It is used for curtains, drapes, upholstery, bedding, cushions, and carpets.

Polyester’s durability, resistance to fading, and wide range of available textures and finishes make it a popular choice for enhancing the aesthetics and functionality of homes.

Tires

Polyester is an essential component in the manufacturing of tires. It is a reinforcement material in tire cords, providing strength and stability.

Polyester tire cords contribute to the tire’s structural integrity, allowing it to withstand the pressure, load, and friction encountered during use.

Conveyor Belts

Polyester fabric is utilized in the production of conveyor belts. Its high tensile strength, durability, and resistance to abrasion make it suitable for conveying various materials in industries such as mining, manufacturing, and logistics.

Safety Belts

Polyester is used to produce safety belts, commonly known as seat belts. Its high strength and resistance to stretching make it a reliable material for ensuring passenger safety in vehicles.

Padding, Upholstery, Cushioning, and Insulation

Polyester is employed for padding and cushioning in various applications. It is used in upholstered furniture, mattress padding, pillows, cushions, and stuffed toys.

Polyester’s resilience, softness, and ability to retain shape make it ideal for comfort and support. It is also used as insulation in jackets, sleeping bags, and cold-weather gear.

Gloves & Mitts

The polyester fabric produces gloves and mitts, particularly those used in sports and outdoor activities.

It offers durability, flexibility, and moisture-wicking properties, providing comfort and protection during various athletic pursuits.

Bottles

Polyester, in the form of polyethylene terephthalate (PET), is widely used in the manufacturing of bottles. It is a common material for beverage bottles, food containers, and other packaging applications.

PET bottles are lightweight, shatter-resistant, and have excellent clarity, making them popular in the packaging industry.

Its versatility, durability, and desirable properties have made it valuable in various industries, from fashion and home furnishings to automotive and packaging.

Where Is Polyester Fabric Produced?

Polyester fabric is produced in several countries worldwide, with Asia being a significant manufacturing hub. Here are some key regions and countries known for their polyester fabric production:

China

China is the largest producer of polyester fabric globally. It has a well-established textile industry and a vast manufacturing infrastructure.

China’s production capabilities cover a wide range of polyester fabrics, from apparel textiles to home furnishings and industrial applications.

Taiwan

Taiwan is a significant player in the polyester fabric industry, mainly known for its technical textile production.

The country has advanced manufacturing facilities and expertise in producing high-quality polyester fabrics for various applications, including sportswear, outdoor gear, and technical textiles.

Korea

South Korea is another significant producer of polyester fabric. Korean textile manufacturers are known for their innovation and ability to produce various polyester fabrics with different properties and finishes.

They cater to various sectors, including fashion, home furnishings, and technical textiles.

India

India has a thriving textile industry and is a significant producer of polyester fabric.

The country has a strong presence in domestic and international markets, producing polyester fabrics for diverse applications such as apparel, home textiles, and industrial uses.

India’s textile sector is known for its versatility, offering various polyester fabric options.

Japan

Japan has a long history of textile production and is known for its expertise in producing high-quality polyester fabrics.

Japanese manufacturers focus on advanced technologies and precision in fabric production, producing textiles with exceptional performance.

The country produces polyester fabrics for various industries, including fashion, technical textiles, and home furnishings.

Indonesia

Indonesia has emerged as a significant player in the polyester fabric industry.

The country has a well-established textile sector is known for producing polyester fabrics for garments, upholstery, and other applications.

Indonesian manufacturers often blend traditional and modern production techniques, catering to domestic and international markets.

Apart from these significant producers, polyester fabric is also manufactured in other countries, including the United States, where some production still occurs.

However, in recent years, polyester fabric production has become more concentrated in Asia due to lower labor costs and established supply chains.

Is Polyester Synthetic?

Yes, polyester is indeed a synthetic fabric. It is not directly derived from natural sources like cotton or wool. Instead, it is an artificial material created through chemical processes.

Polyester is derived from a polymer called polyethylene terephthalate (PET), which is formed through a chemical reaction between petroleum-based chemicals such as ethylene glycol and terephthalic acid.

These chemicals undergo polymerization, forming long chains of repeating units that comprise the polyester fiber. The synthetic nature of polyester provides certain advantages, such as durability, wrinkle resistance, and ease of care.

