Hemming and seaming are important steps in finishing a garment edge-on. Overlock is an affordable way to create a durable edge finish on your clothing. You can also use hemming and seam allowances to adjust the fit of your clothing without having to take it apart or change the pattern pieces.

Finally, learn how to edge finish garments so they look neat and professional when you’re done.

What Are The Types Of Edge Finishes?

Hemming is a finishing technique used to seal edges of fabric together by sewing over the raw edge with a straight stitch or zigzag stitch. Overlock is similar to hemming, but instead of stitching over the raw edge, it uses an automated machine to sew through multiple layers on the same line.

Seaming is a process that joins two pieces of fabric together by sewing along one edge then pulling the seam allowance up so it’s hidden inside the seam allowances of both fabrics. Finally, you can use binding tape or glue to secure your seams and finish your project off nicely.

Edge Finish

Edge finishes are a type of finish that is used on knives, saws and other tools to add an extra layer of protection against wear and tear. They come in a variety of materials like chrome, hard rubber or plastic and can be customized to fit the specific needs of your project.

Some edge finishes are permanent while others can be removed with heat or water if you need to switch out blades or boards on your saw for example. There are also decorative edge finishes available that can give your workpiece a more finished look. When selecting an edge finish, make sure to take into account the material it’s going onto as well as the intended use for the tool being treated with it.

Overlock

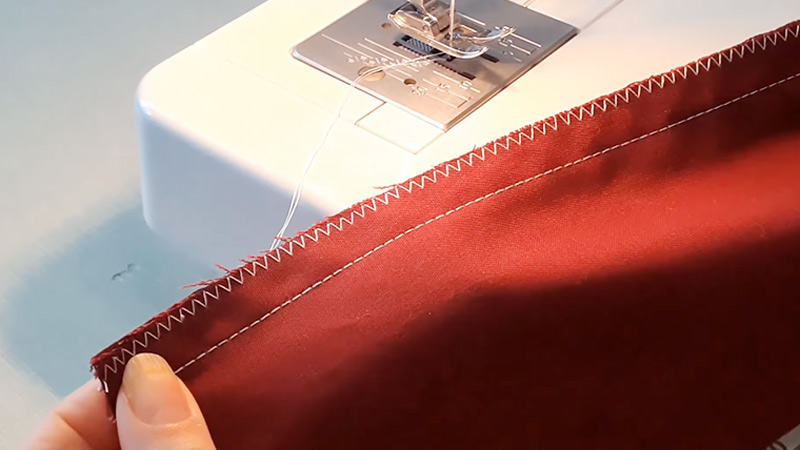

Edge finishes are a type of hemming that give your garment an extra-clean finish. There are three main types of edge finishes: overlock, zigzag and French seams.

Each has its own benefits and drawbacks, so you should choose the one that best suits the look you’re going for on each project. Overlock is by far the most common type of edge finish, but it’s also the most difficult to execute correctly due to its complicated stitch pattern.

Zigzag edges are easy to make but can be less durable than overlock or French seam edges, so they’re usually used on softer fabrics like cotton lawns rather than more sturdy materials like denim jeans

Hemming

Hemming is a technique used to trim the hems of clothing without cutting into the fabric. It’s a simple process that uses an edge such as a seam allowance, bias tape or hemmed collar to cut around the garment’s periphery.

Hemming can be done manually or with machines, and it’s often required for items like skirts, blouses and jumpsuits that have curved edges or stretchy fabrics. There are different hemming techniques available depending on what type of edge you choose to use: French hems are trimmed with a straight edge; serged hems require special sergers; and zigzag hems result in more-even cuts when finished by hand or machine using basic sewing tools like scissors and needle nose pliers .

Be sure to consult your sewing pattern before beginning your project so you know which steps need to be taken in order to achieve the desired look.

Seaming

Edge finishes can be made in a variety of ways, including stitching, binding and hemming. Seaming is the best option for creating a finished look that’s durable and seamless.

Make sure to use the right tool for the job to avoid ripping or tearing your fabric. Different edge finishes require different techniques, so be sure to familiarize yourself with each one before you start sewing.

Be patient – it may take some time but once you get used to seaming and edge finishing, it’ll become a breeze.

What is a finished edge?

A finished edge is the final, smooth and polished surface on a piece of wood or other material. It’s usually done when the material is cut or shaped into its final form.

