Have you ever noticed blue sparks emanating from your sewing machine motor and wondered if it’s cause for concern? In the sewing world, the performance of your machine’s motor is crucial for smooth and efficient stitching.

However, the appearance of blue sparks might raise questions about safety and functionality. So, should a sewing machine motor have blue sparks?

In this exploration, we delve into the reasons behind the enigmatic blue sparks, addressing whether they signal a problem or are simply a normal part of the sewing machine’s operation.

Join us as we demystify this phenomenon, providing insights into what could be causing these sparks and offering guidance on whether intervention is necessary.

Understanding your sewing machine’s behavior ensures not only a seamless sewing experience but also helps you maintain the longevity of your cherished crafting companion. Gain insights to make informed decisions, ensuring a safe and enjoyable sewing experience.

Should A Sewing Machine Motor Have Blue Sparks?

The presence of blue sparks emitted from a sewing machine motor can be a cause for concern.

Let’s delve into various aspects of blue sparks in sewing machine motors, addressing potential causes, the significance of regular maintenance, and providing guidance on when to seek professional help.

Understanding the Basics

Sewing machines are intricate devices with motors at their core, powering the mechanisms that drive the needle and facilitate smooth stitching. These motors can exhibit sparks during operation, and the color of these sparks might vary. So, do blue sparks do any damage?

Blue sparks, in particular, can be a point of intrigue and, at times, apprehension for sewing enthusiasts.

Normal Wear and Tear

One of the common reasons for observing blue sparks is the natural wear and tear of the motor’s components. As a sewing machine operates, friction between moving parts can generate sparks.

In well-maintained machines, these sparks are often minimal and not cause for alarm. However, if the machine has been in use for an extended period without proper care, the wear on components can escalate, leading to more visible sparks.

Electrical Connections and Wiring

Another factor contributing to blue sparks could be issues with electrical connections or faulty wiring within the sewing machine. Loose connections or damaged wires can disrupt the electrical flow, causing sparks.

Regularly inspecting the power cord, plug, and internal wiring for any signs of wear or damage is essential to prevent electrical issues that may manifest as sparks during operation.

Lubrication and Maintenance

Proper lubrication reduces friction between moving parts in a sewing machine motor. Lack of lubrication can result in increased friction, leading to overheating and, consequently, the production of sparks.

Regular maintenance, including cleaning and oiling the machine, can significantly minimize the risk of sparks and ensure the motor’s longevity.

Quality of Components

The quality of the sewing machine’s components plays a significant role in its overall performance. Machines with subpar or worn-out components may be more prone to sparking.

Investing in a high-quality sewing machine with durable and well-manufactured parts can provide a smoother and safer sewing experience.

Signs of Concern

While some sewing machine motor sparking is normal, certain signs indicate potential issues requiring attention. If the blue sparks are accompanied by unusual noises, erratic behavior in stitching, or a burning smell, it’s crucial to investigate further.

These symptoms may suggest more serious problems with the motor or other internal components.

Safety Considerations

Ensuring the safety of the sewing machine operator is paramount. If blue sparks are consistently visible, it’s advisable to disconnect the machine from the power source immediately. A machine exhibiting persistent sparking without addressing the underlying issues may pose a safety risk.

