Troubleshooting and maintaining your Toyota sewing machine is vital for every sewing enthusiast. Whether you’re a seasoned seamstress or a novice, understanding how to diagnose and resolve common issues can save you time and money.

This comprehensive guide will walk you through the essential steps to troubleshoot, fix, and perform basic repairs on your Toyota sewing machine.

We’ll provide clear and practical solutions, from addressing stitching problems to tackling mechanical issues.

Additionally, you’ll discover preventive measures to keep your machine in peak condition, ensuring it remains a reliable companion for your creative sewing endeavors. Welcome to the world of Toyota sewing machine troubleshooting and repair.

Common Toyota Sewing Machine Problems

Toyota sewing machines are known for their durability and reliability, but like any mechanical device, they may encounter issues from time to time.

This guide aims to provide comprehensive troubleshooting steps to help you identify and rectify common problems that may arise with your Toyota sewing machine.

Here’s a step-by-step guide to help you identify and resolve common problems:

Tools and Supplies for Troubleshooting:

- Screwdrivers.

- Lint Brush or Compressed Air.

- Needles.

- Thread.

- Extra Bobbins.

- Sewing Machine Oil or Lubricant.

- Tweezers or Small Pliers.

- User Manual.

- Replacement Parts.

- Lighting.

- Magnifying Glass.

- Multimeter.

- Sewing Machine Brush.

- Sewing Machine Cover or Case.

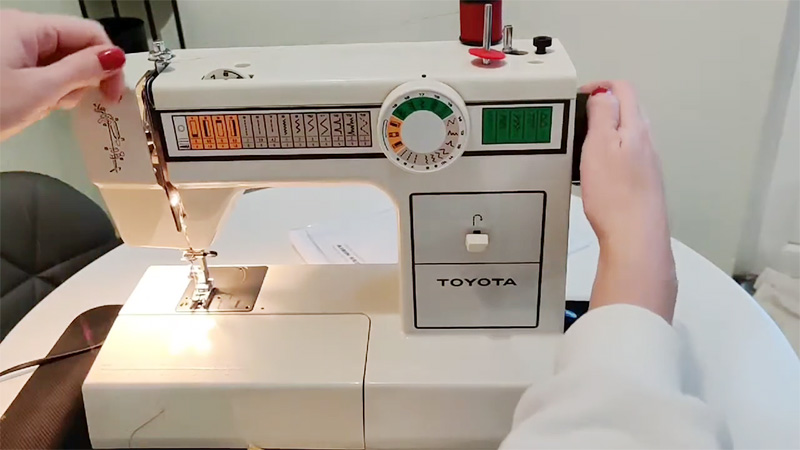

Machine Not Powering On

When your Toyota sewing machine refuses to power on, you can take the following steps to address the issue:

- Check the Power Source: Ensure the sewing machine is plugged into a functional electrical outlet. If there’s any doubt, consider trying a different outlet or testing it with another device to verify its functionality.

- Circuit Breaker: If the power source is confirmed to be working, check if the fuse or circuit breaker of the machine has blown. Replace the fuse or reset the circuit breaker as necessary.

- Inspect the Power Cord and Plug: Inspect the power cord for any visible damage or fraying. If any issues are found, consider replacing the power cord to rectify the problem.

Thread Breakage or Tension Issues

Problems related to thread breakage or tension can be frustrating but are often resolved with a few adjustments:

- Bobbin Winding: Ensure that the bobbin is wound evenly and inserted correctly. Uneven winding can lead to thread breakage during sewing.

- Thread Quality and Type: Verify that you are using the correct type and quality of thread for the fabric you are working with. Inappropriate thread choices can cause tension problems.

- Thread Path: Carefully check that the thread is threaded correctly through the machine, following the threading guide provided in your user manual.

- Tension Adjustment: Adjust the tension settings based on the fabric and thread you use. Incorrect tension can result in thread breakage or uneven stitching.

Needle Issues

Needle-related problems can cause stitching issues. Address them as follows:

- Needle Type and Size: Confirm that you are using the appropriate type and size of needle for the fabric being sewn. A bent or damaged needle can lead to stitching problems.

