Selecting the appropriate gauge wire for a sewing machine ensures safe and efficient operation. The gauge of wire, referring to its thickness, directly impacts the machine’s electrical performance and safety.

With the myriad sewing machines available, ranging from household models to industrial-grade equipment, understanding the significance of wire gauges is paramount.

A correctly sized wire ensures that the machine receives the necessary power without risking overheating or electrical hazards.

In this guide, we’ll explore why the gauge of wire matters for sewing machines, the potential risks of using the wrong gauge, and how to make an informed choice to safeguard both the machine and its users.

What Gauge Wire for Sewing Machine?

The gauge of wire commonly used for sewing machine power cords is typically 16 gauge. This gauge suits most household sewing machines and provides adequate power transmission without being excessively thick or cumbersome.

Choosing the appropriate gauge of wire is essential to ensure the safe and efficient operation of your sewing machine.

However, it’s always advisable to consult the manufacturer’s specifications for your specific sewing machine model to confirm the recommended wire gauge for power and extension cords.

This ensures compatibility and minimizes the risk of electrical issues or damage to the machine. If you’re unsure about the correct gauge of wire, consider seeking advice from a qualified electrician or the manufacturer.

Why Does Gauge Wire for Sewing Machine Matter? Exploring the Importance of Performance and Safety

The gauge of wire for a sewing machine is a critical consideration due to its significant impact on its performance, safety, and longevity.

Here’s why the gauge of wire for a sewing machine matters:

Electrical Safety

Using the correct gauge wire is paramount for electrical safety. Thicker wires (lower gauge numbers) can handle higher currents without overheating, reducing the risk of electrical fires or damage to the machine.

Optimal Performance

The correct gauge wire ensures the sewing machine receives the necessary power without voltage drops or fluctuations. This helps maintain consistent and reliable performance during sewing tasks.

Prevention of Overheating

Incorrectly sized wires, particularly ones that are too thin, can lead to overheating as they struggle to accommodate the electrical load. Overheating can damage the wiring, electrical components, and even the sewing machine’s motor.

Machine Compatibility

Different sewing machines have varying power requirements. Using the correct gauge wire ensures compatibility with your machine’s specific needs, preventing potential damage or malfunction.

Compliance with Standards

Electrical wiring standards exist to ensure safety and performance. Using the appropriate gauge wire helps adhere to these standards, reducing the risk of accidents and ensuring regulatory compliance.

Longevity of Equipment

Appropriately sized wiring reduces stress on electrical components, extending the lifespan of the sewing machine. It minimizes the need for repairs or replacements and helps maintain the machine’s value over time.

Safety of Users

Adequate wiring reduces the risk of electrical hazards, such as shocks or fires, which can endanger the safety of users. Using the correct gauge wire, you prioritize your own safety and that of others using the sewing machine.

Types of Gauge Wire Available for Sewing Machines

The wire gauge for sewing machines typically refers to the electrical wiring used within the machine or for power cords and extension cords.

The most common types of wire gauges available for sewing machines are:

16-Gauge Wire

This is the most commonly used gauge for sewing machine power cords. It suits most household sewing machines and provides adequate power transmission without being excessively thick or cumbersome.

18-Gauge Wire

Slightly thinner than 16-gauge wire, 18-gauge wire can also be used for sewing machine power cords, particularly for machines with lower power requirements or shorter cord lengths.

20-Gauge Wire

Thinner than both 16-gauge and 18-gauge wire, 20-gauge wire may be suitable for smaller, lower-power sewing machines or use in shorter-length extension cords.

Extension Cord Wire

Extension cords come in various wire gauges, typically ranging from 16-gauge to 12-gauge. While not specific to sewing machines, extension cords may be used with sewing machines when additional reach is needed.

How To Choose the Right Gauge Wire for Sewing Machine? Expert Tips and Guidelines

Choosing the right gauge wire for a sewing machine involves considering several factors to ensure safety, compatibility, and optimal performance. Here’s a step-by-step guide:

Check Manufacturer Specifications

Review the user manual or specifications provided by the sewing machine manufacturer. They often include recommendations for the appropriate gauge wire for power cords and extension cords.

Determine Power Requirements

Understand the power requirements of your sewing machine. Consider factors such as voltage, current draw, and wattage to determine the appropriate gauge wire to handle the electrical load safely.

Calculate Wire Length

Measure the distance between the sewing machine, the power outlet, or any extension cords you plan to use. Longer wire lengths require thicker gauges to minimize voltage drop and ensure efficient power transmission.

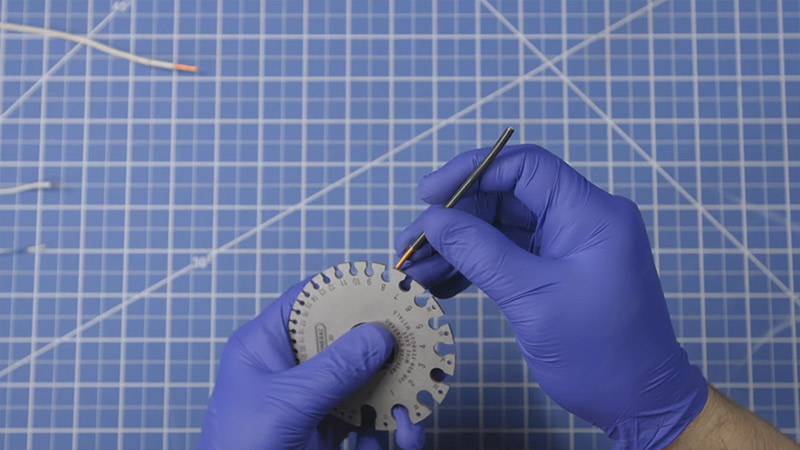

Consult Wire Gauge Charts

Refer to wire gauge charts or tables available online or in electrical engineering references. These resources provide guidelines for selecting the appropriate gauge wire based on current capacity and wire length.