However, it is essential to note that polyester production relies on non-renewable petroleum resources and has environmental implications, including pollution and waste accumulation.

Efforts are being made to address these concerns through recycling and developing more sustainable alternatives.

Is Polyester Breathable?

Polyester is generally considered to be less breathable compared to natural fibers such as cotton or linen. This is because polyester fibers are tightly packed and do not allow for as much air circulation as natural fibers.

The tightly woven structure of polyester fabric restricts airflow and can trap heat and moisture against the skin, leading to a less breathable and potentially less comfortable feel.

However, advancements in textile technology have led to the development of moisture-wicking and breathable polyester fabrics.

These fabrics are engineered to have improved breathability by incorporating unique moisture-wicking properties that help to draw sweat away from the body and promote evaporation.

Additionally, using mesh or lightweight constructions can enhance the breathability of polyester garments. While polyester is generally considered less breathable, variations and innovations within the fabric offer improved breathability.

Is Polyester Fabric Stretchy

Polyester fabric is typically less stretchy than other materials like spandex or elastane. This is because polyester fibers have a high stability and resistance to stretching. Polyester fibers’ tightly packed and rigid nature limits their ability to stretch and recover.

However, some polyester blends may incorporate elastane or other stretch fibers to enhance the fabric’s stretchiness. These blends offer improved flexibility and comfort, allowing for better freedom of movement.

It’s important to note that the stretchiness of polyester fabric can vary depending on its specific composition and construction, so it’s always recommended to check the label or product specifications for information on stretch properties.

How to Dye Polyester Fabric?

Dyeing polyester fabric requires special considerations due to the synthetic nature of the fibers. Unlike natural fibers, polyester is not easily dyeable with traditional water-based dyes.

However, there are specific dyes and methods available that allow for successful polyester fabric dyeing. Here are some general steps to dye polyester fabric:

Select the Right Dye

Look for dyes that are specifically formulated for synthetic fibers like polyester. One common type is dispersed dye, designed to bond with polyester molecules. Make sure to follow the dye manufacturer’s instructions for best results.

Prepare the Dye Bath

Fill a large stainless steel or enamel pot with enough water to submerge the fabric. Follow the dye manufacturer’s instructions regarding the water-to-dye ratio and the recommended temperature for dyeing.

Pre-Treat the Fabric (Optional)

Some polyester fabrics may have a finish or coating that prevents proper dye absorption. Pre-treat the fabric with a dye carrier or a pre-dyeing agent recommended for polyester to enhance dye uptake. Follow the instructions provided with the pre-treatment product.

Wet the Fabric

Thoroughly wet the polyester fabric in warm water. This helps to ensure even dye penetration.

Add the Dye

Dissolve the dispersed dye powder in a small amount of hot water according to the manufacturer’s instructions. Stir until the dye is fully dissolved, then add it to the bath.

Heat the Dye Bath

Gradually heat the dye bath to the recommended temperature specified by the dye manufacturer. Stir the dye bath occasionally to ensure an even distribution of the dye.

Immerse the Fabric

Carefully place the wet fabric into the dye bath, ensuring it is fully submerged. Stir the fabric continuously or move it around to promote even dye penetration.

Dyeing Time

The dyeing time can vary depending on the dye, fabric type, and desired color intensity. Follow the dye manufacturer’s instructions, but the polyester fabric should typically be kept in the dye bath for at least 30 minutes to ensure the color takes full. Nylon may require less time.

Rinse and Wash

After achieving the desired color, remove the fabric from the dye bath and rinse it thoroughly under warm water to remove any excess dye. Then, wash the fabric using a mild detergent to remove any remaining dye particles.

Dry and Finish

Allow the dyed fabric to air dry or tumble dry according to the fabric care instructions. Once dry, iron the fabric if necessary.

Remember always to follow the instructions the dye manufacturer provides for the best results and to ensure safety precautions are taken during the dyeing process.

It’s also a good idea to conduct a small dye test on a fabric swatch or inconspicuous area before dyeing the entire piece to ensure the desired color and outcome.

How to Remove Adhesive from Polyester Fabric?

