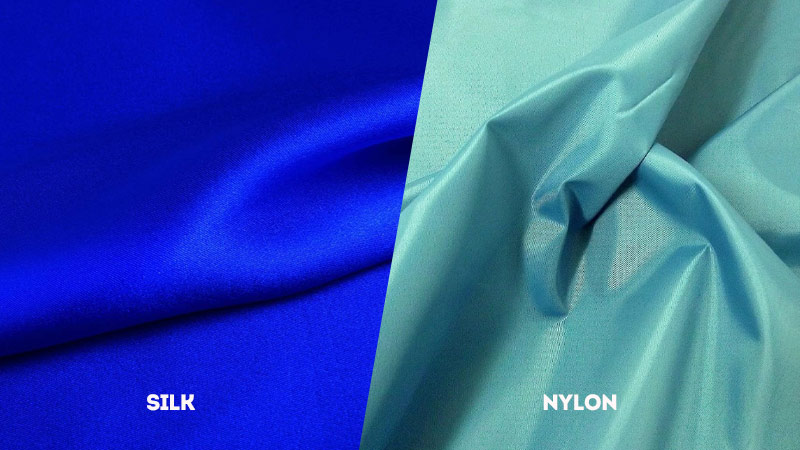

Silk and nylon are two distinct materials widely used in the textile industry, each offering unique characteristics and properties. Silk is a natural fiber derived from silkworms, known for its soft texture, luxurious luster, and excellent moisture absorption.

On the other hand, nylon is a synthetic material made from petrochemicals, recognized for its strength, durability, and versatility. These materials differ in various aspects, including texture, strength, elasticity, breathability, care requirements, cost, and more.

Understanding the differences between silk and nylon can help in making informed choices when selecting materials for clothing, accessories, or other applications.

Key Differences Between Silk Vs Nylon

Silk and nylon are two different materials used in textiles and other applications. They have distinct properties, origins, and uses. Here are the key differences between silk and nylon:

Source

- Silk: Silk is derived from the cocoons of silkworms. These silkworms are specifically bred for their silk production. The larvae of certain moth species spin cocoons made of continuous silk filaments. The cocoons are carefully harvested, and the silk fibers are extracted for further processing.

- Nylon: Nylon, on the other hand, is a synthetic material derived from petrochemicals. It is not obtained from any natural source. Nylon is created through a complex manufacturing process called polymerization, where petroleum-derived substances are chemically transformed into long chains of synthetic fibers.

Manufacturing Process

- Silk: The manufacturing process of silk involves several steps. First, the cocoons are boiled or exposed to heat to kill the silkworms and prevent them from breaking the silk threads.

Then, the cocoons are carefully unwound to extract the continuous silk filaments. These filaments are spun together to create silk threads, which can be further woven into fabric. - Nylon: Nylon is manufactured through a chemical process known as polymerization. Petrochemicals, such as crude oil or natural gas, serve as the raw materials.

These petrochemicals undergo various chemical reactions to create a polymer, a long chain of repeating units. The resulting polymer is then melted and extruded through fine holes to form nylon fibers. These fibers can be spun and woven into nylon fabric.

Texture

- Silk: Silk has a soft and smooth texture that is often described as luxurious. It has a gentle drape and a natural luster, giving it an elegant appearance. The smoothness of silk against the skin adds to its comfort and appeal, making it a favored choice for high-end clothing and bedding.

- Nylon: Nylon, in contrast, has a coarser and rougher texture compared to silk. It lacks the inherent softness and smoothness of silk. While it may not offer the same luxurious feel, nylon excels in strength and durability, making it suitable for various applications that prioritize robustness over texture.

Strength

- Silk: Silk is relatively strong, considering its delicate appearance. However, it is not as durable as nylon and can be more prone to damage, such as tearing or stretching. Silk fibers have a moderate tensile strength, which makes them suitable for a range of clothing and textile applications but requires proper care to maintain longevity.

- Nylon: Nylon is renowned for its exceptional strength and durability. It is known to be one of the strongest textile fibers, with a high tensile strength. Nylon fabrics can withstand heavy use, abrasion, and stretching without losing their structural integrity. These qualities make nylon a preferred choice for products that require long-lasting and robust materials.

