Sewing machines are invaluable tools for countless crafters and seamstresses, enabling them to bring their creative visions to life. Central to the sewing machine’s functionality is its motor, which drives the needle and powers the sewing process.

However, like any mechanical component, sewing machine motors can encounter issues that disrupt the smooth operation. In this guide, we delve into the realm of Sewing Machine Motor Troubleshooting, providing a comprehensive resource to help you identify and address a wide range of common motor problems.

From issues like erratic speed control and overheating to peculiar noises and electrical malfunctions, we’ll guide you through 30 essential steps to diagnose and potentially resolve these challenges, ensuring your sewing machine remains a reliable partner in your crafting journey.

30 Sewing Machine Motor Troubleshooting

Troubleshooting sewing machine motor issues can help you identify and potentially resolve problems without the need for professional repair.

Here are 30 steps to help you diagnose and address common sewing machine motor problems:

1. Motor Not Running Smoothly

When your sewing machine’s motor isn’t running smoothly, it’s often due to inadequate lubrication in the motor area. Properly lubricate the designated areas with sewing machine oil according to your machine’s manual to reduce friction and ensure even motor operation.

If this doesn’t resolve the issue, inspect the speed control mechanism for potential adjustments or signs of wear.

2. Motor Not Running at All

A sewing machine motor that refuses to run can be a frustrating obstacle. Start by verifying that the power cord is securely plugged into a functional electrical outlet.

Carefully examine the power cord for visible damage, such as fraying or exposed wires. Additionally, check your home’s electrical panel for blown fuses or a tripped circuit breaker.

Inspect the foot pedal for loose wires or damage.

3. Motor Spinning Too Fast

If your motor races at an uncontrollable speed, begin by adjusting the speed control to a lower setting. Should this adjustment prove ineffective, scrutinize the speed control for loose connections or damaged components.

Proper lubrication of the speed control mechanism as per your machine’s manual can also help ensure it functions correctly.

4. Motor Spinning Too Slow

Conversely, if your motor is running sluggishly, test its responsiveness by increasing the speed control to its maximum setting. If it continues to perform slowly, it may be a sign of a worn or damaged motor, necessitating professional inspection or replacement.

5. Intermittent Motor Operation

Intermittent motor operation can disrupt your sewing flow. To tackle this, first, examine the power cord and foot pedal connections. Loose or damaged wires can cause sporadic issues, so make sure all connections are secure.

Should the problem persist, inspect the foot pedal for internal issues.

6. Motor Overheating

Extended sewing sessions can lead to motor overheating. To prevent this, periodically allow the machine to rest and cool down. Check for any obstructions around the motor that may obstruct airflow.

Regularly clean the machine and lubricate moving parts to mitigate the risk of overheating.

7. Loud or Unusual Noises

Unusual noises emanating from the motor area can be disconcerting. Open the machine’s casing and check for loose screws, nuts, or bolts. Examine moving parts for signs of wear or damage, and apply lubrication as necessary.

Squeaking or grinding noises may indicate a need for additional lubrication.

