The efficient operation of a sewing machine depends significantly on the intricate mechanical components, especially the gears.

Over time, these gears can experience wear and tear, leading to a decline in performance and potentially costly repairs. Understanding the factors behind sewing machine gear wear is essential for every enthusiast.

This article explores the primary causes of sewing machine gear wear, ranging from friction and heat generated during sewing to the impact of excessive use and the influence of the materials and needles used.

By grasping these key factors, you can adopt preventative measures and maintenance practices to extend the life of your sewing machine’s gears, ensuring it remains a reliable and efficient tool for your creative endeavors.

What Causes Sewing Machine Gear Worn Down?

Like any form of mechanical wear and tear, sewing machine gear wear can be attributed to several underlying causes. Understanding these factors is crucial for maintaining the longevity and efficiency of your sewing machine.

Here are the primary reasons why sewing machine gears may become worn down:

Friction and Heat

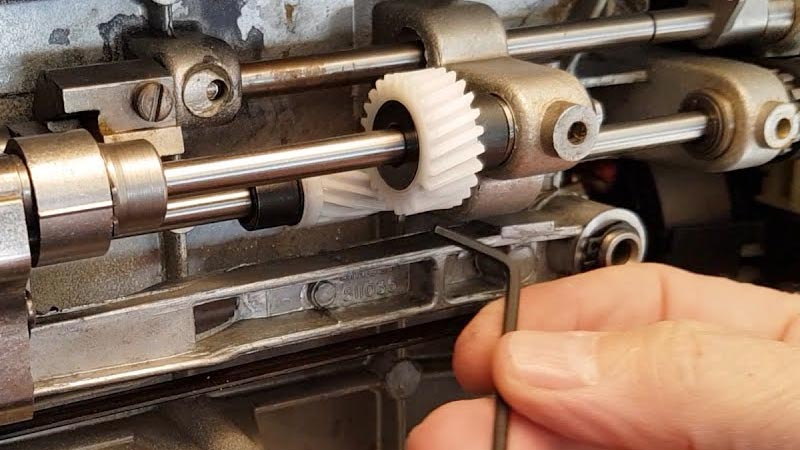

Gears within a sewing machine are intricate mechanical components that continually rotate and engage with one another during the sewing process. This ongoing movement generates friction and heat.

Over time, the friction can gradually erode the gear teeth, causing them to lose their original shape and, as a result, their efficiency. The heat generated from this friction can also contribute to premature wear.

Lack of Lubrication

Adequate lubrication is essential to reduce friction and heat within the gear mechanism. Gears need to be well-oiled to ensure smooth and efficient operation.

When gears lack proper lubrication, the teeth can grind against each other, leading to an accelerated rate of wear and diminishing the overall performance of the sewing machine.

Excessive Use

Sewing machines that experience prolonged use, whether for extended hours or without regular breaks, are more susceptible to gear wear and tear.

While sewing machine gears are designed to handle a certain level of stress, continuous and excessive use can surpass their intended capacity, causing them to deteriorate more rapidly.

Sewing Heavy Fabrics

Sewing thick or heavy fabrics, such as denim, canvas, or upholstery materials, can impose additional strain on the gears.

While sewing machines are typically designed to handle a range of materials, consistent use with heavy fabrics can expedite the process of wear and tear due to the extra stress placed on the gears.

Damaged Needles

Sewing with damaged or bent needles can also contribute to gear damage. When a needle is compromised, it can interfere with the gear mechanism, potentially chipping or breaking the gear teeth as it moves through the machine.

This interference further exacerbates wear on the gears.

Foreign Objects

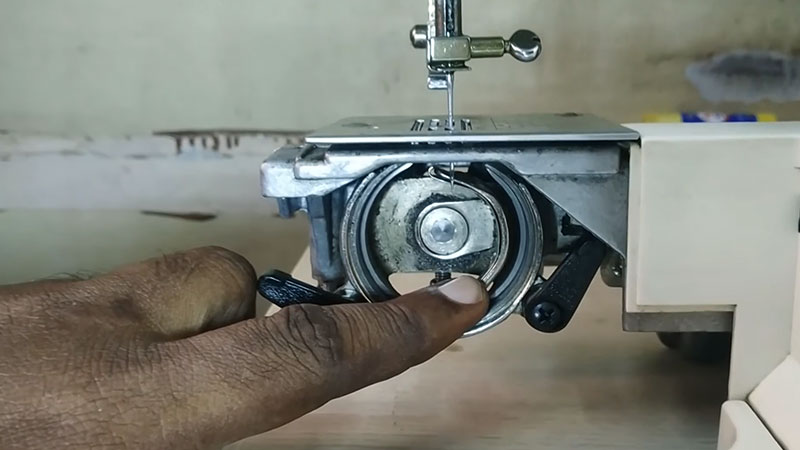

Occasionally, foreign objects, such as pins, needles, or broken thread fragments, can inadvertently find their way into the sewing machine’s mechanical components. These foreign objects can disrupt the gear mechanism and, over time, cause damage to the gears.

