Warp knitted fabric is a fascinating textile that offers a range of unique properties and applications. Unlike its counterpart, weft-knitted fabric, warp-knitted fabric is created by interlocking loops of yarn in a zigzag pattern along the length of the fabric.

This distinct construction technique imparts warp-knitted fabric with exceptional characteristics such as high elasticity, resistance to runs, and ease of production.

These qualities make it popular in intimate apparel, swimwear, sportswear, and mosquito netting industries. However, it is essential to delve deeper into the world of warp-knitted fabric, exploring its advantages, disadvantages, care requirements, and environmental considerations.

By understanding the intricacies of warp-knitted fabric, we can better appreciate its versatility and make informed decisions about its use in various applications.

What is Warp Knitted Fabric?

Warp-knitted fabric is a type of textile produced by intermeshing loops in knitting elements rather than interlacing warp and weft yarns as in weaving.

It is similar to woven fabric, as warp beams also supply yarns. However, the construction method differs. In warp knitting, each needle or hook in the machine creates a loop using the warp yarns, forming a series of parallel rows of loops.

This results in a fabric that is stretchable, durable, and has good shape retention. Warp-knitted fabric is produced at a constant, continuous width, making it suitable for various applications, including apparel, lingerie, sportswear, and technical textiles.

History of Warp Knitted Fabric

The history of warp-knitted fabric dates back to the late 18th century. The credit for its invention is often attributed to a mechanic named Josiah Crane, who is believed to have developed the concept in 1775.

It is believed that Crane sold his invention to Richard March, who subsequently obtained a patent (No. 1186) for a warped frame in 1778. During the three years between Crane’s invention and March’s patent, March likely discussed the device with Morris, who submitted a similar patent.

Since then, warp knitting technology has evolved significantly, producing diverse and versatile fabrics in various industries today.

Characteristics of Warp Knitted Fabric

Warp-knitted fabrics have several distinctive characteristics that set them apart from other fabrics. Here are some of the critical attributes of warp-knitted fabrics:

Run Resistant

Warp-knitted fabrics are known for their excellent run resistance. This means that if a thread or yarn is snagged or broken, the damage is limited to a small area and does not cause the entire fabric to unravel.

Closer and Flatter

Warp-knitted fabrics have a closer structure compared to weft-knit fabrics. The loops formed in warp knitting are intermeshed closely, resulting in a fabric with a smoother surface.

This characteristic gives warp-knitted fabrics a more refined appearance and makes them suitable for applications with a flat texture.

Less Elastic

Warp-knitted fabrics generally have less elasticity compared to weft-knit fabrics. The loops in warp knitting are interlocked, creating a stable and less stretchable fabric.

This characteristic makes warp-knitted fabrics ideal for shape retention and stability applications.

Versatility

Warp-knitted fabrics come in various variations, offering weight, texture, and appearance versatility. Different warp-knitted structures, such as tricot and raschel, provide unique characteristics and can be used for various purposes.

Durability

Warp-knitted fabrics are known for their durability and strength. The intermeshed loops create a robust fabric structure that can withstand wear and tear, making them suitable for applications requiring longevity and abrasion resistance.

Continuous Widt

Warp-knitted fabrics are produced at a constant, continuous width. The fabric can be manufactured in large widths without seams or joins.

The absence of seams allows for efficient production and reduces the risk of weak points in the fabric.

Types of Warp Knitted Fabric

Tricot

Tricot is one of the most common and widely produced types of warp-knitted fabric. It is known for its smooth, delicate, and closely knit structure. Tricot fabrics are commonly used in lingerie, intimate apparel, swimwear, and sportswear due to their excellent stretch and recovery properties.

Mirror Satin

Mirror satin is a warp-knitted fabric that features a lustrous and glossy surface. It has a luxurious appearance and is often used in high-end lingerie, eveningwear, and decorative applications.

Powernet

Powernet is a warp-knitted fabric with an open and breathable construction. Its net-like appearance and elasticity characterize it. Powernet fabrics are commonly used in shapewear, compression garments, and swimwear to provide support, control, and shaping.

