Sewing machine buttonholes are a vital component of many sewing projects, from clothing to home decor. However, they can be a source of frustration when issues arise.

Sewing machine buttonhole troubleshooting is essential for ensuring your buttonholes are neat, precise, and free from any problems.

In this guide, we will explore Sewing Machine Buttonhole Troubleshooting, and provide practical solutions to address these challenges.

Whether you’re a seasoned sewist or just starting your sewing journey, understanding how to troubleshoot buttonhole problems is crucial. It ensures your garments and projects not only look professional but also function correctly.

With the right techniques and know-how, you can conquer buttonhole issues and gain confidence in your sewing abilities, ultimately elevating the quality of your creations.

Sewing Machine Buttonhole Troubleshooting: 9 Common Problems

Here are 9 common problems that you may encounter:

The Buttonhole Is Too Small Or Too Large For The Button

This can cause the button to be loose or tight in the buttonhole, which can affect the appearance and function of your garment.

You should measure your button and adjust the buttonhole size accordingly on your machine.

You can use the buttonhole foot or the buttonhole lever to set the correct size for your button.

The Buttonhole Is Not Centered Or Aligned On The Fabric

This can cause the buttonhole to look crooked or uneven on the fabric, which can affect the appearance and function of your garment.

You should mark the position and direction of the buttonhole on the fabric before sewing. You can use a ruler, a pencil, a tailor’s chalk, or a washable marker to make the marks.

You should also make sure that the fabric is straight and flat under the presser foot.

The Buttonhole Is Not Stitched Properly Or Completely

This can cause the buttonhole to look sloppy or unfinished on the fabric, which can affect the appearance and function of your garment.

You should check your machine settings and thread quality before sewing. You should also use a high-quality thread that matches your fabric color and weight.

The Buttonhole Is Not Cut Open Or Cut Too Much

This can cause the buttonhole to be closed or frayed on the fabric, which can affect the appearance and function of your garment.

You should cut open your buttonhole carefully and neatly after sewing. You can use a seam ripper, a pair of scissors, or a buttonhole cutter to cut open your buttonhole.

You should also place a pin or a needle at each end of the buttonhole to prevent cutting beyond the stitches.

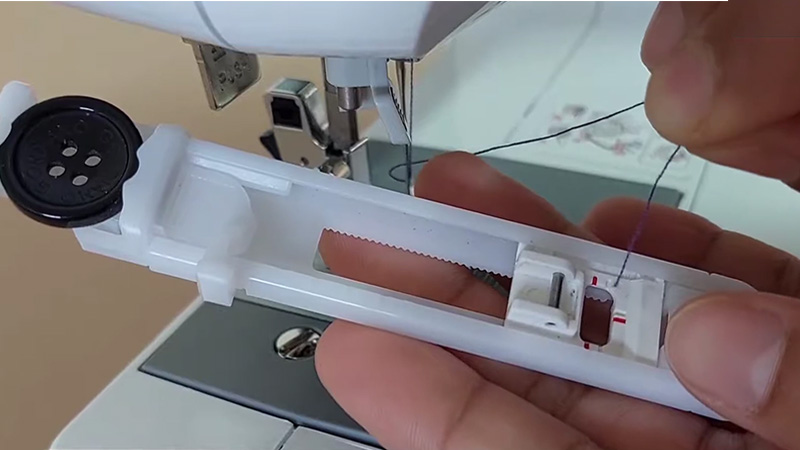

The Buttonhole Stitches Are Loose Or Tight

This can cause the buttonhole to look irregular or distorted on the fabric, which can affect the appearance and function of your garment.

You should adjust your machine tension according to your fabric and thread type and weight.

You should also check your bobbin thread and make sure it is wound evenly and inserted correctly into the bobbin case. You should test your tension on a scrap piece of fabric before sewing your buttonhole.

