In the realm of sewing, the mastery of various facing techniques is akin to unlocking the gateway to professional craftsmanship. Facings, those subtle yet impactful elements, hold the power to transform a mere fabric into a tailored masterpiece.

With each stitch and fold, facings bestow structure, clean lines, and a touch of elegance upon garments. From neckline facings ensuring a crisp finish to hem facings providing weight and drape, the world of sewing facings is as diverse as it is essential.

Embark on a journey through this guide as we explore the array of facing types, unveiling the artistry behind each stitch.

1. Shaped Facing

A shaped facing in sewing is a specialized type of fabric piece sewn to the edge of a garment, tailored to match its contours. This facing adds a polished touch by providing structure, clean edges, and a professional finish.

Commonly used in intricate areas like curved necklines or armholes, the shaped facing ensures a secure fit while preventing fabric distortion. This technique demands precise cutting and stitching to create a seamless integration with the garment.

Shaped facings offer both functionality and aesthetics, showcasing the art of merging form and function in sewing projects.

2. Bias Tape Facing

Bias tape facing is a versatile sewing technique involving strips of fabric cut on the bias – a diagonal angle to the fabric grain. It’s sewn along the garment’s edges, often used for curved or raw edges like necklines and armholes.

Bias tape facing encases the raw edge, providing a neat finish, preventing fraying, and ensuring flexibility in curved areas. It adds a pop of color or contrast when visible, enhancing the overall design.

This technique requires careful stitching and pressing to achieve a clean and professional result. Bias tape facings exemplify both functionality and creativity in garment construction.

3. ‘All-in-one’ Facing

An ‘all-in-one’ facing is a multifunctional sewing technique used to finish garment edges in a streamlined manner. It involves creating a single piece of fabric that serves as both the facing and the lining of a garment.

This technique is commonly employed for bodices or tops with intricate necklines and armholes. The ‘all-in-one’ facing provides a clean edge while concealing seam allowances, giving a polished appearance.

It also eliminates the need for a separate lining, making it efficient and lightweight. Skillful stitching and careful pressing are crucial to achieving a seamless integration of both facing and lining within a single piece of fabric.

4. Extended Facing

An extended facing is a sewing method used to create a broader and more visible decorative edge on a garment. It involves sewing a separate piece of fabric along the edge, extending beyond the garment’s seam line.

This technique adds a touch of design flair and contrast to hems, cuffs, or openings like necklines. The extended facing not only provides a unique aesthetic but also reinforces the edge, preventing fraying and adding structure.

Precision in cutting and sewing ensures a clean and stylish finish, showcasing the art of incorporating functional design elements into clothing construction.

5. Outside Facing

An outside facing is a distinctive sewing technique where a separate fabric piece is attached to the outer surface of a garment, creating a visible decorative detail.

Unlike traditional facings that are usually hidden inside the garment, outside facings are intentionally exposed, adding a creative element to the design.

This method is often used for adding contrasting colors, textures, or patterns to hems, cuffs, or edges of garments. While providing a unique and eye-catching look, outside facings also reinforce the edges and prevent fraying.

Expert stitching and careful attention to detail are essential to achieve a polished and well-executed outside facing.

6. Hem Facings

Hem facings are specialized fabric strips sewn along the hemline of a garment to provide structure, weight, and a clean finish. Unlike traditional folded hems, hem facings are sewn on the inside of the garment, encasing the raw edge.

This technique is commonly used in garments made from lightweight or delicate fabrics, where a traditional folded hem might be too bulky or difficult to execute neatly.

Hem facings help maintain the garment’s shape, prevent fraying, and add a subtle weight to ensure the hem hangs evenly. Attaching hem facings requires precise stitching and careful pressing to achieve a professional and polished result.

7. Placket Facing

A placket facing is a sewing technique used to create a neat and functional opening in a garment, typically for closures like buttons or zippers. It involves sewing a strip of fabric onto the edges of the opening to reinforce and finish it.

Placket facings are commonly used in areas like shirt cuffs, button-down shirt fronts, and dress or skirt slits. They provide structure, prevent fraying, and create a clean edge for attaching closures.

Placket facings can be visible or hidden, depending on the design, and require precise stitching and careful folding to achieve a professional and secure finish that ensures both functionality and aesthetics.

