Industrial sewing machines are the unsung heroes of the textile and garment manufacturing industries. They are the workhorses that ensure efficiency, precision, and consistency in the production of clothing, fabric, and various sewn items.

With their remarkable power and speed, industrial sewing machines enable businesses to meet high production demands without compromising on quality.

The world of industrial sewing machines is vast and diverse, offering a range of options to cater to specific needs and tasks.

Whether you’re a seasoned professional or just starting, understanding the various types of industrial sewing machines and their applications is essential for choosing the right tool to excel in your craft or business.

In this article, we will delve into the fascinating world of industrial sewing machines, exploring their different types and the unique roles they play in the world of textile and garment manufacturing.

1. Sewing Needle

A sewing needle is an essential tool for hand-sewing. It is a long, slender object with a pointed tip at one end and a hole at the other to hold the thread.

Throughout the centuries, it has been made from a variety of materials.

Originally, needles were made of bone or wood, but in modern times, they are usually made out of high carbon steel wire. This steel wire is then nickel- or 18K gold-plated to protect it from corrosion.

This makes the needles more durable and longer-lasting. By using the appropriate needle for the project, the results can be more precise and accurate..

2. Overlock

An overlock stitch is a type of stitching that is used to finish the edges of fabric. It is often used to hem, seam, or edge fabric, and is created with an overlock sewing machine.

This type of machine is equipped with a number of different stitching options and is able to cut the edges of the fabric as it is fed through the machine.

This helps to ensure a neat and professional-looking finish.

Some overlock machines are made without cutters, so the edges of the fabric will have to be cut manually before they can be sewn. An overlock stitch is a great way to add a professional finish to any garment or other textile project.

3. Lockstitch

A lockstitch is a type of stitch made by a sewing machine which consists of two threads; an upper thread and a lower thread. The upper thread passes through a needle and is looped around the lower thread before it is pulled through the fabric.

This creates a locking mechanism, as the two threads interlock with each other to form a strong and secure stitch. The lockstitch is the most common type of stitch used in dress shirts, and is often referred to as “single needle stitching”.

This term refers to the fact that only one needle is used to create the stitch, rather than two or more needles. This type of stitch is very secure and resilient, meaning that it can withstand a lot of wear and tear before it has to be replaced.

It also provides a neat and tidy look, as the stitches are even and consistent in size and shape.

4. Overlock Sewing Machine

An overlock sewing machine, commonly known as a serger, is a specialized industrial or domestic sewing machine designed for edging, hemming, and finishing fabric edges.

It trims the fabric while simultaneously encasing the cut edge with thread, preventing fraying and creating a neat, professional finish. Overlock machines typically use multiple threads (usually 3 to 5) to sew, trim, and overcast the fabric edges in a single pass.

They are essential in the garment industry for creating durable and clean seams on a wide range of fabrics, including knitwear. Overlock machines are valued for their speed and efficiency in producing finished, polished-looking garments.

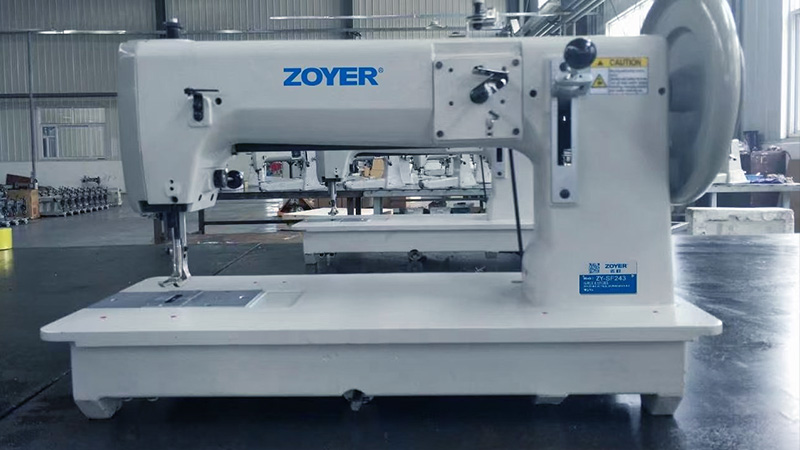

5. High Quality Industrial Double Needle Lockstitch Sewing Machine Rotary

The High-Quality Industrial Double Needle Lockstitch Sewing Machine with Rotary Hook is a precision tool engineered for professional sewing tasks. This specialized machine features two needles and a rotary hook system, ensuring precise and secure stitching on a wide range of fabrics and materials.

