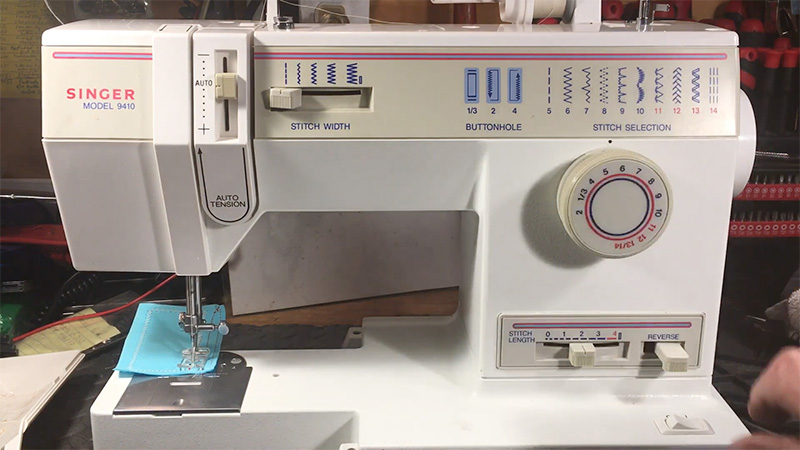

The Singer 9410 sewing machine is a versatile and popular choice among sewing enthusiasts. However, like any mechanical device, it may encounter issues from time to time.

Troubleshooting a Singer 9410 can save you time, money, and frustration by helping you identify and resolve common problems that may arise during your sewing projects.

Whether you’re dealing with threading issues, tension problems, or stitch irregularities, this guide will provide you with practical solutions to keep your Singer 9410 running smoothly.

By understanding how to troubleshoot and address these issues, you can ensure a seamless sewing experience and maximize the lifespan of your beloved machine.

So, let’s dive into the world of Singer 9410 troubleshooting and equip you with the knowledge needed to overcome any sewing hiccups that may come your way.

Why Singer 9410 Disassembly? [Troubleshooting a Singer 9410]

Here are 9 possible reasons:

To Clean And Oil Your Machine

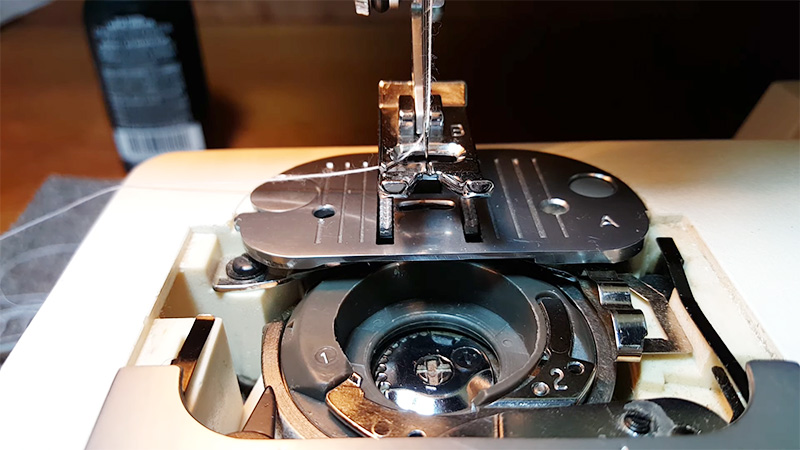

Dust, lint, and dirt can accumulate in your machine and interfere with its functions and parts, such as the bobbin case, the feed dogs, the tension discs, and the needle bar.

Cleaning and oiling your machine regularly can help it run smoothly and efficiently and extend its lifespan. You may need to disassemble some parts of your machine to access and clean them properly.

To Replace Or Repair Broken Or Worn-Out Parts

Your machine may have some parts that are broken or worn out due to normal wear and tear or accidental damage.

For example, the needle clamp screw, the presser foot lifter, the thread cutter, or the spool pin. Replacing or repairing these parts can improve your machine’s performance and safety.

You may need to disassemble some parts of your machine to remove and replace them with new ones.

To Adjust Or Calibrate Your Machine

Your machine may need some adjustments or calibration to ensure proper alignment and performance of its parts, such as the needle, the hook, the feed dogs, and the tension.

Adjusting or calibrating your machine can prevent sewing problems such as skipped stitches, thread breakage, fabric puckering, or needle drop.

To Troubleshoot Or Diagnose Your Machine

Your machine may have some issues that are not obvious or easy to fix, such as electrical problems, timing problems, or mechanical problems.