DIY Troubleshooting

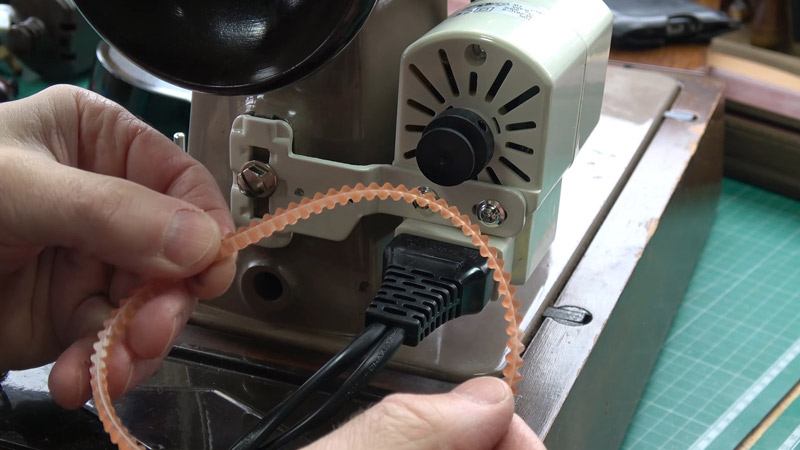

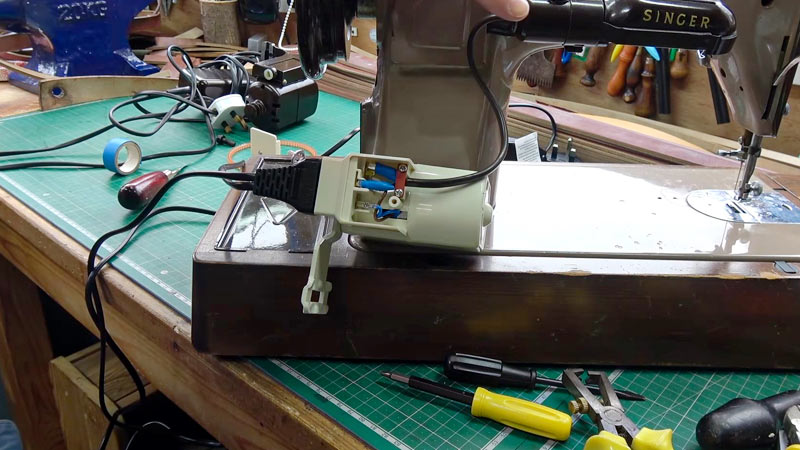

For sewing enthusiasts who enjoy a hands-on approach, some troubleshooting steps can be taken to identify and address minor issues.

These include checking and tightening electrical connections, examining the power cord and plug for damage, and ensuring proper lubrication of moving parts.

However, it’s crucial to exercise caution and seek professional assistance if uncertain or if the issues persist.

Professional Assessment

When in doubt or when the sewing machine exhibits signs of more complex problems, seeking the expertise of a professional technician is highly recommended.

A trained technician can conduct a thorough assessment, identify the root cause of motor sparking, and perform any necessary repairs or replacements. This not only ensures the operator’s safety but also extends the lifespan of the sewing machine.

How to Stop Motor Brushes from Sparking?

To minimize sparking in sewing machine motor brushes, follow these steps:

Clean the Brushes

Regularly clean the sewing machine motor brushes to remove any dust or debris. Disconnect the machine from power before cleaning. Use a soft brush or compressed air to clean the area around the brushes gently.

Check Brush Quality

Ensure the brushes are in good condition. Worn-out or damaged brushes can cause increased sparking. Replace brushes that show signs of wear. Consult the sewing machine’s manual for guidance on appropriate brush replacements.

Proper Lubrication

Lubricate the motor bearings as recommended by the manufacturer. Well-lubricated bearings reduce friction, preventing excessive sparking. Use the appropriate oil or grease specified in the machine’s manual.

Adjust Brush Tension

Inspect the tension of the brushes against the commutator. Brushes that are too tight can cause sparking. Adjust the tension according to the machine’s specifications. Consult the manual for guidance on proper brush tension adjustment.

Check Commutator Condition

Examine the commutator, the segmented copper disc inside the motor. Ensure it’s clean and smooth. Clean the commutator using a fine abrasive material if there are any rough spots or deposits. Be cautious not to damage the surface.

Correct Alignment

Verify that the brushes are aligned correctly with the commutator. Misalignment can lead to uneven wear and sparking. Adjust the brush position according to the manufacturer’s guidelines.

Inspect Wiring

Examine the motor’s wiring for any signs of damage or fraying. Damaged wiring can contribute to sparking. Replace or repair any faulty wiring, and ensure all connections are secure.

Control Voltage Fluctuations

Use a voltage stabilizer or surge protector to regulate the power supply. Fluctuations in voltage can cause sparking. Stable voltage ensures consistent motor performance.

Avoid Overloading

Do not overload the sewing machine by attempting to sew through materials that exceed its capacity. Overloading can strain the motor, leading to increased electric motor brush sparking. Use the machine within its specified limits.

Maintain a Clean Sewing Area

Keep your sewing area clean to prevent dust and lint from entering the motor. Regularly clean the machine and surrounding workspace to reduce the risk of debris interfering with motor performance.

