Embarking on a creative sewing project can be invigorating, but frustration can quickly set in when your trusty Kenmore sewing machine encounters a glitch.

This comprehensive troubleshooting guide is your go-to resource for addressing common issues that may arise.

From thread jams to tension adjustments, each step is meticulously outlined to empower you to resolve problems right in the comfort of your own space.

Delve into a detailed journey of diagnoses and solutions supported by expert tips and cautionary advice.

With this guide, you’ll rekindle your sewing endeavors and gain newfound confidence in maintaining and repairing your Kenmore sewing machine.

14 Vital Problems of Kenmore Sewing Machine

While Kenmore sewing machines are generally reliable, like any mechanical device, they can experience various issues.

Here are some vital problems you might encounter:

1. Thread Jamming

Improper threading is a common issue. Ensure the thread is correctly passed through all guides and tension disks. Also, use good quality thread suitable for your machine.

A damaged or dull needle can cause thread jams or breaks. Replace the needle if needed.

2. Uneven Stitches

Incorrect tension settings can lead to uneven stitches. Adjust the upper and lower thread tensions as needed. Improper bobbin winding can also cause stitching irregularities. Wind the bobbin carefully.

3. Excessive Vibration

Check for loose screws, nuts, or parts and tighten them as needed. Lack of lubrication can lead to increased friction and noise. Follow the manufacturer’s guidelines for lubrication.

4. Needle Breakage

Ensure you’re using the correct type and size of needle for the fabric you’re working with. Check the needle for alignment; improper alignment can cause breakage.

5. Feed Dogs Not Advancing Fabric

Ensure the feed dogs are in the raised position. Some machines have a switch or lever to lower or raise them. Clean any lint or debris that may be obstructing their movement.

6. Bobbin Tension Problems

If the bobbin tension is too tight or loose, it can affect the quality of the stitches. Adjust the bobbin tension following the machine’s manual.

7. Fabric Not Feeding Properly

Check for any obstructions around the feed dogs and remove them. Ensure the presser foot is down, as it helps guide the fabric.

8. Bobbin Thread Showing on Top

Check that the bobbin is correctly inserted and threaded. Adjust the tension settings for both the upper and lower threads.

9. Needle hitting the Bobbin Case.

Ensure you’re using the correct needle type and size for the fabric. Check if the needle is inserted correctly and not bent.

10. Puckering

Make sure the needle is appropriate for the fabric. A sharp needle is needed for woven fabrics, while a ballpoint needle is better for knits. Ensure the machine is clean from lint and debris, as this can affect the quality of stitches.

11. The Machine is Running Slowly

Check if the machine is lubricated correctly according to the manufacturer’s guidelines. Ensure the machine is not set to a slow speed setting if it has adjustable speed.

12. Bobbin Winder is Not Working

Ensure the bobbin is placed correctly on the winder. Check for any obstructions in the bobbin winding mechanism.

13. Thread Getting Tangled in Bobbin Area

Ensure the bobbin is inserted in the bobbin case correctly. Clean the bobbin area from lint and debris.

14. Presser Foot Lifter Not Working

Check for any obstructions around the presser foot lifter mechanism. Ensure the presser foot lifter is not stuck or jammed.

Troubleshooting Guide for Kenmore Sewing Machine

Encountering issues with your Kenmore sewing machine can be frustrating, but a systematic approach can often help resolve common problems.

Follow this comprehensive troubleshooting guide for step-by-step solutions:

Power and Basic Setup

Begin by ensuring the foundational elements are for your machine to function correctly.

- Check Power Connection: Start by confirming that the sewing machine is securely plugged into a working power outlet. If using an extension cord, ensure it’s in good condition.

- Foot Pedal Connection: Verify that the foot pedal is securely connected to the machine. Loose connections can prevent proper operation.

- Fuse or Circuit Breaker Inspection: If the machine still doesn’t start, inspect the fuse or circuit breaker on both the machine and the power outlet. Replace or reset as needed.

Thread-related Issues

Threading is a fundamental aspect of sewing. Ensuring it’s done correctly can save you from various complications.

- Threading Inspection: Carefully rethread the machine, following the threading guide provided in the manual. Pay close attention to ensure the thread passes through all necessary guides and tension disks.