Elasticity

- Silk: Silk possesses a moderate level of elasticity. It has a natural ability to stretch and recover without losing its shape. This elasticity contributes to the comfortable fit of silk garments and allows for ease of movement. However, silk does not have as high elasticity as certain synthetic materials like nylon.

- Nylon: Nylon is known for its high elasticity. It has excellent stretch and recovery properties, allowing it to return to its original shape after being stretched or compressed. This elasticity makes nylon fabrics highly flexible and suitable for applications that require materials to withstand stretching and movement, such as sportswear and hosiery.

Breathability

- Silk: Silk is highly breathable and offers good moisture absorption. It allows air to circulate and helps regulate body temperature, keeping the wearer cool in hot weather and warm in cold weather. The breathable nature of silk makes it comfortable to wear and suitable for various climates.

- Nylon: Nylon, in comparison, is less breathable than silk. It has lower moisture absorption properties, which can result in reduced airflow and potential moisture buildup. While nylon fabrics may not offer the same level of breathability as silk, they are often designed with additional features or treatments to enhance moisture-wicking capabilities for improved comfort during physical activities.

Moisture Absorption

- Silk: Silk has good moisture absorption properties. It can absorb moisture from the skin and wick it away, allowing for breathability and comfort. Silk’s ability to regulate moisture helps in keeping the wearer dry and cool in hot weather, making it suitable for garments that require moisture management.

- Nylon: Nylon has relatively low moisture absorption capabilities. It does not absorb moisture well and may retain sweat or moisture against the skin. However, nylon fabrics are often engineered with moisture-wicking technologies or treated to enhance their ability to pull moisture away from the body for improved comfort during physical activities.

Thermal Properties

- Silk: Silk has excellent thermal properties. It is a natural insulator, providing warmth in cold weather and retaining body heat. The structure of silk fibers creates air pockets that help to trap heat. Silk garments can provide a comfortable and cozy feel during colder seasons.

- Nylon: Nylon, in comparison, has less inherent thermal insulation. It does not possess the same level of natural warmth as silk. Nylon fabrics are generally lightweight and offer less insulation against cold temperatures. However, they can be combined with other materials or layered for added warmth in cold weather.

Allergies

- Silk: Silk is often considered hypoallergenic and suitable for individuals with sensitive skin or allergies. It is less likely to cause irritation or allergic reactions compared to many synthetic materials. The natural properties of silk make it gentle and soothing on the skin, making it a popular choice for those with sensitivities.

- Nylon: Nylon, on the other hand, can cause allergies or skin irritations in some individuals. Some people may be sensitive to the synthetic fibers or chemicals used in the production of nylon. It is advisable for those with allergies or skin sensitivities to consider alternative materials or seek nylon products specifically designed for sensitive skin.

Shrinkage

- Silk: Silk may shrink when exposed to improper care, such as high temperatures or aggressive washing methods. It is important to follow the recommended care instructions for silk garments to avoid shrinkage and preserve their shape and size. Proper handling and gentle washing techniques are essential for maintaining the integrity of silk fabrics.

- Nylon: Nylon, in general, is resistant to shrinkage. It can withstand higher temperatures and is less prone to significant size changes when subjected to washing or drying. This shrink-resistant property of nylon makes it a practical choice for items that require regular washing or exposure to heat.

Cost

- Silk: Silk is known for its luxurious and high-end reputation, which often translates into a higher cost. The labor-intensive production process, limited availability, and sought-after qualities of silk contribute to its relatively expensive price range. Silk garments and products are considered investments due to their quality and elegance.

- Nylon: Nylon, in contrast, is relatively inexpensive compared to silk. The synthetic nature of nylon and its efficient manufacturing process contribute to its affordability. Nylon is widely produced and available, making it a cost-effective option for a range of applications, including everyday clothing and various industrial uses.

Luster

- Silk: Silk has a natural luster that adds to its overall beauty and visual appeal. The inherent sheen of silk gives it an elegant and luxurious look, enhancing the appearance of garments and fabrics made from this material. The luster of silk can vary depending on the specific type of silk and its processing.