The Edge of the Fabric is Cut and Trimmed

The finished edge on a piece of fabric is usually cut and trimmed to create an even look on all sides. This process begins by cutting the fabric along its longest side, then trimming any excess material away. Next, you will need to mark the edges where the hem will be sewn in. Finally, stitch through both top and bottom hems using a zigzag or French seam stitch so that your fabric has an even finish from end to end.

The Edges are Sewn Together with a Stitch That Goes Through the Top and Bottom Hem

When you sew together two pieces of cloth, it’s important that you use a stitch that goes through both top and bottom hems—this creates an edge which is smooth (and doesn’t have any folds). To do this, start at one corner of your piece of fabric and sew straight down until you reach the other corner—then turn right-side out so that it can be seen. Make sure not to leave any gaps between these stitches as this could cause wear over time.

This leaves an Even Finish on All Sides

By sewing together your edges in this way, each side will have an even finish from end-to-end—no matter how long or short your piece of fabric may be. This ensures that everything looks tidy when completed, no matter how large or small it may be.

What is the reason for edge finishes?

Edge finishes are a type of finish that is used on various surfaces, such as wood and metal. They are created by applying a sealant or coating to the edge of the material and then polishing it until it’s smooth.

There are many reasons why someone might want an edge finish on their materials: It can make the material look more luxurious, it can protect the material from moisture and corrosion, and it can add strength to the material.

There are a few reasons why you might see finished edges on clothing. One reason is to make the garment look neat and tidy. By adding an edge finish, it can help create a more polished appearance for your outfit. Another reason is that this type of finish can be used to decorate the edges of fabric. This makes them look more attractive and adds extra strength to the fabric as well. Finally, some people like having finished edges because they feel it makes garments more comfortable to wear – especially when moving around in them or wearing them during hot weather conditions.

What is Edge finishes in needle work?

Edge finishes are a type of needle work that is used on fabrics to give them a smooth and finished appearance. They are made up of small, sharp pieces of metal that have been welded or glued together.

Sewing Machine Edge Finish

The edge finish on a sewing machine needle is important for two reasons: it helps the stitches stick to the fabric, and it prevents fraying. The type of edge finish your sewing machine uses depends on the kind of fabric you’re sewing. Overlock machines have an extra-fine edge which is perfect for fragile fabrics like lace. Hand seams use a very fine edge that’s also great for delicate materials like silk thread.

Overlock Machine Edge Finish

An overlock machine has an extremely sharp edge which is used to create ultra-smooth seams without any rips or tears. This type of finishing allows you to sew clothing with intricate details such as sequins and piping without having to worry about them deteriorating in time or coming apart at the seams later on down the road.

Hand Seam Edge Finish

Hand seam edges are usually less precise than those found on overlock machines and straight stitch machines because they aren’t designed for seamless finishes; instead, they’re meant for creating close but non-totally smooth joins between different pieces of fabric together (similarly to how we do when we hem clothes). They can be either serged or zigzag stitched using specialized tools, so they will generally look nicer than standard raw edges but take longer to achieve due to their greater level of difficulty in execution.

What is the name of edge finishing?

Hemming is the name of a process that finishes an edge by attaching it to the fabric underneath with stitches or zigzag stitches. Overlock is a type of hemming in which the machine sews two pieces of fabric together, creating a “double hem” effect.

Wedging is also used for edge finishing and involves pressing one piece of fabric against another so they cling together and form an even edge along their joint-point. Flanged hemming uses narrow strips of metal or plastic to create an edgeless finish on curved edges by pushing them into creases before stitching them down securely.

Shirttail hemming is simply folding over one end of the Fabric then stitch it closed from behind – this creates a finished look without any raw ends exposed.

What is seam finishing?

Seam finishing is the process of trimming away excess fabric along the seam lines before sewing it together. This allows for a neater, more finished look when your project is completed.

There are two main methods for seam finishing: serging and binding. Serging is a popular choice because it’s easy to do, but Binding provides a more durable finish that looks nicer over time.

Be sure to read your sewing instructions carefully so you know how much allowance to trim off each side of your seams.

To Recap

There are a few different types of edge finishes, and each has its own advantages and disadvantages. When choosing an edge finish, it is important to consider the type of project you are working on as well as your personal preferences.

Leave a Reply