- Needle Insertion: Ensure that the needle is inserted correctly with the flat side facing the back of the machine. It should be fully seated and securely tightened.

- Needle Alignment: Check if the needle is properly aligned. Misalignment can result in the needle hitting the presser foot or bobbin case, causing stitching problems.

Uneven Stitching

Inconsistent stitching or skipped stitches can often be rectified with these adjustments:

- Feed Dogs: Ensure the feed dogs are engaged and free from obstructions. They are responsible for moving the fabric smoothly under the needle.

- Cleaning and Maintenance: Regularly clean the feed dogs, bobbin area, and needle plate to prevent the accumulation of lint, dust, and thread remnants, which can significantly improve stitching quality.

- Bobbin Tension: Check the bobbin tension for proper adjustment. An improperly adjusted bobbin tension can lead to uneven stitching.

Machine Making Unusual Noises

Unusual noises can indicate a mechanical issue that requires attention. Here’s how to address them:

- Lint and Debris: Inspect the machine for accumulated lint, debris, or foreign objects. Carefully remove any obstructions to prevent further damage.

- Oil the Machine: Ensure that the machine is adequately lubricated. A lack of lubrication can cause friction and result in unusual noises during operation.

- Check for Loose Parts: Examine the machine for loose screws, nuts, or bolts that may be contributing to the noise. Tighten them as needed to resolve the issue.

Sings That Your Toyota Sewing Machine Needs to Be Repaired

A well-maintained sewing machine should operate smoothly and consistently. However, certain signs may indicate it requires attention or repair.

Here are key indicators that your Toyota sewing machine may need professional servicing:

Irregular Stitching

Irregular stitching, such as uneven or skipped stitches, often indicates underlying issues with the sewing machine. It can be caused by incorrect tension settings, an improperly threaded machine, or a timing problem.

Addressing this requires careful rethreading, tension-setting adjustment, and potentially consulting the user manual for timing adjustments.

Unusual Noises

Unusual noises can be disconcerting and signify potential problems within the machine. These sounds may be the result of worn-out or poorly lubricated components.

Regular maintenance, including proper lubrication, can help mitigate this issue. If unusual noises persist, it’s advisable to consult a professional technician for a thorough examination.

Needle Breakage or Bending

Needle breakage or bending indicates that the needle is under stress. This may be due to various reasons, including using the wrong type or size of the needle, sewing over pins, or attempting to work with exceptionally thick materials. Proper needle selection and handling are crucial to prevent this issue from occurring.

Bobbin Winding Problems

Bobbin winding problems can be frustrating and lead to uneven stitches. This issue is often related to misaligned or damaged parts within the bobbin winding mechanism.

Careful inspection and, if necessary, realignment or replacement of these components can restore proper bobbin winding functionality.

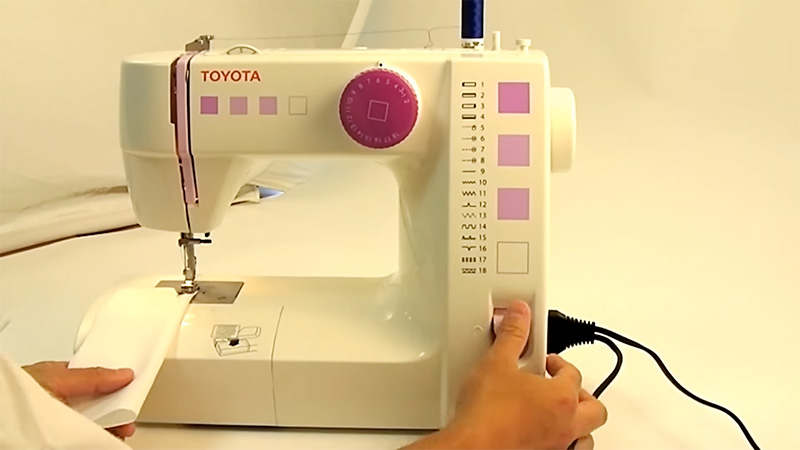

Difficulty in Stitch Selection

Difficulty in selecting stitches can be attributed to mechanical or electronic issues with the machine’s stitch selection mechanism.

