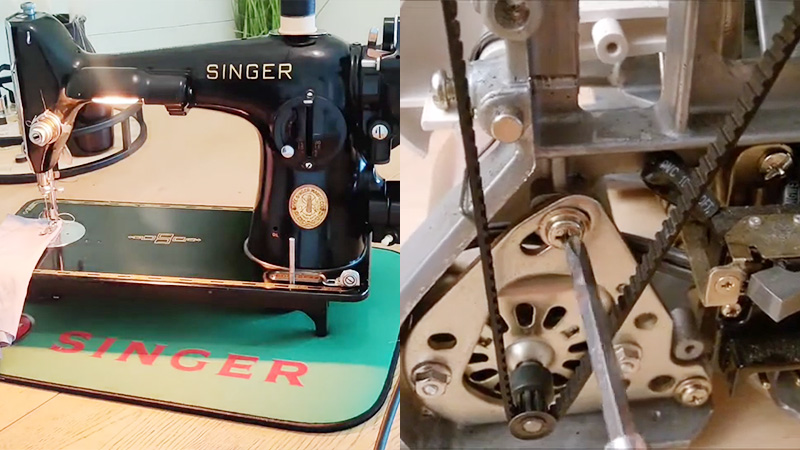

When it comes to selecting a sewing machine, one of the fundamental decisions you’ll face is choosing between a potted motor or a belt-driven system.

In this exploration, we’ll delve into the world of sewing machine motors to help you understand the potted motor vs belt driven motor differences and make an informed choice. A “potted motor” refers to an integrated, sealed motor that’s neatly enclosed within the sewing machine’s body.

On the other hand, “belt-driven” machines rely on a system of belts and pulleys to transfer power from a separate motor to the machine’s mechanisms. Each system has its unique set of advantages and considerations that can influence your sewing journey.

Whether you’re a seasoned sewist or just embarking on your creative endeavors, understanding the distinctions between potted motors and belt-driven machines is crucial.

Potted Motor vs. Belt

The choice between a potted motor and a belt-driven system in sewing machines is a fundamental decision that impacts the machine’s operation and your sewing experience. Here’s a comparison of the two:

Potted Motor

Integration

Potted motors are compact and integrated into the sewing machine’s body. They are sealed and require minimal maintenance.

Quiet Operation

They tend to operate quietly, which can be beneficial if you prefer a noise-free sewing environment.

Space-Saving and Convenience

Potted motors save space and provide a sleek, modern look to the sewing machine. They are user-friendly and convenient for sewists who prioritize ease of use and minimal setup.

Low Maintenance

Potted motors typically require less maintenance since they are sealed and protected from dust and debris.

Belt-Driven System

Power and Control

Belt-driven systems often offer more power and control, making them favored by professional and experienced sewists. They can handle heavy fabrics and demanding projects.

Tactile Experience

The use of belts and pulleys provides a more tactile sewing experience, allowing you to feel and control the machine’s power.

Maintenance

Belt-driven machines may require occasional belt replacements and more regular maintenance, including oiling and cleaning.

Historical Appeal

Belt-driven systems have a traditional, vintage charm that appeals to sewists who appreciate craftsmanship and heritage.

Versatility

They can be more versatile, allowing you to work with a wider range of fabrics and tackle intricate sewing tasks.

In summary, choosing between a potted motor and a belt-driven system depends on your sewing style, preferences, and specific needs. If you prioritize convenience, space-saving, and quiet operation, a potted motor may be ideal.

However, if you seek greater power, control, and hands-on sewing experience, a belt-driven system may be the better choice. Your decision should align with your sewing goals and the type of projects you plan to undertake.

Which One Do I Need?

The choice between a potted motor and a belt-driven system for your sewing machine depends on several factors, including your sewing needs, preferences, and the types of projects you plan to tackle. Here are some considerations to help you determine which one you need:

Potted Motor

You may need it if, you’re a beginner or casual sewist looking for a user-friendly, low-maintenance machine. You value a quiet and compact sewing machine.

You primarily work on lightweight to medium-weight fabrics and don’t need excessive power. Convenience and ease of use are top priorities for you.

Belt-Driven System

You may need it if, you have experience in sewing and require more control and power for heavy fabrics or complex projects. You enjoy the tactile experience of sewing and appreciate the heritage and craftsmanship associated with belt-driven machines.

Versatility is crucial, and you want a machine that can handle a wide range of fabrics and sewing tasks. You’re willing to invest more time in maintenance and occasional belt replacements.