Thread Jams

Repeated thread jams or obstructions within the sewing machine can impose additional stress on the gears. When the machine attempts to sew with these obstructions in place, it can lead to gear wear and tear as the gears work against the resistance.

Age and Quality of the Machine

The sewing machine’s overall quality, including its gears’ materials and artistry, can significantly impact its durability.

Cheaper or older sewing machines may have gears that are more prone to wear and tear due to lower-quality components or an extended period of use.

How Can You Prevent Sewing Machine Gear from Wearing Down?

Preventing sewing machine gear wear is essential for maintaining the longevity and efficiency of your sewing machine.

Sewing machine gears are intricate mechanical components vital to the machine’s functionality, and they can experience wear and tear over time.

To keep your machine’s gears in excellent condition and prevent them from wearing down, here are some effective strategies and tips:

Regular Maintenance

Regular maintenance is one of the most critical steps in preventing gear wear. Consult your sewing machine’s user manual to learn how to correctly clean and oil your machine.

Regular cleaning and oiling reduce friction and heat in the gear mechanism, preserving the gear teeth and ensuring smooth operation.

Use the Right Needles

Always use high-quality, undamaged needles appropriate for the type of fabric you’re sewing. Needles bent or damaged can interfere with the gear mechanism and contribute to gear wear. Replace needles as soon as you notice any signs of damage.

Avoid Overloading

Sewing machines have their limits. Avoid overloading your machine with heavy fabrics or multiple layers of material. Excessive stress on the gears can lead to accelerated wear and tear. Consider a machine designed for heavy-duty use if you need to sew heavy materials.

Choose the Right Thread

Select the correct thread weight for your sewing project. Using the appropriate thread reduces unnecessary stress on the machine’s gears. A mismatch between the thread weight and fabric type can strain the gears.

Sew at a Moderate Speed

Avoid sewing at excessively high speeds. Sewing too fast can place additional strain on the gears. Sew at a moderate pace to reduce wear and prolong the life of the gears.

Handle Thread Jams Promptly

If you encounter thread jams or obstructions during sewing, stop the machine immediately and address the issue. Continuing to sew with obstructions can stress the gears significantly, potentially causing damage.

Inspect for Foreign Objects

Regularly inspect your sewing machine for foreign objects that may have inadvertently found their way into its mechanical components.

This can include pins, needles, or remnants of broken thread. Removing these foreign objects promptly prevents gear disruption.

Sew with Proper Tension

Ensure that your sewing machine’s tension settings are correctly adjusted. Incorrect tension can lead to unnecessary stress on the gears. Consult your machine’s manual to set the tension correctly for different types of fabric.

Choose the Right Machine

The overall quality of the sewing machine itself plays a significant role in gear durability. Invest in a higher-quality sewing machine that is designed to withstand heavy use. Such machines often come with better-built gears that are more resistant to wear and tear.

Regular Servicing

Schedule periodic servicing of your sewing machine by a professional technician. Regular maintenance checks can help detect and address potential gear issues before they become significant problems. This proactive approach can extend the life of your machine’s gears.

FAQs

How often should I clean and oil my sewing machine to prevent gear damage?

To prevent gear damage, clean and oil your sewing machine every 8 to 10 hours or as your machine’s manual recommends.

Can using the wrong type of thread cause sewing machine gear wear?

Yes, using the wrong thread type may lead to sewing machine gear wear due to increased friction, strain, and tension on the gears.

What should I do if I encounter persistent thread jams in my sewing machine?

When experiencing persistent thread jams, immediately stop sewing, remove the fabric, and clear the jam. Inspect for any damage or disruption to the gears and address as needed.

Is there a way to determine the quality of gears in a sewing machine before purchasing it?

Research the brand and model and read reviews to assess gear quality in a sewing machine. Higher-quality machines typically have durable gears designed for more prolonged use.

Can using damaged needles lead to gear damage?

Yes, using damaged needles can damage your sewing machine gears. They may interfere with the gear mechanism and potentially cause wear and tear.

To Recap

The longevity and efficiency of your sewing machine’s gears are integral to your sewing experience. Sewing machine gear wear is an inevitable outcome of prolonged use, but understanding its root causes empowers us to take proactive steps in prevention.

Whether through regular maintenance, the use of high-quality needles and threads, or the choice of a well-built sewing machine, numerous strategies are at our disposal to mitigate gear wear.

By implementing these preventive measures and remaining vigilant for potential issues, you can extend the lifespan of your sewing machine’s gears and ensure that it continues to stitch flawlessly, preserving your ability to create beautiful and functional garments and projects for years to come.

Leave a Reply