Satinet

Satinet is a warp-knitted fabric that resembles satin in its appearance and drape. It has a smooth, silky surface and is often used in lingerie, nightwear, and apparel that requires a luxurious touch.

Weftlock

Weftlock is a type of warp-knitted fabric that combines warp and weft-knitting characteristics. It has a unique construction that allows for increased stability, strength, and dimensional stability.

Weftlock fabrics are commonly used in activewear, outerwear, and technical textiles.

Tri-skin

Tri-Skin is a warp-knitted fabric comprising three layers, resulting in a sandwich-like structure. The middle layer provides stability and structure, while the outer layers offer a soft and comfortable touch.

Tri-skin fabrics are used in sports apparel, medical textiles, and protective clothing applications.

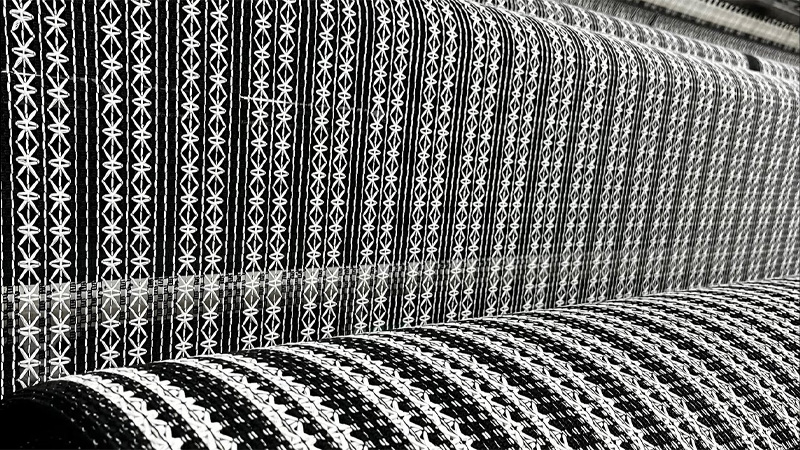

Jacquard

Jacquard is a warp-knitted fabric that incorporates intricate patterns and designs. It is produced using a Jacquard mechanism, allowing for the creation of complex and detailed motifs.

Jacquard fabrics are commonly used in fashion, upholstery, and home textiles.

Simplex

Simplex is a type of warp-knitted fabric known for its stability and durability. It has a firm and compact structure, making it suitable for applications that require strength, such as automotive interiors, upholstery, and technical textiles.

How Are Knit Fabrics Made?

Yarn Preparation

The first step in making knit fabrics is the preparation of yarn. Yarn can be made from various materials such as cotton, wool, polyester, or blends of different fibers.

The yarn is typically spun and twisted to create a continuous strand.

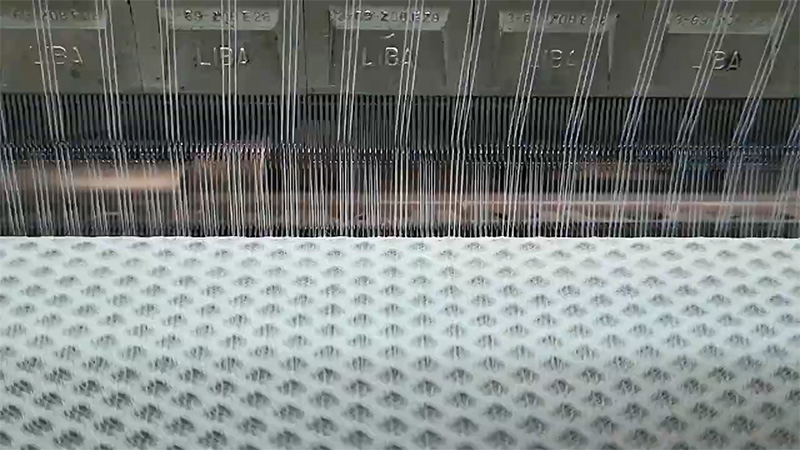

Knitting Machine Setup

Knitting machines are used to create knit fabrics. The appropriate knitting machine is selected based on the desired fabric type and construction. The machine has the required needles, hooks, or other knitting elements.