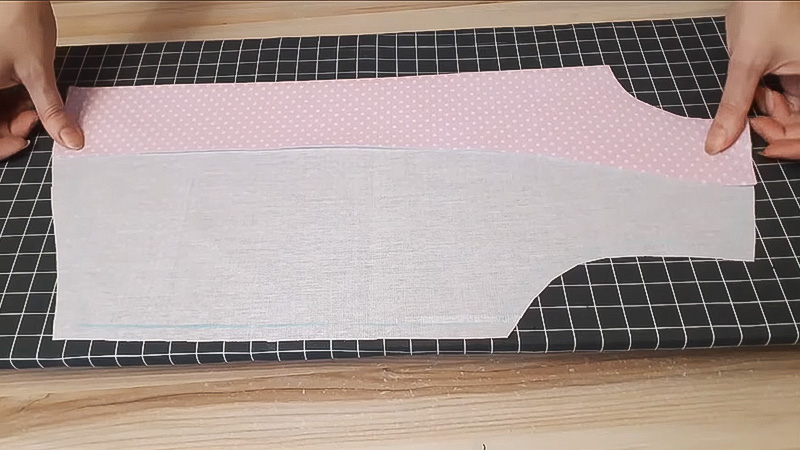

8. Separate Facing

A separate facing in sewing refers to a fabric piece that is cut separately from the main garment fabric and attached to the garment’s edges to create a clean and polished finish.

It is often used to reinforce openings like necklines, armholes, or button plackets. Unlike techniques where the facing and garment are cut as one piece, a separate facing is attached after the main seams are sewn.

This technique allows for easier finishing and provides stability, preventing fabric distortion or stretching. Accurate stitching, understitching, and careful pressing are essential to achieve a seamless integration of the facing and ensure a professional outcome.

9. Stitch Facing

A stitch facing is a simple and effective sewing technique used to finish raw edges on a garment without the need for a separate facing piece. It involves folding the fabric’s raw edge inward and stitching it in place, creating a clean and tidy finish.

Stitch facings are commonly used on lightweight fabrics or when a more subtle edge is desired. This technique works well on straight edges like hems, armholes, and necklines.

While providing a neat appearance, stitch facings may not offer the same level of structure and stability as traditional facings. Skillful stitching and careful attention to detail are crucial for achieving a polished stitch-facing finish.

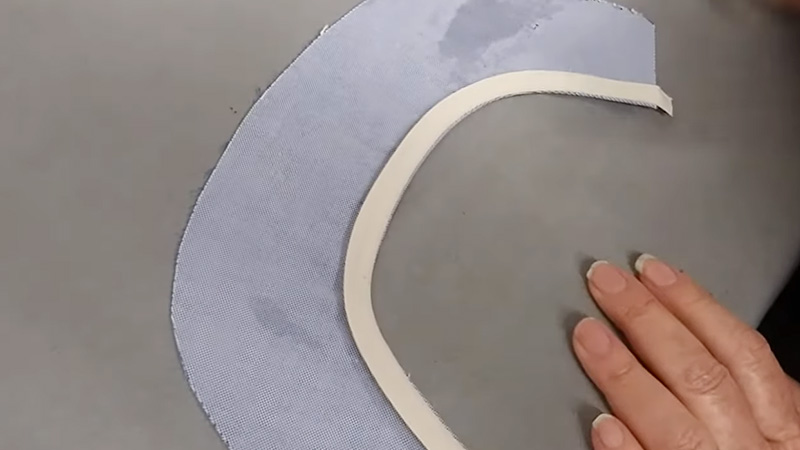

10. Armhole Facing

An armhole facing is a sewing technique used to finish the raw edges of armholes in garments, providing a clean and polished appearance. It involves sewing a fabric strip to the armhole’s edge, encasing the raw fabric and preventing fraying.

Armhole facings contribute to the stability of the armhole area, preventing stretching and sagging over time. This technique is commonly employed in sleeveless garments, dresses, blouses, and tops.

Accurate stitching, clipping or notching curves, and careful pressing are essential for a professional-looking armhole facing. By adding structure and a refined edge, armhole facings contribute to the overall quality and longevity of the garment.

11. Front Opening Facing

A front opening facing is a sewing technique used to finish the edges of a garment’s front opening, where buttons, hooks, or other closures are placed.

This facing adds a neat and structured finish to the edge, ensuring that the garment maintains its shape and stability. The facing is usually sewn to the garment’s front edges and encases the raw edges, preventing fraying.

It is commonly used in jackets, coats, blouses, and dresses with button or snap closures. Precise stitching, understitching, and careful pressing are important for a professional outcome.

The front opening facing not only enhances the garment’s aesthetics but also contributes to its overall functionality and durability.

Conclusion

In the world of sewing, mastering the art of facings opens up a realm of creative possibilities and professional finishes. From neckline facings that maintain shape to bias tape facings adding a touch of flair, each technique serves a unique purpose.

The ‘all-in-one’ and extended facings showcase innovation, while outside facings and placket facings infuse designs with personality. Hem facings and stitch facings exemplify versatility, offering solutions for different fabrics and styles.

These techniques emphasize meticulous stitching, precise cutting, and skilled pressing to achieve a polished result. With an array of facing types at hand, sewists can elevate their creations to new heights, merging form and function seamlessly.

Leave a Reply