Removing adhesive from polyester fabric requires gentle techniques to avoid damaging the fabric. Here are steps to remove adhesive from polyester fabric:

Soak the Glue

Start by soaking the affected area in cold water. This helps to soften the adhesive and make it easier to remove. Allow the water to penetrate the fabric for a few minutes.

Blot the Glue

Once the adhesive is soaked, gently blot the glue with a wet sponge or cloth. Be careful not to rub or scrub the fabric, which can spread the adhesive or push it deeper into the fibers. Instead, lightly dab the area to lift the softened glue.

Apply Acetone (Or Acetone-Based Product)

If the adhesive persists, you can use acetone to break it further down further. Acetone is commonly found in nail polish removers. Apply a small amount of acetone to a cotton swab or a clean cloth.

Target the Seam and Work Outward

Start at the seam or edge of the stuck glue and work outward. This prevents spreading the adhesive over a larger area of the fabric. Apply the acetone gently and avoid saturating the fabric with excess liquid.

Blot Away Excess

As you apply the acetone, blot the area with a clean cloth. This helps to absorb the softened glue and remove it from the fabric. Continue blotting until the adhesive is no longer transferring onto the cloth.

Rinse and Wash

After removing the adhesive, rinse the fabric thoroughly with cold water to remove any residue or remaining acetone.

Then, wash the garment or fabric according to the care instructions to remove any lingering traces of adhesive or acetone.

It’s essential to perform a spot test on a small, inconspicuous area of the fabric before applying acetone or any other solvent to ensure it does not cause damage or discoloration.

Additionally, acetone may not be suitable for all types of adhesive. If you are uncertain or hesitant, it’s advisable to seek professional assistance or consult a dry cleaner for guidance on removing adhesive from polyester fabric.

How to Fix Snags in Polyester Fabric?

Snags are a common problem in polyester fabric, but they can be fixed with simple steps. Here’s how to fix snags in polyester fabric:

Locate the Snag

Identify the snagged thread on the fabric. It may be sticking out or pulled out of place. Please take note of its location before proceeding.

Pull the Thread to the Back

Gently pull the snagged thread to the backside of the fabric. You can use a needle, a crochet hook, or even your fingers to guide the thread through. Be careful not to pull too forcefully, as this can cause further damage.

Secure the Thread

Once the snagged thread is on the backside of the fabric, tie a small knot at the end to secure it. This prevents the snag from unraveling further. You can trim any excess thread with scissors, ensuring it is not visible from the front.

Repair Large or Noticeable Snags (Optional)

If the snag is significant or noticeable, sew a needle and matching thread. Choose a thread color that closely matches the fabric.

Start sewing slightly before the snag and continue sewing over it, following the direction of the fabric’s weave. Use tiny, even stitches to secure the fabric and blend the repaired area with the rest.

Smooth Out Wrinkles

Warm iron presses the fabric, particularly around the repaired snag. Set the iron to a low or medium heat setting suitable for polyester fabric.

A pressing cloth or placing a piece of cotton fabric between the iron and the polyester is essential to prevent melting or scorching. Gently press the fabric, being careful not to apply too much pressure.

By following these steps, you can effectively fix snags in polyester fabric and restore its appearance. It’s always recommended to handle the fabric with care and avoid rough surfaces or sharp objects to prevent future snags.

How to Clean Polyester Fabric?

Cleaning polyester fabric is a relatively straightforward process. Here are some general steps to effectively clean polyester fabric:

Check the Care Label

Before cleaning, always check the care label on the polyester fabric for any specific instructions or restrictions.

The care label provides valuable information regarding the recommended water temperature, detergent type, and any other specific care instructions for the fabric.

Sort and Prepare the Fabric

Separate your polyester fabric from other garments or items and sort them according to color and level of dirtiness. This helps prevent color bleeding and ensures appropriate cleaning.

Machine Wash

Polyester fabric can typically be machine-washed. Set your washing machine to a warm water temperature and select a gentle or delicate cycle.

Use an all-purpose detergent suitable for synthetic fabrics. Follow the manufacturer’s instructions for the appropriate amount of detergent based on the load size.