Casting on

The process begins by casting the stitches onto the knitting machine. The yarn is threaded through the machine and connected to the needles or hooks.

The stitches are formed by wrapping the yarn around the needle and pulling it through a loop.

Knitting Process

Once the stitches are cast on, the knitting process begins. The knitting machine is operated, and the needles or hooks are manipulated to form loops.

The loops are interwoven with each other to create a fabric structure. The knitting machine may have different mechanisms and movements to develop stitch patterns.

Row Formation

As the knitting machine continues to operate, rows of stitches are formed. The needles or hooks move in a specific pattern to create the desired stitch structure.

The rows’ direction can be horizontal (weft knitting) or vertical (warp knitting), depending on the type of knit fabric produced.

Fabric Formation

With each row of stitches, the fabric grows and takes shape. The loops interlock with each other, creating a cohesive fabric structure. The fabric width and length increase as more rows are knitted.

Finishing

Once the desired length of fabric is achieved, the knitting process is completed. The fabric is then removed from the knitting machine. It may undergo various finishing processes such as washing, dyeing, printing, or other treatments to enhance its appearance, texture, or performance.

Cutting and Sewing

After finishing, the knit fabric is typically cut into pattern pieces according to the desired garment or product. These pieces are then sewn together to create the final product, such as a sweater, t-shirt, or other knitted item.

What is Warp Knitted Fabric Used for?

Mosquito Netting

Warp-knitted fabrics are commonly used for producing mosquito netting. The close-knit structure of these fabrics helps to prevent mosquitoes and other insects from entering enclosed spaces, providing protection against mosquito-borne diseases.

Tulle Fabrics

Tulle is a lightweight, sheer fabric often used in wedding dresses, veils, and other formal attire. Warp-knitted fabrics are utilized in tulle production, providing a delicate and airy texture.

Sportswear

Warp-knitted fabrics are popular in sportswear due to their stretchability, durability, and moisture-wicking properties. These fabrics are used for creating athletic wear, such as leggings, jerseys, and performance garments.

Shoe Fabric

Warp-knitted fabrics find application in the production of shoe materials. The fabrics can be engineered to provide breathability, flexibility, and support, making them suitable for various types of footwear, including sneakers, athletic shoes, and casual shoes.

Fabrics for Printing and Advertising

Warp-knitted fabrics are often utilized as substrates for printing and advertising purposes. These fabrics’ stable and flat surface allows for high-quality graphics, logos, and design printing, making them ideal for banners, flags, signage, and promotional materials.

Coating Substrates

Warp-knitted fabrics are used as coating substrates in various industries. These fabrics can be coated with different materials to enhance their properties, such as waterproofing, flame resistance, or abrasion resistance.

Coated warp-knitted fabrics find applications in the automotive, marine, and protective clothing industries.

Laminating Backgrounds

Warp-knitted fabrics are used as backings or backgrounds for laminated products. They provide stability, strength, and dimension to laminated materials used in sectors like home furnishings, upholstery, and automotive interiors.

How Do You Wash Warp Knitted Fabric?

Washing warp knitted fabric requires a gentle approach to avoid damaging its delicate structure. Here’s a step-by-step guide to washing warp knitted fabric:

Check the Care Label

Before washing warp-knitted fabric, always refer to the care label attached to the garment or fabric. The care label provides instructions and guidelines for cleaning and caring for the fabric.

Choose the Right Detergent and Water Temperature

Select a gentle detergent suitable for delicate fabrics. Avoid using bleach or fabric softeners, as they can harm the fabric. For warp-knitted fabric, use cold water instead of hot water, which can cause shrinkage and damage to the fabric.