- Nylon: Nylon, in contrast, does not have an inherent luster. It is a synthetic material that lacks the natural shine of silk. Nylon fabrics typically have a more matte or semi-glossy appearance, depending on the specific finish or treatment applied during manufacturing.

Care Requirements:

- Silk: Silk requires delicate care to maintain its quality and longevity. It is generally recommended to hand wash silk garments or opt for dry cleaning. Silk fabrics should be handled gently, avoiding harsh detergents, high temperatures, and vigorous rubbing. Following the specific care instructions provided for silk products is crucial to prevent damage or loss of luster.

- Nylon: Nylon is relatively easy to care for compared to silk. Most nylon fabrics can be machine washed without significant risk of damage. They can withstand regular washing and drying at moderate temperatures. However, it is still important to check the care labels on nylon items for any specific instructions or precautions.

Dyeing

- Silk: Silk has excellent dye absorption properties, allowing it to hold dyes well. It can achieve vibrant and rich colors when dyed, enhancing its visual appeal. The dyeing process for silk can be performed using various techniques, resulting in a wide range of color options and patterns.

- Nylon: Nylon is easily dyed due to its synthetic nature and receptive fibers. It can be dyed with relative ease, resulting in vivid and long-lasting colors. The dyeing process for nylon often involves applying colorants to the fabric or yarn during production, ensuring even and consistent dye distribution.

Environmental Impact

- Silk: Silk has a relatively low environmental impact compared to some synthetic materials. It is a natural fiber derived from silkworms and is biodegradable. However, silk production may involve chemicals in the degumming and dyeing processes, and it requires considerable energy and resources for cultivation, processing, and manufacturing.

- Nylon: Nylon, being a synthetic material derived from petrochemicals, has a higher environmental impact compared to silk. The production of nylon involves the extraction and processing of non-renewable resources. Additionally, nylon is non-biodegradable, meaning it does not break down easily in the environment. However, efforts have been made to develop eco-friendly or recycled nylon alternatives.

Uv Resistance

- Silk: Silk offers good UV resistance and provides some level of protection against the harmful effects of the sun’s ultraviolet (UV) rays. While it is not completely impervious to UV radiation, silk can help shield the skin from sunburn and minimize UV-related damage. This makes silk a favorable choice for clothing and accessories intended for sun-exposed environments.

- Nylon: Nylon, in comparison, has limited UV resistance. It does not naturally provide significant protection against UV rays and may allow some penetration of UV radiation through the fabric. However, nylon fabrics can be treated with UV-resistant coatings or additives to enhance their ability to block UV rays, especially in outdoor and sun-sensitive applications.

Flame Resistance

- Silk: Silk has inherent flame-resistant properties. It is difficult to ignite and has a self-extinguishing nature. When exposed to flames, silk tends to smolder and may char rather than quickly catching fire. This natural flame resistance makes silk a safer choice for clothing and textiles, reducing the risk of rapid spreading of fire.

- Nylon: Nylon is not inherently flame-resistant and can melt or burn when exposed to flames or high heat. Untreated nylon fabrics have the potential to ignite and continue burning. To enhance flame resistance, nylon can be treated with flame-retardant chemicals, but it is important to note that treated nylon is not as flame-resistant as natural fibers like silk.

Uses

- Silk: Silk is renowned for its luxurious feel and elegant appearance, making it a preferred choice for high-end clothing such as dresses, blouses, and lingerie. It is also commonly used in the production of fine silk bedding, scarves, ties, and upholstery. Silk’s lightweight and breathable nature make it suitable for warm-weather garments as well.

- Nylon: Nylon’s strength, durability, and versatility make it suitable for a wide range of applications. It is commonly used in sportswear, activewear, swimwear, and hosiery due to its moisture-wicking properties and stretchability. Nylon’s strength also makes it ideal for various industrial uses, including ropes, parachutes, tire cords, and automotive components.

Historical Significance

- Silk: Silk has a long and significant historical legacy. Its production originated in ancient China around 4,000 years ago and was closely guarded for centuries. Silk trade routes, such as the famous Silk Road, played a crucial role in connecting civilizations and facilitating cultural exchange. Silk has been highly valued and associated with luxury, wealth, and refinement throughout history.

