A bobbin pin is a fundamental sewing machine component which is pivotal in the stitching process. This small yet crucial device, typically metal or plastic, secures the bobbin during sewing.

As the machine operates, the bobbin pin facilitates the controlled release of the lower thread, ensuring proper tension and contributing to the formation of precise and balanced stitches.

The design and characteristics of bobbin pins may vary across sewing machine models, influencing their usage and functionality.

Understanding the significance and correct application of the bobbin pin is essential for achieving optimal sewing results and mastering the art of precision stitching.

What Is a Bobbin Pin On a Sewing Machine?

A bobbin pin on a sewing machine is a small metal or plastic rod that holds the bobbin in place during sewing. This crucial component secures the bobbin within the machine, preventing it from shifting or falling out.

As the sewing machine operates, the bobbin pin allows the controlled unwinding of the lower thread, contributing to proper tension and even stitches.

The design of bobbin pins may vary among sewing machine models, including fixed or removable types and horizontal or vertical orientations.

Following the sewing machine manual’s guidelines ensures correct usage, promoting optimal sewing performance and stitch quality.

How Does a Bobbin Pin Function in a Sewing Machine?

A bobbin pin in a sewing machine serves several important functions to ensure the machine’s smooth operation and the creation of quality stitches.

Here’s how a bobbin pin functions:

Securing the Bobbin

The primary function of a bobbin pin is to hold and secure the bobbin in its designated place within the sewing machine. This prevents the bobbin from moving around or falling out during the sewing process.

Facilitating Thread Tension

The bobbin pin, in conjunction with the bobbin case or holder, regulates the tension of the lower thread. Proper tension is crucial for achieving balanced stitches and preventing loose or tight stitching issues.

Thread Unwinding

As the sewing machine operates, the bobbin pin allows the bobbin to rotate smoothly. This rotation allows the lower thread to unwind controlled, ensuring a consistent thread feed during the stitching process.

Contributing to Stitch Quality

The correct placement and function of the bobbin pin directly impact the quality of stitches. A well-secured bobbin, facilitated by the bobbin pin, helps maintain uniform tension and prevents thread snags or tangles, resulting in neat and even stitches.

Coordination with Upper Thread

The bobbin pin coordinates with the upper thread and needle to create a lockstitch. This interplay between the upper and lower threads is essential for forming a secure and durable stitch.

Preventing Thread Jamming

Properly functioning bobbin pins help prevent issues like thread jamming or bird’s nesting, where the lower thread becomes entangled and disrupts the sewing process.

Enhancing Sewing Machine Performance

The overall efficiency and performance of the sewing machine are optimized when the bobbin pin is correctly used. It contributes to the smooth flow of both upper and lower threads, resulting in a more reliable and efficient sewing experience.

7 Different Types of Bobbin Pins Used in Sewing Machines

The design of bobbin pins can vary among different sewing machine models and brands. The types of bobbin pins used in sewing machines include:

1. Fixed Bobbin Pins

These bobbin pins are permanently attached to the sewing machine and cannot be removed. They are an integral part of the machine’s design and are often found in simpler or older models.

2. Removable Bobbin Pins

Some sewing machines have bobbin pins that can be detached. This feature allows easier cleaning, maintenance, and replacement of the bobbin pin.

3. Horizontal Bobbin Pins

In machines with a horizontal bobbin pin, the bobbin sits on the pin horizontally. This design is common in many household sewing machines.

4. Vertical Bobbin Pins

Other machines feature a vertical bobbin pin where the bobbin is inserted into the pin vertically. Industrial sewing machines often use this design.

5. Spring-Loaded Bobbin Pins

Certain bobbin pins have a spring-loaded mechanism, using a spring or latch to keep the bobbin securely in place. This design ensures that the bobbin stays in position during sewing.

6. Friction-Fit Bobbin Pins

In machines with friction-fit bobbin pins, friction and gravity hold the bobbin in place. This type may not have a spring or latch and relies on the snug fit of the bobbin on the pin.

7. Thread Guide or Slot on Bobbin Pins

Some bobbin pins come with an attached thread guide or slot, helping to guide the thread as it comes off the bobbin. This feature aids in maintaining proper tension and preventing thread snags.

How Do You Effectively Use a Bobbin Pin in Your Sewing Machine?

Effectively using a bobbin pin in your sewing machine is crucial for achieving well-balanced stitches and ensuring the overall functionality of the machine.

Here is a step-by-step guide on how to effectively use a bobbin pin:

Refer to Your Sewing Machine’s Manual

Every sewing machine model may have specific instructions and features related to the bobbin pin. Consult your sewing machine manual for accurate information on your machine’s location, type, and usage of the bobbin pin.