Its robust construction and advanced technology make it ideal for industrial sewing applications, such as garment manufacturing, upholstery, and leatherwork.

The rotary hook mechanism enhances efficiency, minimizing thread breakage and allowing for high-speed sewing without compromising stitch quality. This sewing machine is a valuable asset for businesses seeking top-notch craftsmanship and durability in their sewing operations.

6. Single Needle Chain Stitch Machine

The Single Needle Chain Stitch Machine is a versatile industrial sewing device designed for various applications. It utilizes a single needle to create a distinctive chain stitch, characterized by a series of interlocking loops on one side of the fabric and a single thread on the other.

This machine is commonly employed in industries like agriculture, bag manufacturing, and packaging for its ability to securely close bags and other materials.

It offers efficient and robust stitching, making it well-suited for heavy-duty tasks. Its simplicity and reliability make it a popular choice for operations requiring a strong, single-thread stitch to hold materials together securely.

7. Coverstitch

A coverstitch is a type of stitch used in sewing and creating garments. It is formed by two or more needles which add straight stitches to the fabric, and a looper thread on the opposite side of the fabric that creates a zig-zag pattern in between the straight stitches.

The result is parallel lines of straight stitches on one side of the fabric with an overcast stitch on the reverse side. This type of stitch provides a professional, finished look to the garment and is commonly used for hems and seams in clothing.

Additionally, it can also be used to attach bindings, reinforce pockets, and to attach elastic and other fabrics. Coverstitching is a great way to add a professional finish to any garment.

8. Flat Seam Machine

A flat seam machine is an industrial sewing device designed to create flat, smooth, and virtually invisible seams on various fabrics and textiles. It achieves this by joining two pieces of fabric with minimal bulk and a flat seam, making it ideal for applications where comfort and a sleek appearance are crucial.

Flat seam machines are often used in the production of activewear, lingerie, swimwear, and other garments where seam visibility can be unsightly or uncomfortable.

These machines offer precision stitching and ensure that the finished product maintains a clean and professional look, enhancing the overall quality and comfort of the final product.

9. Baby Lock Regalia Sewing Machine

The Baby Lock Regalia Sewing Machine is a high-quality, advanced sewing machine designed for quilting and sewing enthusiasts seeking top-tier performance.

It boasts a wide range of features and capabilities, including a large throat space, precision stitching, and a powerful motor. The Regalia is known for its user-friendly interface, allowing for easy customization of stitch patterns and settings.

It also offers a variety of quilting options, making it a favorite among quilters for both free-motion and computer-guided quilting. With its robust construction and advanced technology, the Baby Lock Regalia Sewing Machine is a reliable choice for those who demand precision and versatility in their sewing and quilting projects.

10. Zigzag Sewing Machine

The zigzag sewing machine is a versatile and essential tool in the world of sewing and textile work. This machine is designed to create zigzag stitches, which involve a back-and-forth movement of the needle, allowing for added stretch and flexibility in seams.

It is commonly used for various applications, such as finishing fabric edges, sewing buttonholes, creating decorative patterns, and working with stretchy or knitted fabrics.

The zigzag sewing machine’s ability to produce both straight and zigzag stitches makes it a fundamental choice for both basic and advanced sewing projects. Its versatility and ease of use make it a staple in the sewing world.

Conclusion

The evolution of industrial sewing machines is a testament to human ingenuity and the relentless pursuit of efficiency and precision in the world of sewing and textile manufacturing.

From the earliest mechanical devices to today’s highly advanced models, these machines have revolutionized industries and empowered artisans and manufacturers alike.

The diverse range of industrial sewing machines available today ensures that there’s a perfect fit for every application, whether it’s delicate embroidery, heavy-duty leatherwork, or high-volume production in the garment industry.

The technological advancements, automation, and versatility offered by these machines have elevated the quality and efficiency of sewing projects across the board.

So, whether you’re a hobbyist, a small business owner, or part of a large-scale manufacturing operation, industrial sewing machines provide the tools to turn your creative ideas and production needs into reality.

These remarkable machines continue to play a pivotal role in the world of sewing, making it easier than ever to achieve professional-level results.

Leave a Reply