Ultimately, the choice between a potted motor and a belt-driven system depends on your sewing goals and preferences. If you’re uncertain, consider the following:

Try Before You Buy

If possible, test both types of machines to see which one feels more comfortable and suits your sewing style.

Consult with Experts

Visit a sewing machine dealer or speak with experienced sewists who can provide insights based on their own experiences.

Consider Your Projects

Think about the types of projects you’ll be working on most frequently. If you plan to work with heavy materials or intricate designs, a belt-driven system might be a better fit.

Remember that there’s no one-size-fits-all answer, and both potted motor and belt-driven systems have their merits. The right choice is the one that aligns with your sewing needs and enhances your overall sewing experience.

What Are the Different Types of Sewing Machine Motors?

Sewing machine motors come in various types, each designed to meet specific sewing needs. Here are some of the common types of sewing machine motors:

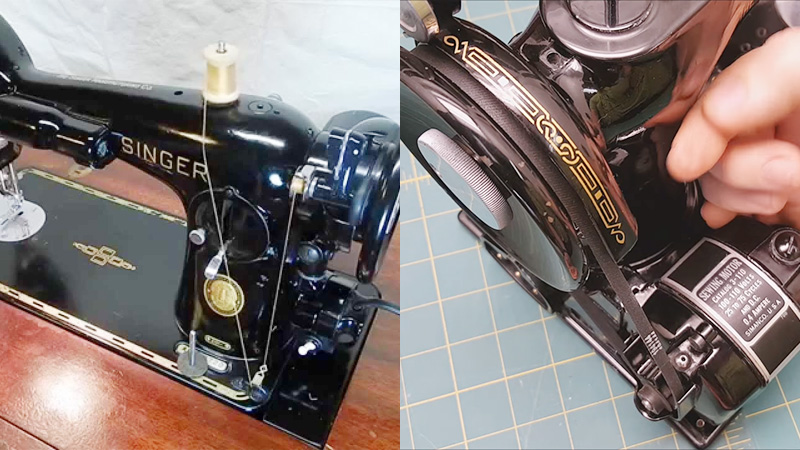

Potted Motor

Potted motors are compact, integrated motors that are enclosed within the sewing machine’s body. They are sealed to protect against dust and debris, requiring minimal maintenance.

Potted motors are known for their quiet operation and space-saving design. They are commonly found in modern sewing machines and are user-friendly, making them suitable for beginners and casual sewists.

Belt-Driven Motor

Belt-driven motors rely on a system of belts and pulleys to transfer power from a separate motor to the sewing machine’s mechanisms. These motors are often found in vintage or heavy-duty sewing machines.

Belt-driven systems can offer greater power and control, making them suitable for heavy fabrics and demanding sewing tasks.

They provide a tactile sewing experience and are favored by experienced sewists who appreciate hands-on control.

Servo Motor

Servo motors are a type of electronic motor that allows for precise speed control and are commonly used in industrial and commercial sewing machines.

They are energy-efficient and can be adjusted to provide the exact amount of power needed for a particular sewing task.

Servo motors offer quiet operation and are known for their responsiveness. They are suitable for a wide range of sewing applications and are often found in professional settings.

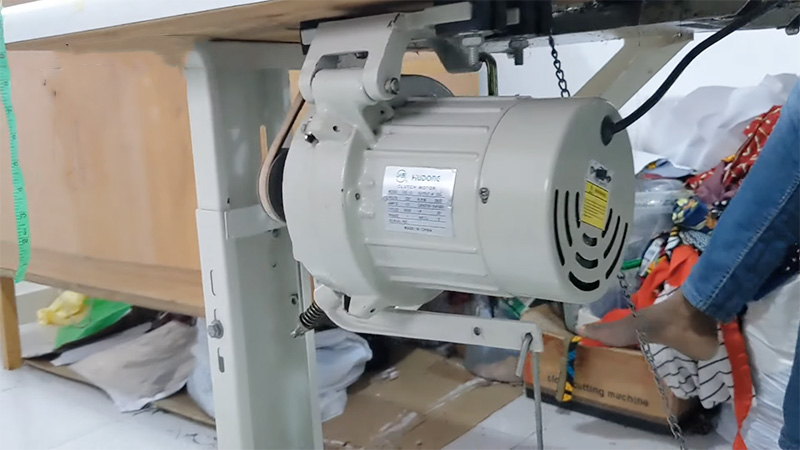

Clutch Motor

Clutch motors are often used in industrial sewing machines and provide high-speed operation. They have a clutch mechanism that engages and disengages the motor, allowing for quick starts and stops. Clutch motors are powerful but can be noisy and less energy-efficient compared to servo motors.