A thorough review of the user manual for troubleshooting guidance is recommended. If the problem persists, consulting a technician familiar with your specific model may be necessary.

Bobbin Case Issues

Problems with the bobbin case can disrupt the sewing process. This may involve jams or irregular movements. Careful examination of the bobbin case for damage and ensuring proper insertion of the bobbin are key steps in resolving this issue.

Thread Tension Problems

Thread tension problems can have a significant impact on stitch quality. Correcting this issue involves carefully reviewing the machine’s threading process and adjusting the tension settings. A balanced tension ensures even and consistent stitches.

Fabric Jamming

Fabric jamming can occur when the feed dogs fail to move the fabric smoothly. This is often a result of accumulated lint or debris in the feed dogs or throat plate. Regular cleaning and maintenance can prevent this issue from occurring.

Motor Running but Needle Not Moving

When the motor runs but the needle remains stationary, it may indicate a worn-out drive belt or internal mechanical components. Careful inspection of the drive belt for signs of wear and potential replacement is critical in resolving this issue.

Bobbin Thread Tangling

Frequent tangling of the bobbin thread can be a frustrating problem. Issues with bobbin tension or incorrect bobbin insertion may cause this. Thoroughly checking and adjusting bobbin tension and ensuring proper bobbin placement can alleviate this issue.

Loss of Power

A malfunctioning foot pedal, power cord, or internal wiring problem can cause a sudden loss of power or electrical issues. It’s important to examine these components carefully and, if necessary, seek professional assistance in their repair or replacement.

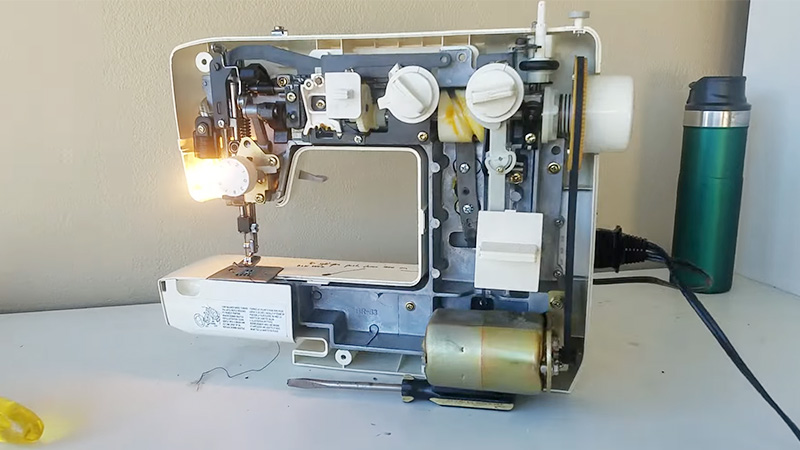

Advanced Troubleshooting and Repairs

Advanced troubleshooting and repairs may be necessary when encountering more complex issues with your Toyota sewing machine.

Here are some advanced techniques and considerations:

Diagnostic Tools and Meters

Diagnostic tools, such as sewing machine diagnostic meters or multimeters, become invaluable in advanced troubleshooting. They allow for precise measurements of electrical continuity and voltage, accurately pinpointing and rectifying electrical issues.

Electrical Component Testing

With the right training and knowledge, you can test electrical components like motors, switches, and circuit boards using a multimeter. This advanced technique enables the precise identification of malfunctioning parts, facilitating targeted repairs.

Timing Adjustment

Timing issues, though intricate, are not insurmountable. When the needle and bobbin hook fall out of sync, addressing this requires high precision. In such cases, entrusting the task to a professional technician with the expertise needed may be best.

Tension Assembly Disassembly

Disassembling and inspecting the tension assembly may be necessary for complex issues relating to tension. This demands utmost care and meticulous documentation of each step to ensure proper reassembly and resolution.

