In the vibrant world of sewing and textile crafts, the term “fuse” takes on a vital role, signifying a process that unites fabrics with precision and purpose. In the realm of sewing, “what does fuse mean in sewing” refers to the art of melding two fabric layers using heat and adhesive materials.

This technique opens the door to a myriad of possibilities, whether reinforcing garment components, creating crisp edges or adding decorative motifs to quilts and clothing.

The act of fusing involves a delicate dance of heat, pressure, and adhesive, resulting in a strong, seamless bond that enhances the durability and aesthetics of textile creations.

From the versatile fusible interfacing that fortifies shirt collars to the whimsical appliqué pieces that adorn quilts, the concept of fusing in sewing weaves a thread of innovation and practicality throughout the fabric of the craft.

This introduction sets the stage for an exploration of the multifaceted world of fusing in sewing.

What Does Fuse Mean In Sewing?

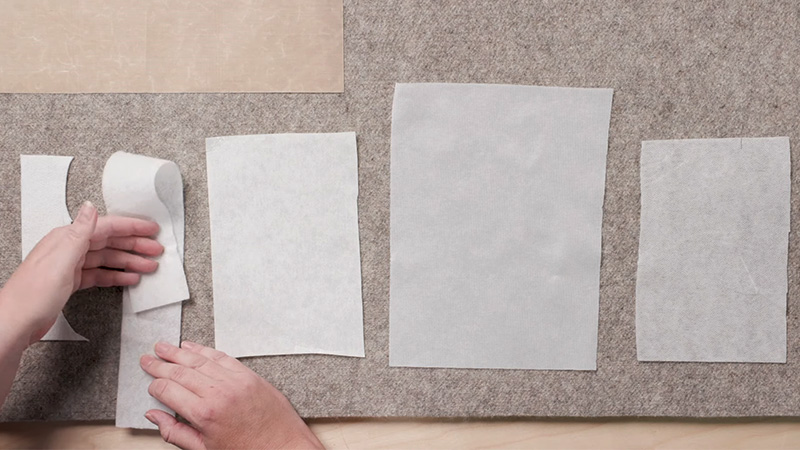

In sewing, the term “fuse” refers to the process of adhering two layers of fabric together using heat and an adhesive material. This adhesive material is often in the form of fusible interfacing or fusible web, which comes in sheets or rolls.

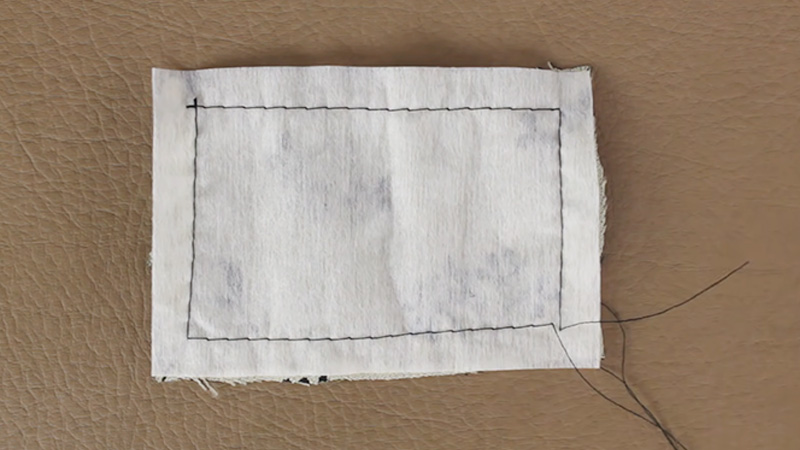

To fuse fabric, you place the fusible material between the layers of fabric, then apply heat, typically with an iron. The heat activates the adhesive, causing it to melt and bond the layers of fabric together.

This process is commonly used in various sewing projects to reinforce areas, add stability, or create decorative elements. Fusible interfacing, for example, is frequently used to strengthen collars, cuffs, and other garment components, while the fusible web is employed in appliqué work to secure fabric shapes onto a background fabric.

Fusing is a convenient and efficient technique in sewing that ensures fabric layers adhere securely without the need for sewing stitches.

What Materials Are Used For Fuse In Sewing?