Troubleshooting or diagnosing your machine can help you identify the cause and the solution to these issues.

To Upgrade Or Modify Your Machine

You may want to upgrade or modify your machine to enhance its features or functions, such as adding a walking foot, a quilting foot, a zipper foot, or a buttonhole foot.

Upgrading or modifying your machine can make it more versatile and suitable for different sewing projects.

You may need to disassemble some parts of your machine to install and attach these accessories.

To Store Or Transport Your Machine

You may want to store or transport your machine for various reasons, such as moving to a new place, traveling with your machine, or storing it for a long time.

Storing or transporting your machine can expose it to dust, moisture, heat, cold, or impact that can damage it.

You may need to disassemble some parts of your machine to protect them from these elements and make it easier to pack and carry them.

To Recycle Or Dispose Of Your Machine

You may want to recycle or dispose of your machine if it is too old, too damaged, or too obsolete for you to use or repair. Recycling or disposing of your machine can help you reduce waste and environmental impact.

You may need to disassemble some parts of your machine to separate them into different materials, such as metal, plastic, rubber, or electronic components.

To Learn More About Your Machine

You may want to learn more about your machine’s structure, function, history, or design for personal interest or educational purposes.

Learning more about your machine can help you appreciate its craftsmanship and innovation and improve your sewing skills and knowledge.

You may need to disassemble some parts of your machine to examine and understand them better.

Have Fun With Your Machine

You may want to have fun with your machine by taking it apart and putting it back together as a hobby or a challenge.

Having fun with your machine can help you relax, enjoy yourself, and express your creativity and curiosity. You may need to disassemble some parts of your machine to explore and experiment with them in different ways.

Singer 9410 Tension Problem

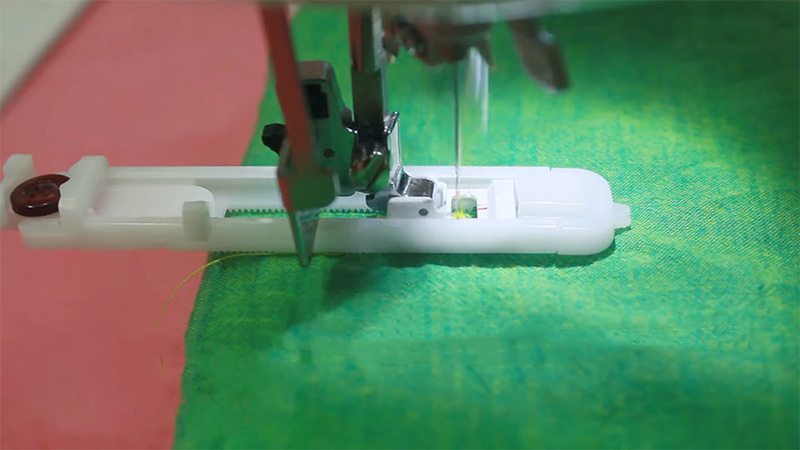

Sewing machine buttonhole troubleshooting can be essential to achieving perfect buttonholes in your sewing projects.

Here are some common problems you may encounter:

Uneven Buttonholes

Uneven buttonholes can occur due to inconsistent fabric tension. Ensure your fabric is evenly fed through the machine and that the presser foot pressure is adjusted correctly. Test on a scrap piece of fabric before sewing on your project.

Buttonhole Stitch Length Variations

Inconsistent stitch length in buttonholes may result from incorrect machine settings. Check your machine’s manual for the recommended settings and ensure you maintain a steady sewing speed.

Buttonhole Ends with Loose Threads

Loose threads at the end of buttonholes can be caused by inadequate thread tension. Adjust the thread tension slightly and perform a test buttonhole to see if it improves.

Buttonhole Stitches Too Tight or Too Loose

Inconsistent buttonhole stitch tension may occur if the bobbin tension is incorrect. Check the bobbin thread and adjust its tension as needed to achieve balanced buttonhole stitches.

Buttonhole Size Inaccuracies

If buttonhole sizes are consistently incorrect, double-check the buttonhole foot settings on your machine. Some machines require manual input of the button’s size.

Fabric Jams or Feeding Issues

Fabric jams during buttonhole sewing can be due to a dull needle or incorrect fabric handling. Ensure you’re using the appropriate needle size and type for your fabric, and guide the fabric smoothly through the machine.