Prepare the Bobbin

Wind the bobbin with the desired thread. Follow the threading guide in your sewing machine manual to ensure the correct winding direction and tension. Trim excess thread, leaving a tail of about 6 inches.

Locate the Bobbin Pin

Identify the bobbin pin on your sewing machine. Depending on your machine’s design, it may be a fixed or removable pin, positioned horizontally or vertically.

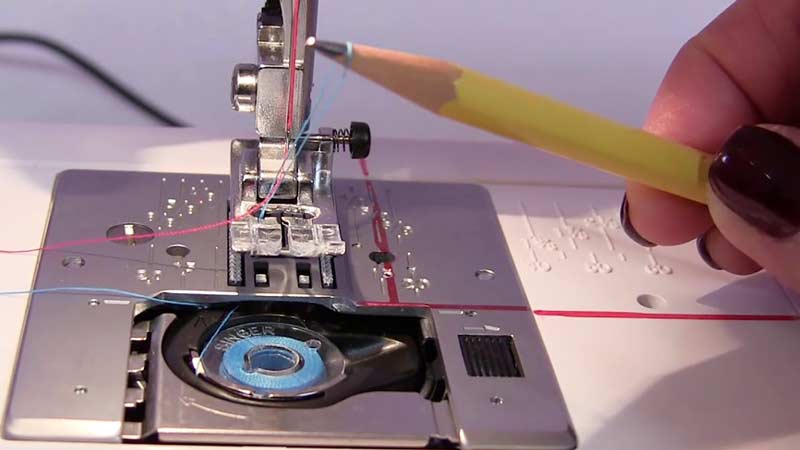

Insert the Bobbin onto the Pin

If your machine has a removable bobbin pin, insert it into the designated hole on the bobbin case. Slide the bobbin onto the pin, ensuring it fits snugly. If your machine has a fixed bobbin pin, place the bobbin onto the pin.

Thread Through the Bobbin Guide

Follow the threading path indicated in your sewing machine manual. You must pass the thread through a slot or guide on the bobbin case to ensure proper tension.

Pull Up the Bobbin Thread

With the needle threaded with the upper thread, lower the needle into the bobbin area and use the handwheel to bring the needle back up. This action should pull up the bobbin thread.

Check for Proper Tension

Once both the upper and lower threads are threaded correctly, check the tension. The threads should be properly tensioned for balanced stitches. Adjust the tension settings if needed, following your sewing machine manual.

Secure the Thread Tails

Hold onto both the upper and lower thread tails as you start sewing to prevent them from getting tangled or pulled into the machine. This is especially important when beginning a new seam.

Regular Maintenance

Periodically, check the bobbin pin and the bobbin case for any lint or debris. Clean the area as your sewing machine manual recommends to maintain optimal performance.

FAQs

What are alternative terms for a bobbin pin?

Alternative terms may include bobbin spindle, bobbin post, or bobbin holder. Terminology varies among sewing machine models, so consulting the manual is recommended for accurate identification.

Can I sew without a bobbin pin?

The bobbin pin is essential for proper thread tension and stitch formation. Attempting to sew without it may lead to thread-related issues, uneven stitches, and potential damage to your sewing machine. Always use the recommended bobbin pin for optimal results.

Why is the correct use of a bobbin pin important for sewing?

The correct use of a bobbin pin is vital for ensuring proper thread tension, preventing tangles or snags, and contributing to the overall quality of stitches.

It enhances the efficiency of the sewing machine, reduces the risk of malfunctions, and promotes a smooth sewing experience.

Can I use any bobbin pin in my sewing machine?

No, using the specific bobbin pin recommended by your sewing machine’s manufacturer is crucial. Using an incompatible bobbin pin may lead to tension issues, poor stitch quality, and potential damage to the machine.

Can a bent bobbin pin be repaired?

A bent bobbin pin may affect the performance of your sewing machine and should be replaced if damaged. Attempting to repair a bent pin may lead to further issues. Consult your machine’s service centre for professional assistance.

To Recap

The bobbin pin emerges as a seemingly modest yet indispensable element in the intricate world of sewing machines.

Its role in securing the bobbin, regulating thread tension, and facilitating controlled unwinding significantly influences the quality of stitches produced.

The diversity in designs and orientations across various sewing machine models underscores its adaptability to different requirements.

A nuanced understanding of the bobbin pin’s function and correct utilization, as outlined in the sewing machine manual, empowers sewers to optimize their crafting endeavours.

In embracing the significance of this unassuming rod, one enhances not only the technical aspects of sewing but also the overall satisfaction derived from creating meticulous and refined stitches.

Leave a Reply