Optional Use of Bleach

If necessary and if the care label allows, you can use chlorine bleach for white or light-colored polyester fabric. Follow the instructions on the bleach packaging for proper usage.

For colored polyester fabric, avoid using bleach to prevent color fading or damage.

Use Fabric Softener

Polyester fabric can be prone to static electricity. Add fabric softener to the rinse cycle to reduce static and improve softness. Alternatively, you can use dryer sheets or wool dryer balls during the drying process.

Spot Treatment for Stains

If there are specific stains on the polyester fabric, consider spot-treating them before washing. Use a mild stain remover or a mixture of detergent and water.

Apply the solution to the stain and gently rub or blot it. Rinse thoroughly before washing.

Dry the Fabric

After washing, remove the polyester fabric from the washing machine promptly. Polyester fabric tends to dry relatively quickly.

You can air-dry or flat the fabric on a clean, dry surface. If you prefer using a dryer, set it to a low heat or delicate setting to prevent excessive heat damage.

It’s important to note that some polyester fabrics may require specific care instructions or professional cleaning. Always refer to the care label and follow any recommended guidelines from the manufacturer or garment retailer.

Following these general steps, you can effectively clean polyester fabric and maintain its appearance and quality.

How to Sew Polyester?

Sewing polyester fabric requires some specific techniques to ensure clean and professional-looking seams. Here are some steps to sew polyester fabric:

Choose the Right Needle

When sewing polyester fabric, it’s best to use a fine needle to prevent damage to the fabric. Opt for a fresh sharp or microtex needle, preferably in size 8.

These needles have a smaller and finer point, which reduces the risk of leaving visible holes or causing runs in the fabric.

Prepare the Sewing Machine

Ensure your sewing machine is set up correctly for sewing polyester fabric. Thread the machine with a suitable polyester thread and insert the appropriate needle.

Set the machine to a small, narrow zig-zag stitch. This stitch type provides flexibility and durability, which is ideal for polyester fabric.

Test the Stitching

Before sewing the actual project, testing the stitch settings on a scrap piece of polyester fabric is always a good idea. This allows you to adjust the stitch length and width to achieve the desired result.

Pin and Align the Fabric

Pin the fabric pieces together, aligning the edges you intend to sew. Use the pins sparingly and position them within the seam allowance to avoid leaving visible holes in the fabric.

Start Sewing

Begin sewing by positioning the fabric under the sewing machine’s foot. Take care to guide the fabric smoothly and evenly through the machine.

Sew along the marked seam line using the tiny, narrow zig-zag stitch. Remember to backstitch at the beginning and end of the seam to secure the stitches.

Trim Excess Threads and Press

Once the seam is sewn, trim any excess threads or loose ends. Then, press the seam with a warm iron on a low or synthetic heat setting.

Place a pressing cloth or a piece of cotton fabric between the iron and the polyester to prevent melting or scorching.

Consider Cross-Grain Placement

When laying out the fabric pieces, consider placing them cross-grain rather than lengthwise. Polyester fabric tends to have less stretch along the cross-grain, which can help maintain the shape and stability of the finished garment or project.

You can successfully sew polyester fabric by following these steps and using appropriate techniques. Remember to take your time, sew slowly, and make any necessary adjustments to achieve the best results.

Practice on scraps or test pieces can also help you become more comfortable sewing polyester fabric before tackling more significant projects.

Polyester Fabric Pros and Cons

Pros of Polyester Fabric:

- Strength and Durability: Polyester fabric is known for its strength and durability. It is resistant to stretching, shrinking, and abrasion, making it a long-lasting material.

- Wrinkle Resistance: Polyester fabric has excellent wrinkle resistance, which means it maintains its shape and appearance even after extended periods of wear or storage.

- Moisture Resistance: Polyester has low absorbency and doesn’t readily absorb moisture. It dries quickly and is less susceptible to mold or mildew than natural fibers.

- Easy Care: Polyester fabric is relatively easy to care for. It can be machine-washed and dried and generally requires minimal ironing.

- Versatility: Polyester fabric is versatile and can be used for various purposes. It is commonly used in clothing, home furnishings, upholstery, and other applications.

- Cost-Effective: Polyester fabric is often more affordable than natural fibers, making it a popular choice for cost-conscious consumers.