Hand Wash or Use a Delicate Cycle

You have two options for washing warp-knitted fabric. Firstly, you can hand wash the fabric in a basin or sink filled with cold water and a small amount of gentle detergent.

Gently agitate the fabric in the soapy water, then rinse it thoroughly with cold water. Secondly, you can use a delicate or gentle cycle washing machine if the care label allows. Place the fabric in a mesh laundry bag to protect it from tangling or stretching during the wash.

Avoid Wringing or Twisting

After washing, carefully remove the fabric from the water or washing machine. Avoid wringing or twisting the fabric, which can stretch or distort its shape. Instead, gently squeeze out excess water by pressing the fabric between your hands or rolling it in a clean towel.

Dry Flat or Hang to Dry

Lay the warp-knitted fabric flat on a clean towel or drying rack to air dry. Avoid using a dryer, as the heat can cause shrinkage and damage the fabric. If hanging the fabric to dry, use clothespins or hangers to avoid stretching or distorting the fabric’s shape.

Iron on Low Heat if Needed

If ironing is required, use a low heat setting on your iron. Avoid using steam or high temperatures, as they can damage the fabric. Place a pressing or a thin, clean cloth over the fabric to protect it while ironing.

How to Care for Warp Knitted Clothes?

Caring for warp-knitted clothes involves specific considerations to ensure longevity and maintain appearance and functionality. Here are some general care guidelines for warp-knitted garments:

Washing

When washing warp-knitted clothes, use cold water and mild detergent for delicate fabrics. Avoid using bleach, fabric softeners, or harsh chemicals, as they can damage the fibers and affect the garment’s elasticity. Gently hand wash or use a gentle cycle in the washing machine to minimize stretching or distortion of the fabric.

Drying

After washing, it is essential to handle warp-knitted clothes carefully during drying. Avoid wringing or twisting the fabric, as this can cause it to lose its shape and elasticity.

Instead, gently squeeze out excess water and lay the garment flat to dry on a clean towel or drying rack. If using a dryer, set it to a low heat or delicate cycle to prevent excessive heat exposure that could damage the fabric.

Ironing

Warp-knitted clothes generally do not require ironing, as the fabric is naturally stretchy and resilient. However, if ironing is necessary, use a low heat setting and avoid using steam.

Placing a pressing or a thin, clean cloth over the garment is recommended to protect it while ironing. Be gentle and avoid applying excessive pressure to prevent flattening or distorting the fabric’s texture.

Storage

Proper storage is essential to maintain the quality of warp-knitted clothes. Store them in a cool, dry place away from direct sunlight, as prolonged exposure to sunlight can cause fading or discoloration.

It is preferable to fold the garments neatly and store them in a drawer or on shelves. If hanging is necessary, use padded hangers to prevent stretching or sagging of the fabric.

Handling

When wearing and handling warp-knitted clothes, be mindful of sharp objects or rough surfaces that could snag or damage the fabric. Avoid excessive pulling or stretching, especially when removing or putting on the garments. Handle them gently to minimize the risk of runs or snags.

How to Sew Warp Knitted Fabric?

Select the Right Needle and Thread

When sewing warp-knitted fabric, choosing the appropriate needle and thread is essential. Opt for a ballpoint or stretch needle, as these needles are designed to penetrate knit fabrics without damaging or snagging the yarns. For the thread, use a polyester or nylon thread that has some stretch to it, ensuring it can withstand the elasticity of the fabric.

Prepare the Sewing Machine

Set up your sewing machine for sewing stretch fabrics. Install the recommended knitting needle and adjust the machine’s settings, such as stitch length and tension, to accommodate the specific characteristics of warp-knitted fabric. Testing the settings on a scrap piece of cloth may be helpful to ensure the stitches are balanced and the fabric feeds smoothly.

Pin or Use Clips

When sewing warp-knitted fabric, avoid using pins, as they can leave permanent holes or snags in the fabric. Instead, use clips or fabric weights to hold the fabric layers together during the sewing process. Clips or weights are handy for aligning seams and preventing shifting while sewing.