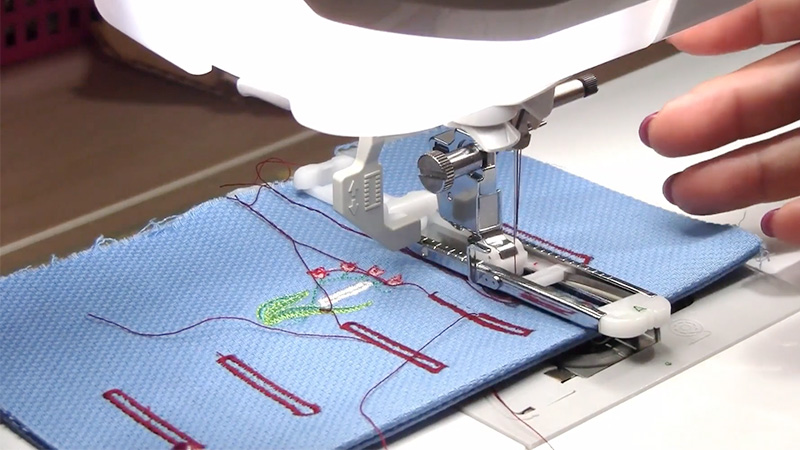

The Fabric Puckers Or Wrinkles Around The Buttonhole

This can cause the buttonhole to look bumpy or uneven on the fabric, which can affect the appearance and function of your garment. You should stabilize your fabric before sewing your buttonhole.

You can use a fusible interfacing, a tear-away stabilizer, or a wash-away stabilizer to reinforce your fabric and prevent it from puckering or wrinkling.

You should also press your fabric before and after sewing your buttonhole to smooth out any creases or folds.

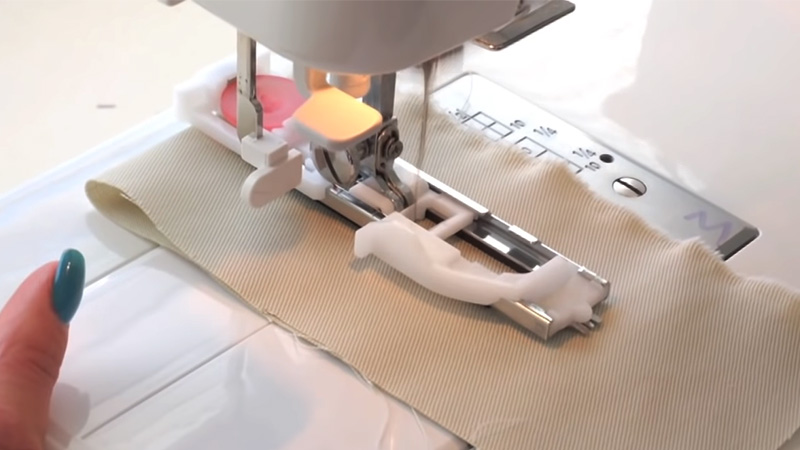

The Fabric Feeds Unevenly Or Gets Stuck Under The Presser Foot

This can cause the buttonhole to look crooked or incomplete on the fabric, which can affect the appearance and function of your garment.

You should use the right presser foot for your machine and your fabric type and weight. You should also use a feed dog cover, a walking foot, or a roller foot to help the fabric feed smoothly and evenly under the presser foot.

You should also make sure that the fabric is not too thick or too thin for your machine and that it does not have any pins, buttons, or zippers that can get caught under the presser foot.

The Needle Breaks Or Bends While Sewing The Buttonhole

This can cause the buttonhole to look incomplete or damaged on the fabric, which can affect the appearance and function of your garment.

You should use a high-quality needle that is compatible with your machine model and suitable for your fabric type and weight. You should also replace your needle after every project or after sewing for about 8 hours.

You should also avoid sewing over any hard objects, such as pins, buttons, or zippers, that can damage your needle.

The Machine Jams Or Stops While Sewing The Buttonhole

This can cause the machine to malfunction or damage while sewing the buttonhole, which can affect its performance and safety. You should check your machine for any dust, lint, or dirt that can clog or interfere with its functions and parts, such as the bobbin case, the feed dogs, the tension discs, and the needle bar.

You should also check your machine for any loose or broken screws, wires, or components that can cause the machine to jam or stop.

You should clean and oil your machine regularly according to your manual’s instructions and have it serviced and calibrated periodically by a qualified technician.

Sewing Machine Buttonhole Troubleshooting: 9 Common Solutions

Troubleshooting sewing machine buttonhole issues can help you overcome common problems and achieve flawless results.

Here are nine common buttonhole problems and their respective solutions:

Uneven Buttonholes

Ensure even fabric tension by using the correct presser foot pressure for your fabric. Test on a fabric scrap to determine the ideal settings and adjust your machine accordingly.

Buttonhole Stitch Length Variations

Maintain a steady sewing speed and ensure the machine is set to a consistent stitch length. Refer to your machine’s manual for recommended settings.

The Buttonhole Ends with Loose Threads

Adjust the thread tension slightly to prevent loose threads. Test your buttonhole settings on a fabric scrap until the tension is balanced.