Fusing in sewing involves the use of various materials to bond fabric layers together. Here are the materials commonly used for fusing in sewing:

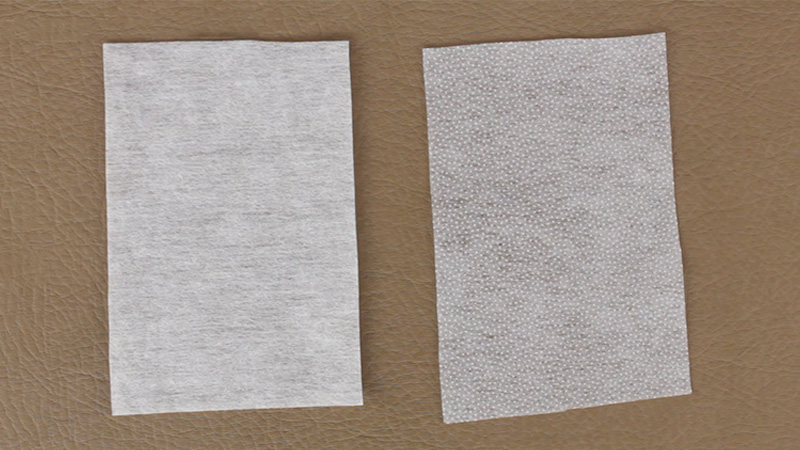

Fusible Interfacing

Fusible interfacing is one of the most widely used materials for fusing in sewing. It is a lightweight fabric with adhesive on one side, designed to add structure, stability, and reinforcement to areas of garments, such as collars, cuffs, and facings.

Fusible Web

Fusible web, available in sheets or rolls, is a versatile adhesive material used in appliqué work. It allows you to attach fabric shapes or motifs to a background fabric with an iron, creating decorative designs.

Heat-Activated Adhesive Sheets

These are thin, heat-activated adhesive sheets used to bond fabric layers temporarily or for specific sewing projects like quilting. They are often referred to as “wonder under” or “heat n’ bond.”

Fusible Batting

Fusible batting, also known as fusible fleece, is used in quilt-making. It combines batting with a heat-activated adhesive, allowing you to fuse quilt layers together while quilting.

Double-Sided Fusible Tape

This tape has adhesive on both sides and is used to temporarily bond fabric layers together before sewing. It’s especially handy for securing hems or seams in place.

Iron-On Patches

Iron-on patches come with adhesive on one side, allowing you to repair fabric by simply applying heat with an iron. They are commonly used for mending garments.

Adhesive Backing for Embroidery

Embroiderers often use adhesive backing or stabilizers to secure fabric while stitching intricate embroidery designs, ensuring the fabric doesn’t pucker or stretch during the process.

Fusible Hem Tape

Fusible hem tape is a quick solution for creating temporary hems. It can be used to adjust the length of garments without sewing, making it convenient for temporary alterations.

Fusible Seam Tape

Seam tape with adhesive on one side is used for reinforcing and stabilizing seams in knit fabrics, preventing them from stretching out of shape during sewing.

These materials offer a range of options for fusing in sewing, catering to different project requirements, from adding structure to decorative embellishments to temporary fixes.

What Is The Purpose Of Fusing?

Fusing, in the context of sewing and textiles, serves various purposes, offering versatile solutions for different projects and applications:

Strengthening Fabrics

Fusible interfacing and fusible batting add strength and stability to fabrics, preventing them from stretching or fraying. This is especially useful in areas like collars, cuffs, and waistbands of garments.

Creating Clean Edges

Fusing is employed to create clean, crisp edges on fabric pieces, ensuring they maintain their shape and do not fray when cut. This is vital for intricate details in sewing projects.

Appliqué Work

Fusible web and adhesive backing materials are ideal for appliqué work. They allow you to attach fabric shapes or motifs securely to a background fabric, enhancing the visual appeal of quilts, clothing, and home decor items.

Temporary Bonds

Double-sided fusible tape and hem tape are used to create temporary bonds between fabric layers. This is particularly useful for securing hems, seams, or pattern pieces in place before sewing.

Quilting

Fusible batting or fusible fleece is commonly used in quilting. It holds the quilt layers together, eliminating the need for basting, and provides a lightweight yet warm layer inside quilts.

Mending and Repairs

Iron-on patches are a quick and effective solution for repairing holes, tears, or worn areas in fabric garments. They adhere to the fabric when heated with an iron, extending the life of clothing items.

Embroidery Stabilization

Adhesive backing materials are essential for machine embroidery. They stabilize the fabric during stitching, preventing puckering or distortion, and can be easily torn away after embroidery is complete.

Temporary Alterations

Fusible hem tape and seam tape allow for temporary alterations to clothing items, making it convenient to adjust the length or fit of garments without permanent stitching.