Start With a Stretch Stitch

Begin sewing with a stretch stitch, such as a narrow zigzag or a stretch stitch setting available on your sewing machine. These stitches allow the fabric to maintain its stretch and elasticity without causing the seams to pop or break.

Test different stretch stitches on scrap fabric to determine the most suitable stitch for your particular warp-knitted fabric.

Seam Finishing

Consider using a seam finishing technique that suits the fabric’s properties. For warp-knitted fabrics, options like a mock overlock stitch, serging, or using a stretchy seam tape can help prevent fraying and ensure the durability of the seams. These techniques also enhance the fabric’s stretch and flexibility.

Handling Seam Allowances

Warp-knitted fabrics tend to have some inherent stretch, so it is essential to handle seam allowances appropriately. Trim down excessive seam allowances to reduce bulk and prevent added tension on the fabric.

Additionally, pressing the seams open or to one side with a low-heat iron can help flatten the seams without compromising the fabric’s elasticity.

Test and Adjust

Sewing a sample or conducting tests on scrap fabric before sewing your final project is advisable. This allows you to familiarize yourself with the fabric’s behavior, make necessary adjustments to your machine settings or stitches, and ensure the desired outcome.

How Does Warp Knitted Fabric Impact the Environment?

Like any other textile production, warp-knitted fabrics can have positive and negative environmental impacts. Here’s how warp-knitted fabric production can affect the environment:

Resource Consumption

The production of warp-knitted fabric often involves using synthetic fibers such as polyester, nylon, or acrylic derived from petroleum or other fossil fuel sources.

Extracting and processing these non-renewable resources contribute to environmental degradation and carbon emissions. Additionally, the production of synthetic fibers requires energy and water, further straining natural resources.

Chemical Usage

The manufacturing process of warp-knitted fabric may involve using chemicals, dyes, and finishing agents. Some of these substances can be harmful to human health and the environment.

If not adequately managed, releasing chemical pollutants during production and dyeing processes can contribute to water pollution and soil contamination.

Microplastic Pollution

Synthetic fibers in warp-knitted fabrics can shed microplastic particles into waterways, especially when laundered. These microplastics are incredibly harmful to aquatic life, as marine organisms can ingest and bioaccumulate in the food chain. The release of microplastics from synthetic fibers is a growing concern for the health of ecosystems and aquatic biodiversity.

Energy and Water Consumption

Producing warp-knitted fabric often requires significant amounts of energy and water. Energy consumption contributes to greenhouse gas emissions and climate change, while water usage impacts freshwater resources, especially in regions prone to water scarcity.

Additionally, the dyeing and finishing processes can be water-intensive, leading to wastewater pollution if not properly treated.

What Are the Advantages and Disadvantages of Warp-Knitted Fabric?

Warp knitted fabrics offer several advantages and disadvantages, which can vary depending on factors such as the specific application, the quality of the fabric, and the production process. Here are some of the key advantages and disadvantages of warp knitted fabrics:

Advantages of Warp Knitted Fabric

- Production Efficiency: Warp-knitted fabric can be produced rapidly and efficiently on specialized machines. The continuous loop formation allows for high-speed production, making it suitable for large-scale manufacturing.

- Stretch and Flexibility: Warp knitted fabric possesses inherent elasticity and stretch, contributing to its excellent drape and ability to conform to body contours. This characteristic suits garments that require a comfortable and form-fitting fit, such as swimwear, activewear, and lingerie.

- Run Resistance: One of the notable advantages of warp-knitted fabric is its resistance to runs or ladders. The interlocking loop structure provides stability and prevents the fabric from quickly unraveling when a loop is broken. This feature enhances the durability and longevity of garments made from warp-knitted fabric.

Disadvantages of Warp Knitted Fabric

- Stability and Durability: Warp-knitted fabric may have less stability and durability than woven fabric. It can lose shape, especially if subjected to excessive stretching or tension. The fabric may stretch out of shape, resulting in garments that do not retain their original fit.