- Bobbin Winding: Wind the bobbin evenly and correctly. Make sure it’s appropriately inserted into the bobbin case. Uneven winding can lead to thread tension issues.

- Needle Examination: Look closely at the needle for any signs of damage, bending, or dullness. If you find any issues, replace the needle with a suitable one for your fabric.

Stitching Irregularities

Stitching problems can often be resolved by adjusting tension settings and ensuring the correct needle is used.

- Adjust Tension Settings: Experiment with the upper and lower thread tension settings. Make minor adjustments and observe the stitching until you achieve even and balanced results.

- Needle Compatibility: Verify that you’re using the correct needle type and size for the fabric you’re working on. Using the wrong needle can lead to stitching irregularities.

Feed Dogs and Fabric Movement

Proper fabric movement is crucial for smooth sewing. Issues in this area can lead to uneven stitches.

- Feed Dog Position: Check if the feed dogs are raised. Some machines have a switch or lever to control their position. Ensure they’re in the correct position for regular sewing.

- Clean Feed Dogs: Remove any lint, thread, or debris obstructing the feed dogs’ movement. A clean workspace contributes to smoother fabric feeding.

Noise and Vibration

Unusual noises or excessive vibration can be signs of mechanical issues. Addressing these can prolong the life of your machine.

- Inspect for Loose Parts: Carefully examine the machine for any loose screws, nuts, or parts. Tighten them to stabilize the machine’s operation.

- Lubrication: Follow the manufacturer’s guidelines for lubricating the machine. Proper lubrication reduces friction and minimizes noise. Regular maintenance in this regard is critical to a smoothly functioning machine.

Needle Breakage

Needle breakage is common but can often be prevented with proper usage and maintenance.

- Correct Needle Usage: Ensure you use the appropriate needle type and size for the fabric you work with. A fine needle is suitable for lightweight fabrics, while a heavier needle is needed for thicker materials.

- Needle Alignment: Check if the needle is properly inserted and aligned. A misaligned needle can lead to breakage. Insert the needle according to the machine’s instructions, and ensure it’s tightened securely.

- Replace Dull or Damaged Needles: If the needle shows signs of wear, such as burrs or bends, replace it promptly. A sharp needle ensures smooth stitching.

Bobbin Issues

The bobbin plays a crucial role in the stitching process. Addressing bobbin-related problems can improve overall sewing performance.

- Tension Adjustment: Follow the machine’s manual to adjust the bobbin tension correctly. This is crucial for achieving balanced and consistent stitching.

- Bobbin Winder Functionality: Ensure the bobbin is correctly placed on the winder and winds smoothly. Check for any obstructions in the winding mechanism that may affect its operation.

- Bobbin Compatibility: Make sure you’re using the correct type and size of bobbin for your Kenmore sewing machine. Using an incorrect bobbin can lead to tension issues.

Additional Issues

If you encounter a problem not covered in the previous steps, exploring the manual and considering seeking professional assistance is essential.

Refer to the Manual: Your Kenmore sewing machine’s manual is valuable. Consult it for specific troubleshooting steps, maintenance guidelines, and tips for optimal performance.

How to Repair Your Sewing Machine at Your Home?

Repairing your Kenmore sewing machine at home can be cost-effective and satisfying.

Here’s a step-by-step guide to help you with common issues:

Gather Supplies and Tools

Before you start, gather the necessary supplies and tools:

- Screwdrivers

- Tweezers or small pliers

- Sewing machine oil or lubricant

- Cleaning brush

- Replacement parts

- User manual for reference

Safety First

Before beginning any repair, make sure to unplug the sewing machine. This precautionary measure ensures you won’t be exposed to electrical hazards while working on the machine.