Consider Safety Standards

Ensure that the selected wire gauge complies with relevant safety standards and regulations for electrical wiring. Using wires that meet recognized standards helps ensure safe operation and reduces the risk of electrical hazards.

Choose a Suitable Wire Type

Select a wire type suitable for electrical applications and meets safety standards. Copper wire is commonly used for sewing machine power cords due to its conductivity and durability.

Evaluate Flexibility and Durability

Consider the flexibility and durability of the wire, mainly if it will be used in a sewing machine that requires frequent movement or adjustments. Flexible, high-quality cables are less prone to breakage or wear over time.

Seek Professional Advice if Unsure

If you’re unsure which gauge wire to choose or how to determine the appropriate size, consider seeking advice from a qualified electrician or the sewing machine manufacturer.

They can provide guidance based on your specific needs and ensure that you select the right wire gauge for your sewing machine.

What Safety Considerations Should You Know About Wire Gauges for Sewing Machines?

When dealing with wire gauges for sewing machines, it’s crucial to prioritize safety. Here are some essential safety considerations to keep in mind:

Electrical Safety

Using the correct gauge wire is paramount to prevent electrical hazards. Ensure that the wire can safely handle the electrical load required by the sewing machine without overheating or causing electrical issues such as short circuits or fires.

Compatibility

Verify that the wire gauge matches the sewing machine’s power requirements and voltage rating. Using an incompatible gauge could lead to reduced performance, overheating, or damage to the machine.

Insulation

Ensure that the wire has proper insulation to prevent exposure to live wires, which can pose a risk of electric shock. Proper insulation protects the wire from damage and wear over time, ensuring long-term safety and reliability.

Installation

Proper wire installation is crucial for safety. Follow manufacturer guidelines and wiring diagrams to correctly install the wire, avoiding pinching, kinks, or sharp bends that could damage the insulation or wires.

Overloading

Avoid overloading the wire by exceeding its current carrying capacity. Using a wire with too small a gauge for the sewing machine’s power requirements can lead to overheating and electrical hazards.

Always use the appropriate gauge wire for the specific sewing machine model and power requirements.

Regular Inspection

Periodically inspect the wire for signs of damage, such as fraying, cracks, or exposed wires. Replace any damaged wires promptly to prevent safety hazards. Regular maintenance and inspection help ensure the safe and reliable operation of the sewing machine.

Consultation

If unsure about wire gauge selection or installation, seek guidance from a qualified electrician or the sewing machine manufacturer. They can provide expert advice to ensure the wire meets safety standards and suits the sewing machine’s requirements.

Wire Gauge Chart for Sewing Machines

While there isn’t a standard wire gauge chart exclusively for sewing machines, you can use general wire gauge charts to determine suitable wire gauges for sewing machine applications.

Here’s a simplified wire gauge chart that you can refer to:

| Gauge | Diameter (inches) | Diameter (mm) | Max Current (Amps) |

| 10 | 0.1019 | 2.588 | 30 |

| 12 | 0.0808 | 2.053 | 20 |

| 14 | 0.0641 | 1.628 | 15 |

| 16 | 0.0508 | 1.291 | 10 |

| 18 | 0.0403 | 1.024 | 7 |

| 20 | 0.0320 | 0.8128 | 5 |

| 22 | 0.0253 | 0.6438 | 3 |

| 24 | 0.0201 | 0.5105 | 2 |

| 26 | 0.0159 | 0.4039 | 1 |

| 28 | 0.0126 | 0.3200 | 0.5 |

| 30 | 0.0100 | 0.2540 | 0.3 |

FAQs

Is it possible to use wire with a higher gauge number for a sewing machine?

While technically possible, using a higher gauge number (thinner wire) may not adequately handle the electrical load, leading to overheating and potential safety hazards. It’s best to adhere to manufacturer recommendations for wire gauges.

Can using the wrong wire gauge void the warranty of my sewing machine?

Yes, using an incorrect wire gauge that damages the sewing machine could void the warranty. Always follow manufacturer guidelines to maintain warranty coverage.

How do I know if my sewing machine’s wire gauge needs to be replaced?

Signs such as frayed or damaged wiring, overheating, or electrical issues during operation may indicate that the wire gauge needs replacement. If in doubt, consult a qualified technician for inspection and replacement.

Are there specific regulations regarding wire gauges for sewing machines in different countries?

Regulations regarding wire gauges for electrical appliances, including sewing machines, may vary by country. It’s essential to adhere to local electrical codes and regulations to ensure compliance and safety.

Can I upgrade the wire gauge of my sewing machine for better performance?

While it may be tempting to upgrade to a thicker wire gauge for increased power handling, ensuring compatibility with the sewing machine’s electrical system is essential. A qualified technician should make modifications to avoid safety risks and warranty issues.

To Recap

Choosing the correct gauge wire for your sewing machine is essential for ensuring safety, performance, and longevity.

The electrical wiring plays a crucial role in powering the machine efficiently and reliably while mitigating the risks of overheating and electrical hazards.

By adhering to manufacturer recommendations and electrical standards, users can safeguard themselves and their equipment from the dangers of using the wrong wire gauge.

Whether it’s a household sewing machine or an industrial-grade model, investing the time to select the appropriate wire gauge is a fundamental step in maintaining optimal operation and prolonging the lifespan of the sewing machine.

Make informed choices to sew with confidence and peace of mind.

Leave a Reply