Drive Belt Replacement

In older sewing machines with a belt-driven system, replacing worn or damaged belts can breathe new life into the machine. This advanced repair can significantly enhance its performance, prolonging its lifespan.

Gear Replacement

Over time, gears may wear out, leading to many operational problems. Replacing gears is a complex undertaking that might involve carefully disassembling machine parts. This task is recommended for those with a high degree of experience.

Motor Replacement

When faced with a malfunctioning motor, replacing it is a sophisticated endeavor. It calls for an in-depth understanding of electrical systems, which is best entrusted to a professional technician.

Computerized Systems Troubleshooting

Modern, computerized sewing machines often incorporate advanced electronic systems. Troubleshooting and repairing these components necessitate specialized training and expertise in electronic systems.

Sourcing Parts

Identifying reputable sources for replacement parts is crucial. This can be done directly through Toyota or trusted authorized dealers and reliable online retailers.

Documentation and Photos

The importance of comprehensive documentation cannot be overstated. Clear photos and detailed notes taken during disassembly are invaluable references, ensuring a smooth and accurate reassembly process.

Preventive Measures for Future Issues

Preventive measures can help you avoid future issues with your Toyota sewing machine and ensure it continues working smoothly.

Here are some proactive steps to consider:

Regular Cleaning

Regularly clean your sewing machine after each use. Take extra care to remove lint, dust, and debris from the bobbin area, feed dogs, and thread tension disks. A clean machine operates more efficiently and reduces the risk of issues caused by debris accumulation.

Thread Quality

Invest in high-quality thread that is appropriate for the type of fabric you’re using. Cheap or low-quality thread can lead to tension problems, thread breakage, and uneven stitching.

Proper Threading

Follow the threading instructions provided in your user manual meticulously. Improper threading is a common cause of sewing machine issues, including uneven stitching and thread breakage.

Bobbin Maintenance

Ensure bobbins are wound evenly and inserted correctly. Unevenly wound bobbins or improper insertion can lead to thread tension problems, resulting in irregular stitching.

Needle Care

Change the needle regularly, especially when starting a new project or switching to a different type of fabric. A dull or damaged needle can cause a host of stitching problems.

Correct Needle Size

Always use the right needle size for your fabric. Using a needle that is too large can leave unsightly holes, while a needle that is too small may cause the fabric to pucker.

Thread Tension

Adjust the thread tension appropriately for the fabric you’re using. Test on a scrap piece of fabric to ensure the tension is set correctly before starting your project.

Bobbin Case Maintenance

Periodically remove and clean the bobbin case to prevent lint buildup. This ensures proper bobbin tension, which is crucial for balanced stitching.

Oil Regularly

If your sewing machine requires oiling, follow the manufacturer’s oil type and frequency recommendations. Regular lubrication keeps moving parts working smoothly and reduces wear.

Use a Cover

When your sewing machine is unused, cover it to protect it from dust and dirt. A dedicated sewing machine cover or case is ideal for safeguarding against environmental elements.

Proper Storage

Store your sewing machine in a cool, dry place away from direct sunlight and extreme temperatures. Avoid placing it near windows or vents where it could be exposed to dust and drafts.

Can You Fix a Toyota Sewing Machine At Home?

Yes, many basic issues with a Toyota sewing machine can be addressed at home. While some basic troubleshooting and maintenance tasks can be performed at home, more complex repairs for a Toyota sewing machine may require the expertise of a professional technician.

You Can Fix a Toyota Sewing Machine At Home:

Basic Troubleshooting

Simple issues like thread tension problems, threading errors, or minor bobbin-related problems can often be resolved at home with patience and attention to detail. Consult your sewing machine’s user manual for guidance on troubleshooting specific issues.

Routine Maintenance

Regular cleaning and maintenance tasks can be performed at home, such as oiling moving parts, changing needles, and cleaning out lint and debris. Proper maintenance helps prevent common problems and ensures your machine operates smoothly.

Replacing Needles and Bobbins

Replacing dull or damaged needles and correctly inserting bobbins are straightforward tasks you can handle at home. Be sure to use the correct needle size and type for your fabric.