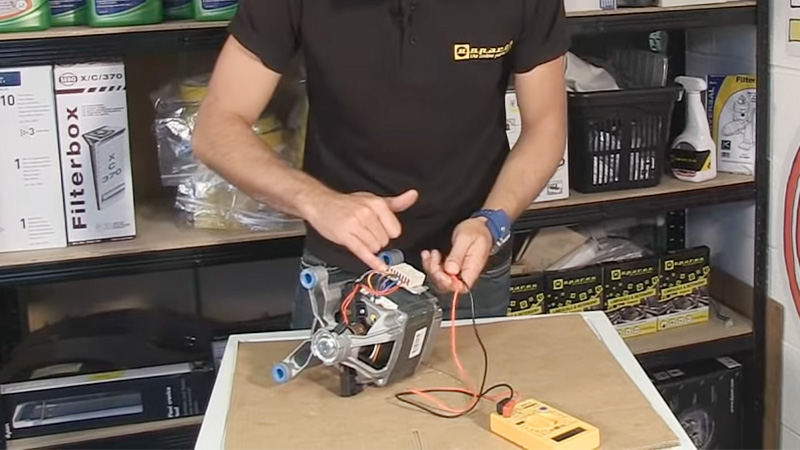

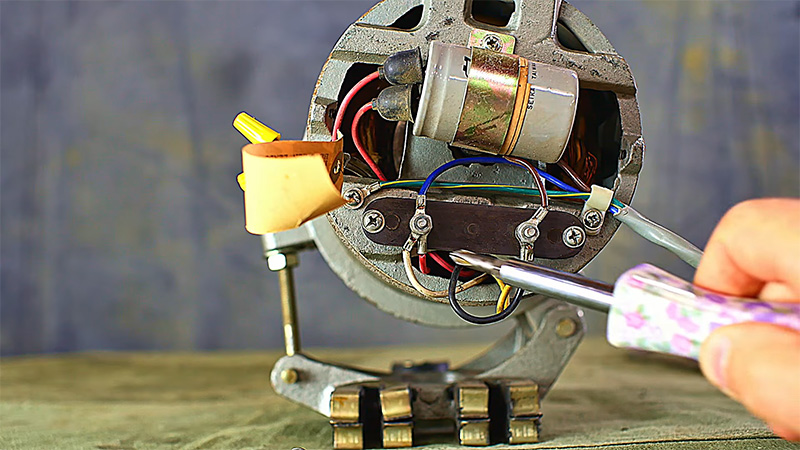

8. Motor Brushes Worn Out

Motor brushes play a crucial role in maintaining electrical contact within the motor. To address this issue, consult your machine’s manual to locate the motor brushes.

Carefully remove and inspect them for wear or damage, and replace them following the manufacturer’s guidelines.

9. Motor Pulley Belt Issues

If you’re experiencing motor pulley belt problems, carefully examine the belt for damage, slipping, or incorrect tension. In cases of damage or slipping, replace the belt with a new one.

Ensure that you adjust the belt tension according to your machine’s manual to maintain optimal performance.

10. Faulty Foot Pedal

A faulty foot pedal can significantly impact motor control. Inspect the foot pedal for loose wires, frayed cables, or physical damage. To test its functionality, press the pedal with your foot.

If any issues are identified, undertake the necessary repairs or consider a replacement. Ensure that the foot pedal cord is securely plugged into the sewing machine.

11. Electrical Issues

Electrical problems can disrupt your sewing machine’s motor. Carefully inspect the wiring for visible damage, exposed wires, or loose connections. Examine both the power cord and foot pedal cord for potential issues.

If an electrical problem is suspected, it’s advisable to consult a qualified technician or electrician for diagnosis and repair.

12. Motor Not Responding to Speed Control

When the motor doesn’t respond to adjustments in the speed control, conduct a thorough inspection of the speed control mechanism. Look for loose wires, damaged components, or misalignment.

Lubricate the mechanism if necessary. Should the problem persist, it’s advisable to seek professional servicing or consider motor replacement.

13. Motor Running in Reverse

A motor running in reverse can be perplexing. Examine the wiring from the foot pedal to the motor, checking for crossed or improperly connected wires.

Confirm that the foot pedal is functioning correctly and that all connections are secure. If necessary, repair or replace components as needed.

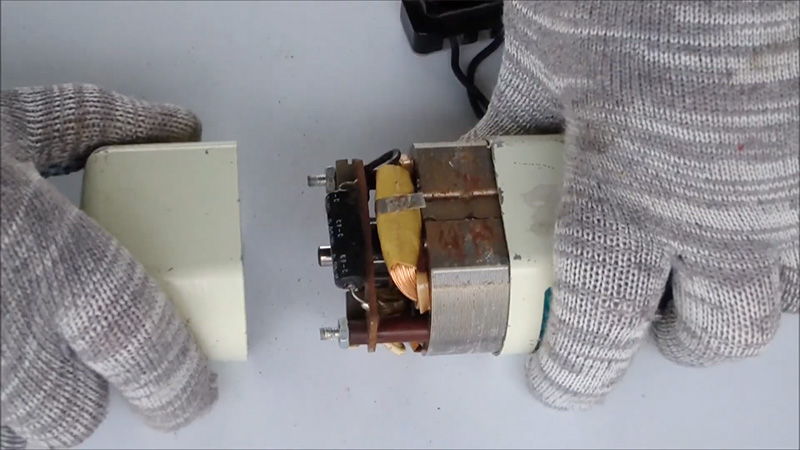

14. Motor Sparking

Sparks or electrical arcing within the motor are serious issues. Immediate action is required: turn off the machine, unplug it, and refrain from using it further.