Buttonhole Alignment Problems

Misaligned buttonholes may result from incorrect markings on the fabric. Use a fabric marker or chalk to mark buttonhole positions accurately before sewing.

Buttonhole Satin Stitch Issues

If the satin stitch on the buttonhole appears uneven or frayed, consider using a stabilizer beneath the fabric to improve stitch quality and prevent fabric distortion.

Machine Error Messages or Malfunctions

If your sewing machine displays error messages or malfunctions during buttonhole sewing, consult your machine’s manual for troubleshooting guidance or consider having it serviced by a professional.

Addressing these common buttonhole problems systematically and making necessary adjustments to your machine settings, fabric handling, and thread tension will help you achieve consistent and flawless buttonholes in your sewing projects.

How Do You Use A 5-Step Buttonhole?

Using a sewing machine with a 5-step buttonhole function can seem complex, but it becomes straightforward with practice.

Here’s a step-by-step guide:

Select the Buttonhole Stitch

Start by choosing the buttonhole stitch on your sewing machine. On many machines, this is indicated by a symbol or the word “buttonhole.” Refer to your machine’s manual to locate the appropriate setting.

Adjust the Buttonhole Foot

Attach the buttonhole foot to your sewing machine. Ensure it’s securely in place, as this foot guides the machine in creating the buttonhole accurately.

Mark the Buttonhole Placement

Use fabric chalk or a removable fabric marker to mark the starting and ending points of the buttonhole on your fabric. Ensure the marks align with your button’s size and position.

Position the Fabric

Place your fabric under the buttonhole foot, aligning the starting mark with the buttonhole foot’s guide. Lower the presser foot to secure the fabric in place.

Begin Sewing

Start the machine and follow these steps:

a. Sew the first leg: The machine will sew the left side of the buttonhole first. Allow it to complete this leg, stopping at the second mark.

b. Sew the bar tack: The machine will automatically create a series of closely spaced zigzag stitches to form the bar tack. Ensure it’s the desired length for your button.

c. Sew the second leg: After the bar tack, the machine will sew the right side of the buttonhole, ending at the starting mark. It will automatically lock the stitches at the end.

Finish and Secure

Lift the presser foot, gently pull out your fabric, and trim any loose threads. Use a seam ripper or small scissors to carefully open the buttonhole by cutting along the center. Be cautious not to cut the stitches.

Test the Fit

Before attaching the button, place it through the buttonhole to ensure it fits correctly. Adjust the buttonhole size if needed by adjusting the stitch width or length settings on your machine.

Using a 5-step buttonhole function on your sewing machine allows you to create precise and tailored buttonholes for your garments.

With practice, you’ll become proficient in this essential sewing skill.

FAQ

Why is my Singer 9410 sewing machine not stitching correctly?

If your stitches are irregular or skipped, check the needle for damage or incorrect installation. Ensure you’re using the appropriate thread and fabric for your project.

Why is my Singer 9410 machine making a loud noise while sewing?

Unusual noises may be due to issues like a loose screw, debris in the machine, or a worn-out part. Inspect and clean your machine regularly, and tighten any loose components.

How can I fix thread tension problems on my Singer 9410?

Adjust the tension dial, rethread the machine, or check for thread jams in the bobbin area. Correcting thread tension can often resolve uneven stitching.

What should I do if my Singer 9410 machine keeps jamming or skipping stitches?

Frequent jams or skipped stitches may be caused by incorrect threading, a bent needle, or debris in the bobbin area. Rethread the machine, replace the needle, and keep the bobbin area clean.

My Singer 9410 machine is not picking up the bobbin thread. How can I fix this?

Ensure the bobbin is correctly loaded, the bobbin tension is adjusted properly, and the upper thread is threaded correctly through the needle. Proper threading and tension adjustments can help solve bobbin-related issues.

Conclusion

Troubleshooting a Singer 9410 sewing machine empowers you to overcome common sewing challenges and keep your machine in excellent working condition.

By following the troubleshooting steps outlined in this guide, you can confidently address issues related to threading, tension, bobbin problems, and more.

Regular maintenance and troubleshooting not only extend the life of your sewing machine but also enhance the quality of your sewing projects.

With a well-maintained and properly troubleshooted Singer 9410, you can tackle a wide range of sewing tasks, from clothing repairs to creative crafting projects, with ease and confidence.

Remember that patience and attention to detail are key when addressing sewing machine issues, and with practice, you’ll become a skilled troubleshooter and sewist. Happy sewing!

Leave a Reply