Thread Selection and Threading

Ensuring you use high-quality thread appropriate for your project and threading your machine correctly are fundamental tasks for achieving optimal stitching results.

Managing Tension

Adjusting thread tension settings to match your fabric and stitching requirements is something you can easily do at home. Begin with small adjustments and test on scrap fabric to achieve the desired results.

Clearing Jammed Fabric

If the fabric gets jammed in the feed dogs or bobbin area, you can carefully remove it and clear any accumulated lint or debris that may be causing the jam.

When to Seek Professional Help?

Knowing when to seek professional help is crucial in maintaining the functionality and safety of your Toyota sewing machine.

Here are some scenarios where consulting a certified technician is recommended:

Electrical Issues

If you suspect or encounter any electrical problems with your sewing machine, it’s best to seek the expertise of a professional. They have the knowledge and tools to diagnose and repair electrical issues safely.

Complex Mechanical Repairs

Advanced repairs like timing adjustments, gear replacements, or motor replacements should be left to experienced technicians. These tasks require a deep understanding of the machine’s internal mechanisms.

Computerized Systems Troubleshooting

Modern sewing machines with advanced electronic components can be challenging to troubleshoot without specialized training. Seeking professional help ensures accurate diagnosis and repair.

Lack of Progress

If you’ve attempted troubleshooting and the issue persists, or if you’re unsure about the cause of the problem, it’s time to consult a professional. They can conduct a thorough assessment to identify and resolve the issue.

Safety Concerns

When you notice any unusual odors, smoke, or sparking, immediately unplug the machine and seek professional help. Continuing to use a machine with these symptoms can pose a safety hazard.

Unfamiliarity with the Machine

It’s best to consult a certified technician when you’re not confident in your ability to perform advanced repairs or adjustments.

Attempting complex repairs without the necessary expertise can lead to further damage. Continuing to use a machine with these symptoms can pose a safety hazard.

Warranty Considerations

Attempting DIY repairs may void the warranty when your sewing machine is still under warranty. It’s advisable to consult the manufacturer or an authorized service center for covered repairs.

Specialized Parts or Tools

Some repairs may require specific parts or tools that are not readily available to the average user. A professional technician will have access to these resources.

FAQs

Why is my Toyota sewing machine not turning on?

If your sewing machine refuses to power on, ensure it’s properly plugged in, and the power source is functioning. Check the power cord for any damage, and if the issue persists, consult the troubleshooting guide for further steps.

How do I fix thread tension issues on my Toyota sewing machine?

Begin by rethreading both the top thread and the bobbin thread. Adjust the tension settings gradually and test on a scrap fabric. Consult the user manual for specific tension adjustment instructions.

What should I do if my Toyota sewing machine makes unusual noises?

Unusual noises may indicate various issues, from a loose part to a need for lubrication. Turn off the machine, unplug it, and inspect for loose screws or foreign objects. If the problem persists, consult the troubleshooting guide.

How often should I oil my Toyota sewing machine?

The frequency of oiling depends on your machine’s model and usage. Refer to the user manual for specific recommendations. Generally, it’s advised to oil areas specified by the manufacturer every 8-10 hours of sewing.

When should I seek professional help for my Toyota sewing machine?

Consider professional help for electrical issues, advanced mechanical repairs, computerized systems troubleshooting, and if you’re unsure about a specific repair.

Additionally, consult the manufacturer or an authorized service center for covered repairs if your machine is under warranty.

Wrap Up

Mastering the art of Toyota sewing machine troubleshooting empowers you to overcome challenges and confidently unleash your creativity.

Following the steps outlined in this guide, you’ve acquired the knowledge to diagnose and address various issues.

Remember, regular maintenance and preventive measures are the foundation of a well-functioning machine.

With each stitch, you’re crafting beautiful creations and preserving your sewing companion’s longevity. Embrace the journey of exploration, learning, and craftsmanship that comes with sewing.

Now, armed with this comprehensive fix and repair guide, you’re well-equipped to conquer any obstacle that comes your way.

Leave a Reply