Buttonhole Stitches Too Tight or Too Loose

Correct bobbin tension if necessary, ensuring it matches the upper thread’s tension. Make adjustments as needed to achieve balanced buttonhole stitches.

Buttonhole Size Inaccuracies

Double-check your buttonhole foot settings, as some machines require manual input of the button’s size. Ensure the settings match your button’s dimensions.

Fabric Jams or Feeding Issues

Use the appropriate needle size and type for your fabric. Ensure smooth fabric feeding by guiding it evenly through the machine, and avoid abrupt starts and stops.

Buttonhole Alignment Problems:

Precisely mark buttonhole positions on the fabric using fabric markers or chalk. Accurate marking ensures your buttonholes align correctly.

Buttonhole Satin Stitch Issues

Place a stabilizer beneath the fabric to improve satin stitch quality and prevent fabric distortion during buttonhole sewing.

Machine Error Messages or Malfunctions

Refer to your machine’s manual to decode error messages or address malfunctions. If issues persist, consider professional servicing or consultation with a sewing machine technician.

By implementing these solutions, you can troubleshoot common buttonhole problems and achieve consistent, professional-quality buttonholes in your sewing projects.

How Do You Use A 5-Step Buttonhole?

Using a sewing machine with a 5-step buttonhole function can seem complex, but it becomes straightforward with practice.

Here’s a step-by-step guide:

Select the Buttonhole Stitch

Start by choosing the buttonhole stitch on your sewing machine. On many machines, this is indicated by a symbol or the word “buttonhole.” Refer to your machine’s manual to locate the appropriate setting.

Adjust the Buttonhole Foot

Attach the buttonhole foot to your sewing machine. Ensure it’s securely in place, as this foot guides the machine in creating the buttonhole accurately.

Mark the Buttonhole Placement

Use fabric chalk or a removable fabric marker to mark the starting and ending points of the buttonhole on your fabric. Ensure the marks align with your button’s size and position.

Position the Fabric

Place your fabric under the buttonhole foot, aligning the starting mark with the buttonhole foot’s guide. Lower the presser foot to secure the fabric in place.

Begin Sewing

Start the machine and follow these steps:

- First step: The machine will sew the left side of the buttonhole. Allow it to complete this leg, stopping at the second mark.

- Second step: Sew the bar tack by adjusting the machine settings if needed. The bar tack is the horizontal section of the buttonhole.

- Third step: Sew the right side of the buttonhole, ending at the starting mark. The machine will automatically lock the stitches at the end.

Finish and Secure

Lift the presser foot, gently pull out your fabric, and trim any loose threads. Use a seam ripper or small scissors to carefully open the buttonhole by cutting along the center. Be cautious not to cut the stitches.

Test the Fit

Before attaching the button, place it through the buttonhole to ensure it fits correctly. Adjust the buttonhole size if needed by adjusting the stitch width or length settings on your machine.

Using a 5-step buttonhole function on your sewing machine allows you to create precise and tailored buttonholes for your garments.

With practice, you’ll become proficient in this essential sewing skill.

FAQ

Uneven buttonholes can result from incorrect machine settings or fabric feed issues. Ensure your machine is set for buttonhole stitching and check for proper fabric alignment.

Fabric puckering can be reduced by using interfacing, adjusting tension settings, and using a stabilizer to support the fabric while sewing buttonholes.

Incorrect buttonhole sizing can be due to inaccurate settings. Double-check your button size and use the correct buttonhole foot for accurate results.

Skipping stitches can be caused by a dull needle, incorrect machine settings, or fabric issues. Replace the needle, ensure proper machine settings, and use appropriate fabric for smoother buttonholes.

Thread issues often result from incorrect threading, using low-quality thread, or a dirty machine.

Re-thread the machine, use high-quality thread, and clean your machine to prevent thread-related problems during buttonhole sewing.

Conclusion

Troubleshooting buttonholes on your sewing machine is a valuable skill that can save you time and frustration during your sewing projects.

By identifying and addressing common issues like stitch irregularities, fabric puckering, or sizing problems, you can achieve flawless buttonholes that enhance the overall quality of your creations.

Regular practice and attention to detail will help you become a proficient buttonhole troubleshooter. As you gain experience, you’ll be able to tackle various fabrics and buttonhole styles with ease, ensuring that your garments and crafts not only look professional but also function perfectly.

So, embrace the art of buttonhole troubleshooting, and watch as your sewing skills soar to new heights, allowing you to create beautiful and functional buttonholes every time you sit down at your sewing machine.

Leave a Reply