Ventilation

Ensure proper ventilation around the motor to prevent overheating. Motors that run too hot can experience increased sparking. Adequate airflow helps dissipate heat.

Professional Inspection

If you’ve tried the above steps and still experience sparking, consider seeking professional assistance. A qualified technician can perform a more thorough inspection and address any underlying issues with the motor.

By following these guidelines, you can minimize motor sparks in sewing machine motor brushes, ensuring smoother operation and prolonging the lifespan of your sewing machine.

Does Blue Sparks Do Any Damage?

Blue sparks in a sewing machine motor can indicate several issues, and while they may not always directly cause immediate damage, prolonged exposure to sparking can lead to problems.

Here’s an explanation of blue sparks and their potential consequences:

Immediate Damage

The blue sparks themselves may not necessarily cause immediate damage. However, the underlying issues leading to arcing can have consequences.

If left unaddressed, a continuous sparking motor can accelerate wear and tear on both the brushes and the commutator.

Brush and Commutator Wear

Prolonged sparking can accelerate the wear of motor brushes and the commutator. Excessive wear can lead to reduced performance and efficiency over time. Regular inspection and maintenance are crucial to prevent significant damage.

Increased Heat Generation

Arcing produces heat; if the sparking is consistent, it can result in elevated temperatures within the motor. Overheating can degrade insulation materials, impact lubrication, and potentially lead to more severe issues if not addressed promptly.

Electrical Interference

Blue sparks may indicate electrical interference, which can affect the overall performance of the sewing machine. In some cases, interference might extend beyond the motor, impacting electronic components and causing malfunctions.

Potential for Fire Hazard

While uncommon, continuous sparking can increase the risk of a fire hazard. This is especially true if flammable materials, such as accumulated lint or dust, are close to the motor. Regular cleaning and maintenance can mitigate this risk.

Loss of Motor Efficiency

The efficiency of the motor diminishes when sparking occurs. Loss of efficiency can result in decreased sewing machine performance, slower operation, or even motor stalling in extreme cases.

FAQs

Why Are Blue Sparks Appearing in My Sewing Machine?

Blue sparks in your sewing machine may be caused by arcing between the motor brushes and the commutator. This can result from issues such as poor brush contact, misalignment, or a damaged commutator.

Do Blue Sparks Immediately Damage the Sewing Machine?

While blue sparks themselves may not cause immediate damage, the underlying issues leading to arcing can result in accelerated wear and tear on the motor brushes and commutator. If left unaddressed, continuous sparking can impact performance and efficiency over time.

Can Blue Sparks Lead to Motor Overheating?

Yes, consistent arcing and blue sparks can generate heat within the motor. Overheating can degrade insulation materials and impact lubrication, potentially leading to more severe issues. It’s crucial to address sparking promptly to prevent excessive heat buildup.

Is Electrical Interference a Concern with Blue Sparks?

Yes, blue sparks may indicate electrical interference, potentially affecting the overall performance of the sewing machine. In some cases, interference can extend beyond the motor, impacting electronic components and causing malfunctions. Addressing sparking helps mitigate this risk.

How Can I Prevent Blue Sparks in My Sewing Machine?

To prevent electric motor sparking, engage in regular maintenance. Clean the brushes and commutator, ensure proper brush alignment and tension, and follow the manufacturer’s guidelines.

Conclusion

The presence of blue sparks from a sewing machine motor can be attributed to various factors, ranging from minor issues to normal wear and tear.

While occasional sparks may not indicate a serious problem, it’s essential to remain vigilant and promptly address any persistent issues.

Regular maintenance, such as cleaning and lubricating the motor components, can contribute to smoother operation and minimize the occurrence of sparks.

If concerns persist or escalate, seeking professional advice from a qualified technician is advisable to ensure the safety and longevity of your sewing machine.

Remember, understanding the nuances of your machine’s behavior empowers you to make informed decisions, fostering a productive and enjoyable sewing experience.

By unraveling the mystery of blue sparks, you can confidently navigate the intricacies of your sewing machine and continue creating beautiful stitches with peace of mind. Demystify and optimize your crafting companion today!

Leave a Reply