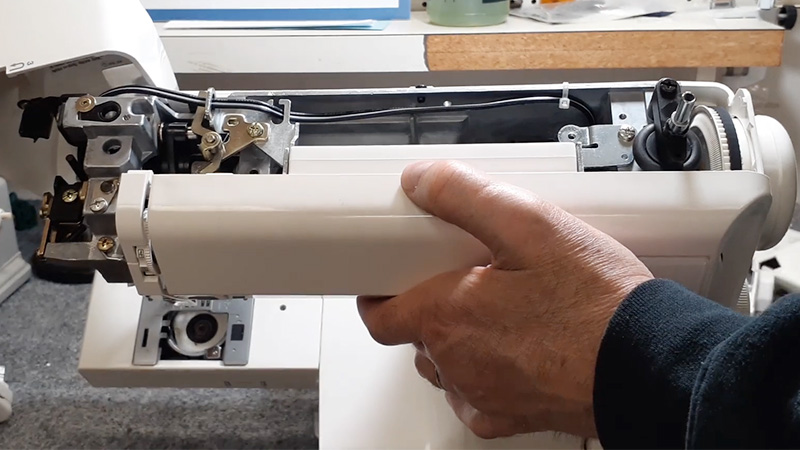

Identify the Problem

Take a close look at your Kenmore sewing machine. Are there any visible signs of damage or issues? Look for loose parts, tangled threads, or any irregularities. This initial inspection will help you pinpoint the specific problem you’re facing.

Cleaning and Maintenance

Cleaning your sewing machine is crucial for its proper function. Lint and debris can accumulate over time, hindering its performance. Use a small brush or a lint roller to remove any built-up lint gently.

Apply sewing machine oil to the recommended areas mentioned in your manual. This will ensure that all moving parts operate smoothly.

Thread Tension Adjustment

Adjusting thread tension may be necessary if your stitches are uneven. Consult your manual for guidance on correctly adjusting the tension settings for your specific model. Make minor adjustments and test on scrap fabric until you achieve balanced stitches.

Bobbin Issues

Examine the bobbin for any signs of uneven winding or damage. Make sure it’s inserted correctly in the bobbin case. Adjust the tension if needed to ensure even stitches.

Needle Replacement

If you notice that the needle is bent, has burrs, or is dull, it’s time for a replacement. Choose a needle that matches the type of fabric you’re using. Installing a fresh, sharp needle can significantly improve your sewing experience.

Fixing Feed Dog Problems

The feed dogs are vital for proper fabric feeding. Ensure they move up and down smoothly as you turn the handwheel.

Clean around the feed dogs to remove any accumulated lint or debris. Lubricate them if necessary to ensure they function correctly.

Addressing Needle Breakage

If you’ve experienced needle breakage, use the correct needle for your fabric. Check if the needle is aligned correctly and tightly secured. Proper needle installation is crucial for preventing breakage.

Fixing Bobbin Winder Issues

A smoothly functioning bobbin winder ensures even winding. Ensure the bobbin is placed correctly on the winder spindle. If you notice any irregularities, inspect the winder mechanism for any obstructions.

Troubleshoot Electrical Problems

If the machine doesn’t start, first, check the power connection. Inspect the power cord for any signs of wear or damage. If there’s still no power, consult a professional technician to handle any electrical repairs.

Test the Machine

After each repair or adjustment, testing the machine on a scrap piece of fabric is crucial. This allows you to ensure the issue is resolved before you resume regular sewing projects.

FAQs

What are the most common issues with Kenmore sewing machines?

Common issues include thread jams, uneven stitching, needle breakage, and bobbin problems.

Can I use this troubleshooting guide for any Kenmore sewing machine model?

While the guide provides general troubleshooting tips, it’s best to consult your specific model’s user manual for model-specific information.

What should I do if I can’t find a solution in the guide?

If you can’t resolve a particular issue, seek assistance from a professional sewing machine technician or contact Kenmore’s customer support.

Is regular maintenance necessary even if there are no visible issues?

Yes, regular cleaning and maintenance are essential to prevent problems from occurring. Follow the manufacturer’s maintenance schedule in your manual.

Can I troubleshoot electrical issues on my own?

It’s not recommended to troubleshoot electrical problems on your own. Consult a qualified technician for any electrical issues with your sewing machine.

Wrap Up

The troubleshooting Kenmore Sewing Machine (Fix & Repair Guide) is your indispensable companion in conquering the challenges that may arise during your sewing endeavors.

This comprehensive guide empowers you with step-by-step solutions, backed by insights and expert tips, to revive your Kenmore sewing machine’s functionality.

With each issue addressed and resolved, you gain both the satisfaction of self-reliance and the assurance of a well-maintained and smoothly operating sewing companion.

As you embark on your creative sewing projects, remember that this guide is your trusted resource, ready to assist you in overcoming any hurdle, ensuring your sewing experiences are consistently enjoyable and productive.

Leave a Reply