Sparks often indicate a significant electrical problem that demands professional attention to ensure safety.

15. Motor Emits a Burning Smell

A burning odor from the motor necessitates prompt action. Turn off the machine and unplug it to prevent further damage. Allow it to cool down, and then carefully inspect the motor and surrounding wiring for signs of overheating or burning.

Address any damaged components or wires promptly to prevent further damage.

16. Motor Switches Off During Use

An unexpected motor shutdown can be frustrating. Investigate potential causes such as overheating, power supply problems, or a faulty circuit breaker.

If overheating is the issue, allow the machine to cool down before resuming sewing. Ensure that the power supply is stable, and if the problem persists, consult an electrician or technician for a proper diagnosis.

17. Motor Vibrates Excessively

Excessive vibration can disrupt your sewing experience. Start by checking for loose screws or parts inside the machine’s casing and tighten them as needed.

Ensure that the sewing machine is placed on a stable surface to minimize vibration.

18. Motor Emits Smoke

Smoke emanating from the motor is a grave sign of a severe electrical problem. Without delay, turn off the machine, unplug it, and disconnect it from the power supply to prevent safety hazards.

Seeking professional assistance is crucial to address this issue properly.

19. Motor Lacks Power

A motor lacking power may be indicative of internal damage or wear. It’s advisable to consult a technician for a thorough inspection and diagnosis. They can assess whether the motor or any internal components need replacement.

20. Motor Circuit Breaker Trips

Repeatedly tripping circuit breakers indicate electrical overload. To mitigate this, reduce the load on the machine by refraining from using multiple appliances on the same circuit.

Consult an electrician to assess the circuit’s capacity and potentially upgrade it to handle the sewing machine’s power requirements.

21. Motor Gets Excessively Hot

To prevent motor overheating, ensure that the sewing machine has proper ventilation and cooling. Check for any obstructions around the motor that might impede airflow.

Regularly clean the machine to prevent dust and debris buildup, which can contribute to overheating.

22. Motor Makes a Clicking Noise

Clicking noises can be bothersome and may signify loose parts or foreign objects within the machine. Open the casing, inspect the components, and tighten any loose screws or parts.

If foreign objects are found, carefully remove them to eliminate the source of the noise.

23. Motor Gets Stuck

A stuck motor is often the result of fabric or thread jammed in the machine. Carefully remove the jammed material and untangle any thread snags. Additionally, clean the bobbin area and remove lint to prevent further jams.

24. Motor is Noisy During Startup

Lubricate moving parts as recommended in the machine’s manual to reduce startup noise. If excessive noise persists, seek professional inspection to identify and address any underlying issues.

25. Motor Makes a Whining Sound

Whining noises may indicate internal component problems. To diagnose and rectify these issues, consult a technician experienced with sewing machine motors.

They can dismantle the motor and inspect internal components for wear or damage.

26. Motor Stalls When Sewing Thick Fabrics

When sewing thick fabrics, ensure your machine is appropriately adjusted for the task. Use the correct needle type and size, and consider attaching a walking foot or even-feed foot to facilitate smooth fabric feeding.

If the motor continues to stall, consult a technician for further assessment.

27. Motor Jerks or Jolts

Check the foot pedal for proper operation. Inspect the wiring for any loose or damaged connections. Ensure the foot pedal cord is securely plugged into the machine and that the cord itself is in good condition.

28. Motor Belt Slips

A slipping motor belt can result in uneven stitching and motor strain. Adjust the belt tension according to your machine’s manual to ensure it’s neither too loose nor too tight.

If the belt is damaged or excessively worn, replace it following the manufacturer’s guidelines.