Direct-Drive Motor

Direct-drive motors are becoming increasingly popular in modern sewing machines. They are integrated directly into the sewing machine’s body, eliminating the need for belts and reducing vibration and noise.

Direct-drive motors are energy-efficient and offer precise speed control, making them suitable for a wide range of sewing tasks. Each type of sewing machine motor has its advantages and is suited to different sewing needs and preferences.

The choice of motor type often depends on factors such as the type of sewing you do, the materials you work with, and your personal preferences for noise level and control.

How to Rewire a Singer-Potted Motor?

Rewiring a Singer potted motor should only be attempted by those with experience in electrical work, as it involves potentially hazardous components.

If you’re not comfortable or experienced with electrical repairs, it’s advisable to seek the assistance of a qualified sewing machine technician or an electrician.

However, if you have the necessary skills and knowledge, here’s a general guide for rewiring a Singer potted motor:

Tools and Materials

- Screwdriver

- Wire strippers

- Electrical tape

- Soldering iron and solder

- Replacement wires (matching the original specifications)

Access the Motor

Open the casing of your Singer sewing machine to access the potted motor. This may involve removing screws or covers, depending on your machine’s design.

Identify the Wiring

Carefully identify the wiring connections in the motor. Take photographs or make notes of the existing connections to ensure you can recreate them accurately.

Using a screwdriver or appropriate tool, carefully disconnect the wires from the motor terminals. Be cautious not to damage the terminals or the wires.

Remove Damaged Wires

If the wiring is damaged or frayed, carefully cut away the damaged sections using wire strippers. Cut replacement wires to the appropriate length, ensuring they match the original specifications in terms of gauge and insulation type.

Strip and Tin the Wires

Strip a small section of insulation from the ends of the replacement wires and tin them by applying solder to the exposed wire ends. This helps ensure good connections.

Reconnect the Wires

Carefully reconnect the replacement wires to the motor terminals following the original wiring configuration. Solder the connections to secure them in place.

Insulate the Connections

After soldering, use electrical tape or heat-shrink tubing to insulate the connections and prevent short circuits.

Test the Motor

Reassemble the sewing machine and plug it in. Test the motor to ensure it operates smoothly without any issues.

Secure Wiring

Secure the replacement wires neatly within the machine’s casing to prevent them from getting tangled or damaged during use.

Once you’ve confirmed that the motor is functioning correctly, reassemble the sewing machine, ensuring all screws and covers are properly secured.

Remember that working with electrical components can be dangerous, and mistakes can lead to electrical hazards or damage to your sewing machine.

If you’re unsure or uncomfortable with any part of the process, it’s best to seek professional assistance from a qualified technician to ensure safety and proper rewiring.

FAQs

Potted motors offer a more compact and space-saving design. They are sealed, require minimal maintenance, and operate quietly. They are often found in modern sewing machines and are user-friendly.

A belt-driven system may be preferred when you need greater power and control, especially for heavy fabrics and demanding sewing tasks. They offer a more tactile sewing experience and are favored by experienced sewists.

Potted motors can handle many heavy-duty sewing tasks, especially on modern sewing machines designed for such purposes. However, for extremely heavy fabrics and industrial-scale work, a belt-driven system may offer more power.

Yes, belt-driven systems generally require more maintenance. Belts may need occasional replacement, and these systems may require regular oiling and cleaning. Potted motors are sealed and need minimal maintenance.

Converting your sewing machine’s motor type (potted to belt-driven or vice versa) can be a complex and costly modification. It often involves significant alterations to the machine’s internal components and is not recommended for most home sewists.

Conclusion

The choice between a potted motor and a belt-driven system for your sewing machine is a critical decision that directly impacts your sewing experience. Both options have their merits and considerations, which we’ve explored in this guide.

Potted motors offer integration, efficiency, and a sleek design, reducing the need for maintenance and providing a compact, user-friendly sewing machine. They are ideal for those who seek modern convenience and minimal fuss.

On the other hand, belt-driven machines harken back to the traditional craftsmanship of sewing.

They offer greater power and control, making them favored by many professionals and dedicated sewists who appreciate the tactile experience of sewing.

Ultimately, the choice comes down to your sewing style, preferences, and specific needs.

Whether you opt for the streamlined efficiency of a potted motor or the hands-on craftsmanship of a belt-driven system, both can yield beautiful and satisfying sewing results.

Leave a Reply