- Nylon: Nylon, in comparison, has a relatively shorter historical timeline. It was developed in the 1930s as a synthetic alternative to silk. Nylon’s creation revolutionized the textile industry, offering a durable and affordable material with versatile properties. The introduction of nylon brought significant changes to various sectors, from fashion to manufacturing, and played a role in the development of synthetic fibers.

Silk Vs Nylon: Comparison Table

| Key Differences | Silk | Nylon |

|---|---|---|

| Source | Natural fiber derived from silkworm cocoons | Synthetic material made from petrochemicals |

| Manufacturing Process | Labor-intensive process involving extracting silk fibers from cocoons | Complex chemical process called polymerization |

| Texture | Soft, smooth, luxurious | Coarser, rougher |

| Strength | Relatively strong, but less durable than nylon | Strong and durable |

| Elasticity | Moderate elasticity | High elasticity |

| Breathability | Excellent breathability | Less breathable |

| Moisture Absorption | Good moisture absorption and wicking properties | Low moisture absorption |

| Thermal Properties | Insulating provides warmth in cold weather | Less insulating can feel colder in winter |

| Allergies | Hypoallergenic, suitable for sensitive skin | Can cause allergies or skin irritations in some individuals |

| Shrinkage | May shrink with improper care | Resistant to shrinking |

| Cost | Expensive | Relatively inexpensive |

| Luster | Natural luster, visually appealing | No inherent luster |

| Care Requirements | Delicate, often requires handwashing or dry cleaning | Easy to care for, machine washable |

| Dyeing | Holds dyes well, vibrant colors | Easily dyed, wide range of color options |

| Environmental Impact | Natural and biodegradable | Synthetic and non-biodegradable |

| UV Resistance | Good UV resistance protects against sun damage | Limited UV resistance, can fade in sunlight |

| Flame Resistance | Naturally flame-resistant | Requires flame-retardant treatment |

| Uses | High-end clothing, lingerie, bedding | Sportswear, hosiery, ropes, industrial fabrics |

| Historical Significance | Prized for thousands of years | Developed in the 1930s as a silk substitute |

Frequently Asked Questions

While silk has a lower environmental impact compared to nylon due to being a natural fiber, both materials have their own environmental considerations. Silk production requires energy and resources, and nylon is derived from non-renewable petrochemicals. However, efforts are being made to develop sustainable practices and recycled options for both materials.

Yes, silk and nylon can be blended together to create fabrics that combine the desirable properties of both materials. Blending silk and nylon can result in textiles that have improved strength, durability, and drape, while still retaining some of the natural luster and softness of silk.

Silk is known for its excellent dye absorption properties and can be easily dyed with vibrant and long-lasting colors. Nylon is also easily dyed, and it can achieve vivid and consistent color results. Both materials offer versatility in terms of dyeing options and color customization.

Silk and nylon can both be used in outdoor activities, but they offer different benefits. Silk provides natural breathability and moisture-wicking properties, making it comfortable in various weather conditions. Nylon, on the other hand, is known for its durability, strength, and water resistance, making it ideal for activities that require robustness and protection.

Silk is a natural fiber and does not typically generate static electricity. However, nylon is a synthetic material that has a higher tendency to build up static charge. Nylon fabrics can create static electricity, especially in dry environments or when rubbed against certain materials. Antistatic treatments can be applied to minimize static buildup in nylon fabrics.

To Recap

Silk and nylon are two distinct materials with their own set of characteristics and advantages. Silk offers a luxurious feel, natural luster, and excellent moisture absorption, making it ideal for high-end garments and bedding.

Nylon, on the other hand, excels in strength, durability, and versatility, making it suitable for sportswear, hosiery, and industrial uses. Both materials have their specific care requirements, environmental impacts, and historical significance.

Understanding the differences between silk and nylon allows for informed decision-making based on desired properties, intended uses, and personal preferences.

Whether it’s for elegance and comfort or durability and functionality, both silk and nylon offer unique qualities to meet diverse needs in the textile industry.

Leave a Reply