Enhancing Decorative Elements

Fusing can be used to enhance decorative elements in sewing projects. It helps secure embellishments like sequins, beads, and rhinestones onto fabric, ensuring they stay in place and withstand wear and washing.

Fusing plays a pivotal role in sewing by offering solutions for reinforcing fabrics, achieving clean finishes, creating decorative elements, and facilitating both permanent and temporary alterations.

It adds versatility and durability to a wide range of sewing and textile applications.

Why Is Fusing Necessary Sewing?

Fusing is a crucial technique in sewing due to its many essential functions, making it necessary for various aspects of sewing and fabric work:

Stability and Support

Fusible interfacing provides stability to lightweight or stretchy fabrics, ensuring they maintain their shape and structure in garments. This stability is crucial for areas like collars, cuffs, and plackets.

Preventing Fraying

Fusing helps prevent fabric edges from fraying when cut. This is especially important for delicate or loosely woven fabrics, ensuring they remain intact during the sewing process.

Reinforcing Seams

Seam tape or fusible seam tape reinforces seams in knits and stretch fabrics, preventing them from stretching out of shape and maintaining the integrity of the garment.

Appliqué and Embellishments

Fusible web and adhesive backing materials are essential for attaching appliqué pieces and embellishments and adding decorative elements to quilts, clothing, and crafts.

Quilting

Fusible batting or fusible fleece streamlines the quilting process by eliminating the need for basting and ensuring the layers of a quilt stay securely together while quilting.

Speed and Convenience

Fusing offers a quicker alternative to sewing in certain situations, such as temporary alterations or repairs. It can save time and effort, making it a convenient choice for busy sewers.

Clean Finishes

Fusing creates clean, neat edges on fabric pieces, allowing for precise and professional-looking results in sewing projects, particularly when working with intricate designs.

Mending and Extending Lifespan

Iron-on patches are invaluable for mending and extending the lifespan of clothing by providing quick fixes for tears and holes, thus reducing waste.

Embroidery Stability

Adhesive backing materials provide stability during machine embroidery, preventing fabric distortion and ensuring intricate embroidery designs turn out flawlessly.

Fusing is necessary for sewing for its role in enhancing fabric stability, preventing fraying, reinforcing seams, and facilitating various decorative and functional aspects of sewing and textile work.

It not only improves the quality and durability of projects but also offers time-saving solutions for a range of sewing needs.

FAQs

What does “fuse” mean in sewing, and why is it important?

In sewing, “fuse” refers to the process of bonding two fabric layers together using heat and adhesive materials. This is essential because it adds stability, prevents fraying, and enables various sewing techniques, such as appliqué and quilt making.

What are the common materials used for fusing in sewing?

Common materials for fusing include fusible interfacing, fusible web, heat-activated adhesive sheets, fusible batting, double-sided fusible tape, iron-on patches, adhesive backing for embroidery, fusible hem tape, and fusible seam tape.

Can you explain how fusing is done in sewing?

Fusing involves placing an adhesive material between fabric layers, applying heat with an iron, and allowing the heat to activate the adhesive, bonding the layers together. This process is used to reinforce, mend, decorate, or stabilize fabric.

What are some practical applications of fusing in sewing projects?

Fusing is used to strengthen garment areas like collars and cuffs, create clean edges on fabric pieces, reinforce seams, attach appliqué designs, streamline quilting, mend clothing, and stabilize fabric during machine embroidery.

Is fusing reversible, or does it permanently alter fabric?

Fusing is typically permanent, as it creates a secure bond between fabric layers. While some fusible materials can be removed with heat and effort, they often leave a residue, making it challenging to completely reverse the process.

Conclusion

In the intricate tapestry of sewing and textile arts, the meaning of “fuse” transcends mere terminology; it embodies a realm of creativity, precision, and functionality.

As we conclude our journey through the realm of fusing in sewing, it becomes evident that this technique is far more than a simple fusion of fabric layers; it’s a binding force that elevates sewing projects to new heights.

From the tailored elegance of fused collars in high-fashion garments to the whimsy of appliqué in quilts, fusing lends its strength, stability, and artistry to countless creations.

It transforms ordinary fabrics into extraordinary masterpieces, creating clean edges, reinforcing seams, and making the sewing process more efficient. Fusing in sewing, in essence, is a testament to the craft’s ability to adapt, innovate, and seamlessly blend tradition with modernity, ensuring that the art of sewing remains as vibrant and relevant as ever.

Leave a Reply