- Pilling and Snagging: Warp-knitted fabric is more susceptible to pilling, which refers to forming small fabric balls on the surface. The loops of the fabric can interlock with loose fibers, resulting in the formation of pills. Additionally, the open-loop structure of warp-knitted fabric can make it more prone to snagging or catching on sharp objects, leading to potential damage.

- Print and Dye Limitations: Compared to other fabric types, such as woven or printed fabrics, warp-knitted fabric can be more challenging to print on or dye. The interlocking loop structure makes it difficult for colors and designs to penetrate evenly, potentially limiting the options for warp-knitted fabrics.

Comparison Table Between Warp Knitted Fabric and Other Fabrics

| Property | Warp Knitted Fabric | Weft Knitted Fabric | Woven Fabric |

|---|---|---|---|

| Construction | Interlocking loops along the length of the fabric | Interlocking loops across the width of the fabric | Interlacing of warp and weft yarns |

| Elasticity | High elasticity and stretchability | Moderate elasticity | Limited elasticity |

| Stability | Less stable, can lose shape over time | Relatively stable | Stable |

| Resistance to Runs | Resistant to runs and ladders | Prone to runs and ladders | Resistant to runs |

| Drape | Good drape and fluidity | Moderate drape | Moderate drape |

| Breathability | Generally breathable | Generally breathable | Varies depending on fabric type |

| Production Speed | Fast production on specialized machines | Fast production on knitting machines | Slower production on looms |

| Pilling | Can be prone to pilling | Can be prone to pilling | Less prone to pilling |

| Design Versatility | Limited design options due to the interlocking loop structure | Varied design options are available | It can be printed and dyed easily |

| Printability and Dyeing | Varied design options are available | Intimate apparel, swimwear, sportswear, mosquito netting | It can be printed and dyed easily |

| Common Applications | Varies depending on the fabric type | T-shirts, socks, knitwear | Shirts, trousers, upholstery |

FAQs

Warp knitted fabric is versatile and can be used for various clothing items, such as intimate apparel, swimwear, sportswear, and mosquito netting. However, its specific suitability may depend on factors such as the desired fit, stretch, and drape required for the garment.

Due to its interlocking loop structure, altering or tailoring warp-knitted fabric can be more challenging than woven fabrics. It is recommended to seek the assistance of a skilled tailor with experience working with knit fabrics to ensure proper alterations without compromising the fabric’s integrity.

To store warp-knitted garments, it is advisable to fold them neatly or hang them on padded hangers to prevent wrinkles and distortion. It is best to store them in a cool, dry place away from direct sunlight to avoid fading or damage.

Warp-knitted fabrics typically require gentle care. It is recommended to wash them in cold water with a mild detergent and avoid using bleach or fabric softeners. Avoid wringing or twisting the fabric during washing to maintain its shape and elasticity. It is best to air dry or use a low heat setting if machine drying is necessary.

Warp-knitted fabric can be recycled or repurposed depending on its composition. However, the recycling process may be more complex due to synthetic fibers. Consider exploring local textile recycling facilities or repurposing options to give the warp-knitted fabric a new life.

To Recap

Warp-knitted fabric is a unique type of textile created by interlocking loops of yarn in a zigzag pattern. It offers several advantages, including high elasticity, resistance to runs, and ease of production.

Warp-knitted fabric finds applications in various industries, such as intimate apparel, swimwear, sportswear, and mosquito netting. However, it is essential to consider its limitations and environmental impacts.

Warp-knitted fabric may be less stable and durable than woven fabric, which can be more prone to pilling and snagging. Additionally, its production may involve synthetic fibers derived from non-renewable resources, contributing to environmental concerns.

Therefore, responsible care and conscious consumption are crucial to maintaining the quality of warp-knitted garments and exploring eco-friendly alternatives when possible.

By understanding its characteristics and making informed choices, we can appreciate the unique qualities of warp-knitted fabric while minimizing its potential drawbacks.

Leave a Reply