Cons of Polyester Fabric:

- Environmental Impact: One of the significant drawbacks of polyester fabric is its environmental impact. Polyester is derived from non-renewable resources such as petroleum, and its production process consumes considerable energy and water resources. Additionally, polyester is not biodegradable, contributing to plastic waste and pollution.

- Lack of Breathability: Polyester fabric is less breathable than natural fibers like cotton or linen. It can trap heat and moisture against the skin, leading to discomfort and sweat.

- Static Build-Up: Polyester fabric is prone to static electricity, which can cause clinging and discomfort. This can be mitigated by using anti-static treatments or fabric softeners.

- Pilling: Polyester fabric is susceptible to pilling, especially in areas of friction. Pilling refers to forming tiny balls or fuzz on the fabric’s surface, which can affect its appearance.

- Retention of Odors: Polyester fabric tends to retain odors, particularly if not adequately cared for. This can require more frequent washing or the use of odor-reducing products.

Comparison Table Between Polyester and Other Fabrics

| Property | Polyester | Nylon | Acrylic |

|---|---|---|---|

| Strength and Durability | High | High | Moderate |

| Wrinkle Resistance | High | Moderate | Moderate |

| Moisture Resistance | Low absorbency | Low absorbency | Low absorbency |

| Breathability | Low | Moderate | Low |

| Easy Care | Easy care | Easy care | Easy care |

| Cost | Affordable | Affordable | Affordable |

| Environmental Impact | Non-biodegradable, energy and water-intensive production process | Non-biodegradable, energy and water-intensive production process | Non-biodegradable, energy and water-intensive production process |

| Static Build-Up | Prone | Prone | Prone |

| Pilling | Prone | Prone | Prone |

| Retention of Odors | Tends to retain | Tends to retain | Tends to retain |

Please note that the properties mentioned in the table can vary based on specific fabric compositions, blends, and finishes.

The performance of fabrics can also be influenced by factors such as fabric construction, weight, and treatment.

It’s always recommended to refer to individual fabrics’ care instructions and specific characteristics when deciding their suitability for a particular use.

FAQs

Yes, polyester fabric is often used for outdoor applications. It is resistant to moisture and UV rays, making it suitable for outdoor furniture, awnings, and umbrellas.

Yes, the polyester fabric can be ironed. However, using a low or synthetic heat setting on your iron is essential. Always place a pressing cloth or a piece of cotton fabric between the iron and the polyester fabric to prevent melting or scorching.

Polyester fabric can be challenging to dye at home due to its synthetic nature. It requires specialized dyes that are specifically formulated for polyester. Following the instructions provided with the dye and conducting a patch test before dyeing the entire fabric is recommended.

Polyester fabric may not be the most suitable choice for individuals with sensitive skin. It is less breathable compared to natural fibers and can cause discomfort for some people. It’s advisable to opt for fabrics like cotton or bamboo that have better breathability and are less likely to cause skin irritation.

To reduce static electricity in polyester clothing, you can try several methods. Using fabric softener in the wash or dryer sheets in the dryer can help reduce static build-up. You can also lightly mist the garment with water or use an anti-static spray before wearing it.

Polyester fabric can be altered or tailored like other fabrics. However, it is recommended to work with an experienced tailor or seamstress familiar with synthetic fabrics. Using the appropriate needle, thread, and sewing techniques is essential to achieve the desired result.

Yes, polyester fabric can be recycled. It is often recycled into new polyester fibers or used to produce various plastic products. Recycling polyester helps reduce the demand for new petroleum-based polyester and minimizes environmental impact.

To Recap

Polyester fabric has its advantages and disadvantages. It offers strength, durability, and ease of care, making it a practical choice for many applications.

However, its environmental impact, non-biodegradability, and energy-intensive production process cannot be overlooked.

As consumers, it is essential to weigh the benefits and drawbacks of polyester and make conscious choices. Exploring alternative fabrics and supporting sustainable practices can help mitigate the adverse effects associated with polyester.

By promoting responsible consumption and considering the long-term impact of our choices, we can contribute to a more sustainable and eco-friendly future.

Let us strive to find a balance between functionality and environmental consciousness in our textile choices.

Leave a Reply