29. Motor Produces a Burning Odor

If a burning odor arises, immediately turn off the machine, unplug it, and allow it to cool down. Carefully inspect the motor and surrounding wiring for signs of overheating or burning.

Address any damaged components or wires promptly to prevent further damage.

30. Motor Speed Inconsistent

Inconsistent motor speed can be frustrating. Inspect the speed control mechanism for loose connections, damaged components, or misalignment. Make necessary adjustments following your machine’s manual.

If the issue persists, consult a technician or sewing machine repair expert to diagnose and resolve the problem.

What Are the Symptoms of a Sewing Machine Motor Problem?

Sewing machines are invaluable tools for crafting, tailoring, and creating beautiful garments, but like any mechanical device, they can encounter issues over time.

One critical component that can experience problems is the sewing machine motor. Recognizing the symptoms of a sewing machine motor problem is essential for maintaining the functionality of your machine and ensuring your sewing projects go smoothly.

Here are some common symptoms to be aware of:

Failure to Start

When you press the foot pedal or power button, the sewing machine doesn’t respond at all. This could indicate a problem with the motor’s electrical connections or internal components.

Intermittent Operation

The machine starts and stops unexpectedly during use, making it difficult to maintain a consistent sewing rhythm. This erratic behavior can disrupt your sewing projects.

Slow or Inconsistent Speed

The sewing machine may run at a slower speed than usual or struggle to maintain a consistent sewing pace. This symptom suggests that the motor is not delivering the necessary power.

Unusual Noises

A healthy sewing machine emits a familiar and relatively quiet mechanical sound during operation. If you hear strange noises like humming, buzzing, grinding, or clicking, it’s a sign that something is amiss with the motor or its components.

Overheating

A motor that quickly becomes hot to the touch during use is a cause for concern. Overheating can lead to motor damage and pose a safety risk. Modern sewing machines often have safety mechanisms to shut down the motor if it overheats.

Burning Smell

An unusual or burning odor emanating from the sewing machine while it’s running is a clear indication of a motor problem. It could result from overheating, electrical issues, or damaged components.

Lack of Power

The motor might struggle to handle thicker fabrics, multiple layers, or challenging sewing tasks. This lack of power can lead to poor stitching quality and frustration.

Inconsistent Stitching

Motor issues can manifest as irregular stitching patterns, skipped stitches, or uneven stitching. These problems can compromise the quality and durability of your sewing projects.

Excessive Vibration

A sewing machine should vibrate moderately while in use, but excessive vibration could be a sign of an imbalanced motor or issues with the machine’s internal components.

Visible Damage

If you notice any visible damage to the motor, such as loose wires, burnt-out components, or physical wear and tear, it’s a clear indication that the motor requires attention and possible replacement.

FAQs

Sudden motor stoppages can occur due to various factors, such as overheating, electrical issues, or thread jams. Begin by allowing the motor to cool down, checking for power supply problems, and inspecting the machine for thread or fabric jams.

Erratic motor behavior might be linked to issues with the speed control mechanism, loose wiring, or damaged foot pedals. Inspect and troubleshoot these components, ensuring all connections are secure.

If you encounter major issues like sparks, smoke, persistent burning smells, or electrical malfunctions, it’s safer to seek professional help. Additionally, if you’re unsure about troubleshooting certain components, consulting a technician is advisable.

It’s essential to use the specific sewing machine oil recommended in your machine’s manual for motor lubrication. Using the wrong type of oil can cause damage.

To Recap

Mastering the art of sewing machine motor troubleshooting empowers crafters and sewing enthusiasts to maintain their beloved machines with confidence.

The 30 comprehensive steps covered in this guide offer a roadmap to diagnose and address a myriad of motor-related issues, from minor inconveniences to potentially serious malfunctions.

By applying these troubleshooting techniques, you can prolong the life of your sewing machine, save on repair costs, and ensure uninterrupted creative endeavors.

Remember that safety is paramount, and for complex or hazardous issues like sparks or smoke, seeking professional assistance is essential. With regular maintenance, care, and a bit of troubleshooting know-how, your sewing machine motor will continue to power your artistic expressions for years to come.

Happy sewing!

Leave a Reply